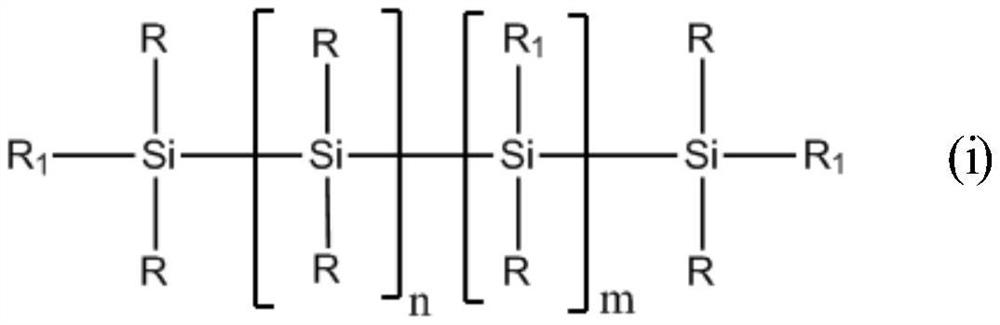

A polysiloxane composition

A polysiloxane and composition technology, which is applied in the fields of addition type mixing silicone rubber and addition type silicone rubber, can solve the problems of uncertain vinyl weight ratio or vinyl mole fraction, inability to calculate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

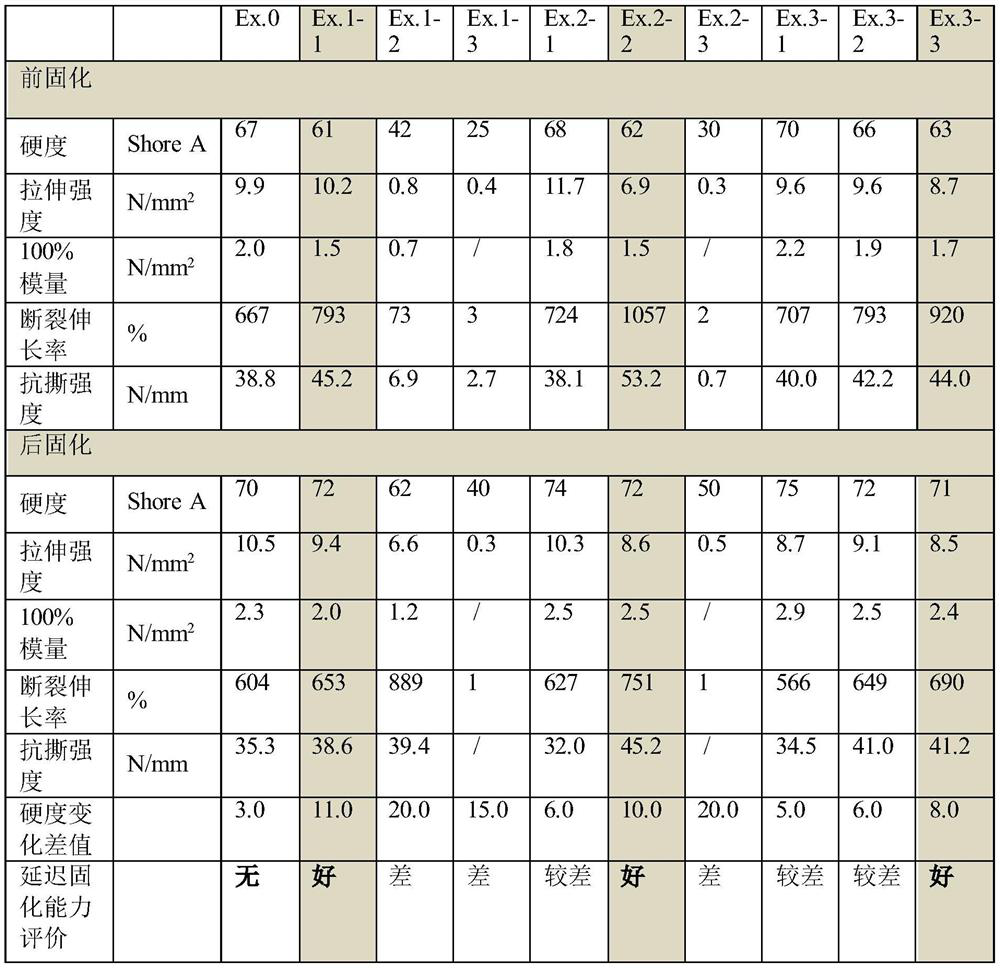

Examples

Embodiment Construction

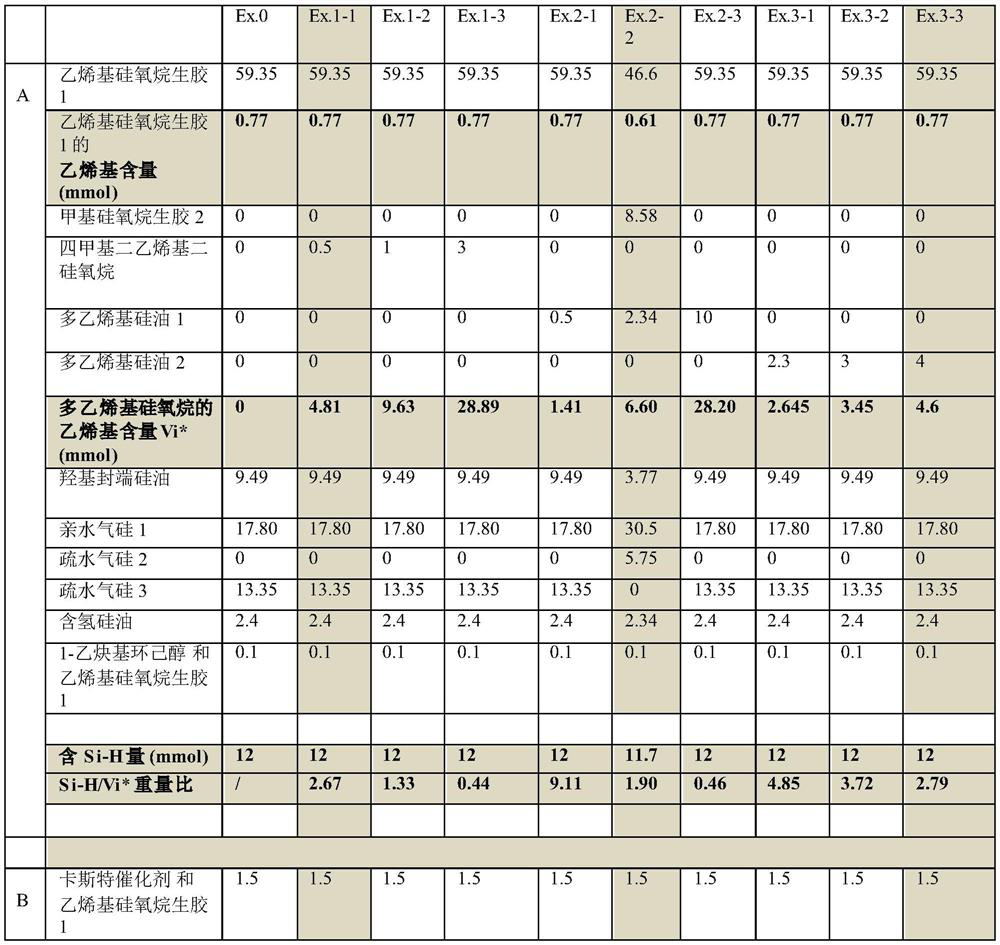

[0057] Vinyl silicone raw rubber 1: a methyl vinyl silicone rubber raw rubber, Mw=500 000g / mol, vinyl content 0.013mmol / g,

[0058] Methylsiloxane raw rubber 2: a kind of dimethyl silicone rubber raw rubber, Mw=500 000g / mol, almost no vinyl,

[0059] Tetramethyldivinyldisiloxane: a polyvinylsiloxane with a vinyl content of 26 wt%, 9.6 mmol / g,

[0060] Polyvinyl silicone oil 1, a kind of polyvinyl siloxane, according to DIN 53019-1-2008 at 25 ℃, Brookfield rotational viscometer measurement viscosity is 1080mPa.s, vinyl content 7.8wt%, 2.82mmol / g, Vinyl mole fraction = 20.7%,

[0061] (20.7% vinyl mole fraction is equivalent to about 20.70 methylvinylsiloxane chains per 100 siloxane chains in the copolymer),

[0062] Polyvinyl silicone oil 2, a polyvinylsiloxane with a viscosity of 1000-3000mm measured at 25°C according to DIN 53019-1-2008 2 / s, vinyl content 3.3wt%, 1.15mmol / g, vinyl mole fraction=9.4%,

[0063] (9.4% vinyl mole fraction is equivalent to about 9.4 methyl vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com