Sewage treatment desliming machine

A technology of sewage treatment and desliming machine, which is used in centrifugal separation of water/sewage treatment, centrifuges, centrifuges with rotating drums, etc., can solve the problems of insufficient centrifugation, poor desliming effect, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

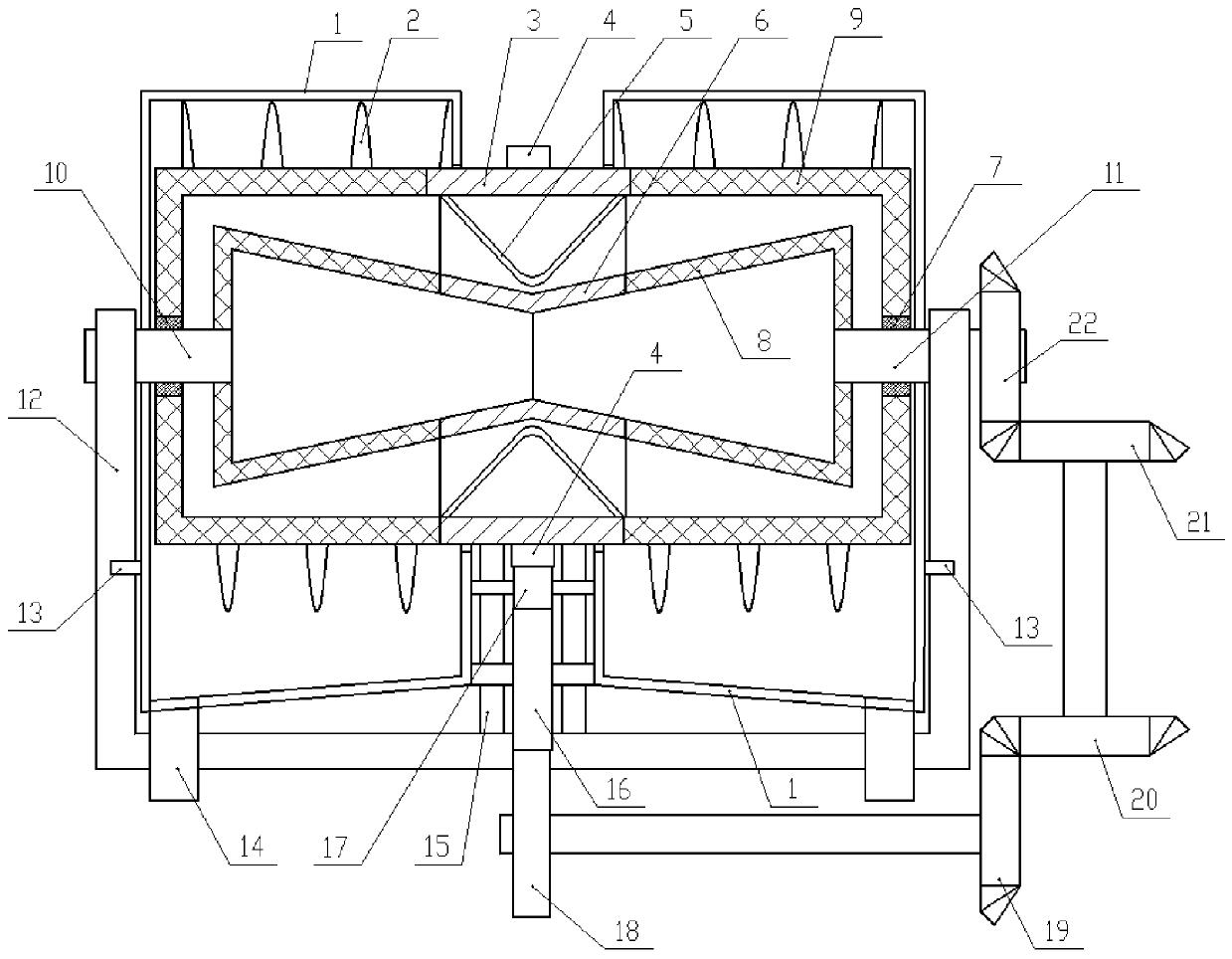

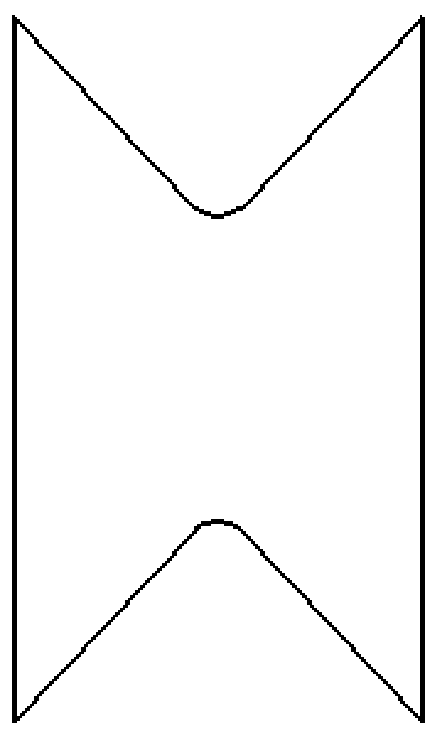

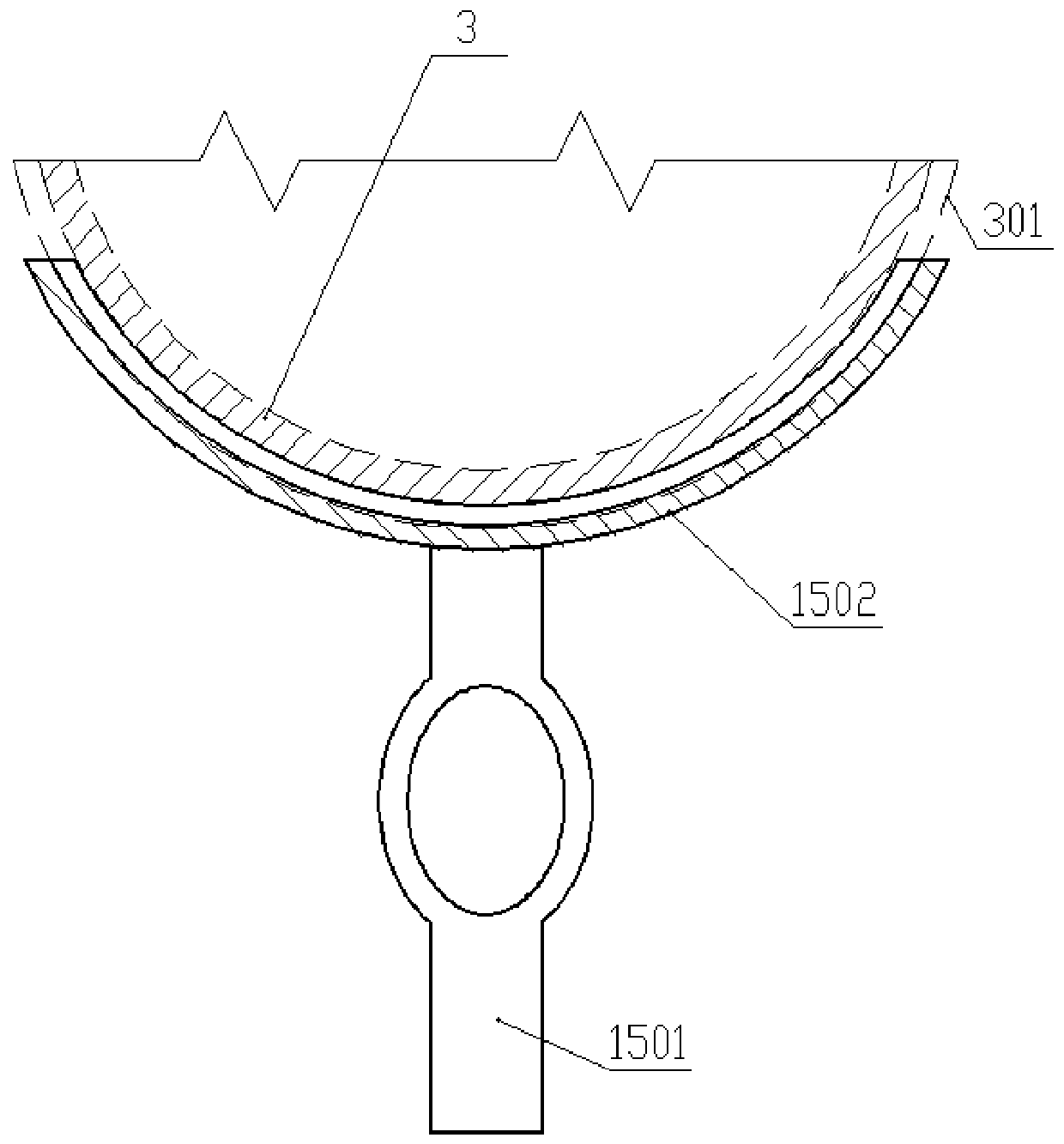

[0015] This embodiment provides a sewage treatment deslimer, which includes a centrifugal pipeline and a casing for a built-in centrifugal pipeline. The centrifugal pipeline can rotate in the casing. In particular, the centrifugal pipeline is horizontally arranged in the casing. In this embodiment The centrifuge tube of the example is double-layered, that is, if figure 1 , the centrifugal pipeline includes an inner pipeline 8 and an outer pipeline 9, the inner pipeline 8 is an hourglass-shaped structure with two ends large and the middle small, and the two ends of the inner pipeline 8 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com