MEMS piezoelectric ultrasonic transducer with horn structure

A piezoelectric ultrasonic and transducer technology, which is applied in the direction of fluid using vibration, can solve the problem of sound wave waste and other problems, and achieve the effect of improving energy conversion efficiency and electroacoustic conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

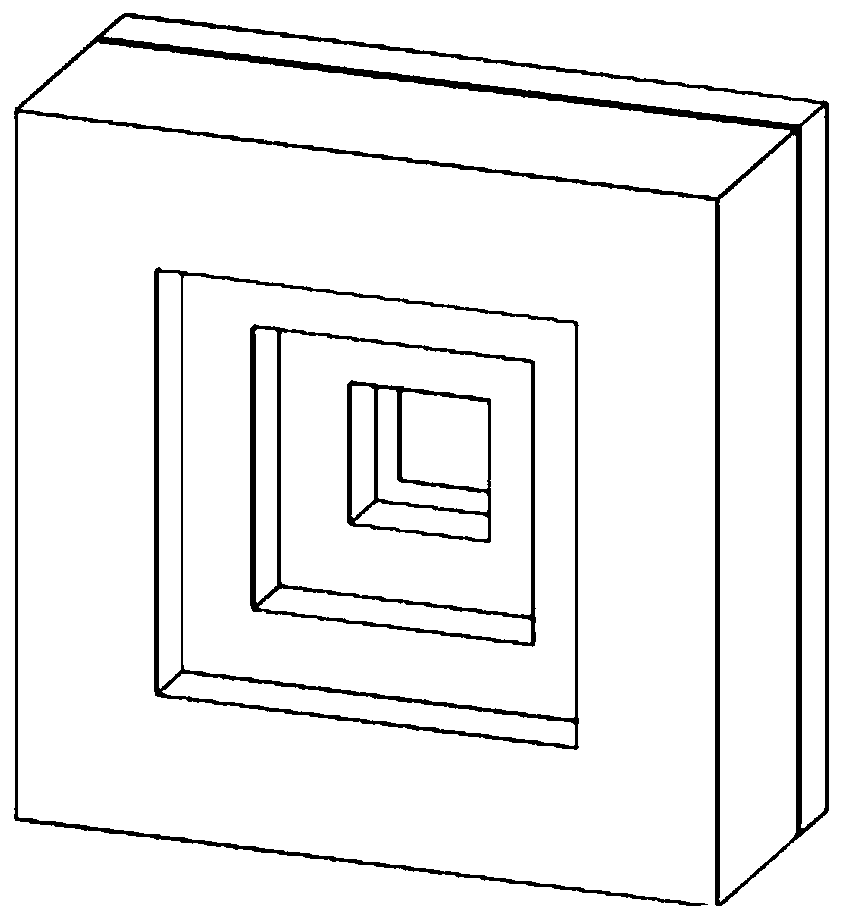

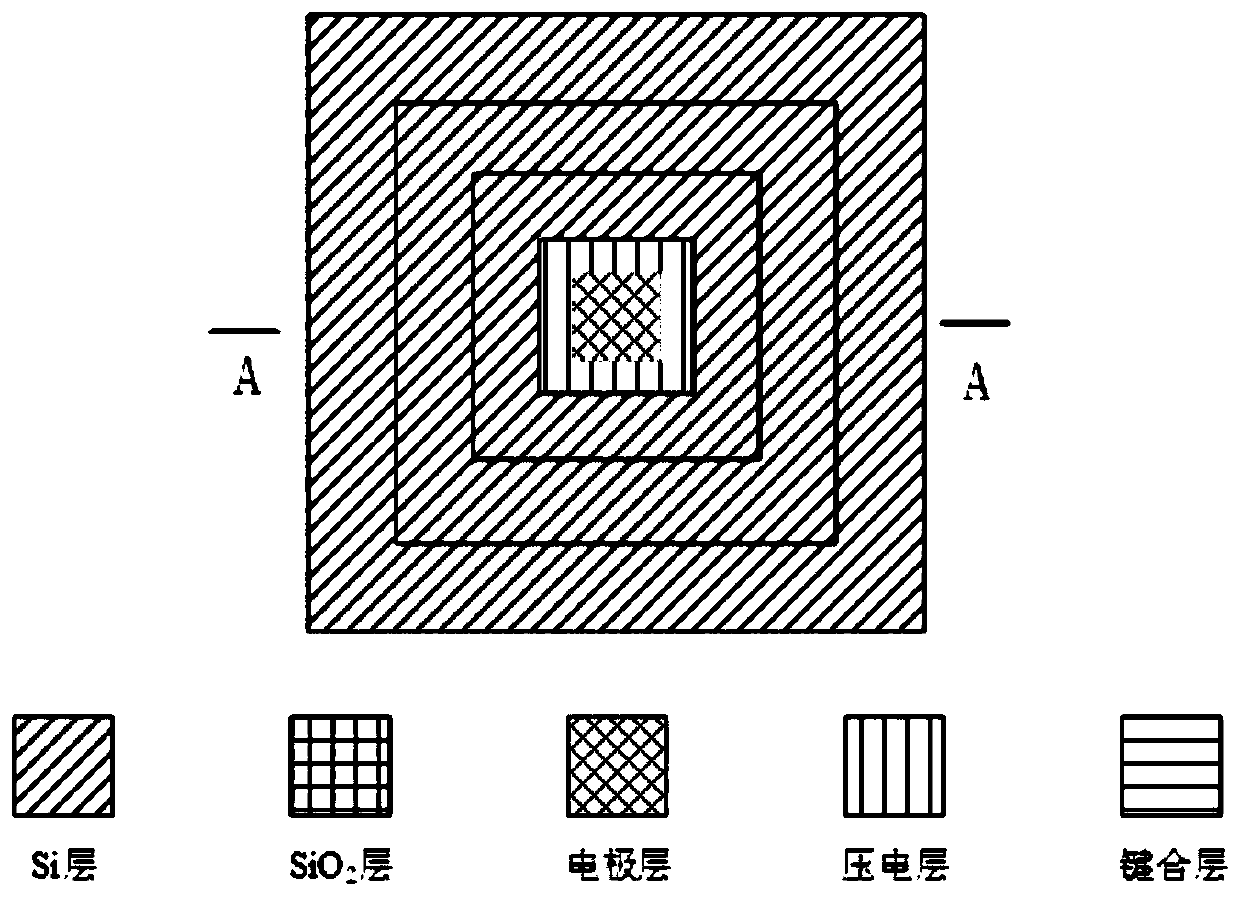

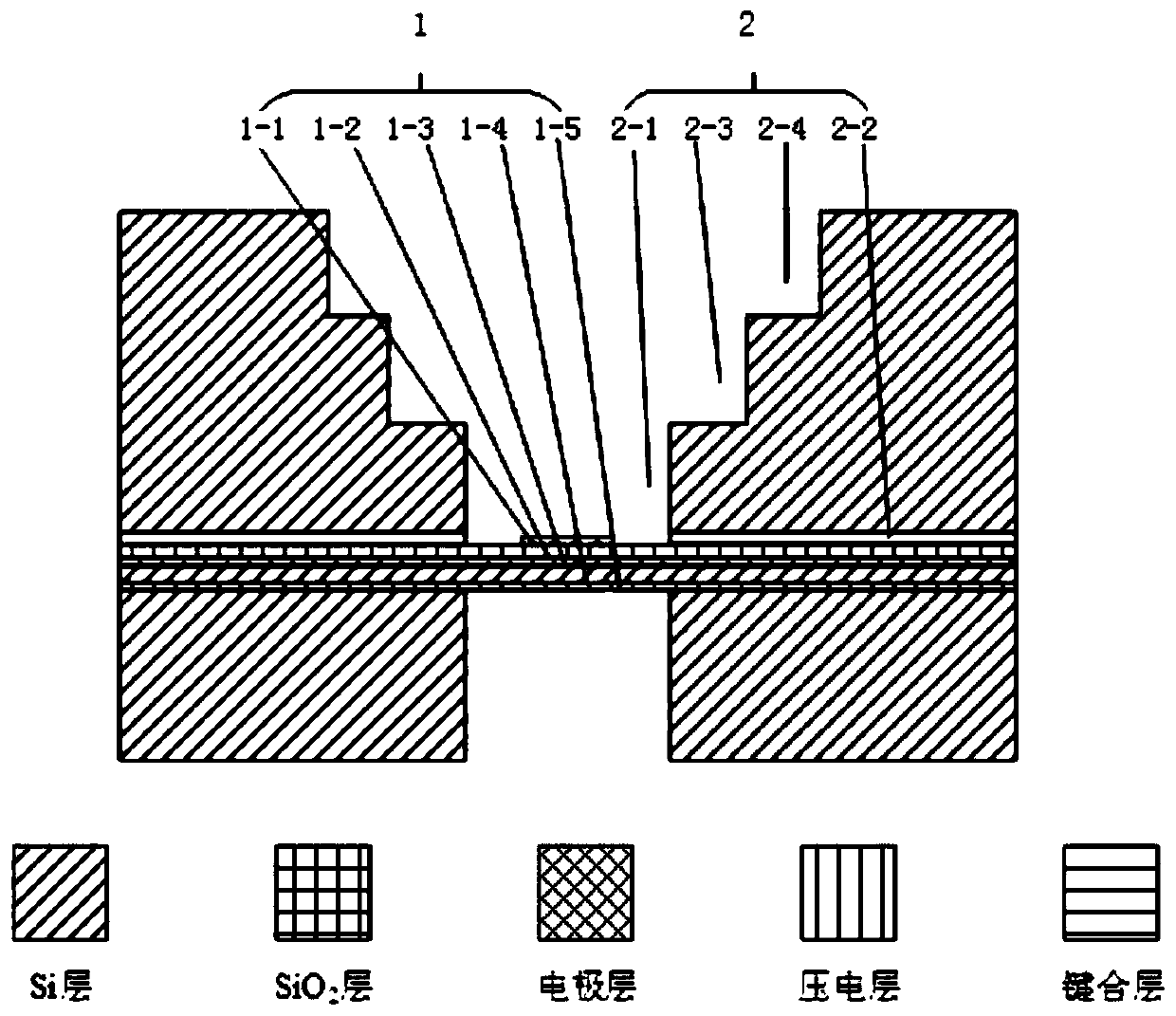

[0041] This embodiment is achieved through the following technical solutions, a MEMS piezoelectric ultrasonic transducer with a horn structure, including a MEMS piezoelectric ultrasonic transducer and a horn-shaped silicon structure, and the horn-shaped silicon structure can be bonded to The upper or lower surface of the MEMS piezoelectric ultrasonic transducer, the cavity in the horn-shaped silicon structure forms at least one acoustic waveguide, and each acoustic waveguide has at least two steps. When the acoustic waveguide has three steps, the first It consists of a stepped sound tube, a second stepped sound tube, and a third stepped sound tube; the cross-sectional area of the first stepped sound tube, the second stepped sound tube, and the third stepped sound tube gradually increases to form a horn-like cavity, which is similar to a horn The shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com