A kind of high-strength viscose fiber non-woven fabric and preparation method thereof

A viscose fiber, non-woven technology, applied in the direction of plant fiber, fiber treatment, rayon made of viscose, etc., can solve the problems of poor compatibility, poor alkali resistance, low cross-linking activity of cellulose molecules, etc. , to achieve the effect of good compatibility and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the high-strength viscose nonwoven fabric provided by the invention comprises the following steps:

[0033] S1. adding the dendritic strengthening agent with a mass ratio of 10:90 to 30:70 into the viscose cellulose solution, stirring evenly and then vacuum defoaming to obtain a modified viscose cellulose solution; the dendritic reinforcing agent When the content is too high, on the one hand, it will reduce the spinnability of viscose fiber, on the other hand, it will lead to excessive cross-linking and reduce the characteristics of viscose fiber itself.

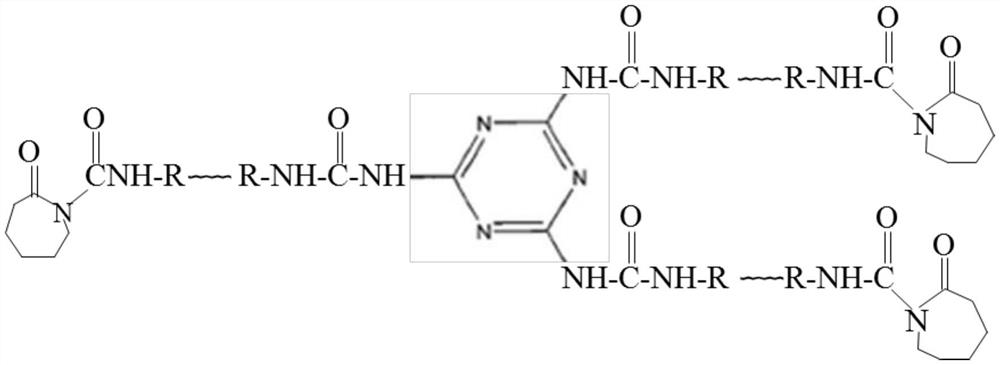

[0034] The structural formula of described dendritic reinforcing agent is as follows:

[0035]

[0036] In the formula, It is an isocyanate-terminated polyurethane prepolymer, R is one of hexamethylene, tolyl or diphenylmethane; the caprolactam at the end of the branch chain undergoes a ring-opening crosslinking reaction under the action of alkali and hot pressure, Improve the strength ...

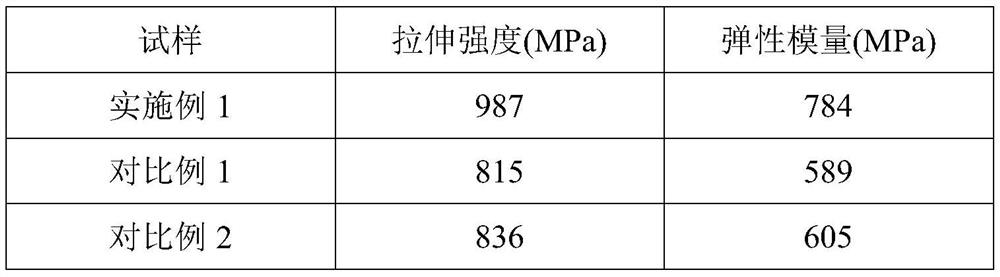

Embodiment 1

[0042] A high-strength viscose fiber non-woven fabric is prepared through the following steps:

[0043] S1. preparation 1000g mass concentration is the viscose cellulose solution of 12%, is 20:80 by mass ratio, 30g dendritic reinforcing agent is added in the viscose cellulose solution, after stirring, carry out vacuum defoaming process, obtain improved Viscose cellulose solution;

[0044] The dendritic reinforcing agent is prepared through the following steps:

[0045] S11. With a molar ratio of 1.2:1, weigh 20.9g of toluene diisocyanate and 50g of polypropylene glycol (molecular weight is about 500), first add polypropylene glycol into a three-necked flask, dry under reduced pressure at 110°C for 1 hour, and then proceed to the reaction At a temperature of 85°C, add toluene diisocyanate and react at a constant temperature for 2 hours to obtain an isocyanate-terminated polyurethane prepolymer with a molecular weight of 3000;

[0046] S12. Weigh 12.6g of melamine and 55g of i...

Embodiment 2 and 3

[0073] Compared with Example 1, Examples 2 and 3 differ in that the quality ratios of the dendritic reinforcing agent and viscose cellulose are shown in Table 2, and the others are basically the same as in Example 1, and will not be repeated here.

[0074] Preparation conditions and mechanical property test results of table 2 embodiment 2 and 3

[0075] Example mass ratio Tensile strength (MPa) Elastic modulus (MPa) 2 10:90 945 815 3 30:70 1010 867

[0076] As can be seen from the test results of Table 2 and Example 1, along with the increase of the mass ratio of dendritic reinforcing agent and viscose cellulose, the tensile strength and modulus of elasticity of viscose fiber nonwoven fabric are all constantly increasing , indicating that appropriately increasing the content of dendritic reinforcing agent helps to increase the tensile strength of viscose fiber nonwoven fabrics, while excessive elastic modulus will lead to a decrease in the elas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com