A plugging material and plugging slurry for protecting low-pressure fractured reservoirs

A plugging material and plugging slurry technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of low plugging success rate, increase the static pressure of the liquid column, increase the degree of leakage, etc., to achieve Improve plugging success rate, balance formation pressure, good plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

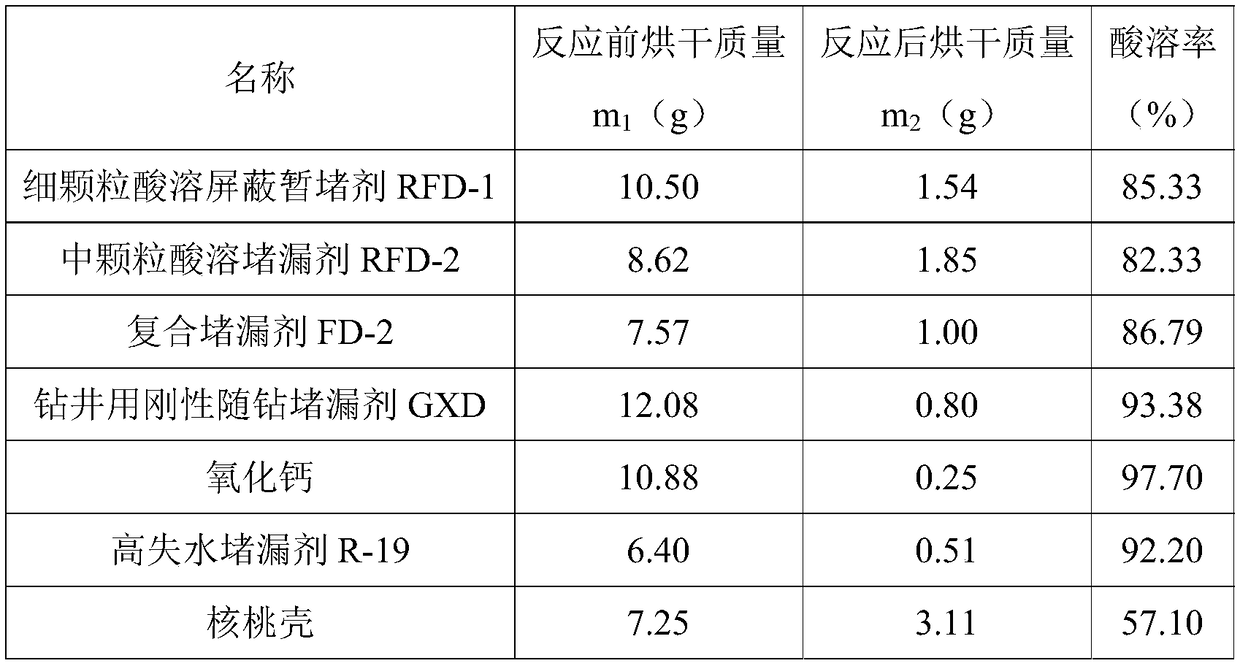

Embodiment 1

[0027] The plugging slurry for protecting low-pressure fractured reservoirs of this embodiment is composed of the following parts by weight: 2 parts of walnut shell with a particle size of 7-20 mesh, 3 parts of walnut shell with a particle size of 5-7 mesh, 2 parts of compound plugging agent FD-2, 1.5 parts of rigid while drilling plugging agent GXD for drilling, 3 parts of fine particle acid-soluble shielding temporary plugging agent RFD-1, 2 parts of medium particle acid-soluble plugging agent RFD -2, 4 parts of high water loss plugging agent R-19, 0.3 parts of calcium oxide, 100 parts of water.

[0028] The method for preparing the plugging slurry is as follows: adding the raw materials of each component except water into water and mixing them uniformly.

Embodiment 2

[0030] The plugging slurry for protecting low-pressure fractured reservoirs in this embodiment is composed of the following components by weight: 3 parts of walnut shells with a particle size of 7-20 mesh, 3 parts of walnut shells with a particle size of 5-7 mesh, 3 parts of compound plugging agent FD-2, 2 parts of rigid while drilling plugging agent GXD for drilling, 2 parts of fine particle acid-soluble shielding temporary plugging agent RFD-1, 2 parts of medium particle acid-soluble plugging agent RFD -2, 5 parts of high water loss plugging agent R-19, 0.2 parts of calcium oxide, 100 parts of water.

[0031] The method for preparing the plugging slurry is as follows: adding the raw materials of each component except water into water and mixing them uniformly.

experiment example 1

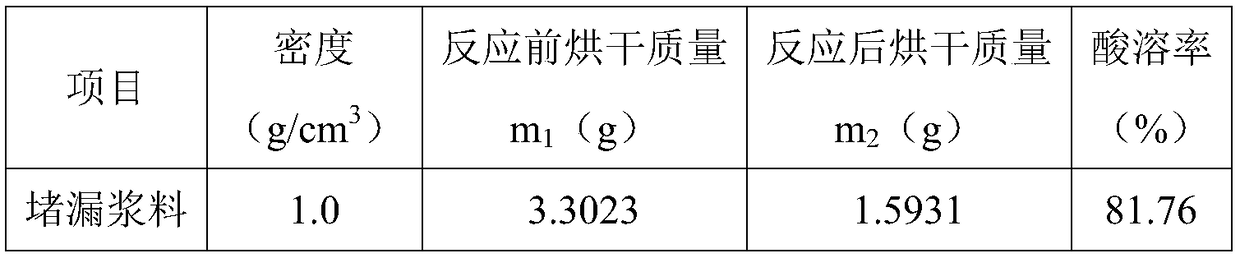

[0032] Experimental example 1 (indoor experiment)

[0033] In this experimental example, the plugging performance of the plugging slurry of Example 2 was tested.

[0034] The experimental method is as follows:

[0035] 1) Take the formula amount of water, add soda ash, sodium sakamoto, high-viscosity sodium carboxymethyl cellulose (HV-CMC), potassium polyacrylate (K-PAM) in sequence, stir at high speed for 10 hours until the mixture is uniform, and then cover and seal. Let stand for 24h to get the base slurry;

[0036] In the base slurry, relative to 100 parts by weight of water, the amount of soda ash is 0.3 parts by weight, the amount of Nasaka clay is 5 parts by weight, the amount of HV-CMC is 0.3 parts by weight, and the amount of K-PAM is 0.3 parts by weight;

[0037] 2) In the base slurry obtained in step 1), a formula amount of walnut shells, a composite plugging agent, a plugging agent while drilling, an acid-soluble plugging agent, a high water loss plugging agent, and calcium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com