Self-rotating type electric stud welding gun suitable for hollow studs

A stud welding and spinning technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of inability to accurately and quantitatively control the lifting speed, the pressing speed and the pressing depth, and the hollow stud arc offset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

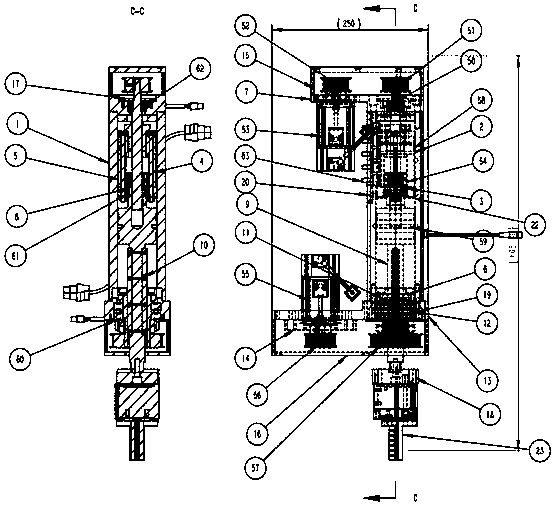

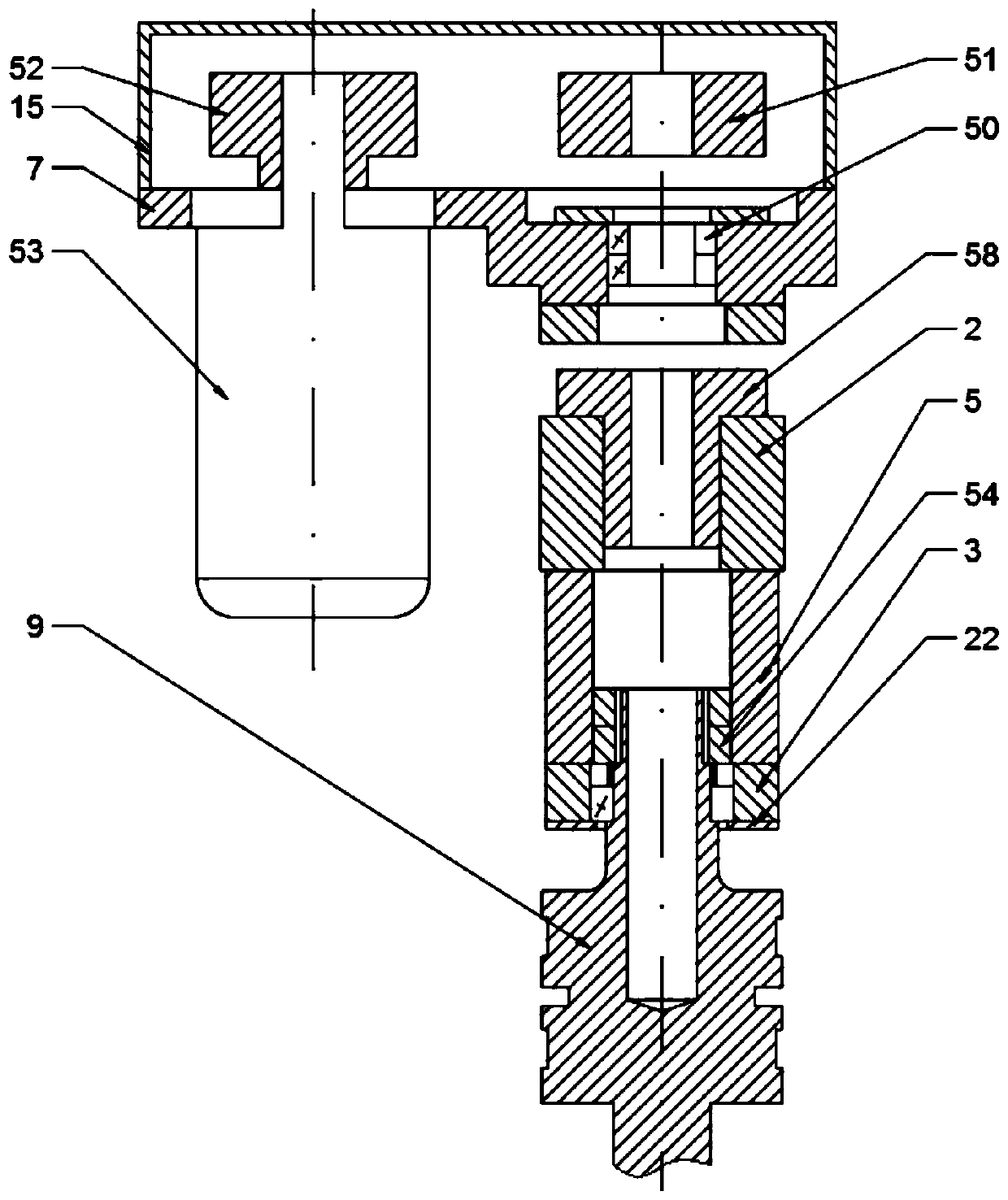

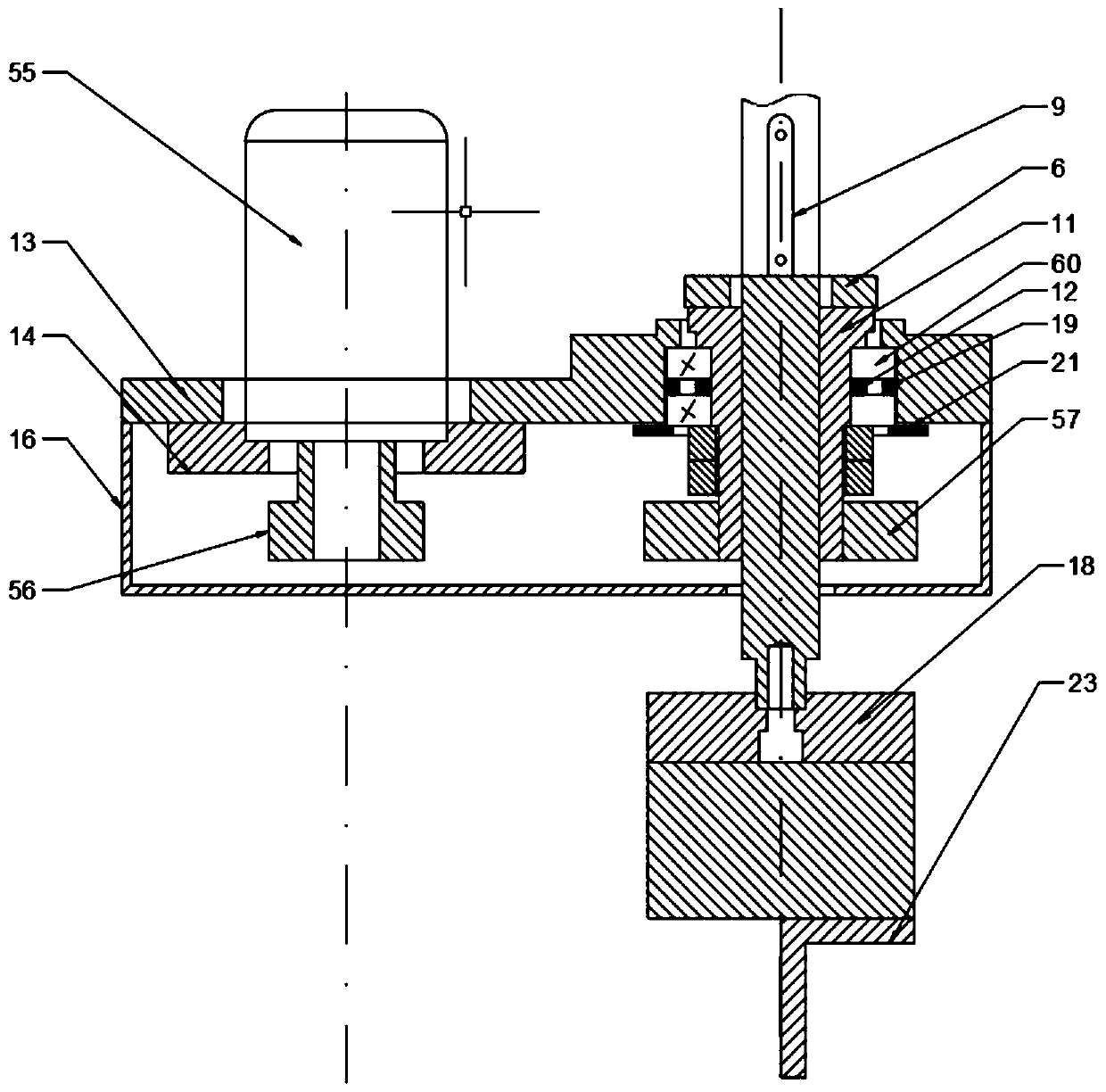

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] Such as figure 1 As shown, the present invention is a self-rotating electric stud welding gun adapted to hollow studs, which includes a cylinder 1, a connector 2, a connector 2 3, a connector 3 4, a buffer pad 5, and a buffer pad 2 6 , connecting piece four 7, connecting piece five 8, piston rod 9, guide block 10, bushing 11, washer 12, connecting piece six 13, connecting piece seven 14, casing one 15, casing two 16, connecting piece eight 17 , connecting piece 9 18, connecting piece 10 19, connecting piece 11 20, retaining piece 21, retaining ring 22, positioning block 23, ball bearing 1 50, synchronous wheel 1 51, synchronous wheel 2 52, servo motor 1 53, tight Solid nut 54, servo motor two 55, synchronous wheel three 56, synchronous wheel four 57, leading screw nut 58, ball bearing two 60, angular contact bearing 61, ball bearing three 62, circumferential positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com