Method and system for realizing dynamic production scheduling in energetic material production process

A production process and dynamic technology, which is applied in the field of dynamic production scheduling in the production process of energetic materials, can solve the problems of complex production scheduling models and optimization algorithms, and it is difficult to meet the actual production scheduling needs, so as to improve the effective output of the system and respond in a timely manner. Production emergencies and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

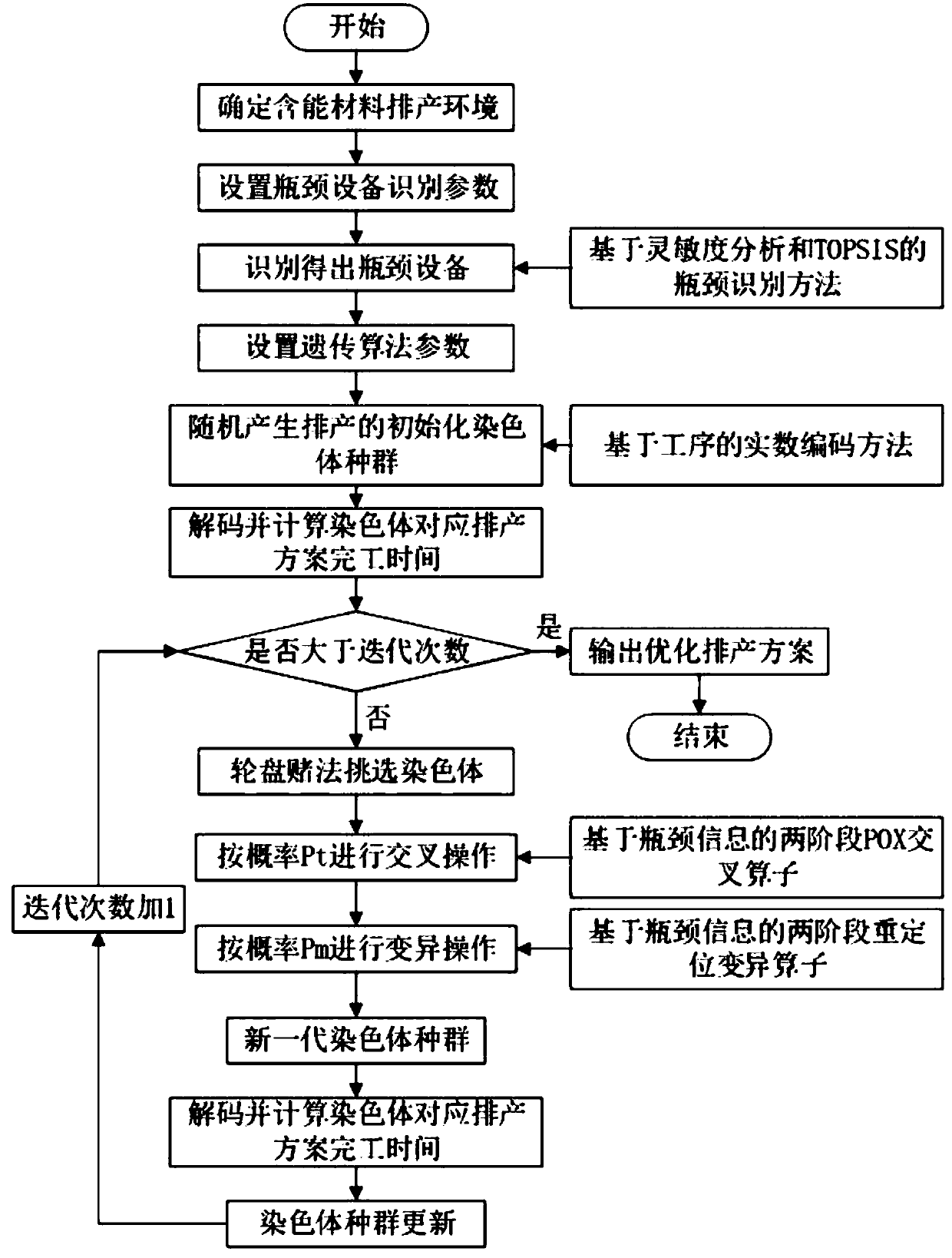

[0047] combined with figure 1 As shown, a method for realizing dynamic scheduling in the production process of energetic materials includes:

[0048]Step A: Select production scheduling tasks according to the production plan, and determine the number of product batches to be scheduled, the number and type of equipment in the production system, and the processing time required for each process of the product, etc.;

[0049] Step B: Set the bottleneck equipment identification parameters, mainly including population size (corresponding to the number of randomly generated scheduling plans), equipment capacity change trend (corresponding to the increase or decrease of equipment processing volume), initial value of equipment capacity change, and equipment capacity change Final value (corresponding to the amount of change in equipment processing, if the trend of change in equipment capability is increasing, the initial value of change in equipment capability is the minimum value of c...

Embodiment 2

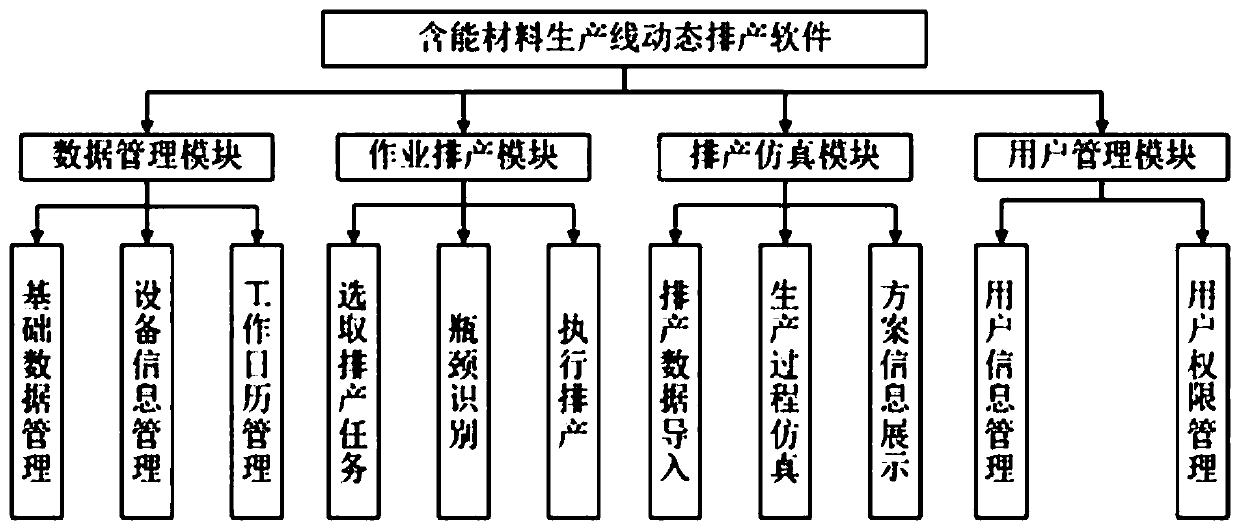

[0057] to combine figure 2 As shown, a system for realizing dynamic scheduling in the production process of energetic materials includes:

[0058] Data management module, including basic data management, equipment information management and work calendar management, used to manage the basic process data of production scheduling and solution data of job scheduling, and store, query, modify and delete data information;

[0059] The job scheduling module includes the submodule of selecting scheduling tasks, the submodule of bottleneck identification and the submodule of executing scheduling, among which:

[0060] Select the production scheduling task sub-module, and select the production scheduling task according to the production plan;

[0061] The bottleneck identification sub-module is used to calculate and identify the bottleneck equipment in the production system of energetic materials;

[0062] Execute the scheduling sub-module, which is used to solve the energetic mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com