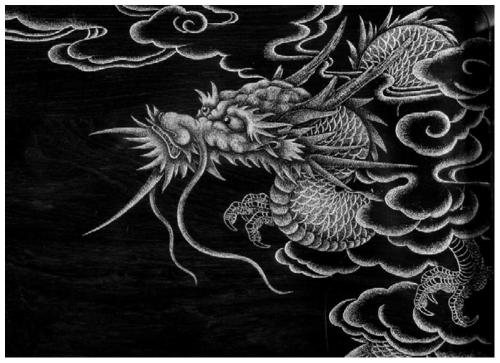

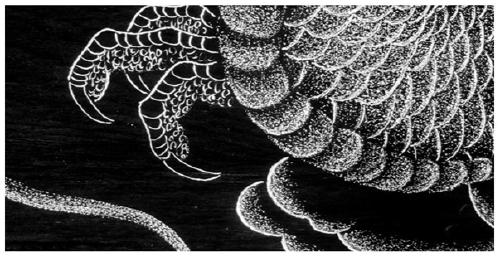

Gold pointing painting and manufacturing method thereof

A production method and lacquer technology, which are applied in special decorative structures, specialized techniques for artistic painting, and processes for producing decorative surface effects, etc. smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] A method for making a lacquer point gold painting, comprising the following steps in sequence:

[0026] 1) Evenly brush the first raw lacquer layer with a thickness of 0.01-0.09mm on the base material. After the paint film of the first raw lacquer layer is completely dry, polish the paint film of the first raw lacquer layer with 2000 mesh sandpaper smooth;

[0027] 2) Then repeat step 1) 8 times;

[0028] 3) Carve out the required pattern grooves on the paint film obtained in step 2) as required;

[0029] 4) At a temperature of 43°C and a humidity of 26%, fill and brush the second raw lacquer layer on the pattern groove carved in step 3);

[0030] 5) At room temperature, prepare two sheets of rice paper, uncover the upper layer of rice paper, then spread 400-600 mesh gold powder on the lower layer of rice paper, then cover the gold powder with the upper layer of rice paper, gently press and rub the two sheets of rice paper to spread the gold powder evenly On the lowe...

Embodiment 1

[0041] A method for making a lacquer point gold painting, comprising the following steps in sequence:

[0042] 1) Evenly brush the first raw lacquer layer with a thickness of 0.01-0.09mm on the base material. After the paint film of the first raw lacquer layer is completely dry, polish the paint film of the first raw lacquer layer with 2000 mesh sandpaper Smooth; (the thickness of this embodiment is about 0.02mm)

[0043] 2) Then repeat step 1) 8 times;

[0044] 3) Carve out the required pattern grooves on the paint film obtained in step 2) as required;

[0045] 4) At a temperature of 43°C and a humidity of 26%, fill and brush the second raw lacquer layer on the pattern groove carved in step 3);

[0046]5) At room temperature, prepare two sheets of rice paper, uncover the upper layer of rice paper, and then spread 400 mesh gold powder on the lower layer of rice paper (it can also be 600 mesh or thicker and finer gold powder, the gold powder of this embodiment is from the sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com