Three-dimensional steel fiber, manufacturing mold and method and concrete applying three-dimensional steel fiber

A steel fiber, three-dimensional technology, which is applied in the field of three-dimensional steel fibers, manufacturing molds and methods, and concrete fields using three-dimensional steel fibers, can solve the problem of limited fiber bridging effect, destroying the shape of three-dimensional steel fibers, and not much utilization and research and development of three-dimensional steel fibers. and other problems, to achieve the effect of improving the ability to resist elastic shock waves, reducing the risk of cracking, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

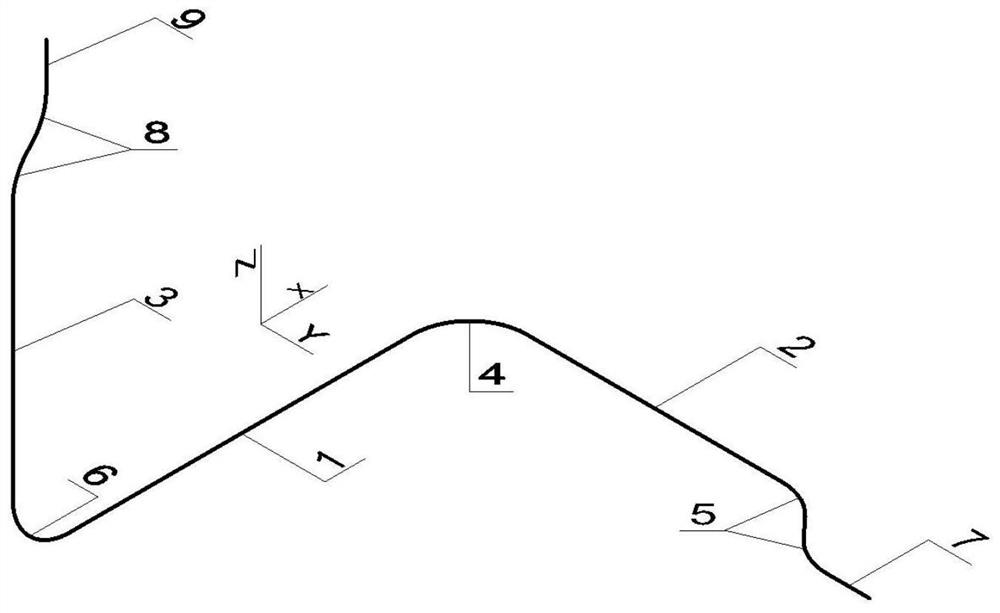

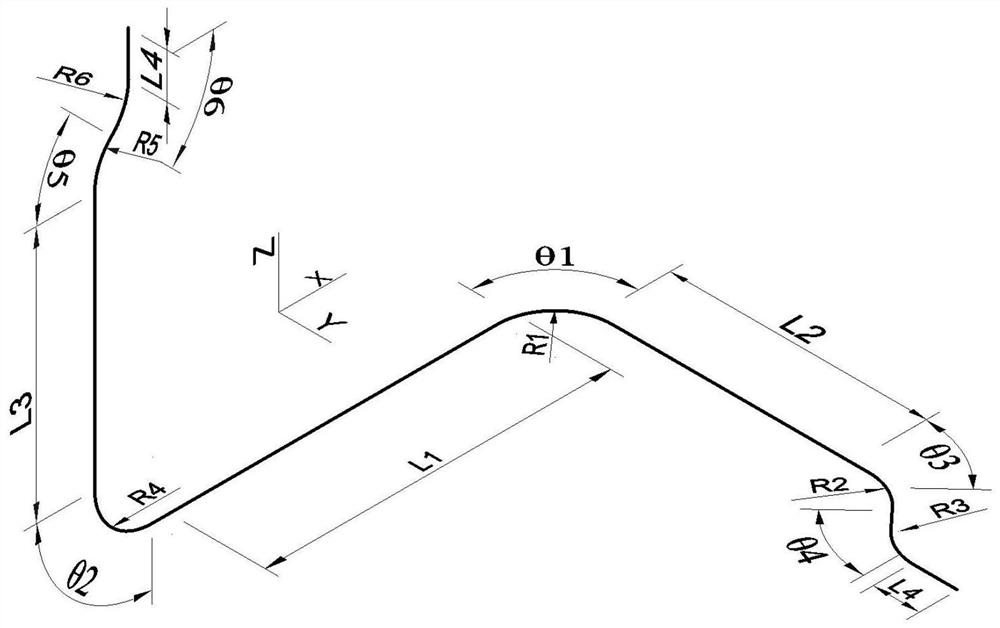

[0064] The nominal tensile strength is not less than 1100MPa, a steel wire having a diameter of 0.55 mm and a length of 44 mm, wherein it is prepared according to the above steps, wherein the length L1 of the line segment 1 is 12.0 mm, and the length L2 of the line segment 2 is 6.0 mm. The length L3 of the linear segment 3 is 6.0 mm, the radius r1 and R4 of the arc segments 4 and 6 are 4.0 mm, the angles θ1 and θ2 are π / 2, and the radius of the two anti-direction small arc of the large circular arc segment 5. And R3 is 2.0mm, the angles θ3 and θ4 are π / 4, and the radius R5 and R6 of the two anti-direction small arcs of the large circular arc section 8 are 2.0 mm, angles θ5 and θ6 are π / 4, two straight segments. The length L4 of 7 and 9 is 2.0mm, and the steel fiber has a long diameter ratio of 80.

Embodiment 2

[0066] The nominal tensile strength is not less than 1100 MPa, a steel wire having a diameter of 0.55 mm and a length of 44 mm, wherein it is prepared according to the above steps, wherein the length L1 of the line segment 1 is 9.0 mm, and the length L2 of the line segment 2 is 9.0 mm. The length L3 of the linear segment 3 is 9.0 mm, the radius R1 and R4 of the arc segments 4 and 6 are 2.5 mm, angles θ1 and θ2 are π / 2, and the radius R2 of the two anti-directional arcs of the large circular arc segment 5. And R3 is 2.0mm, the angles θ3 and θ4 are π / 4, and the radius R5 and R6 of the two anti-direction small arcs of the large circular arc section 8 are 2.0 mm, angles θ5 and θ6 are π / 4, two straight segments. The length L4 of 7 and 9 is 1.5 mm, and the steel fiber has a long diameter ratio of 80.

Embodiment 3

[0068] The nominal tensile strength is not less than 1100 MPa, a steel wire having a diameter of 0.55 mm and a length of 36 mm, wherein it is prepared in the above steps, wherein the length L1 of the line segment 1 is 7.0 mm, and the length L2 of the line segment 2 is 7.0 mm. The length L3 of the linear segment 3 is 7.0 mm, the radius R1 and R4 of the arc sections 4 and 6 are 2.0 mm, the angles θ1 and θ2 are π / 2, and the radius R2 of the two anti-directional arcs of the large circular arc segment 5. And R3 is 2.0 mm, 1.5 mm, angle θ3 and θ4 are π / 4, and the radii R5 and R6 of the two anti-direction small arcs of the large circular arc section 8 are 2.0 mm, 1.5 mm, angle θ5 and θ6. π / 4, the length L4 of the two linear sections 7 and 9 is 1.5 mm, and the steel fiber has a long diameter ratio of 65.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com