Storage tank precooling device for liquefied natural gas filling station

A technology for liquefied natural gas and filling stations, which is applied in liquid bottling, gas/liquid distribution and storage, packaging, etc., and can solve the problems of long pre-cooling of storage tanks and affecting liquefied natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

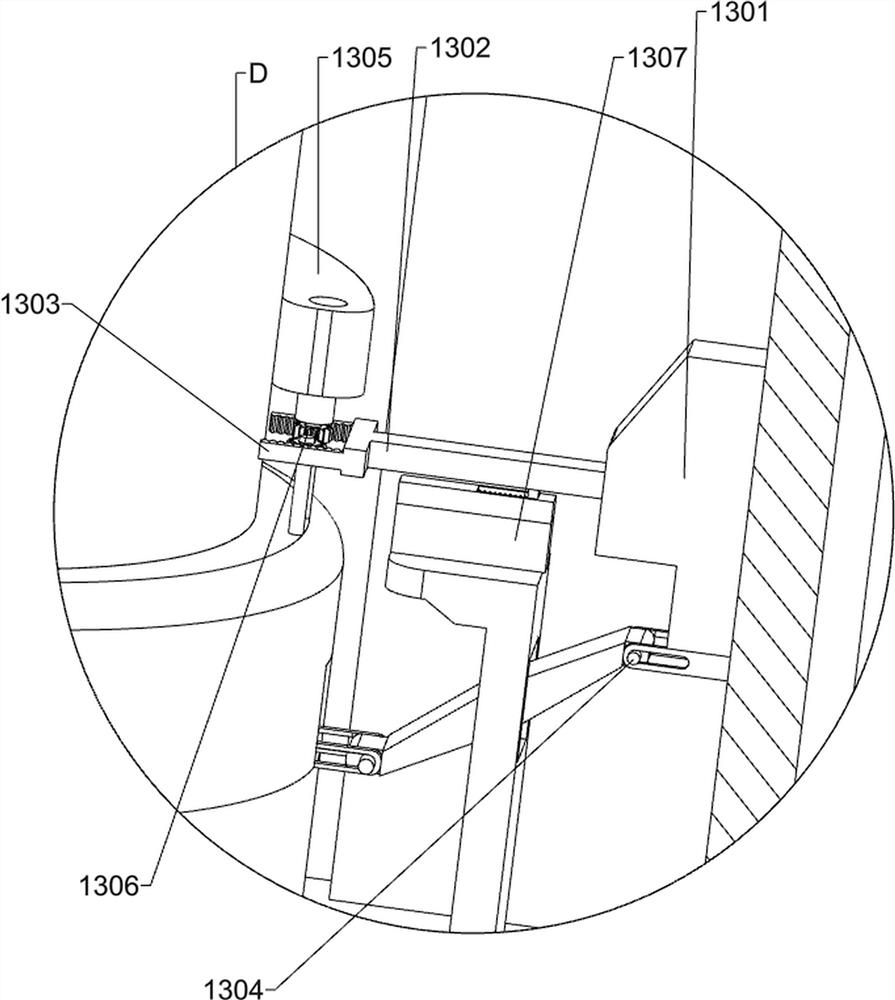

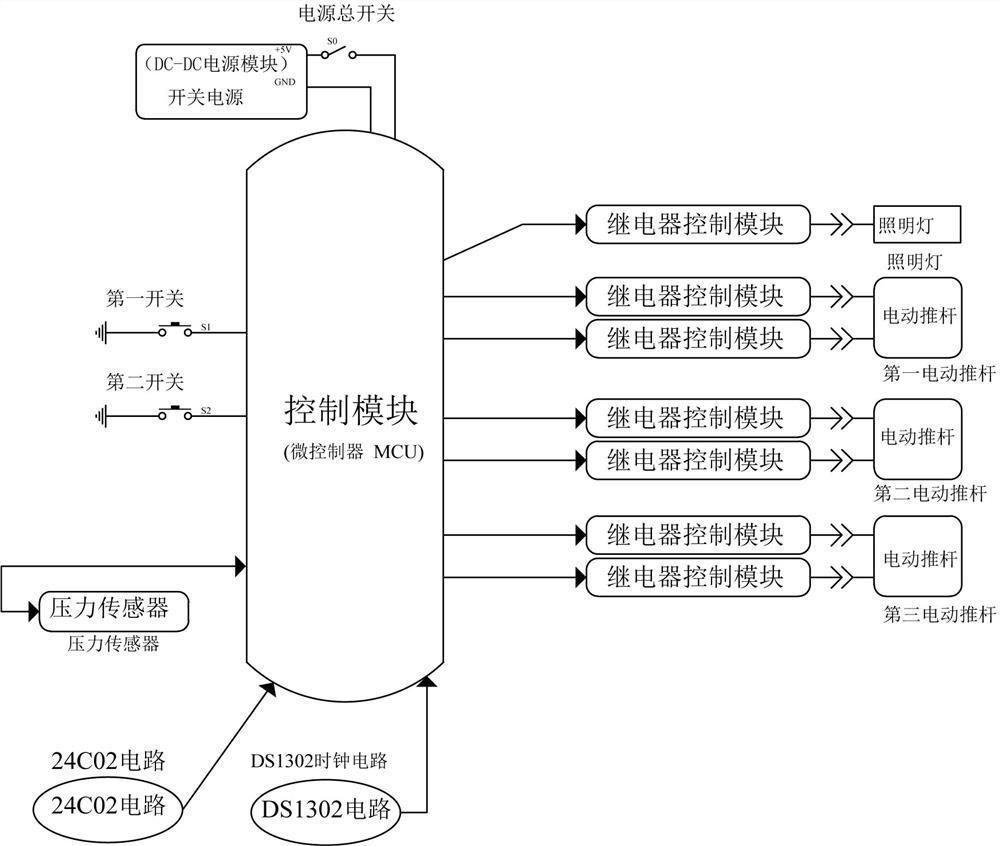

[0034] A storage tank pre-cooling device for liquefied natural gas filling stations, such as Figure 1-14 As shown, it includes a first fixed plate 1, a support seat 2, a liquid nitrogen tank 4, a first switch 5, a second switch 6, a top opening mechanism 8 and a first opening mechanism 9, and the front side of the top of the first fixed plate 1 is provided with There is a support seat 2, a liquid nitrogen tank 4 is placed on the top rear side of the first fixed plate 1, a first switch 5 and a second switch 6 are arranged on the right front side of the top of the first fixed plate 1, and the first switch 5 is on the left side of the second switch 6 On the upper side of the first fixed plate 1 is provided with a top-opening mechanism 8 , and a first opening mechanism 9 is connected between the top-opening mechanism 8 and the first fixed plate 1 .

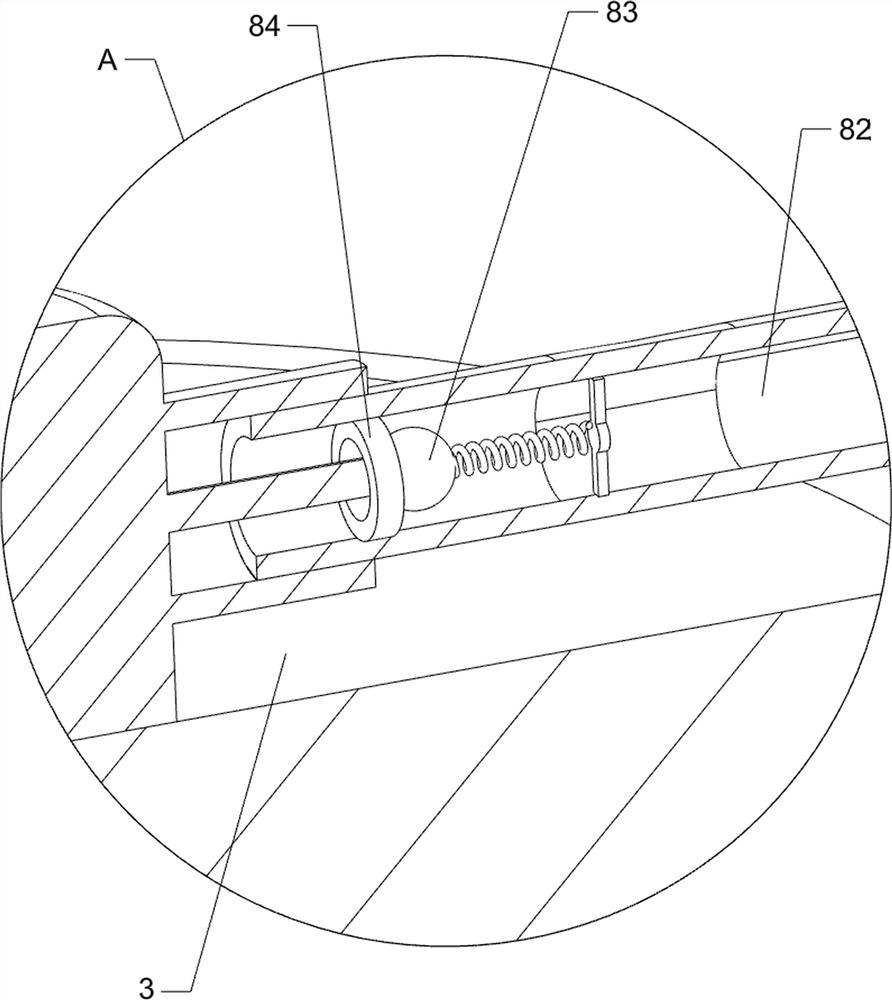

[0035] The push-off mechanism 8 includes a first infusion tube 81, a second infusion tube 82, a top ball 83, an annular stopper 84,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com