Composite top layer varnish stoving technology

A composite surface and baking paint technology, applied in the field of baking paint, can solve the problems of bulging and cracking of the paint surface of the props, and achieve the effect of smooth paint surface and flat board surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in combination with specific embodiments.

[0017] The props referred to in the present invention are display racks or showcases for placing goods or ornaments; the reinforcing glue is special glue for carpentry, preferably wood master green environmental protection universal glue; putty is commonly known as putty, also known as polyester resin putty.

[0018] Technology of the present invention carries out according to the following steps:

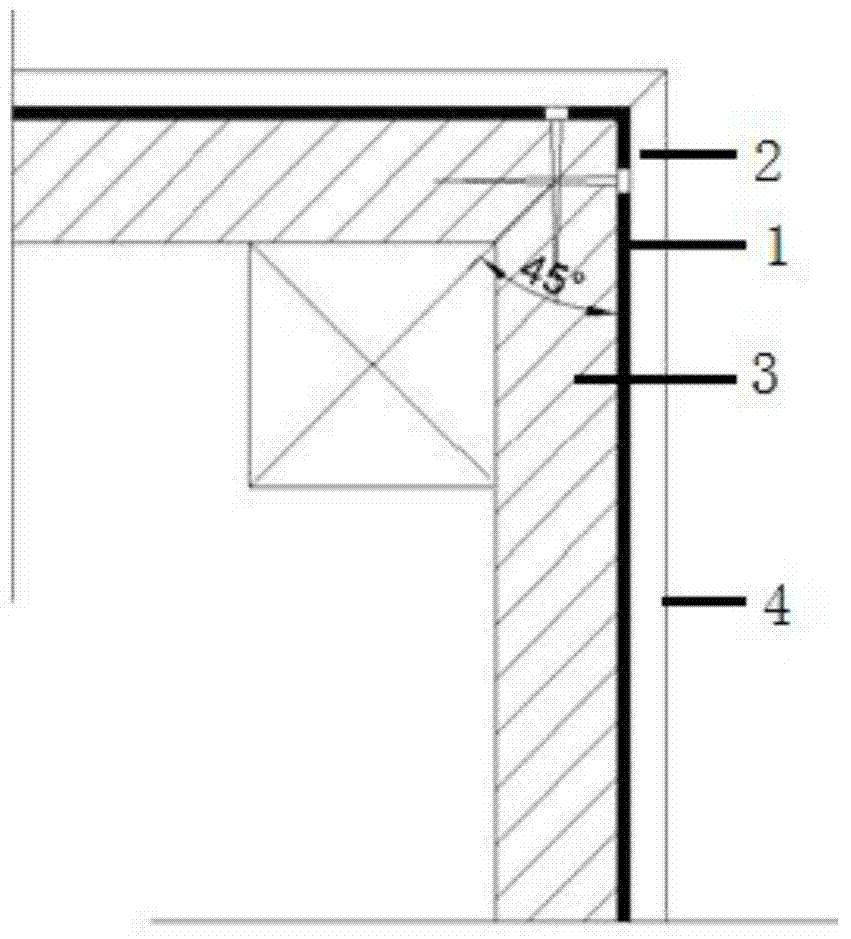

[0019] Step 1: If figure 1 Shown is the prop box made by the method of the present invention, the prop box is coated with glue; the surface layer of the prop is constructed according to the design drawings, most of which are flat, and the surface of individual props is arc-shaped or streamlined. When a prop is not made When it is completed, it is called the prop box. When the prop box is finished, the surface is covered with reinforced glue (1mm wood master green environmenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com