Method for improving efficiency of treating harmful algal blooms by clay based on microbial compound modification

A compound modification and microbial technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve good application prospects, strengthen bridging effect, and enhance removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 7 parts, each part of 0.5g kaolin and 0.1g polyaluminium chloride powder, mix well, sterilize by high-temperature steam at 121°C for 30min, dry in an oven at 80°C for 1h, sterilize under ultraviolet light for 20min, cool To room temperature, 7 parts of type I modified clay are obtained, which are ready for use;

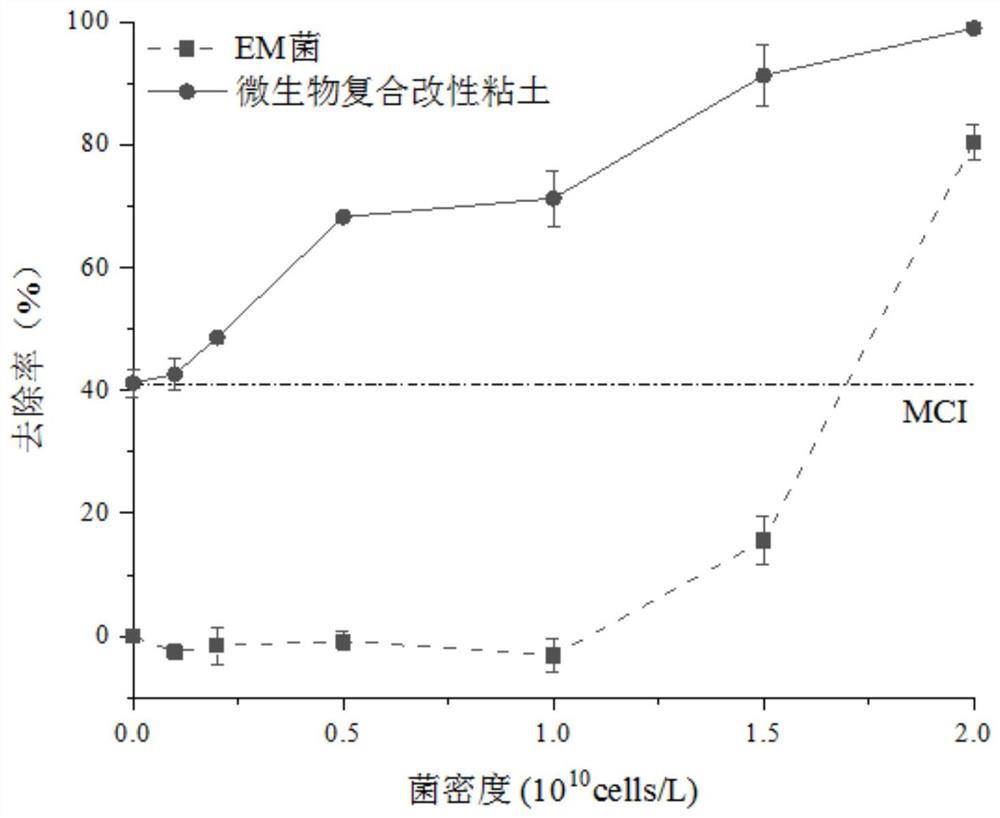

[0025] Dilute the EM bacteria solution with sterile seawater into mother solutions with the same volume and different bacterial densities, and add the above-mentioned Type I modified clay to it, so that each gram of modified clay is respectively equivalent to 0, 10 10 , 2×10 10 , 5×10 10 、10 11 , 1.5×10 11 , 2×10 11 A microbial compound was obtained to obtain a type I microbial compound modified clay stock solution, which was shaken and placed in a constant temperature shaking incubator at 30°C, and matured for 2 hours at an oscillation frequency of 150r / min to obtain a microbial compound modified clay system.

[0026] Among them, the EM bacterial li...

Embodiment 2

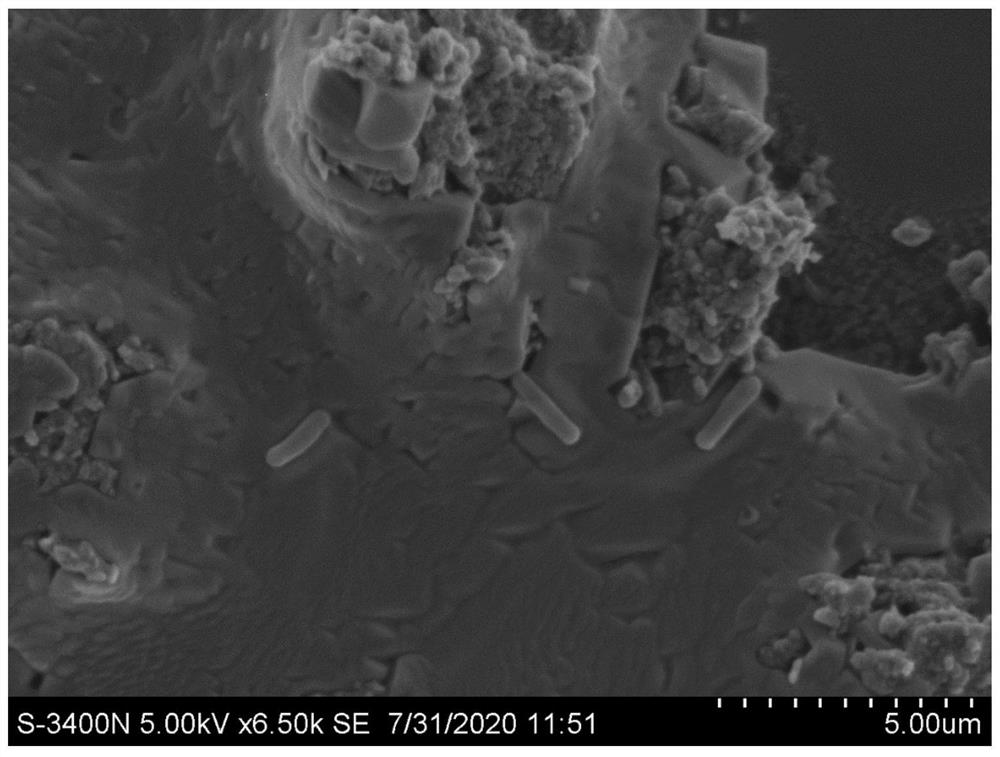

[0030] The above microbial composite modified clay system was centrifuged (8000r / min, 3min), the supernatant was discarded and the sample was completely submerged in 5% glutaraldehyde for 1h. Rinse and soak the samples with 0.1 mol / L phosphate buffer at room temperature for 3 times (10 min each time), dehydrate them with ethanol gradient, and replace them with isoamyl acetate. After drying in a critical point dryer for 3 hours, the samples were fixed with conductive adhesive and sprayed with gold. A scanning electron microscope (S-3400N, Hitachi, JP) was used to observe the solidification of microorganisms on the composite modified clay surface. Such as figure 2 As shown, microorganisms can immobilize on the modified clay surface.

Embodiment 3

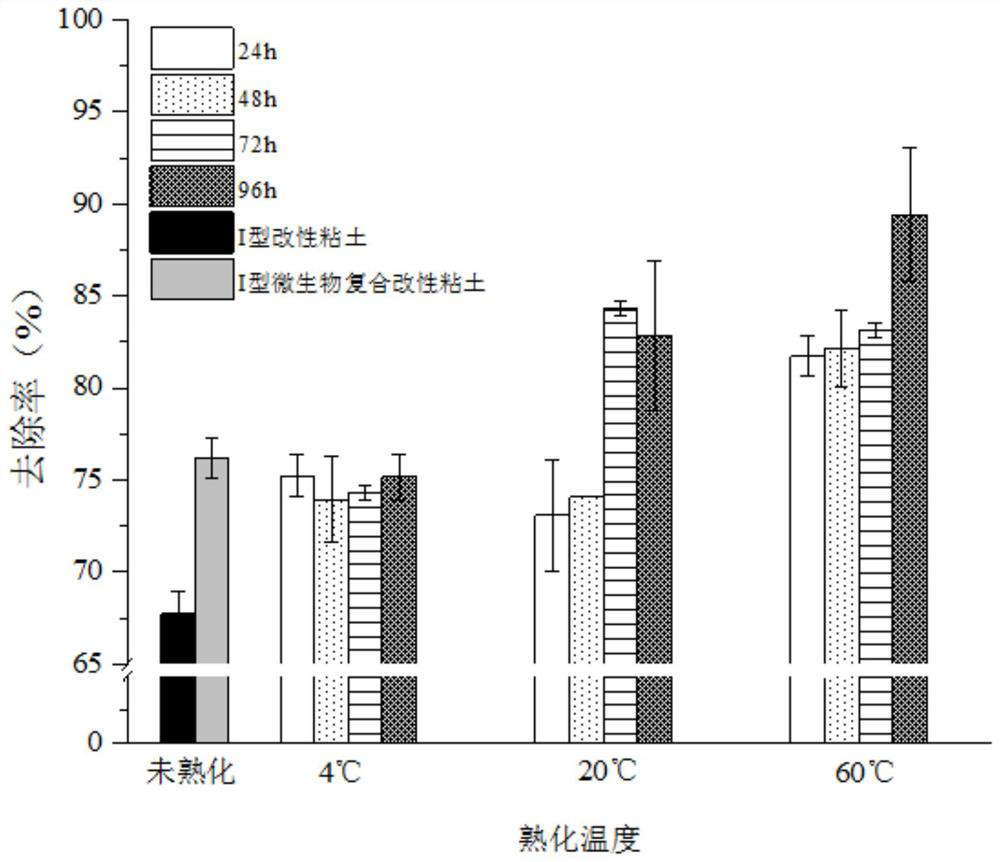

[0032] Prepare microbial composite modified clay system as described in embodiment 1, make every gram of clay solidify 5 * 10 10 After mixing, shake them well and place them in constant temperature shaking incubators at 4°C, 20°C, and 60°C, respectively, and ripen them at each temperature for 4h, 48h, 72h, and 96h at an oscillation frequency of 150r / min, that is, they can be obtained at different temperatures. Microbial compound modified clay system with different curing time.

[0033] Take the algae liquid of Prorocentrum donghaiense in the exponential growth phase (algae cell density is about 1×10 8cell / L) to a 50mL colorimetric tube, add the microbial composite modified clay stock solution that was matured at different temperatures for different times in the algae liquid, so that the final concentration is 0.1g / L. Shake well, let it stand for 24 hours, and calculate its algae removal efficiency (see image 3 ). The results showed that within the appropriate range, the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com