A Process for Lowering the Recrystallization Temperature of 3003 Aluminum Alloy

A technology of recrystallization temperature and aluminum alloy, which is applied in the field of aluminum alloy processing, can solve problems such as uneven grain structure, affecting the surface quality and mechanical properties of aluminum alloy plates, so as to optimize mechanical properties, increase recrystallization nucleation rate, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

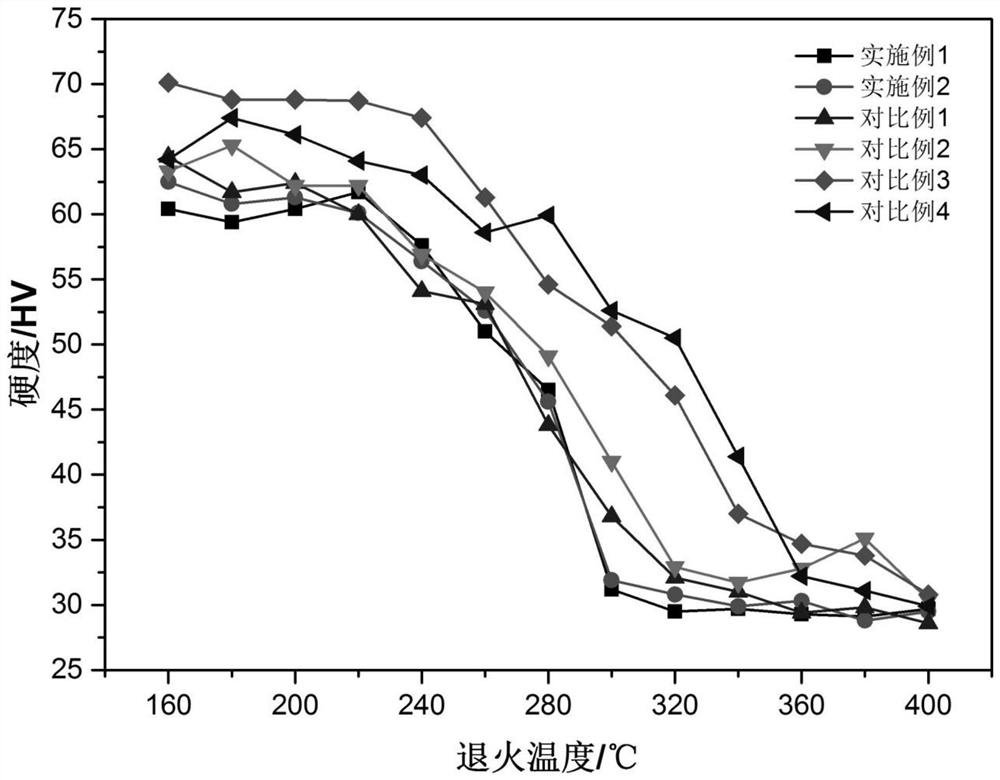

Image

Examples

Embodiment 1

[0024] A process for reducing the recrystallization temperature of 3003 aluminum alloys, comprising the steps of:

[0025] A. Ingredients: Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the ratio. The mass percentage ratio of each element of the 3003 aluminum alloy raw material is as follows:

[0026] Si Fe Cu mn Mg Cr Zn Ti Impurities Al content 0.141 0.544 0.087 1.12 0.002 0.001 0.01 0.017 0.06 margin

[0027] B. Melting and casting: Add the configured aluminum alloy raw materials into the melting furnace and mix them evenly, and then melt them into liquid aluminum alloys at a melting temperature of 750°C. Then pour the melted aluminum alloy melt into a refining furnace for refining at a refining temperature of 730°C. The refining time is 20 minutes, and the refined aluminum alloy melt is left standing at 720°C for 20 minutes;

[0028] C. Degassing and impurity...

Embodiment 2

[0033] A. Ingredients: Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the ratio. The mass percentage ratio of each element of the 3003 aluminum alloy raw material is as follows:

[0034] Si Fe Cu mn Mg Cr Zn Ti Impurities Al content 0.138 0.526 0.092 1.096 0.002 0.001 0.013 0.022 0.06 margin

[0035] B. Melting and casting: Add the configured aluminum alloy raw materials into the melting furnace and mix them evenly to melt into liquid aluminum alloy at a melting temperature of 740°C. Then pour the melted aluminum alloy melt into a refining furnace for refining at a refining temperature of 720°C. The refining time is 20 minutes, and the refined aluminum alloy melt is left standing at 720°C for 20 minutes;

[0036] C. Degassing and impurity removal: Pass the refined aluminum alloy melt into high-purity argon and stir the melt to remove the impurity gas in the alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com