A precise plastic forming method for deep cup-shaped thin-walled parts

A technology of plastic forming and thin-walled parts, which is applied in the direction of household appliances, hollow objects, and other household appliances, etc., can solve the problems of increased processing cycle and cost, reduced internal grain structure performance, increased processing costs, etc., to achieve increased wall thickness Dimensional accuracy and uniformity of wall thickness, improved strength and fatigue life, and the effect of saving tooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

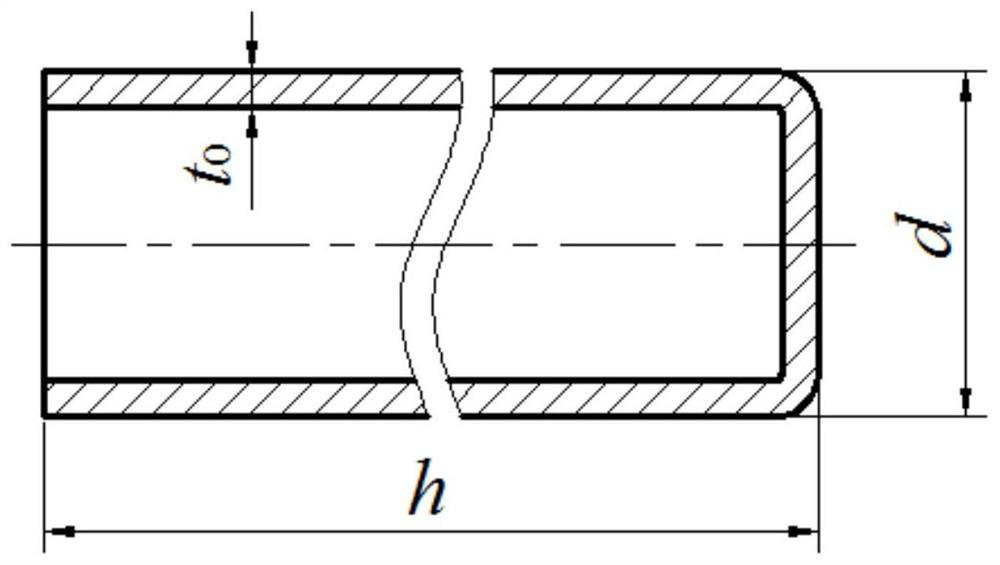

[0040] figure 1 A schematic diagram of the deep cups mentioned in the present invention;

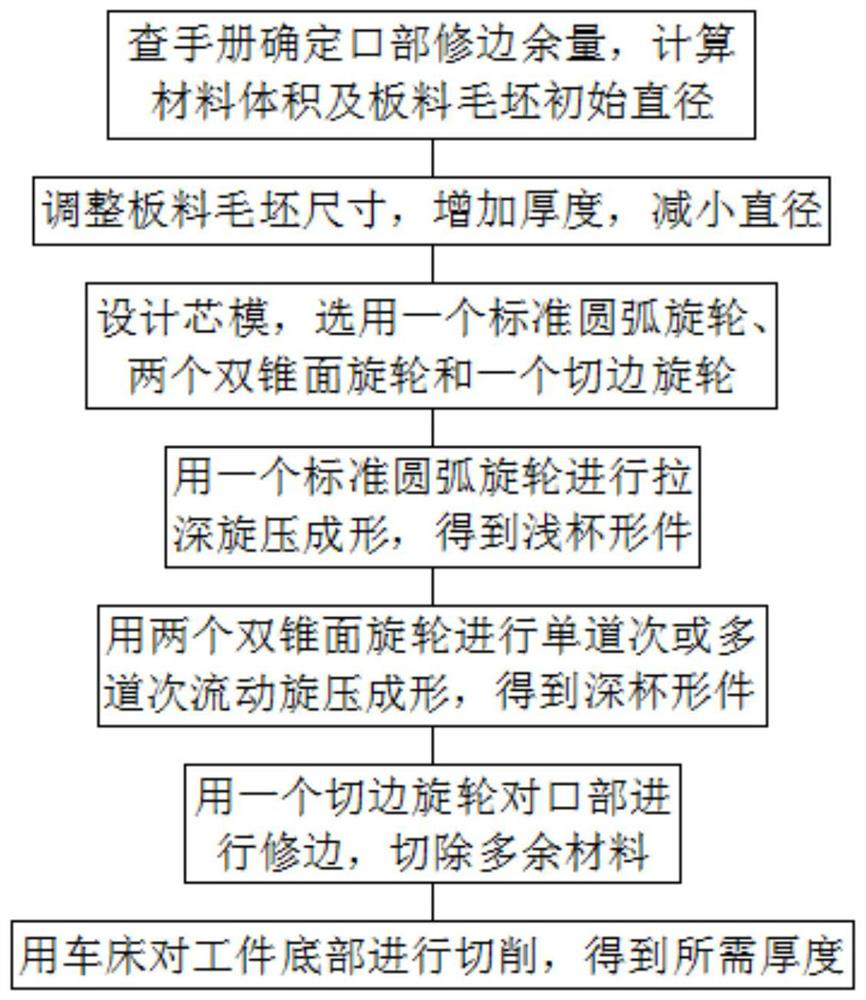

[0041] The material is 08 steel, the outer diameter of the parts D = 80mm, the wall thickness T 0 = 0.6mm, height H = 110 mm. Calculation and design according to the flow of the forming process of the present invention, such as figure 2 Looking:

[0042] (1) Check the manual to know the trim margin: Δ = 5mm, so material volume: v ≈π (H + Δ + 0.25D) DT 0 = 20347mm 3 ; Plate blank initial diameter: D 0 = 2 [v / (πt 0 )] 1 / 2 ≈ 208mm. Deep depth coefficient: 80 / 208 ≈ 0.38, less than one pull-down shaped limit pulse factor 0.46 ~ 0.6, cannot be drawn once.

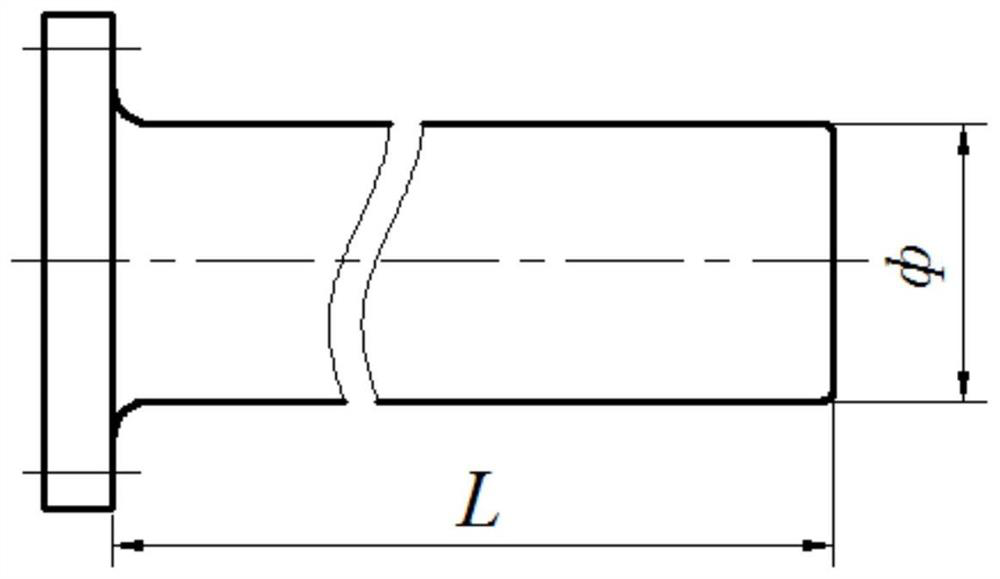

[0043] (2) Since the drawing of 08 steel is better, the depth coefficient m = 0.46 is selected for subsequent design, the slab thickness increase: △ T = (4VM 2 / π-d 2 t 0 ) / [d 2 (1-m 2 )] = 0.33mm, slab thickness: t 1 = T 0 + △ T = 0.93mm. Select T in the actual thickness series 1 = 1.0mm. Therefore, the correction Δt = 0.4mm, slab diamet...

Embodiment 2

[0052] figure 1 A schematic diagram of the deep cups mentioned in the present invention;

[0053] Material is 25 steel, the outer diameter of the parts D = 120mm, the wall thickness T 0 = 0.8 mm, height H = 350mm. Calculation and design according to the flow of the forming process of the present invention, such as figure 2 Looking:

[0054] (1) Check the manual to know the trim balance: Δ = 12mm, so material volume: v ≈π (H + δ + 0.25D) DT 0 = 118164mm 3 ; Plate blank initial diameter: D 0 = 2 [v / (πt 0 )] 1 / 2 ≈434mm. Deep depth coefficient: 120 / 434 ≈ 0.28, less than once the drawside is 0.46 ~ 0.6, which cannot be drawn once.

[0055] (2) Since the drawing of 25 steel is relatively poor, the depth coefficient m = 0.6 is selected for subsequent design, and the slab thickness increase is increased: △ t = (4VM 2 / π-d 2 t 0 ) / [d 2 (1-m 2 )] = 4.63mm, slab thickness: t 1 = T 0 + △ T = 5.43 mm. Select T in the actual thickness series 1 = 6.0 mm. Thus, after correction, Δt = 5.2mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com