Warehouse sealing door

A technology of airtight doors and warehouses, which is applied in the field of warehouse airtight doors, can solve problems such as poor closing of the door bottom, poor sealing performance, and large warehouse doors, so as to increase airtightness and shock resistance, increase heat preservation and airtightness, reduce The effect of noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

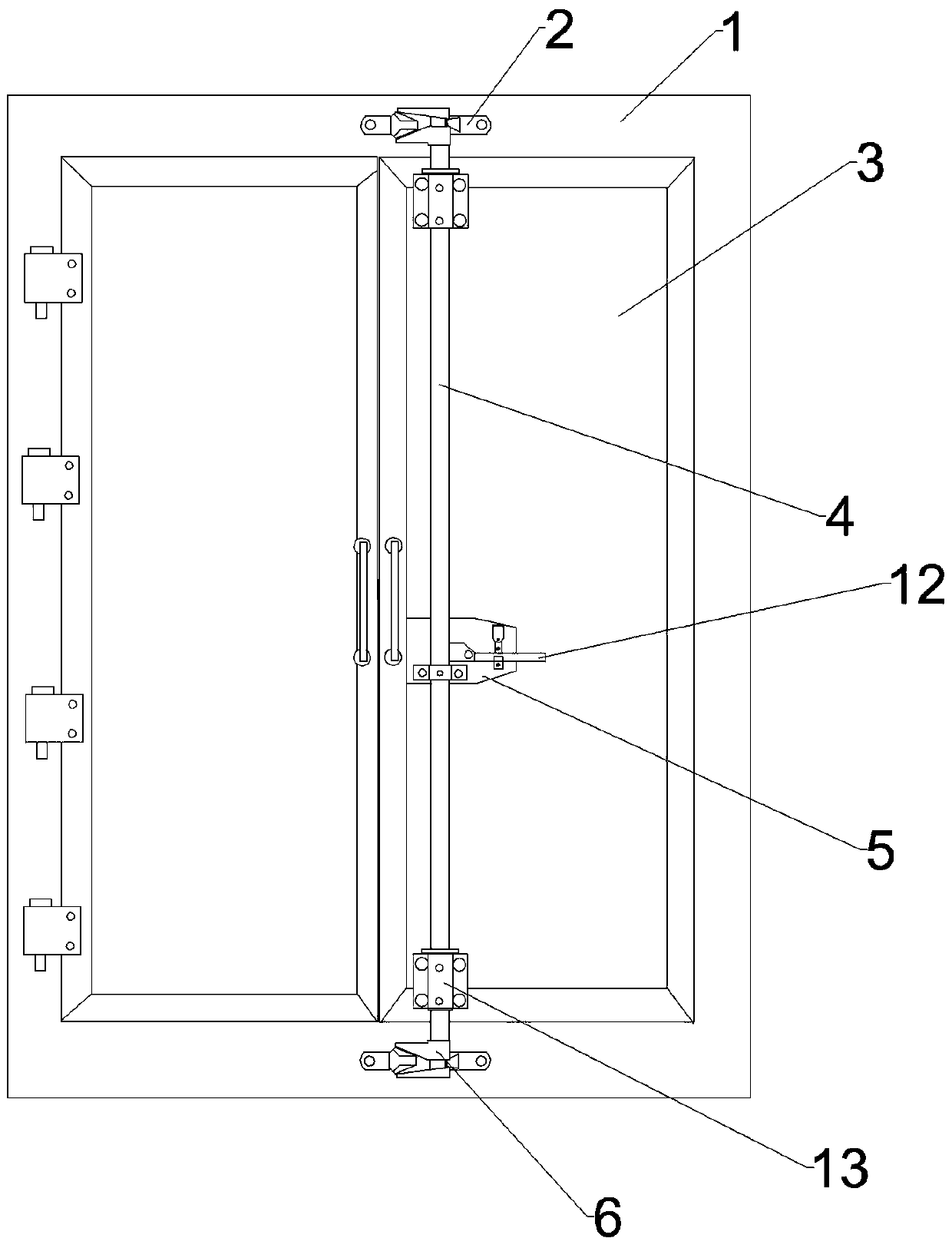

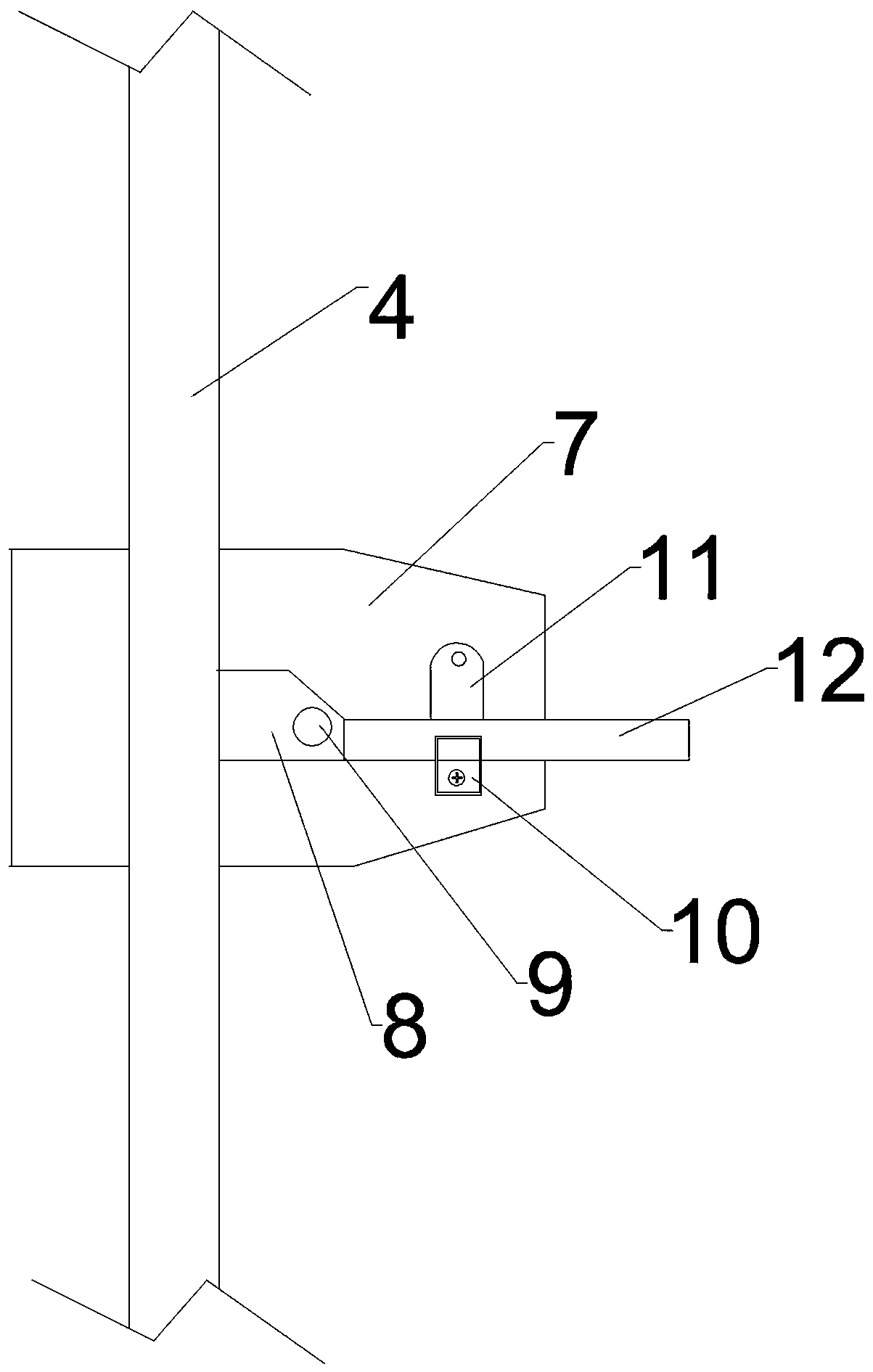

[0043] Such as Figure 1-16 As shown, a warehouse airtight door, the airtight door is a two-way split type, including a door leaf installed on the door frame 1 through a door shaft and a door lock arranged on the door leaf; the door leaf is divided into a left door leaf and a door leaf. The right door leaf; the left door leaf and the right door leaf respectively include a sealed door frame and a door panel 3 arranged in the sealed door frame; the door panel 3 is a five-layer structure, which is successively 37 layers of color steel plate, 39 layers of foaming agent, 38 layers of polyurethane, and 38 layers of polyurethane. Foam agent 39 layers and color steel plate 37.

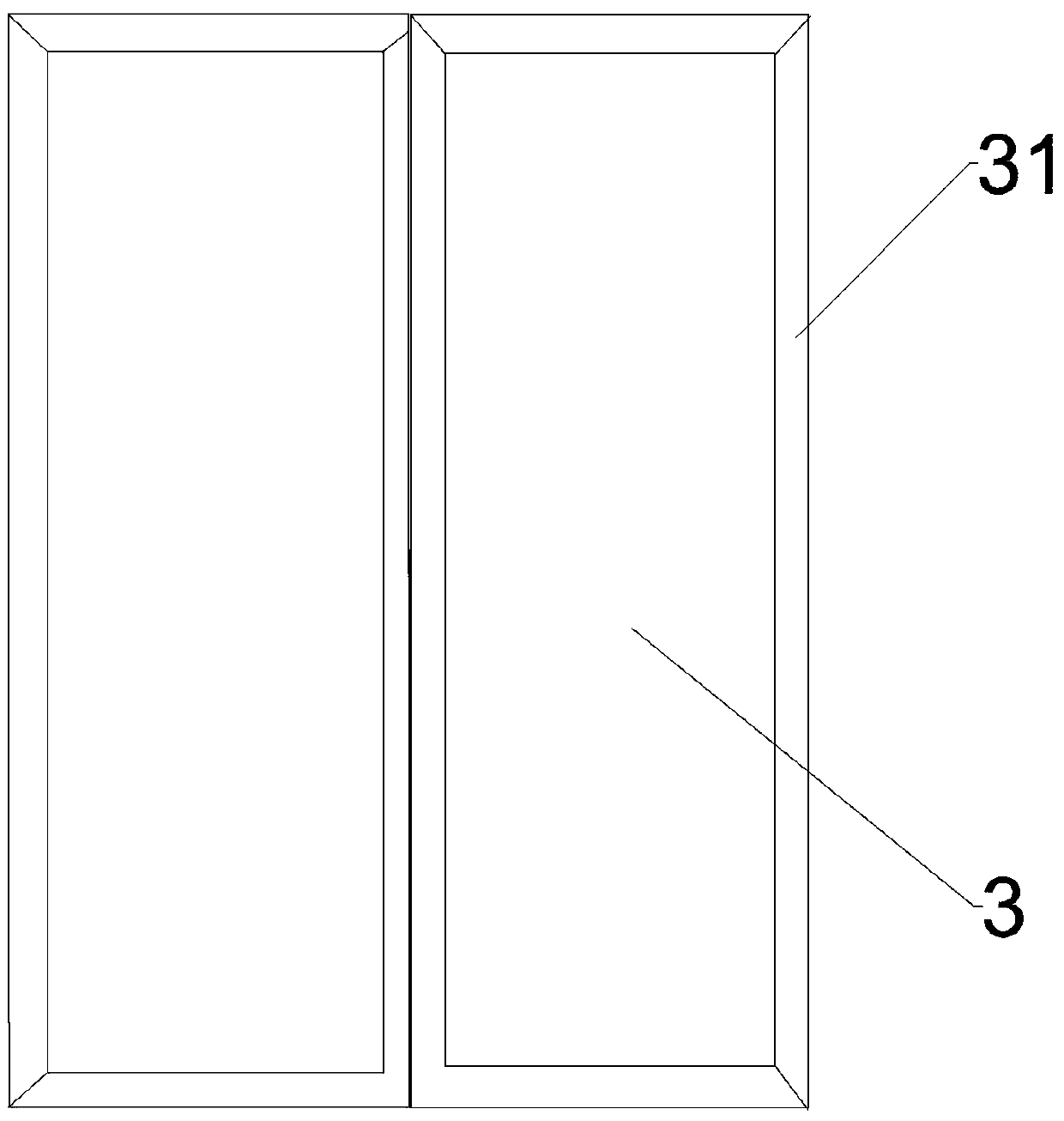

[0044] The sealed door frame is a rectangular structure assembled by four frames 31; the frame 31 is designed in one piece, which includes a hollow layer 32 and a first baffle plate 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com