Shock excitation beam protection device and resonance crusher

A protection device and excitation beam technology, which is applied to roads, road repairs, roads, etc., can solve the problems of being easily affected by the transmission mechanism, such as the lifting mechanism, the acceleration sensor’s continuous accuracy is not good, and the continuous working time is not long. To achieve the effect of prolonging the trouble-free working time, prolonging the continuous working time and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

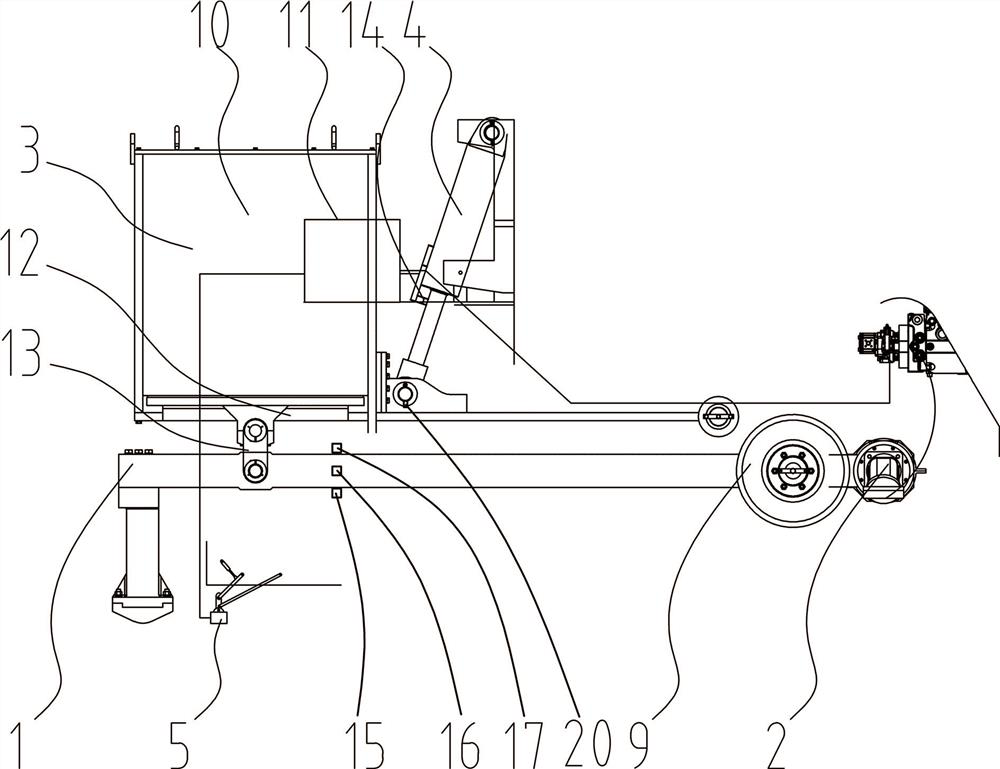

[0040] Such as figure 1 Among them, an excitation beam protection device, it includes a position sensor 14 arranged on the lifting hydraulic cylinder 4, and the position sensor 14 is used to detect the extension length of the lifting hydraulic cylinder 4; the position sensor 14 in this example is preferably A Hall sensor is used, and the Hall sensor is in contact with the piston rod of the lifting hydraulic cylinder 4 or keeps a gap below 1 mm to detect the protruding length of the piston rod. The retracted position is used as the origin, and the previous or preset maximum extension length is used as the memory point. This solution can roughly control the lowering position of the excitation beam 1 .

[0041] It also includes a pressure sensor 20 arranged at one of the hinge positions between the counterweight beam 12 and the lifting hydraulic cylinder 4, or at one of the hinge positions between the counterweight beam 13 and the counterweight beam 12 and the excitation beam 1....

Embodiment 2

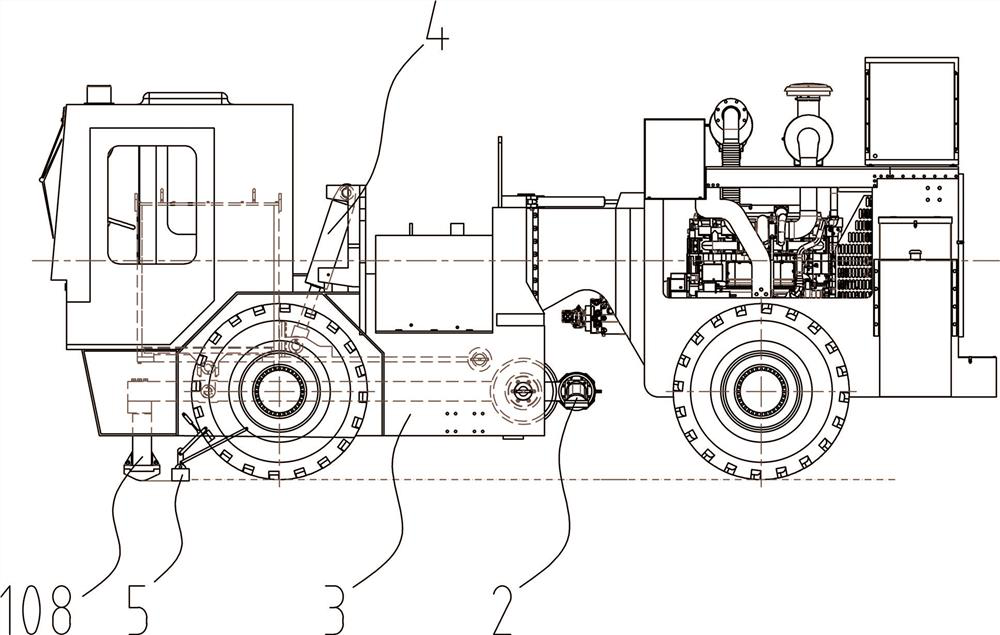

[0054] On the basis of Example 1, such as image 3 , 4 Among them, a resonance crusher adopting the above-mentioned excitation beam protection device, the vehicle body 3 is connected with the excitation beam 1 through the support shaft 7, and a flexible support sleeve 9 is provided between the support shaft 7 and the vehicle body 3, and the excitation One end of the vibration beam 1 is provided with a vibration exciter 2, and the vibration exciter 2 is connected with an excitation motor 8;

[0055] The counterweight shaft 6 of the excitation beam 1 is connected with the counterweight beam 12 through the counterweight rod 13, and one end of the counterweight beam 12 is connected with the vehicle body in a relatively rotatable manner, and the other end is provided with a counterweight 10, and the counterweight beam 12 Connect with the car body through the lifting hydraulic cylinder 4 to control the lifting of the hammer head 108 of the exciting beam 1;

[0056] The position se...

Embodiment 3

[0068] On the basis of Embodiment 2, a protection and detection method for the above-mentioned resonance crusher, comprising the following steps:

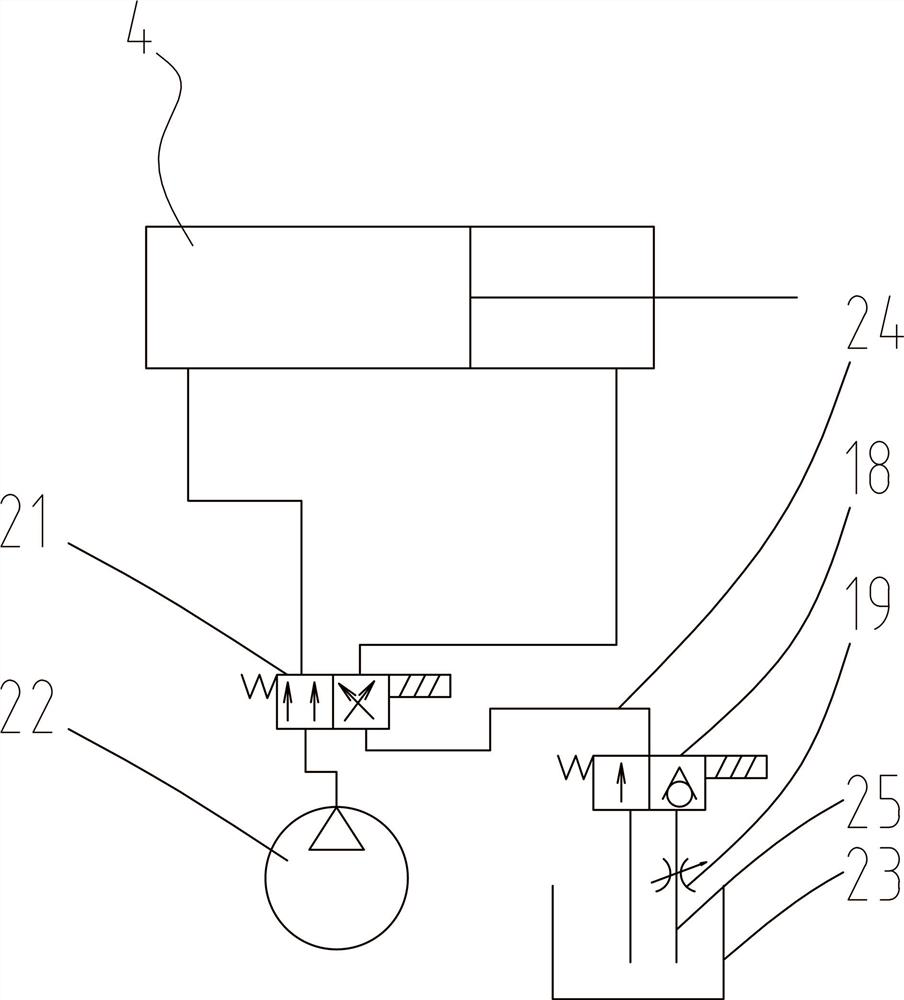

[0069] S1. Before the cement pavement crushing construction, the lifting hydraulic cylinder 4 puts down the counterweight beam 12, and the exciting beam 1 falls accordingly. As the position sensor 14 detects that it has protruded by a preset length, the hammer head 108 approaches the ground. The main control device such as PLC controls the buffer valve 18 to switch from the direct oil return circuit to the oil return branch 25. Since the set flow valve 19 reduces the flow rate, the falling speed of the hammer head 108 slows down until the pressure sensor 20 detects that the pressure is greatly reduced. reduce, that is, the hammer head 108 is in reliable contact with the ground.

[0070] The lifting mechanism puts the excitation beam protection device 5 down. The specific steps are: the air pump works to supply air to the air source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com