Numerically-controlled lathe automatic puller with impact buffering function

A technology for buffering impact on CNC lathes, applied in the field of machinery, can solve problems such as large damage to bar blanks, damage to pullers, poor straightness of CNC lathe tool holders, etc., to achieve simple and practical structure, reduce impact, and avoid straightness reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below with reference to the accompanying drawings and examples.

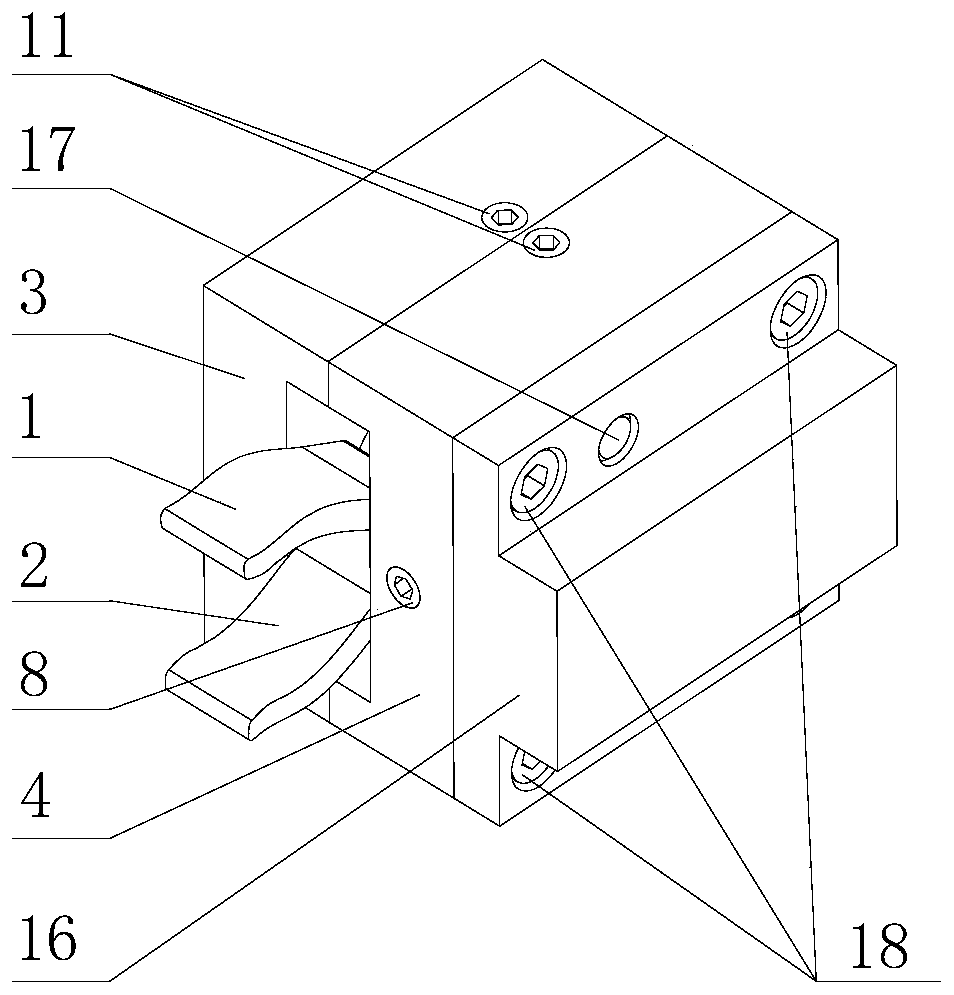

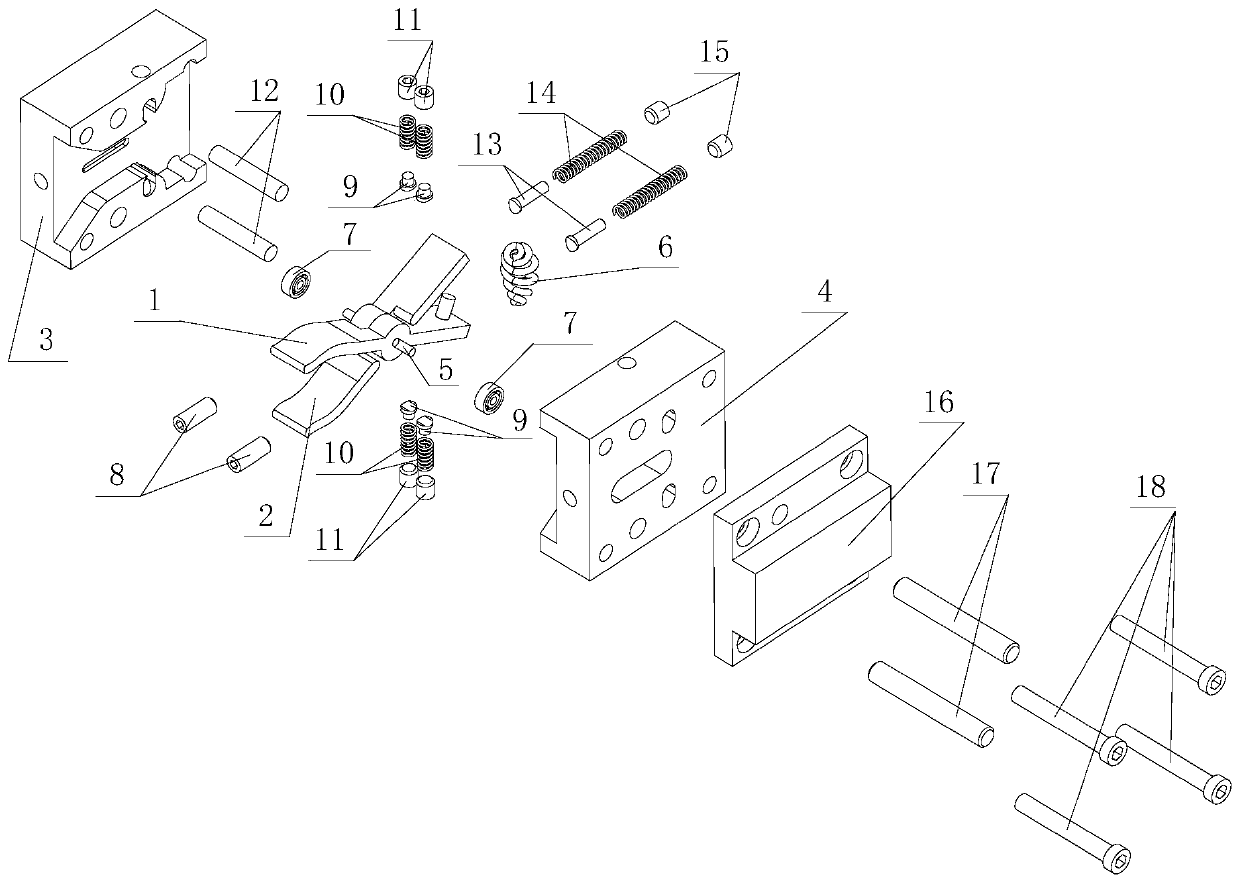

[0049] This embodiment provides an automatic puller for a CNC lathe with a function of buffering shocks, see the attached Figure 1-2, including: a housing, a clamp arm, a bearing 7, an elastic shaft 12, a first buffer assembly and a second buffer assembly;

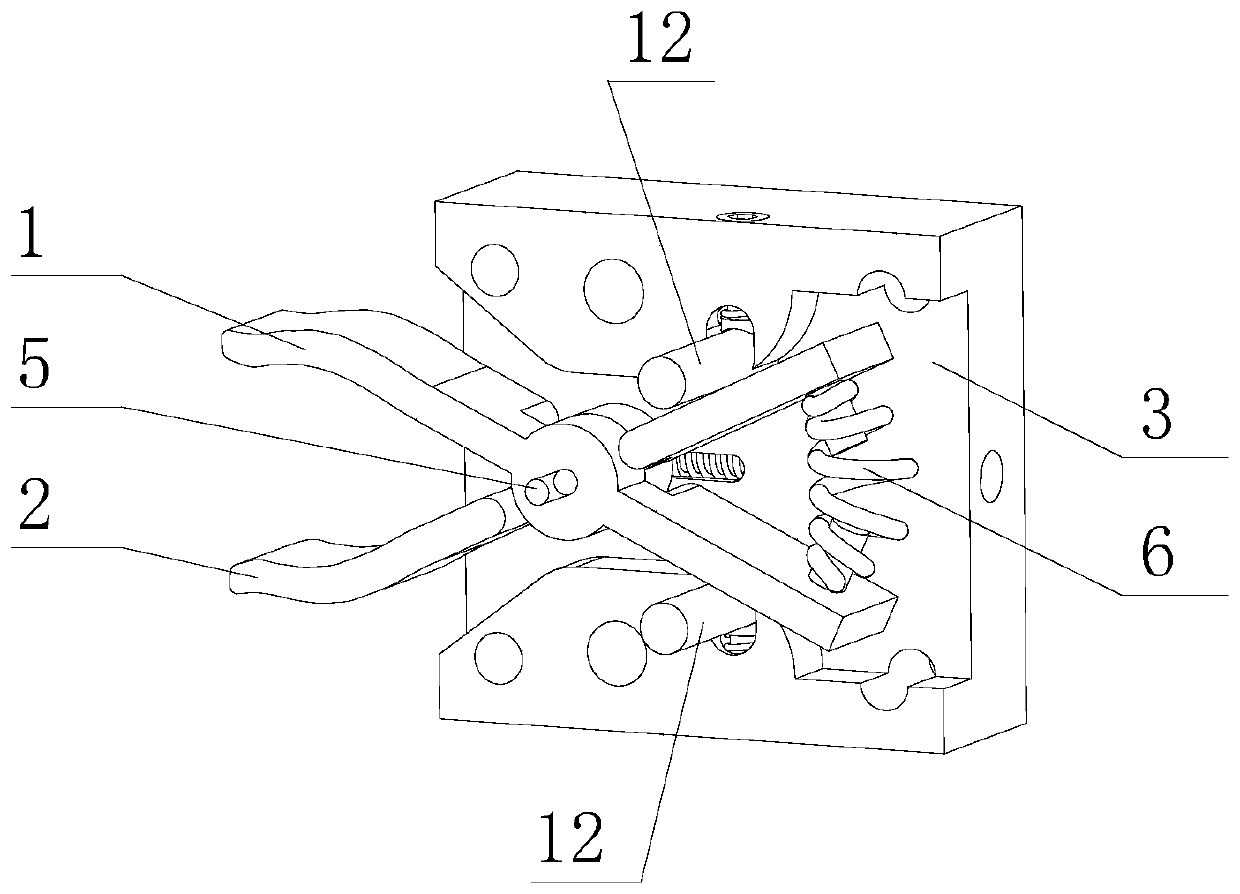

[0050] See attached image 3 , the clamp arm includes: a left clamp arm 1, a right clamp arm 2, a mandrel 5 and a bending spring 6;

[0051] The left jig arm 1 is composed of a stepped cylinder and a straight plate and a curved plate integrally formed on the outer circumference of the large diameter end of the stepped cylinder; an axial through hole is processed on the stepped cylinder; the straight plate and the curved plate They are respectively located on two opposite sides of the stepped cylinder; the straight plate is provided with a connecting head connected with the curved spring 6;

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com