Multifunctional composite dust remover

A composite dedusting and multi-functional technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor fine powder collection ability, high use cost, bag dust removal and sticky bags, etc., to improve the dust removal effect, Long service life and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

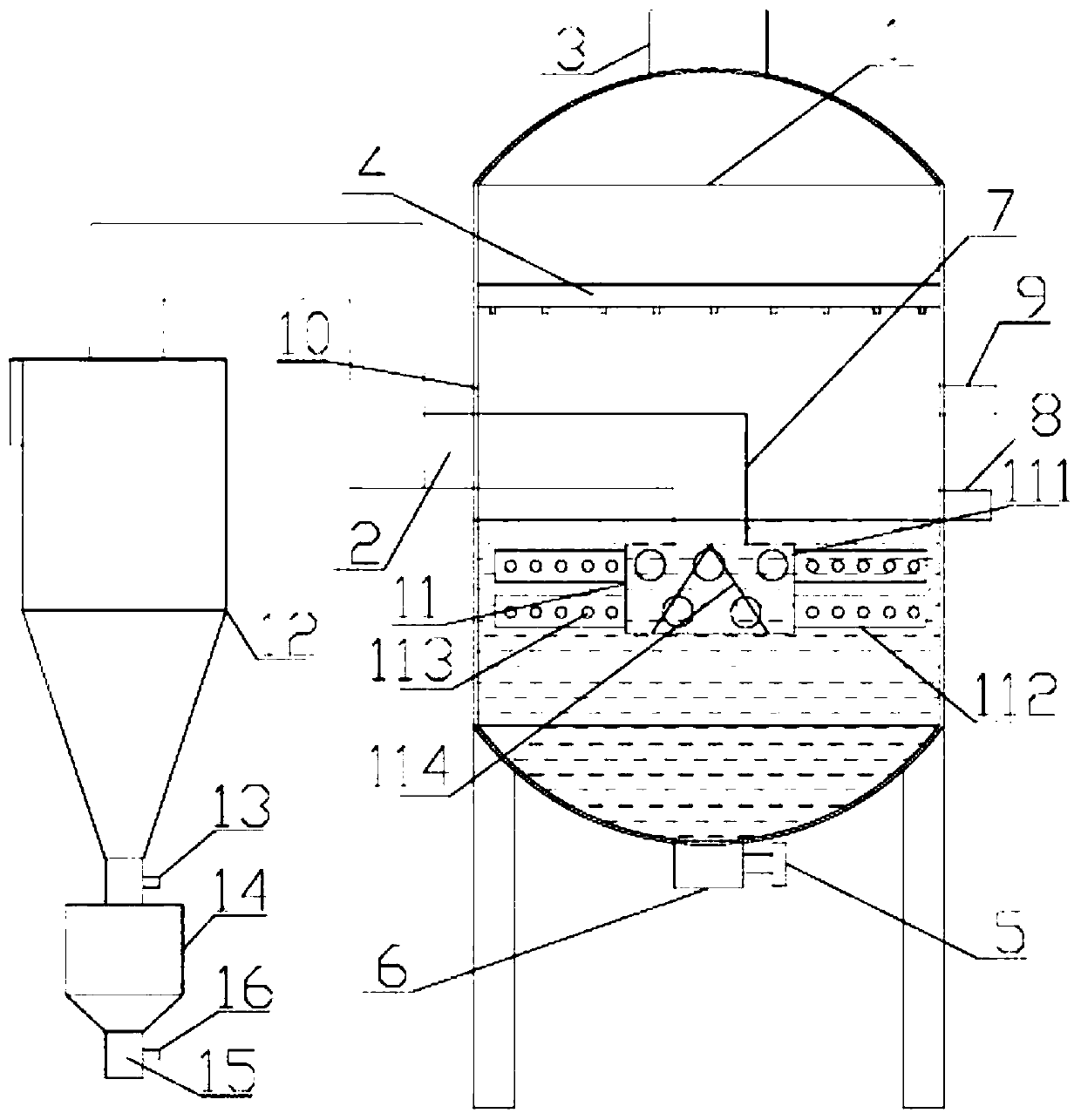

[0015] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0016] Such as figure 1 As shown, a multifunctional composite dust collector of the present invention includes a tank body 1, an air inlet 2, an exhaust outlet 3, a nozzle 4, a valve 5, a sewage outlet 6, a pipeline 7, an air outlet assembly 11 and a cyclone dust collector 12 , the side of described tank body 1 is provided with air inlet 2, and described tank body 1 is provided with the pipeline 7 that communicates with air inlet 2, and described tank body 1 is provided with nozzle pipe 4 above pipeline 7, so The lower end of the pipeline 7 is provided with an air outlet assembly 11, the liquid level in the tank 1 is higher than the height of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap