Active suspension mechanism, AGV and AGV control method

An active suspension and trolley technology, applied to motor vehicles, control devices, suspensions, etc., can solve problems such as easy suspension and rollover, and achieve superior shock absorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

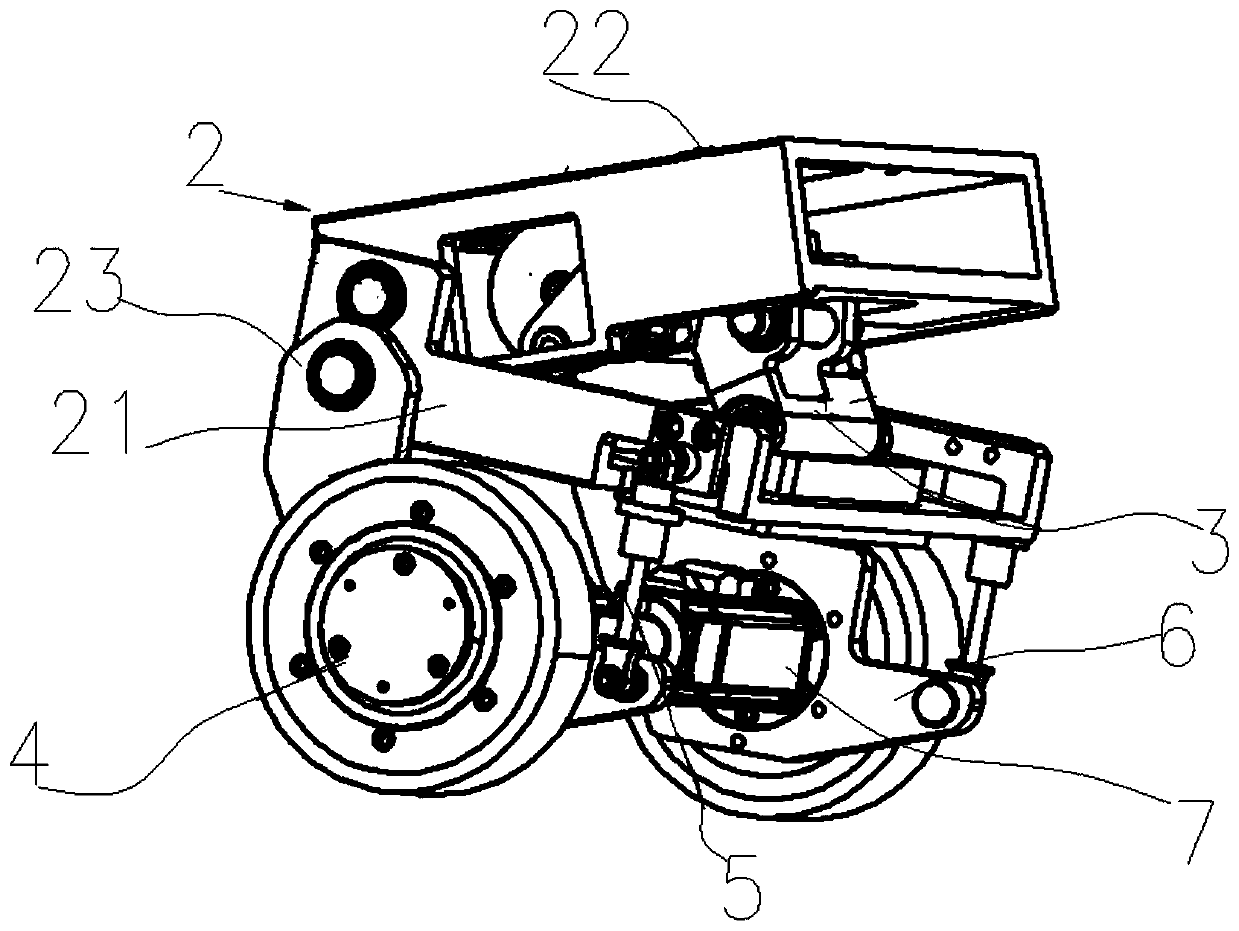

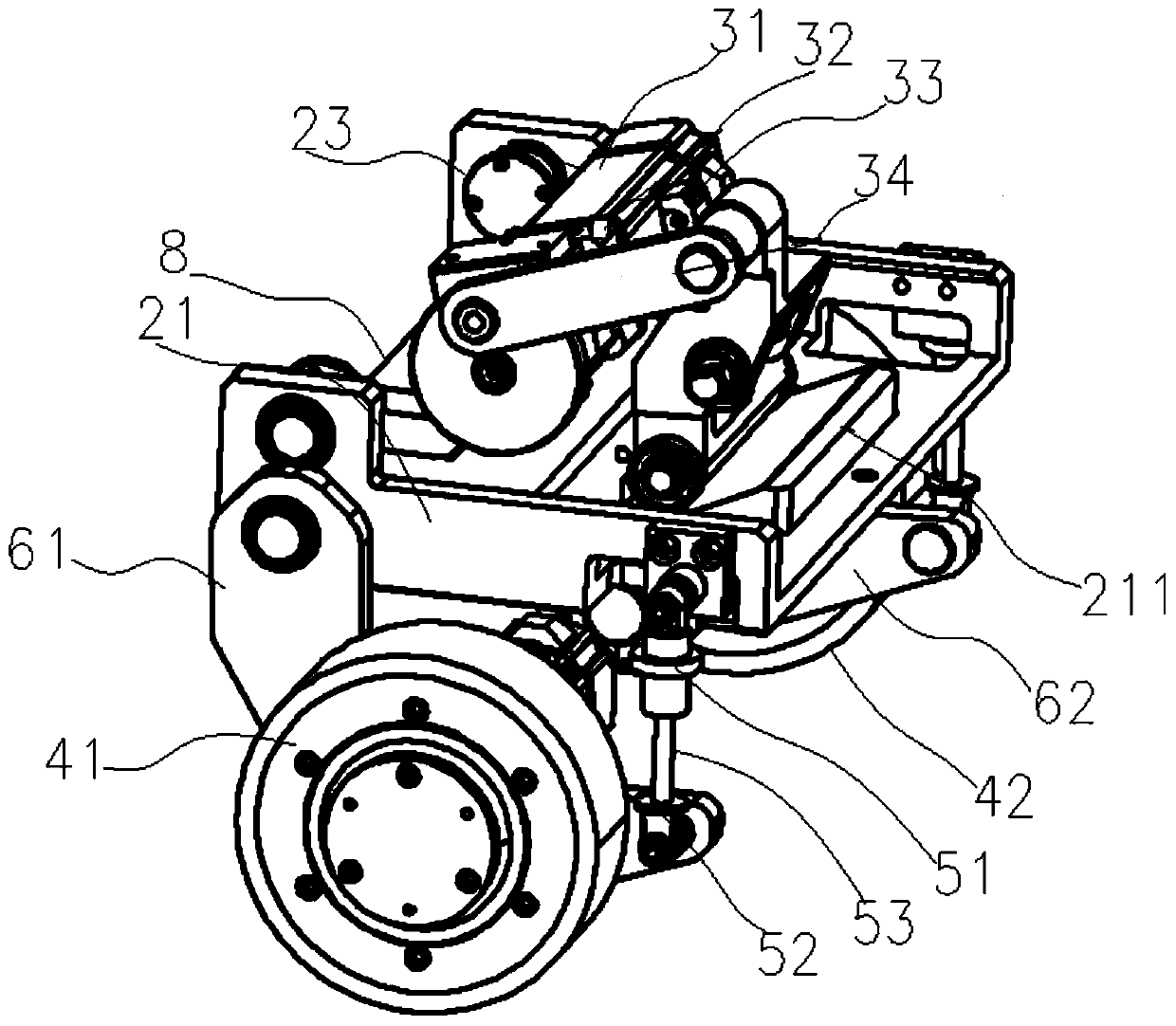

[0042] The embodiment of the present application discloses an active suspension mechanism, such as figure 1 As shown, the active suspension mechanism includes a fixed chassis 2 and a pressing device 2 for pressing down the fixed chassis 2, wherein one end of the fixed chassis 2 is used to connect with the steering wheel 4 of the AGV trolley, and the other end of the fixed chassis 2 is used to connect with the steering wheel 4 of the AGV trolley. The spring shock absorber 5 of the AGV trolley is connected. In this way, the downward pressure of the end of the fixed chassis 2 connected to the spring shock absorber 5 is controlled by the downward pressure applied by the downward pressure device 2 to the fixed chassis 2, and the spring shock absorber 5 stiffness and resistance (especially rebound resistance) is controlled by the downforce exerted by the fixed chassis 2. On the other hand, the friction between the steering wheel 4 of the AGV trolley and the ground is also controlled...

Embodiment 2

[0067] The embodiment of the present application discloses an AGV trolley. The AGV trolley includes a steering wheel 4, a spring shock absorber 5 and an active suspension mechanism, wherein the active suspension mechanism is an active suspension mechanism according to the embodiment of the present application.

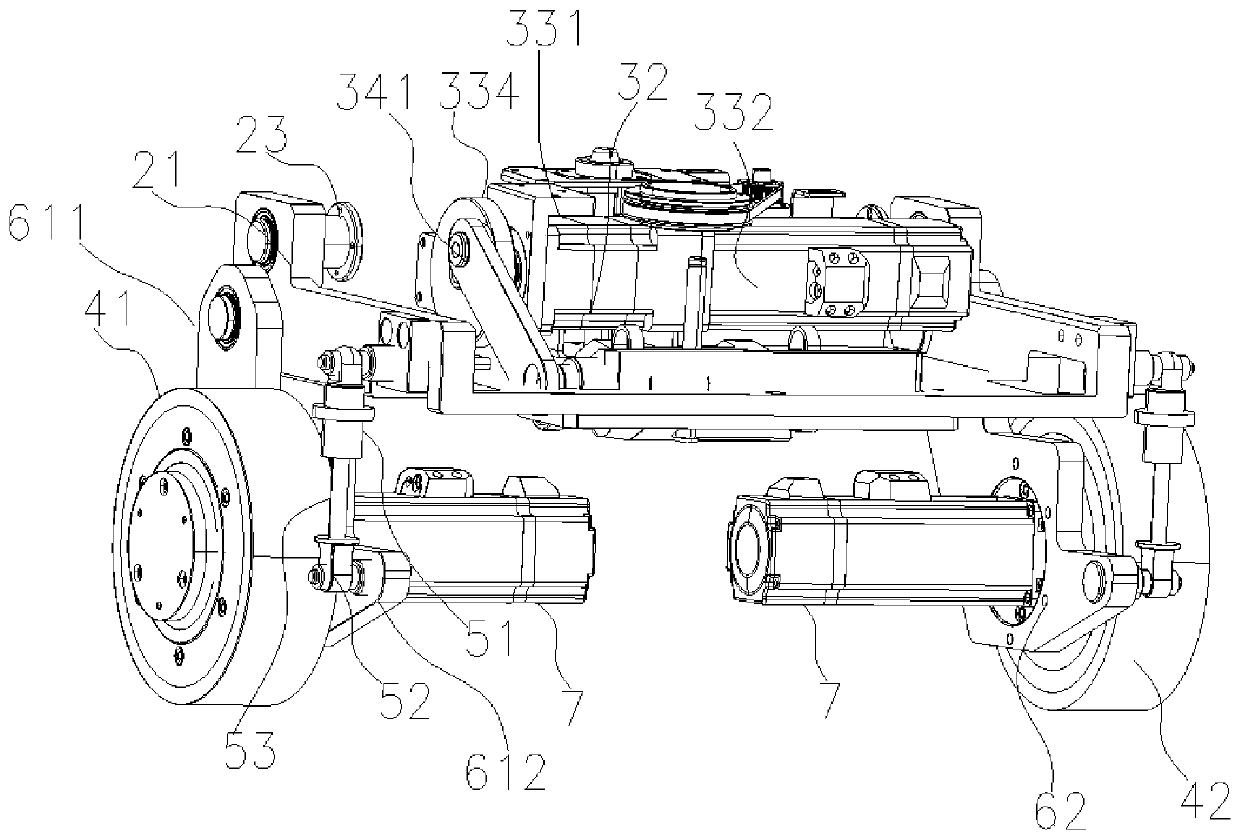

[0068] In the embodiment of this application, as figure 1 , figure 2 , image 3 As shown, the AGV trolley includes a left steering wheel 41 and a right steering wheel 42, and the left steering wheel 41 and the right steering wheel 42 are all located on the outside of the swing device 21. In this way, when the swing device 21 is pressed down, the left steering wheel 41 and the right steering wheel 42 do not It will be lower than the swing device 21, thereby reducing the probability of the left steering wheel 41 and the right steering wheel 42 being stuck.

[0069] In the embodiment of the present application, the AGV trolley also includes a second drive motor 7, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com