Ammonium salt sewage treatment flocculant

A technology for sewage treatment and flocculant, applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, textile industry wastewater treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

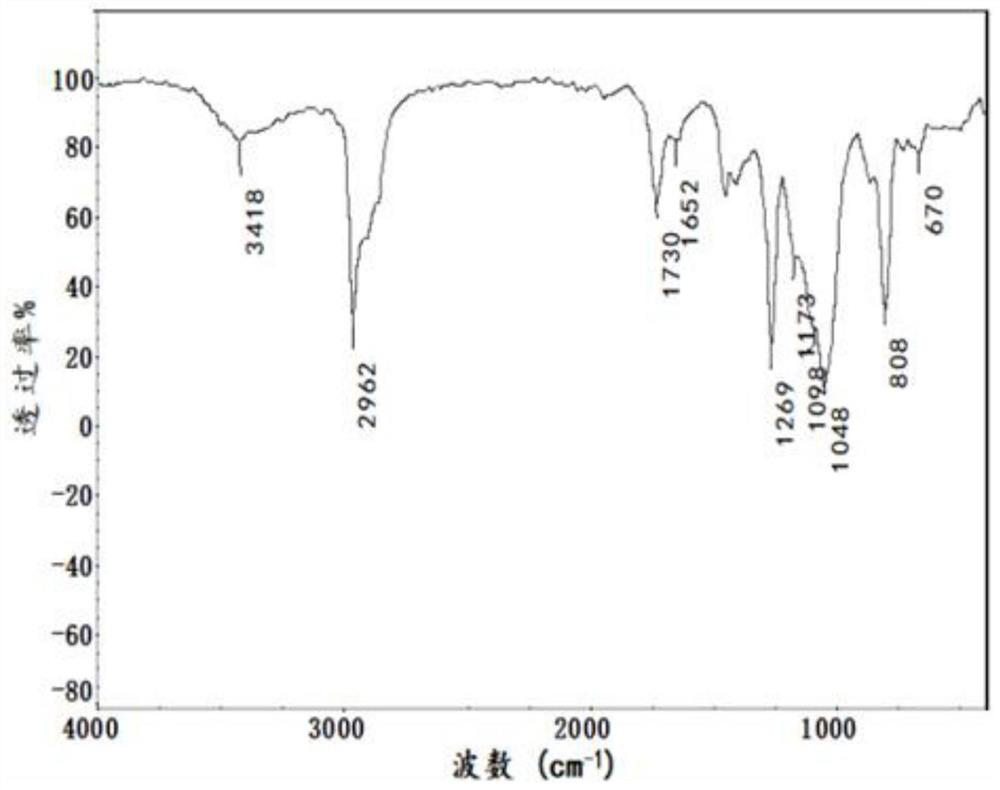

Image

Examples

Embodiment 1

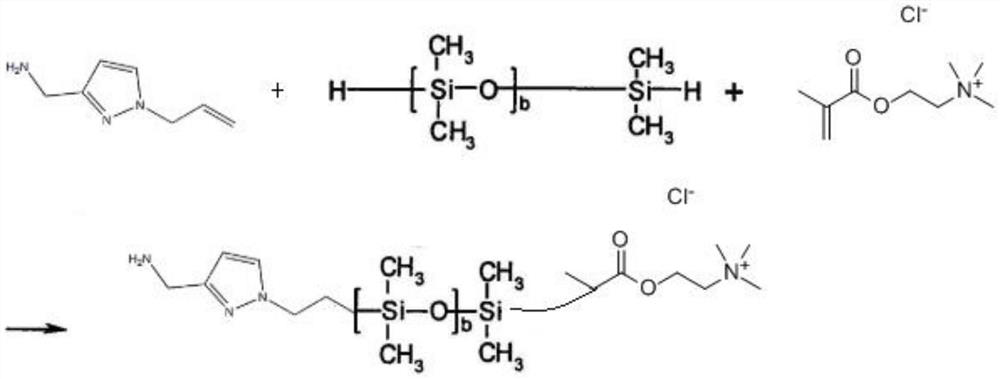

[0024] A kind of ammonium salt sewage treatment flocculant, its specific scheme is as follows:

[0025] 20g of methacryloyloxyethyltrimethylammonium chloride, 0.05g of 3-(aminomethyl)-1-allylpyrazole, 0.5g of 2-(allyloxymethyl)- 18-crown-6-ether, 10g of urea-modified chitosan, added to the reactor, protected by high-purity nitrogen, and 50g of hydrogen-containing silicone oil CAS: 63148-57-2, 150g of tetrahydrofuran, 5g of mass percent Add 3% isopropanol solution of chloroplatinic acid dropwise into the reaction kettle, use high-purity nitrogen protection, control the temperature at 60°C, stir for 2 hours, distill the reaction mixture under reduced pressure to remove tetrahydrofuran, and then obtain the ammonium salt Sewage treatment flocculant.

[0026] Described modified chitosan is a kind of urea modified chitosan, and its preparation method is as follows:

[0027] Mix 15g of chitosan with 150g of acetic acid solution with a concentration of 1% by mass and stir evenly, th...

Embodiment 2

[0034] A kind of ammonium salt sewage treatment flocculant, its specific scheme is as follows:

[0035] With 23g of methacryloxyethyltrimethylammonium chloride, 0.3g of 3-(aminomethyl)-1-allylpyrazole, 0.8g of 2-(allyloxymethyl)- 18-crown-6-ether, 14g of urea-modified chitosan, added to the reactor, protected by high-purity nitrogen, and 60g of hydrogen-containing silicone oil CAS: 63148-57-2, 160g of tetrahydrofuran, 7g by mass The isopropanol solution of chloroplatinic acid with a content of 3-7% is added dropwise into the reaction kettle, protected by high-purity nitrogen, controlled at a temperature of 65° C., stirred for 2.5 hours, and the reaction mixture is distilled off under reduced pressure to remove tetrahydrofuran to obtain the one A flocculant for ammonium salt sewage treatment.

[0036] Described modified chitosan is a kind of urea modified chitosan, and its preparation method is as follows:

[0037]18g of chitosan and 180g of mass percent concentration of 3% a...

Embodiment 3

[0044] A kind of ammonium salt sewage treatment flocculant, its specific scheme is as follows:

[0045] With 30g of methacryloxyethyltrimethylammonium chloride, 0.5g of 3-(aminomethyl)-1-allylpyrazole, 1.2g of 2-(allyloxymethyl)- 18-crown-6-ether, 17g of urea-modified chitosan, added to the reactor, protected by high-purity nitrogen, and 70g of hydrogen-containing silicone oil CAS: 63148-57-2, 170g of tetrahydrofuran, 10g by mass Add the isopropanol solution of chloroplatinic acid with a content of 7% dropwise into the reaction kettle, use high-purity nitrogen protection, control the temperature at 70°C, stir for 4 hours, distill the reaction mixture under reduced pressure to remove tetrahydrofuran, and then obtain the ammonium salt Sewage treatment flocculant.

[0046] Described modified chitosan is a kind of urea modified chitosan, and its preparation method is as follows:

[0047] 20g chitosan and 200g mass percentage concentration are 5% acetic acid solution mixing and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com