Glue applicator for corrugated case bonding machine

A technology for glue supplying devices and corrugated boxes, applied in spraying devices, devices for coating liquid on the surface, packaging, etc., can solve problems such as difficult outflow, difficult cleaning, and blockage of connection ports, so as to achieve smooth glue supply and ensure continuous supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

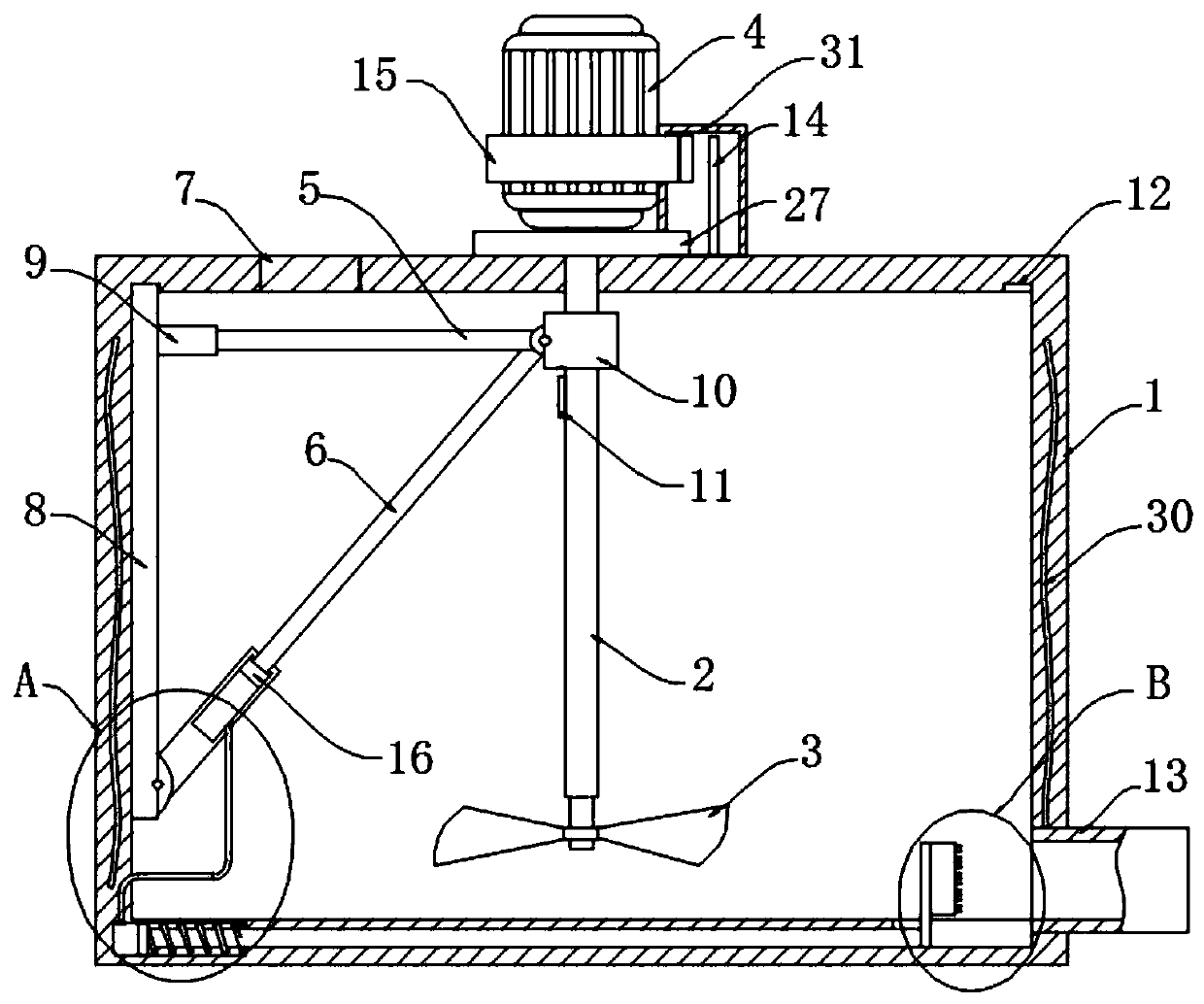

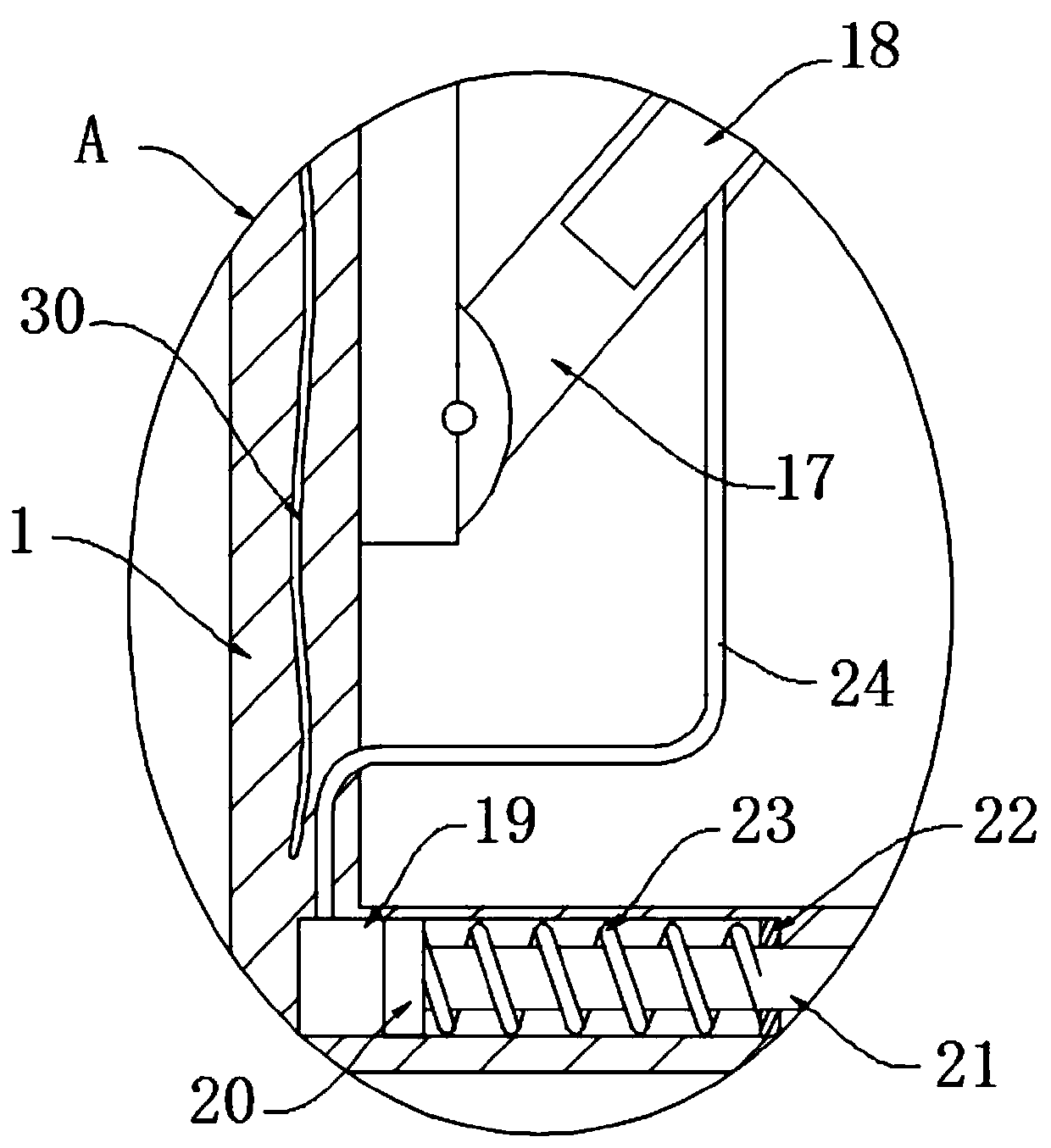

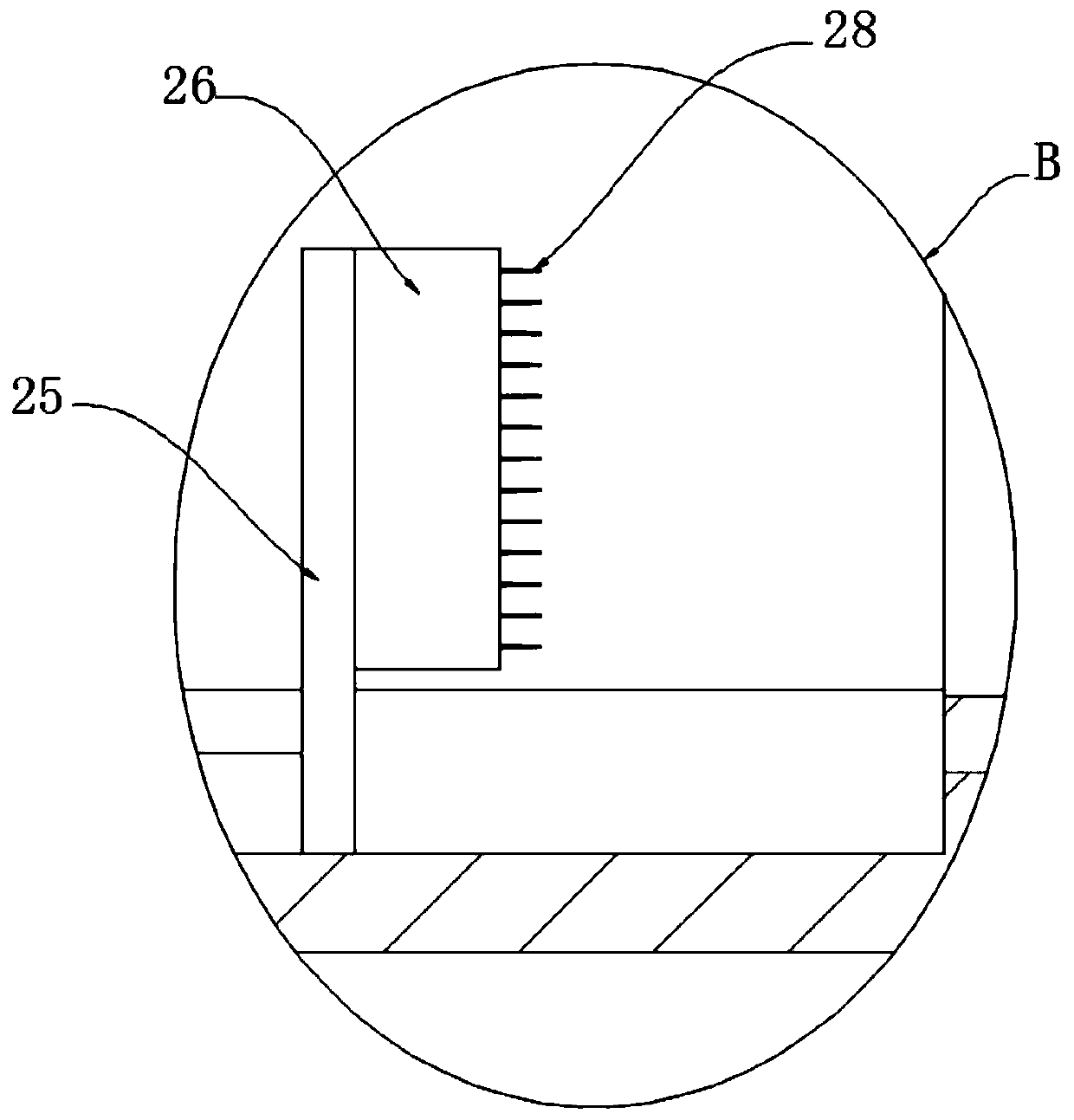

[0027] refer to Figure 1-5 , a glue supply device for a corrugated box gluer, including a housing 1, the top of the housing 1 is provided with a transmission shaft 2, and the end of the transmission shaft 2 located in the housing 1 is welded with a stirring blade 3, and the rotating shaft 2 is in the housing. One end outside the body 1 is connected with a motor 4 through a key interference fit, and the motor 4 is connected with a conductive structure. The part of the transmission shaft 2 located in the housing 1 is spliced with a connecting block 10 that is slidably connected to the transmission shaft 2. The transmission shaft 2 A flat key 11 is welded under the connection block 10, the connection block 10 is connected with a transmission structure, a glue outlet 13 is opened on the bottom side of the casing 1, a glue inlet 7 is opened on the top of the casing 1, and a glue inlet 7 is opened in the inner wall of the casing. A resistance wire 30 is provided;

[0028] The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com