Patents

Literature

35results about How to "Guarantee processing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

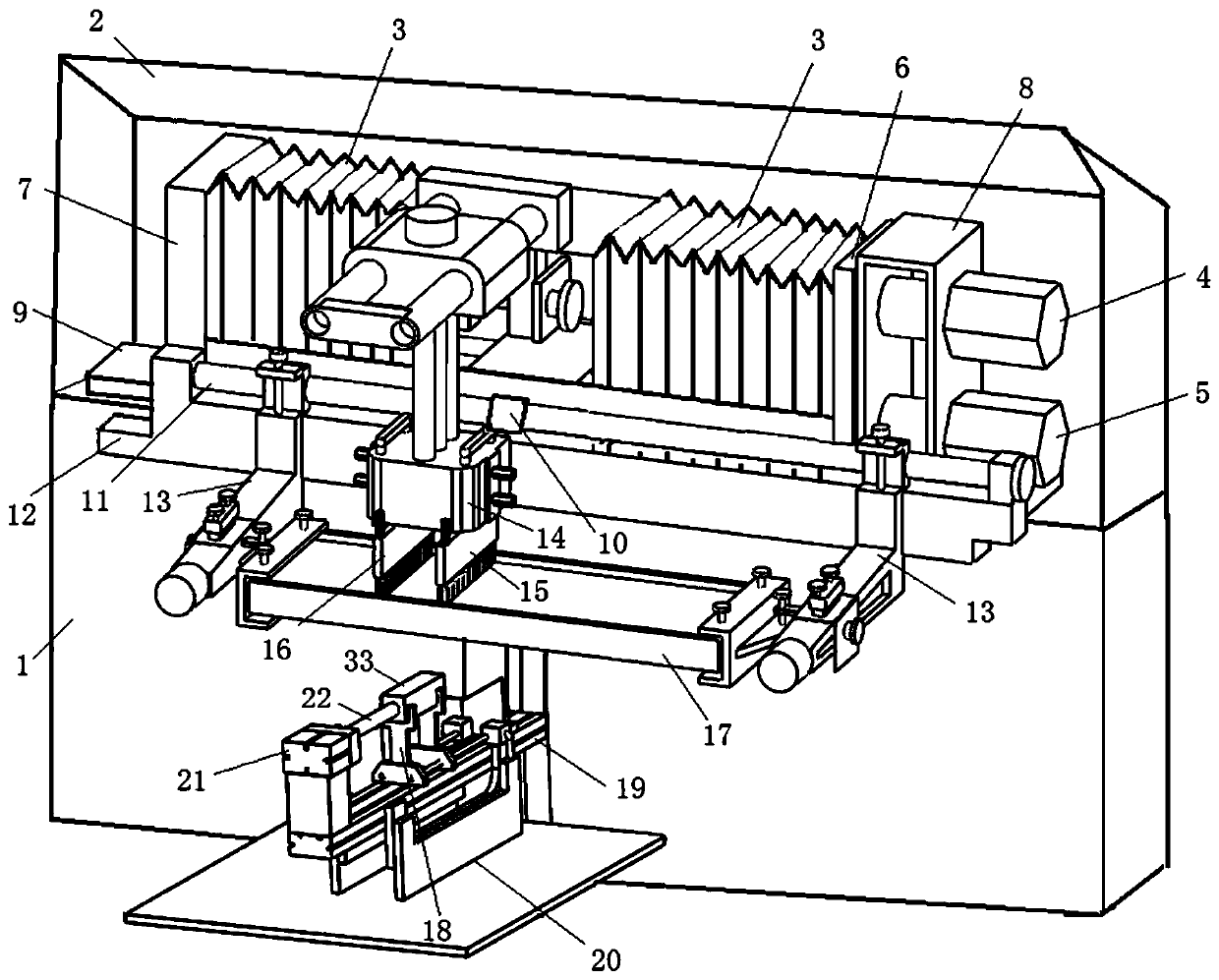

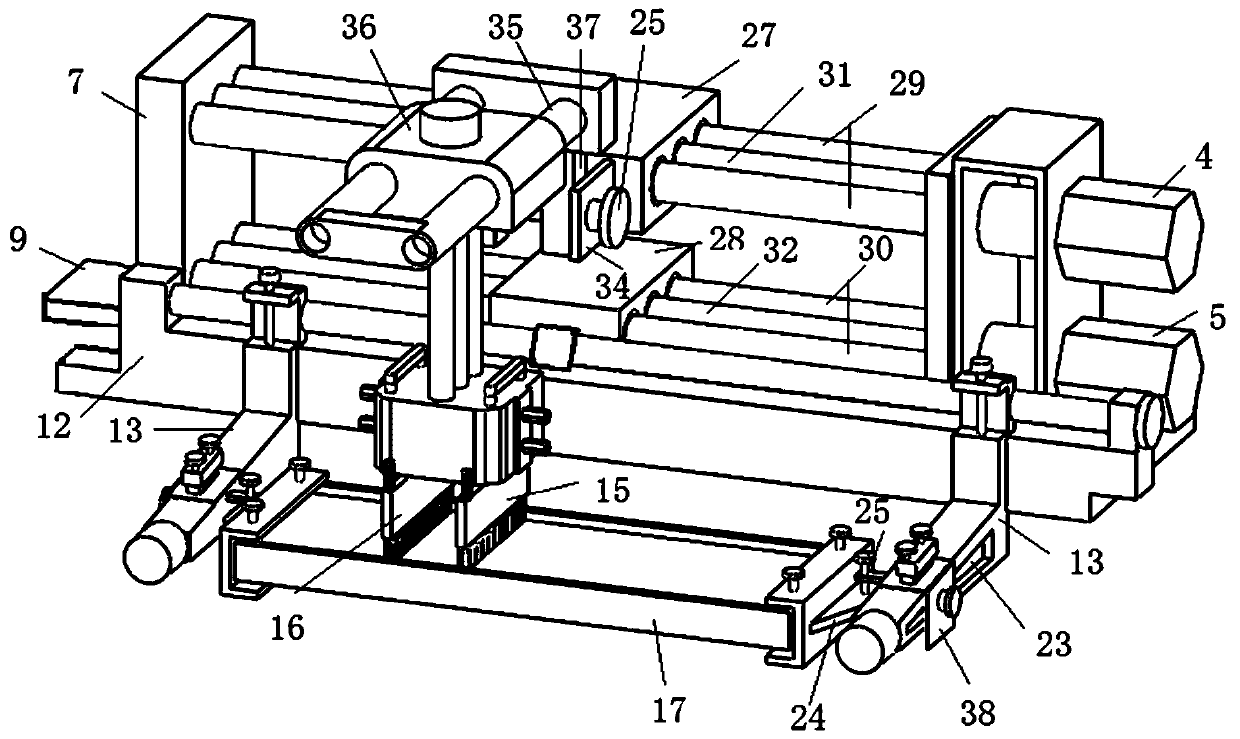

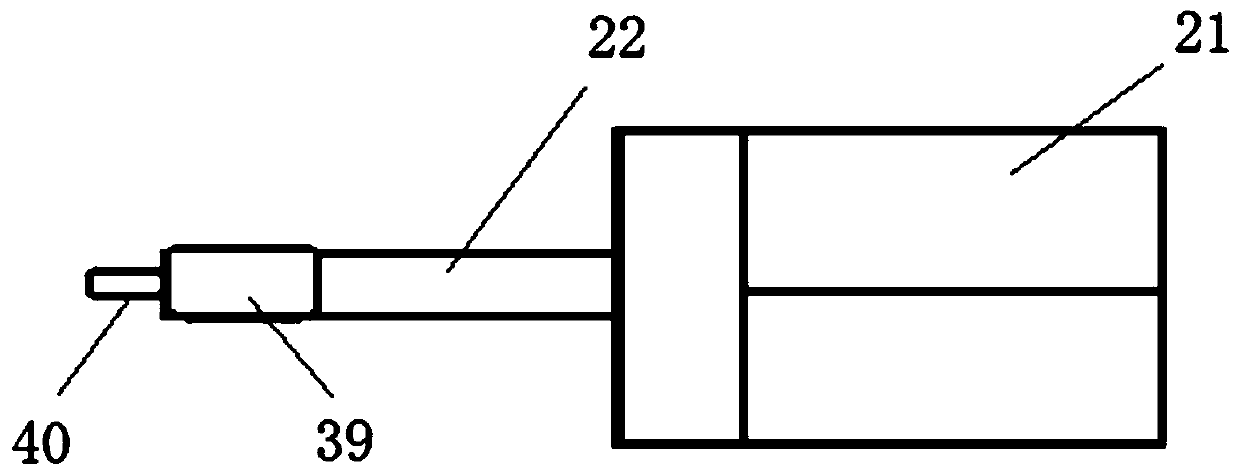

Numerical control machine tool with part inspection function

InactiveCN108818154AGuarantee processing accuracyEfficient extractionMeasurement/indication equipmentsNumerical controlSignal processing circuits

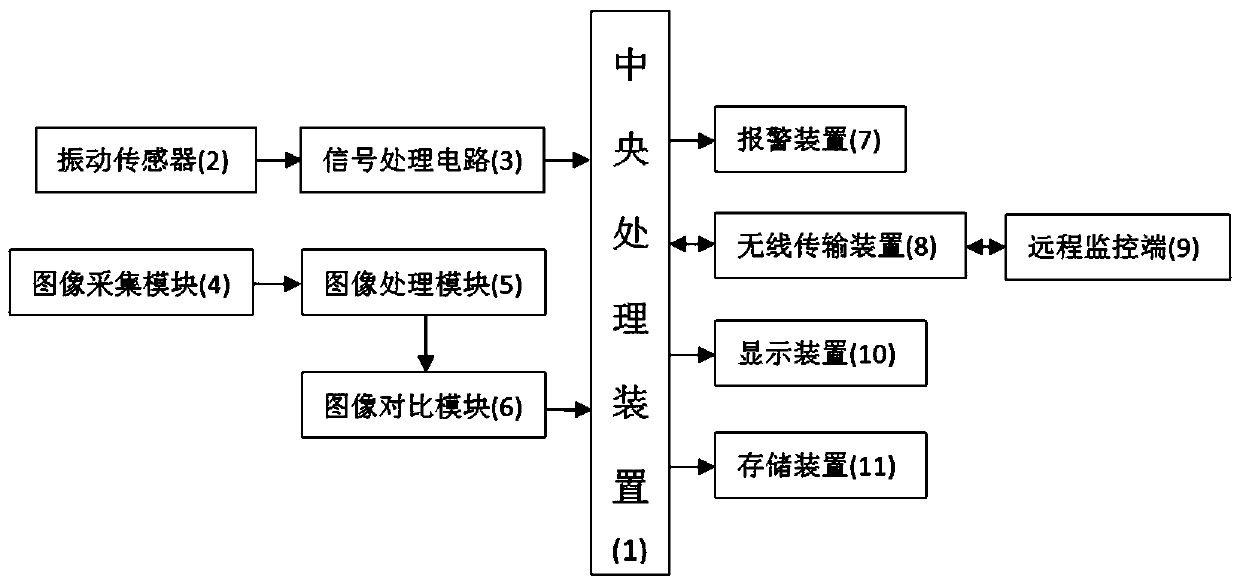

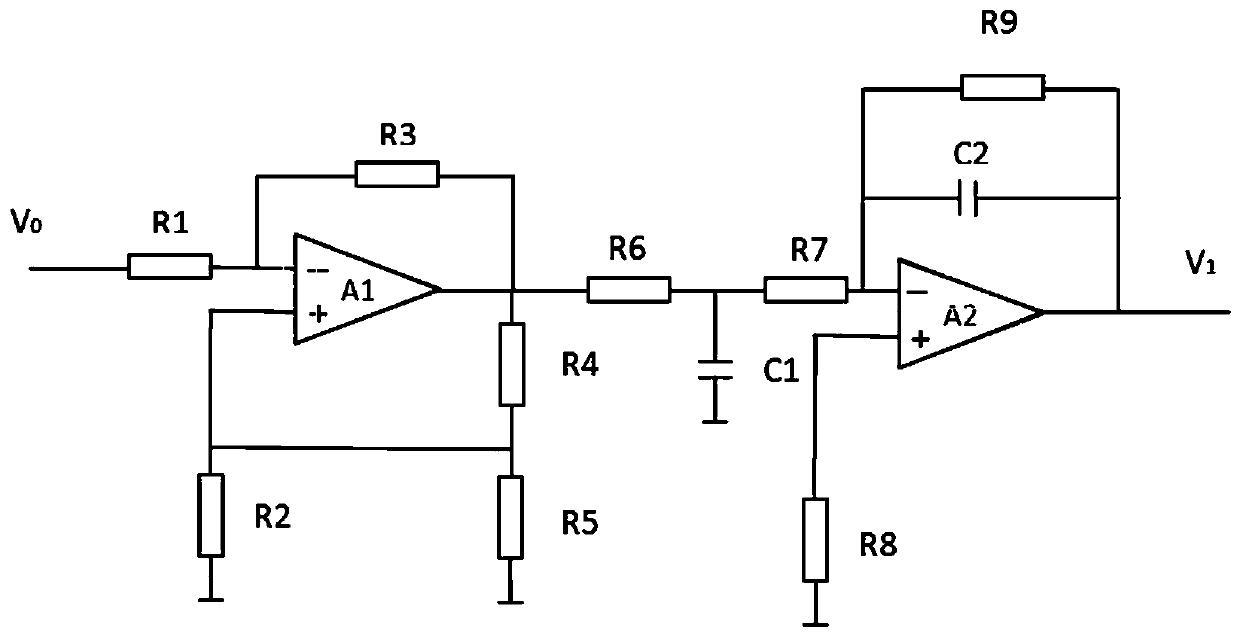

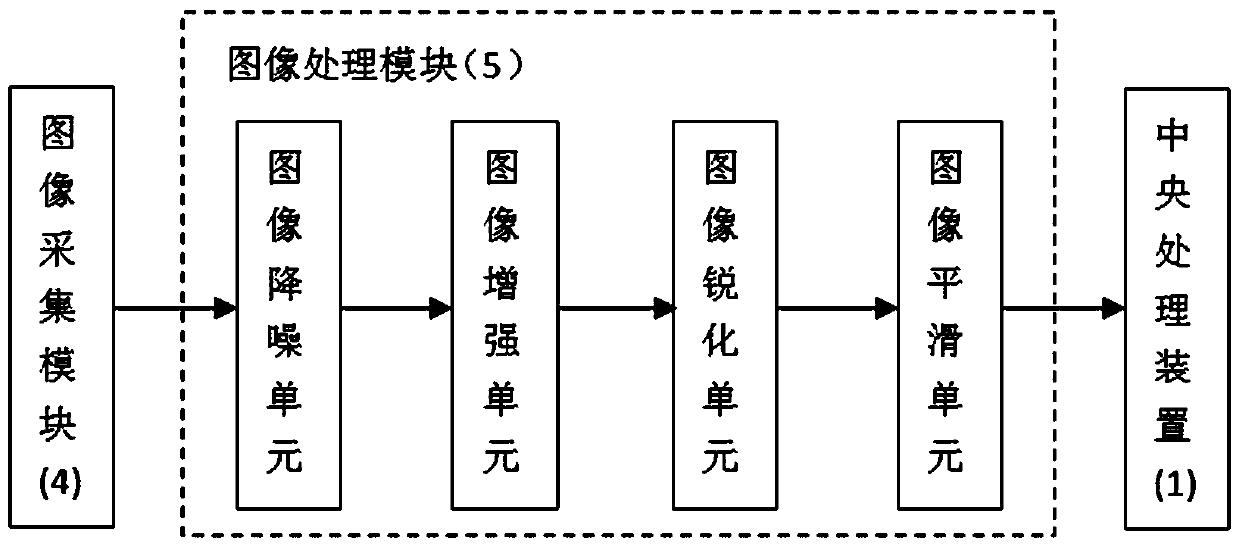

The invention provides a numerical control machine tool with a part inspection function. Through a central processing device, a vibration sensor, a signal processing circuit, an image acquisition module, an image processing module, an image comparison module, an alarm device, a wireless transmission device, a remote monitoring terminal, a display device and a storage device, vibration informationof a cutter during machining is monitored, and the problem that a machining part is not standard due to excessive vibration of the cutter is timely discovered; and meanwhile, the image acquisition module is used for acquiring the image information of the part, and the acquired image is compared with the standard part image after image processing so as to know whether the machined part conforms tothe standard or not. A vibration signal of the cutter during machining is monitored, and the machined part is subjected to image comparison, so that the machining accuracy of the numerical control machine tool is effectively guaranteed. The image processing module sequentially performs image noise reduction, image enhancement, image sharpening and image smoothing on the acquired image.

Owner:ANHUI JIANGJI HEAVY DUTY CNC MACHINE TOOL

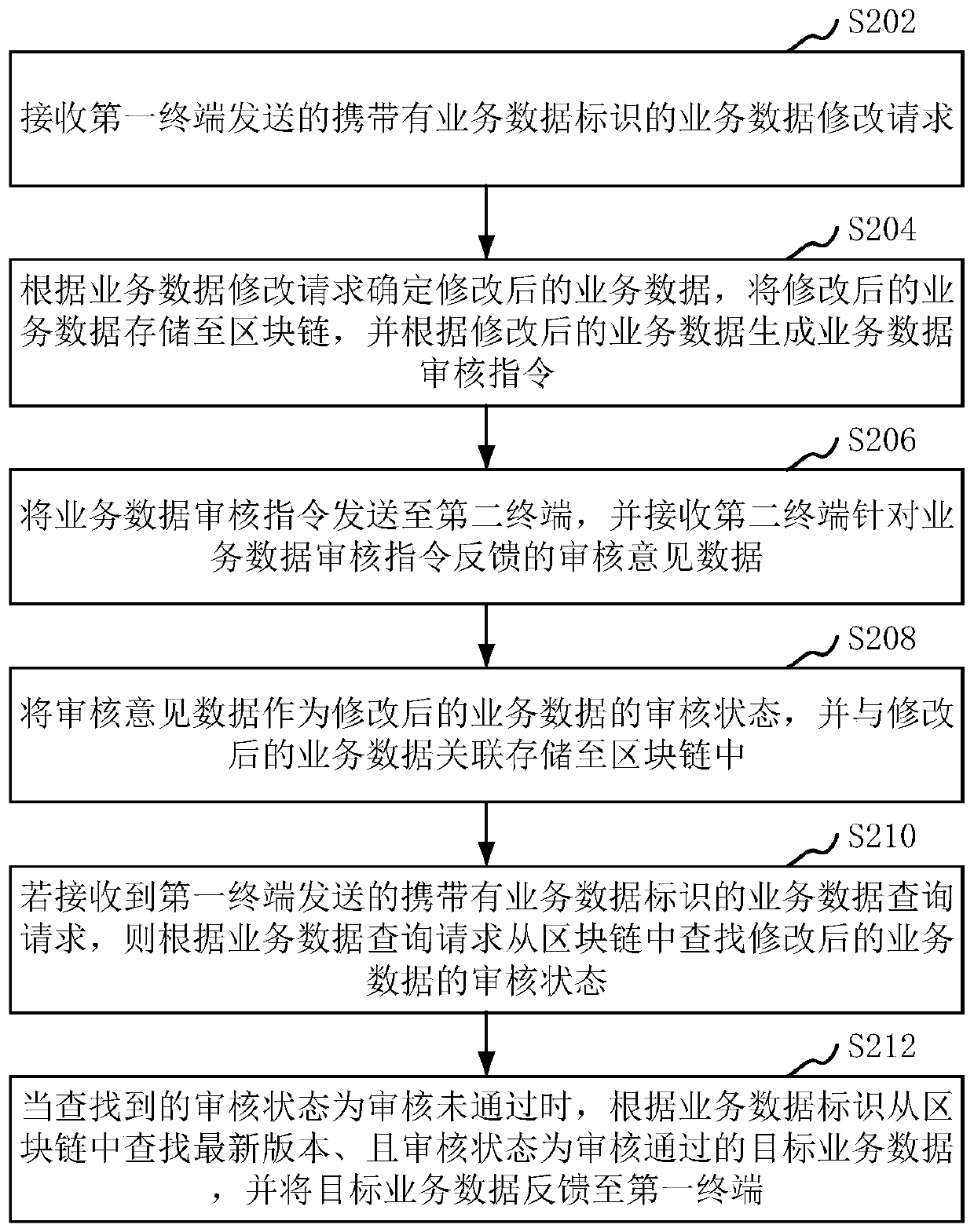

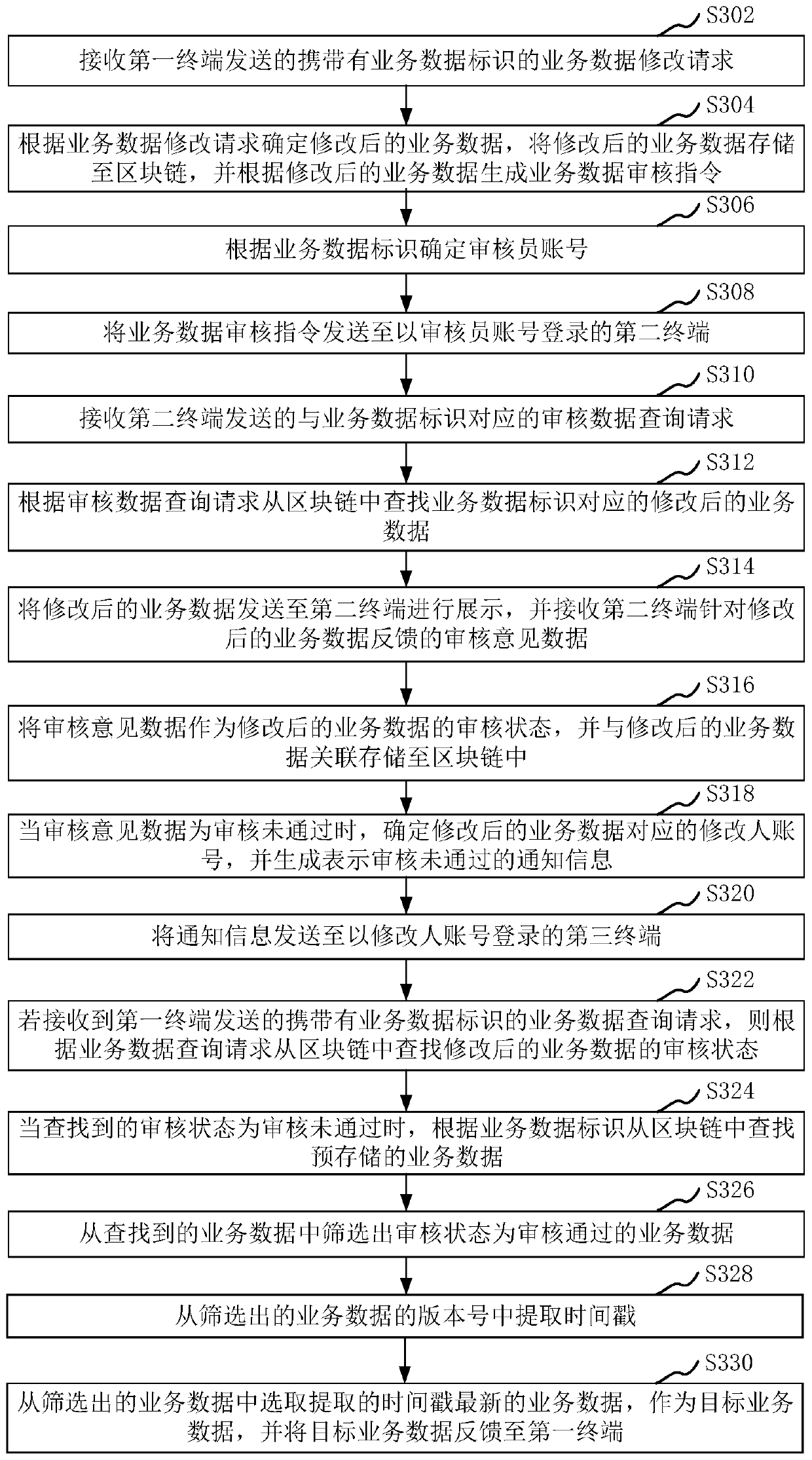

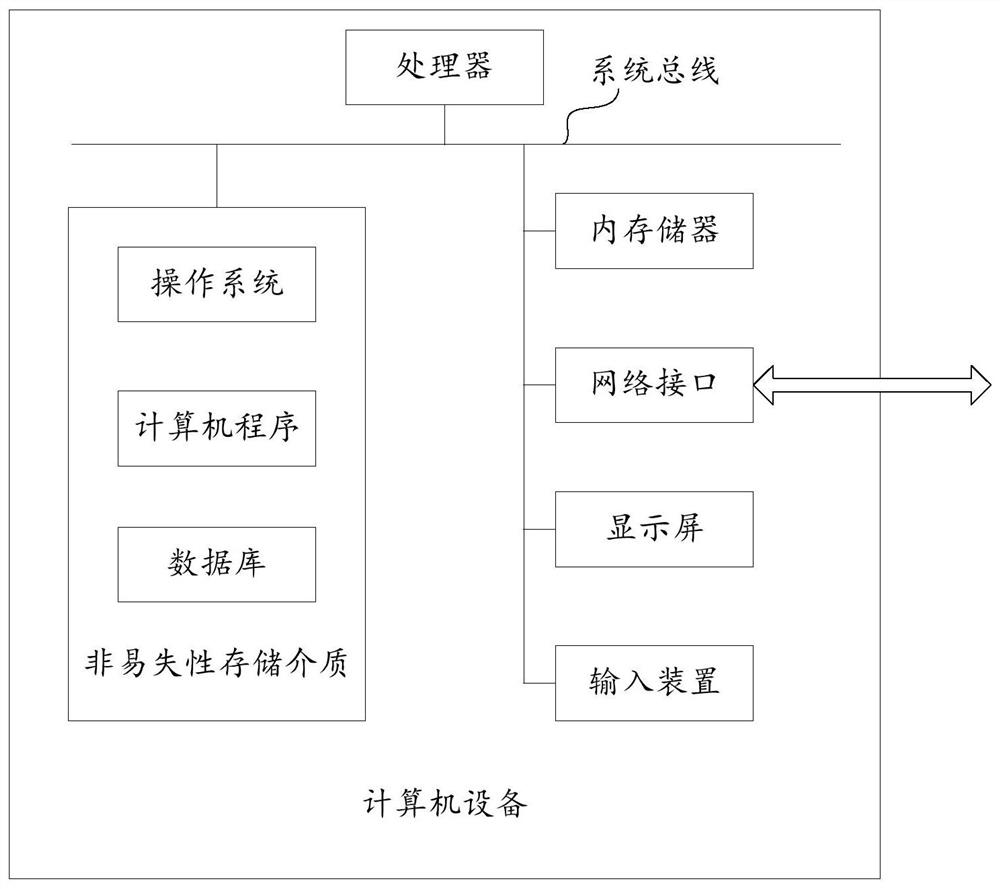

Service data rollback method and device, computer device and storage medium

ActiveCN110213357AFallback implementationGuarantee processing accuracyTransmissionProcess optimizationData query

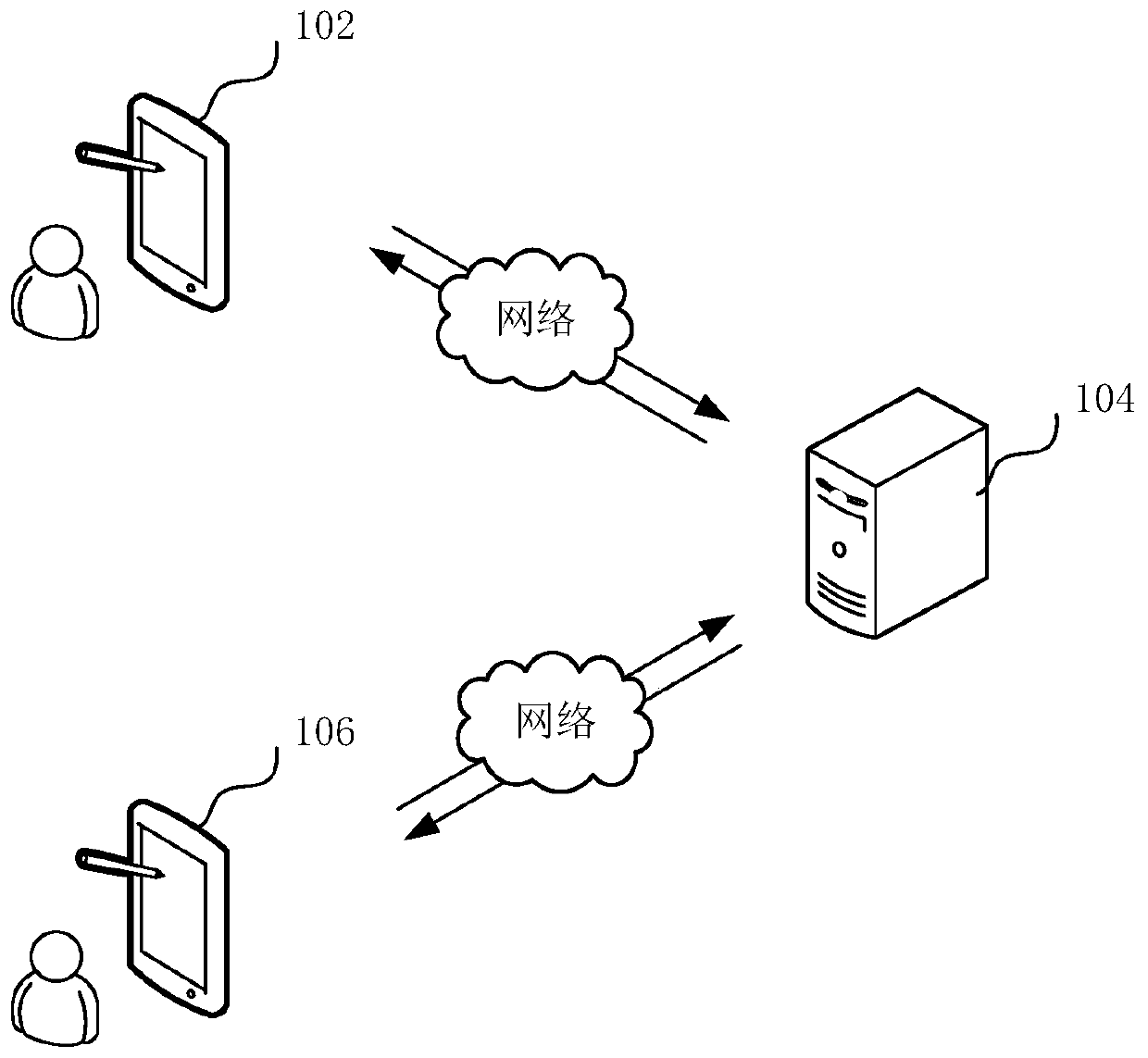

The invention relates to a process optimization technology, and provides a service data rollback method and device, a computer device and a storage medium. The method comprises the following steps: receiving a service data modification request which is sent by a first terminal and carries a service data identifier; storing the modified service data determined according to the service data modification request to a block chain, and generating a service data auditing instruction according to the modified service data; sending the service data auditing instruction to a second terminal, and receiving auditing opinion data correspondingly fed back by the second terminal; storing the audit opinion data serving as an audit state and the modified service data in a block chain in an associated manner; and when a service data query request sent by the first terminal is received and the audit state of the modified service data is that the audit is not passed, searching the latest version from theblock chain according to the service data identifier, and feeding back the target service data of which the audit state is that the audit is passed to the first terminal. By adopting the method, theprocessing accuracy of the service data can be improved.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

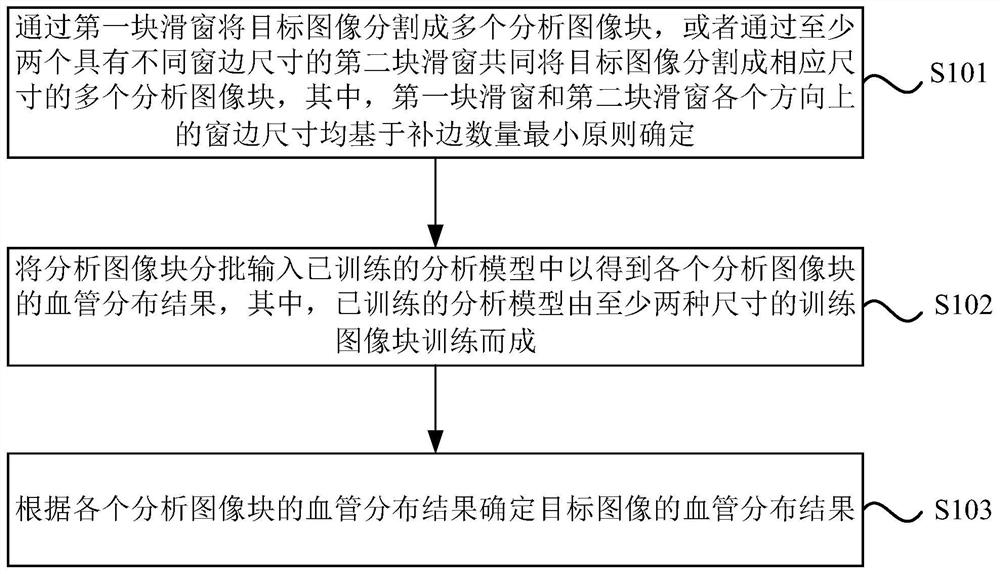

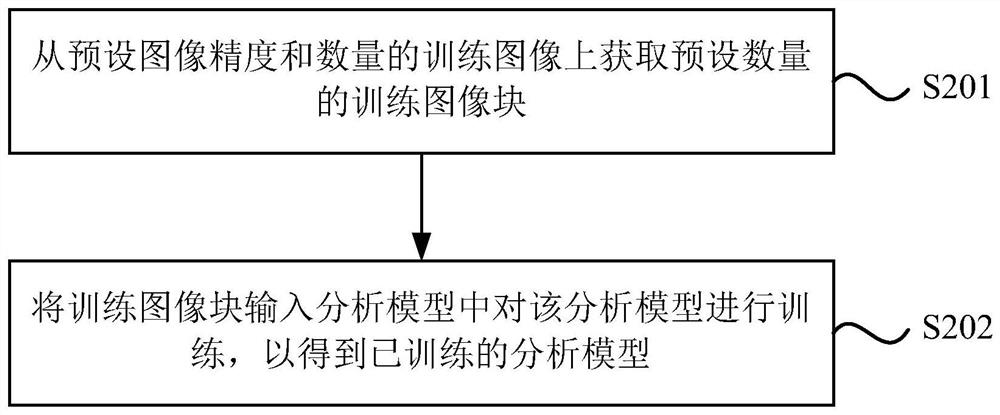

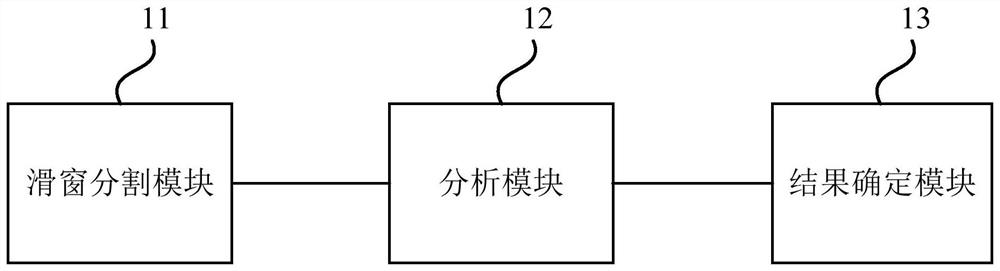

Medical image processing method and device, image processing equipment and storage medium

PendingCN111862033AFast analysisGuarantee processing accuracyImage enhancementImage analysisVessel segmentationEngineering

The embodiment of the invention discloses a medical image processing method and device, image processing equipment and a storage medium. The method comprises: segmenting the target image into a plurality of analysis image blocks through a first sliding window, or jointly segmenting the target image into a plurality of analysis image blocks with corresponding sizes through at least two second sliding windows with different window edge sizes, wherein the window edge sizes of the first sliding window and the second sliding windows in all directions are determined based on the principle that the number of complementary edges is minimum; inputting the analysis image blocks into a trained analysis model in batches to obtain a blood vessel distribution result of each analysis image block, whereinthe trained analysis model is formed by trained training image blocks of at least two sizes; and determining a blood vessel distribution result of the target image according to the blood vessel distribution result of each analysis image block. The problem that a blood vessel segmentation method in the prior art is low in blood vessel segmentation speed is solved.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

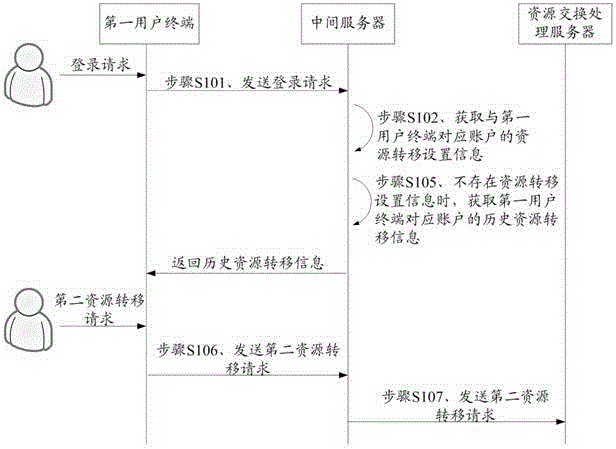

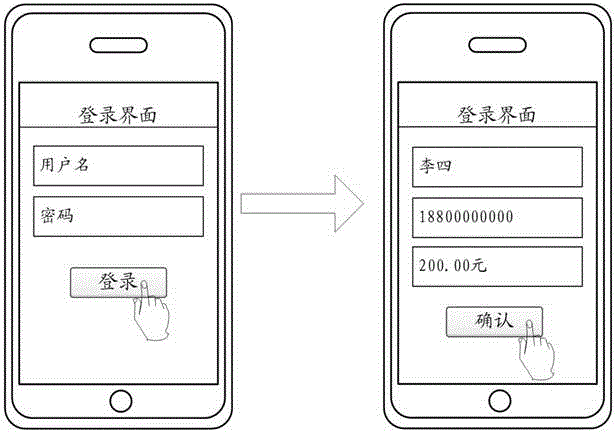

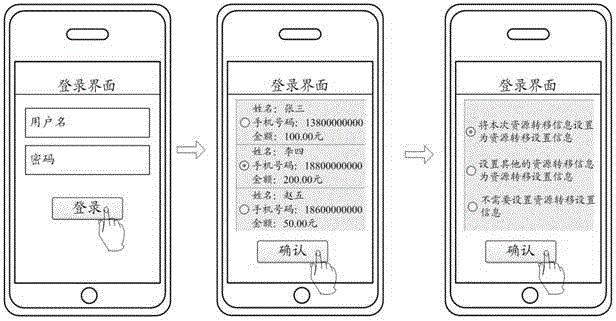

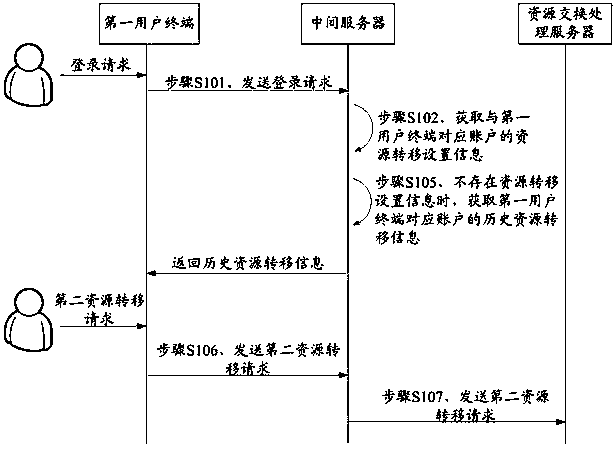

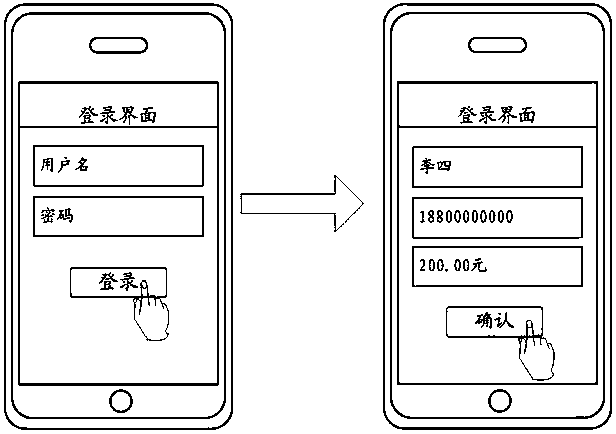

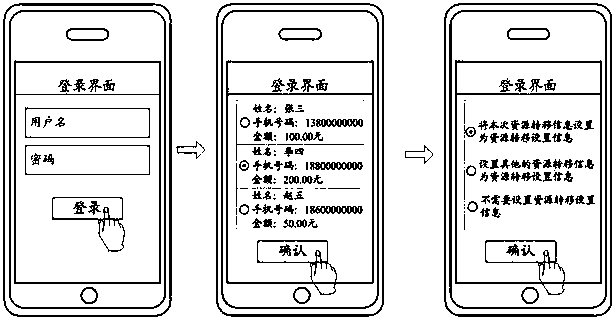

Data processing method, intermediate server and data processing system

ActiveCN104980458AAccurate operationGuarantee processing accuracyFinancePayment architectureData processing systemResource transfer

The invention discloses a data processing method. The method comprises that after an intermediate server receives a login request of a user terminal, resource transfer arrangement information of a corresponding account of the user terminal is obtained and returned to the user terminal, so that the user terminal can achieve fast and safe resource transfer while manual input of any resource transfer information is not required. The invention also discloses an intermediate server and a data processing system. According to the invention, safety of data processing is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

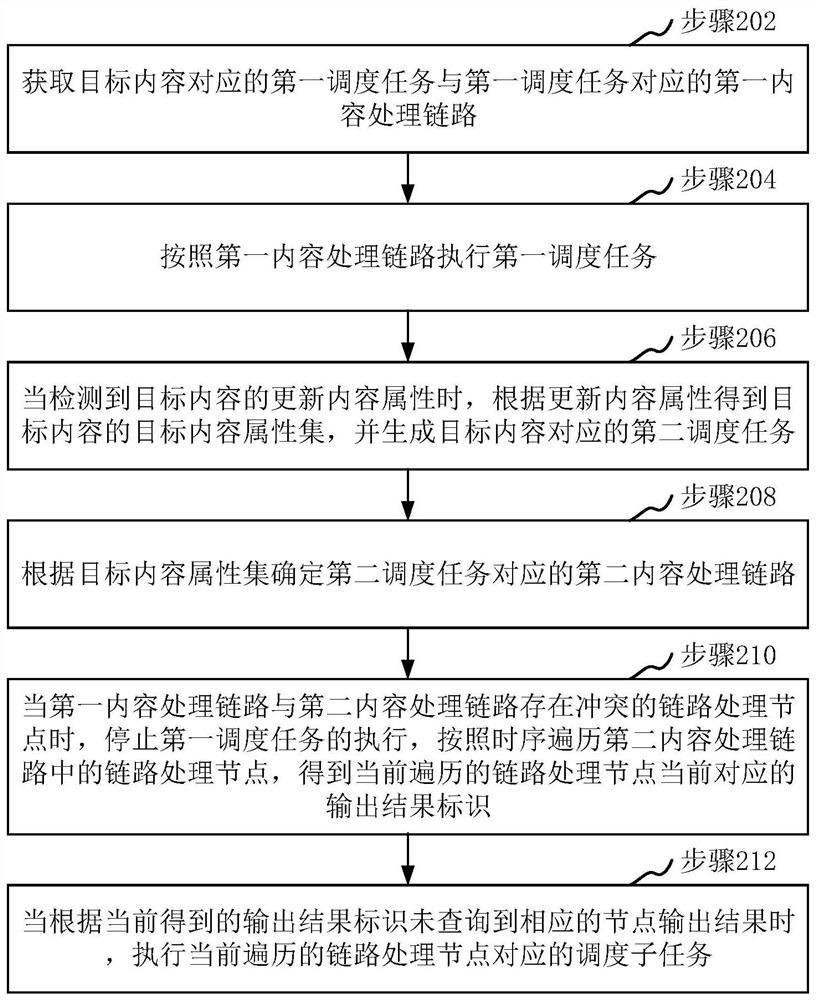

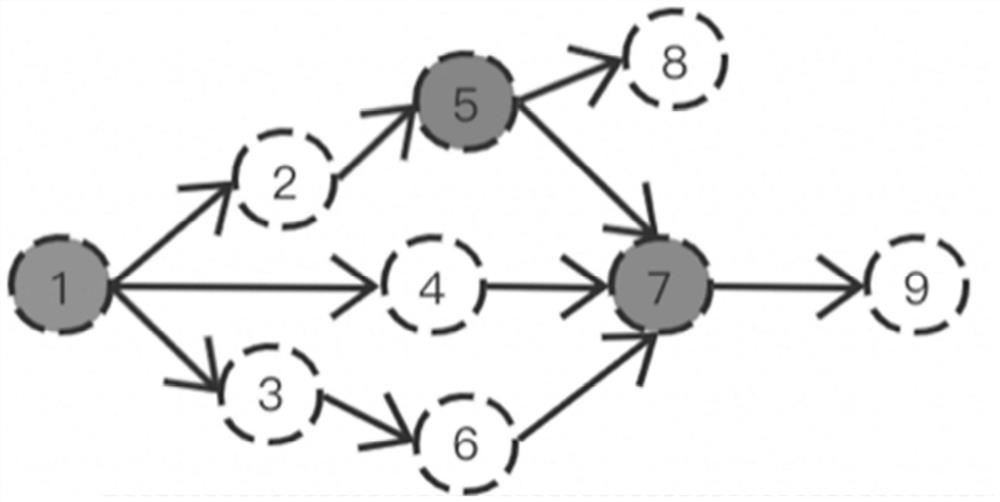

Content processing link adjustment method and device, computer equipment and storage medium

ActiveCN112235396AImprove processing efficiencyGuarantee processing accuracyProgram initiation/switchingResource allocationComputer networkProcessing

The invention relates to a content processing link adjustment method and device, computer equipment and a storage medium. The method comprises the steps of obtaining a first scheduling task of targetcontent and a corresponding first content processing link; executing the first scheduling task according to the first content processing link; when the updated content attribute of the target contentis detected, obtaining a target content attribute set according to the updated content attribute, and generating a second scheduling task of the target content; determining a second content processinglink corresponding to the second scheduling task according to the target content attribute set; when the conflict link processing node exists between the first content processing link and the secondcontent processing link, stopping executing the first scheduling task, and traversing the link processing nodes in the second content processing link according to a time sequence to obtain an output result identifier of the currently traversed link processing node; and when the node output result is not queried according to the output result identifier, executing the scheduling subtask corresponding to the link processing node. By adopting the method, the content processing efficiency can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

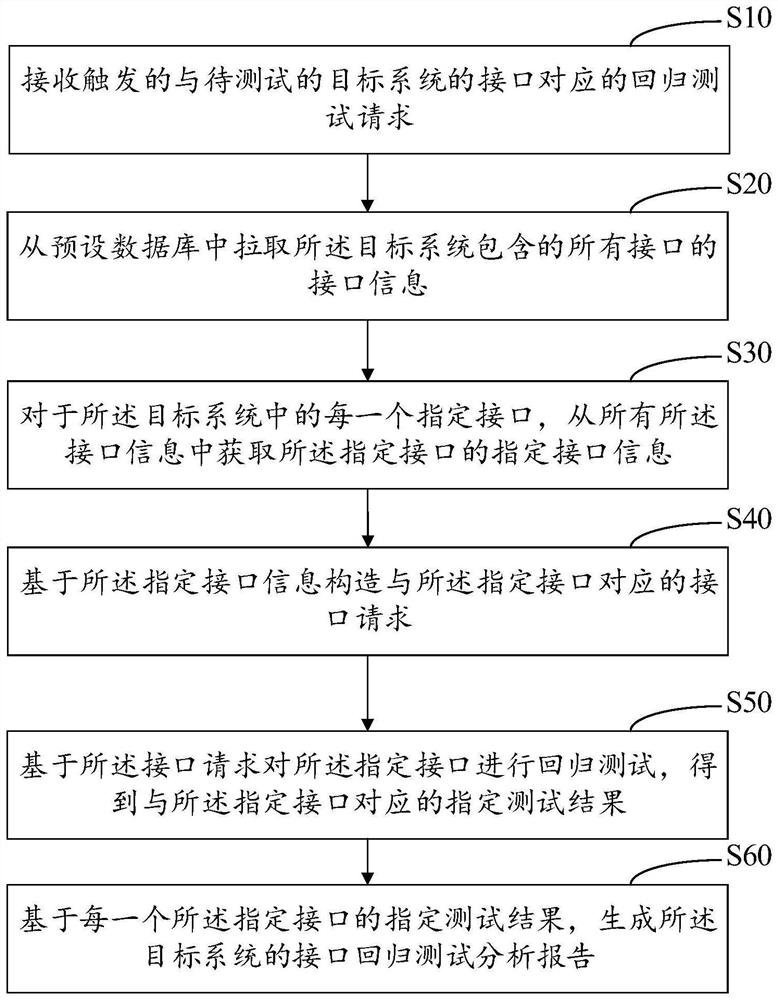

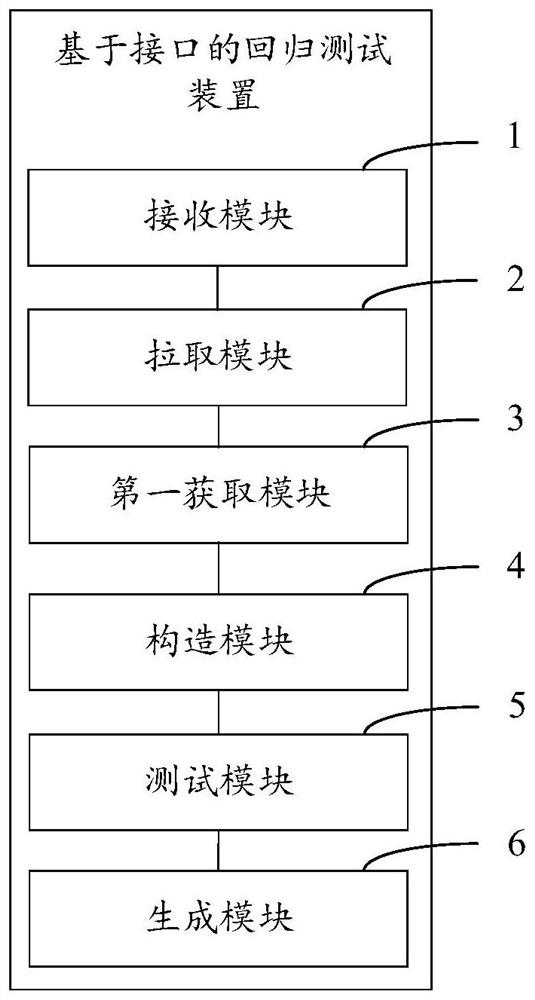

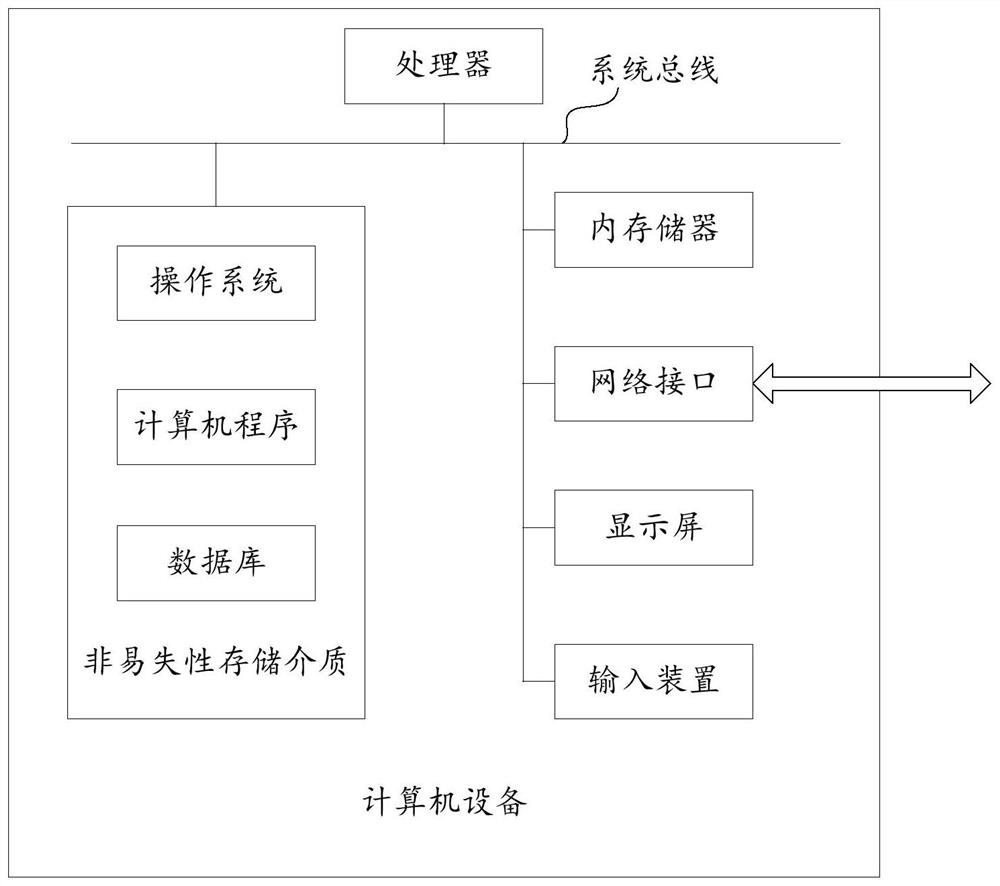

Regression test method and device based on interface, computer equipment and storage medium

PendingCN114817055AReduce workloadAvoid operating errorsSoftware testing/debuggingProcessing accuracyBlockchain

The invention relates to the technical field of artificial intelligence, and provides an interface-based regression test method and device, computer equipment and a storage medium, and the method comprises the steps: receiving a triggered regression test request corresponding to an interface of a to-be-tested target system; pulling interface information of all interfaces contained in the target system; for each specified interface in the target system, acquiring specified interface information of the specified interface from all the interface information; constructing an interface request corresponding to the specified interface based on the specified interface information; performing a regression test on the specified interface based on the interface request to obtain a corresponding specified test result; and based on the specified test result of each specified interface, generating an interface regression test analysis report of the target system. The test efficiency of the regression test of the system interface can be improved, and the processing accuracy of the regression test is ensured. The method can also be applied to the field of block chains, and the specified test result and other data can be stored on the block chain.

Owner:CHINA PING AN PROPERTY INSURANCE CO LTD

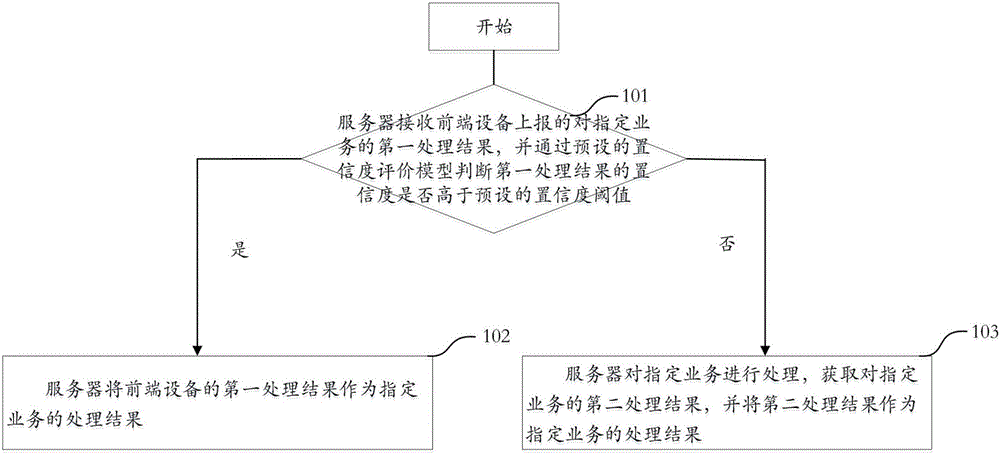

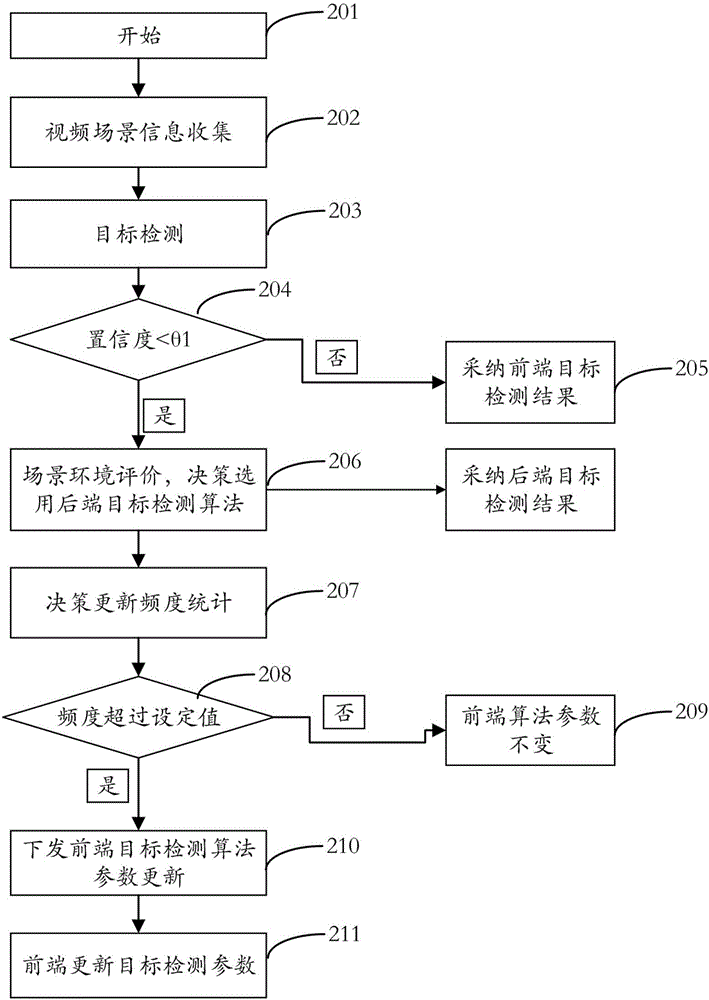

Processing method and server for monitoring service

ActiveCN106682590AGuarantee processing accuracyTake advantage ofCharacter and pattern recognitionResource utilizationMonitoring system

The invention discloses a processing method for monitoring service. A server receives a first processing result of a designated service reported by a front-end device, and a preset confidence degree evaluation model is used for determining whether the confidence degree of the first processing result is higher than a preset confidence threshold or not. If yes, the first processing result will serve as a processing result of the designated service by the server; if not, the server will process the designated service, a second processing result is obtained and the second processing result serves as a processing result of the designated service by the server. The first processing result of the front-end device is evaluated through the server, so that when the confidence degree of the first processing result is higher, the first processing result is adopted, and when the confidence degree of the first processing result is lower, the server carries out further processing on the designated service, and therefore on the premise of ensuring the accuracy of service processing, the resource of the front-end device is fully utilized, and the comprehensive resource utilization ratio of the monitoring system is improved.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

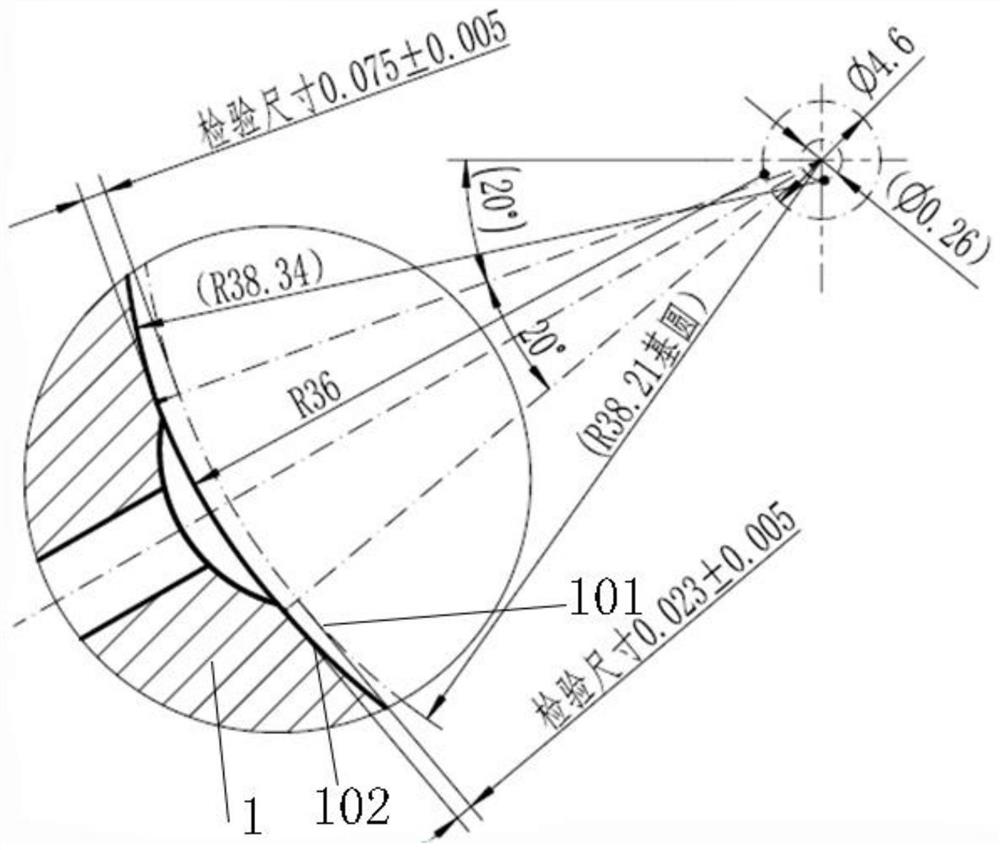

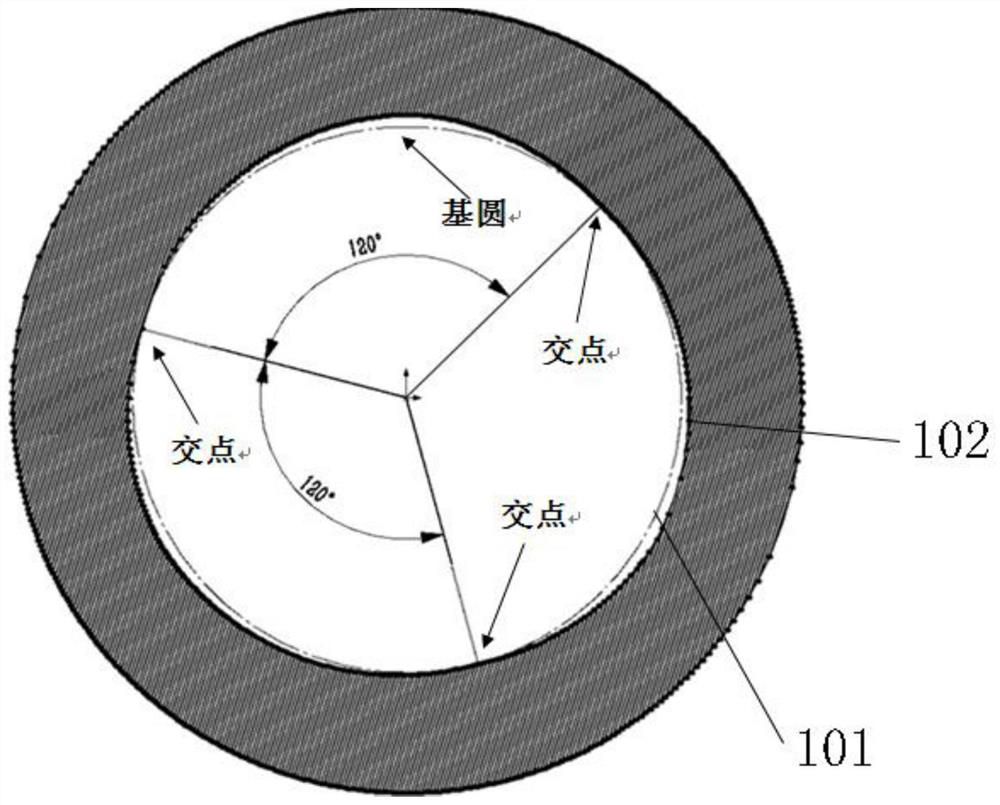

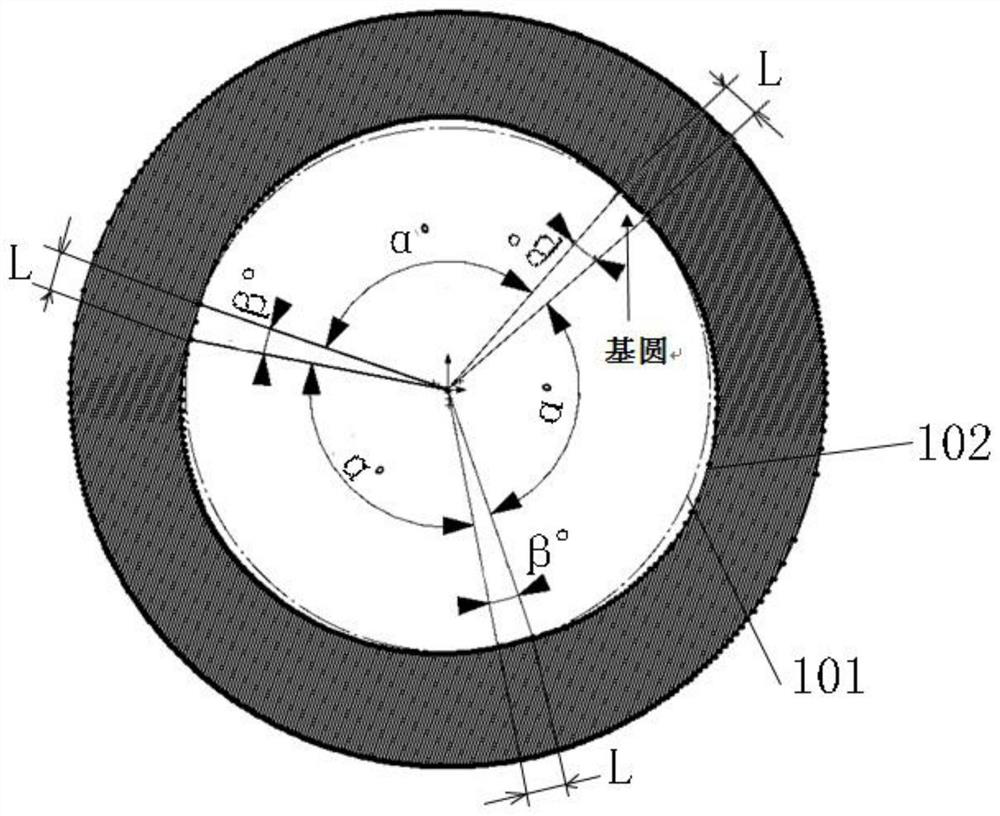

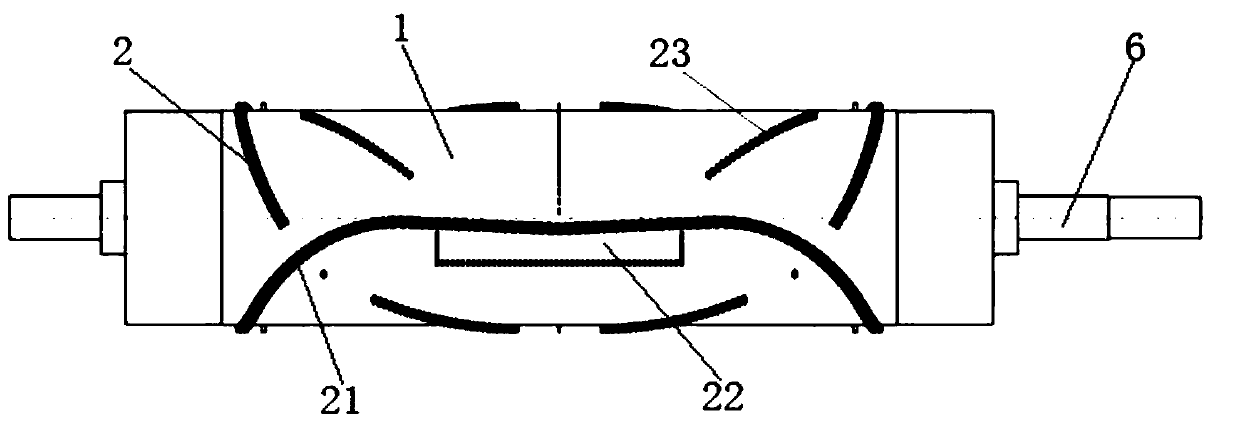

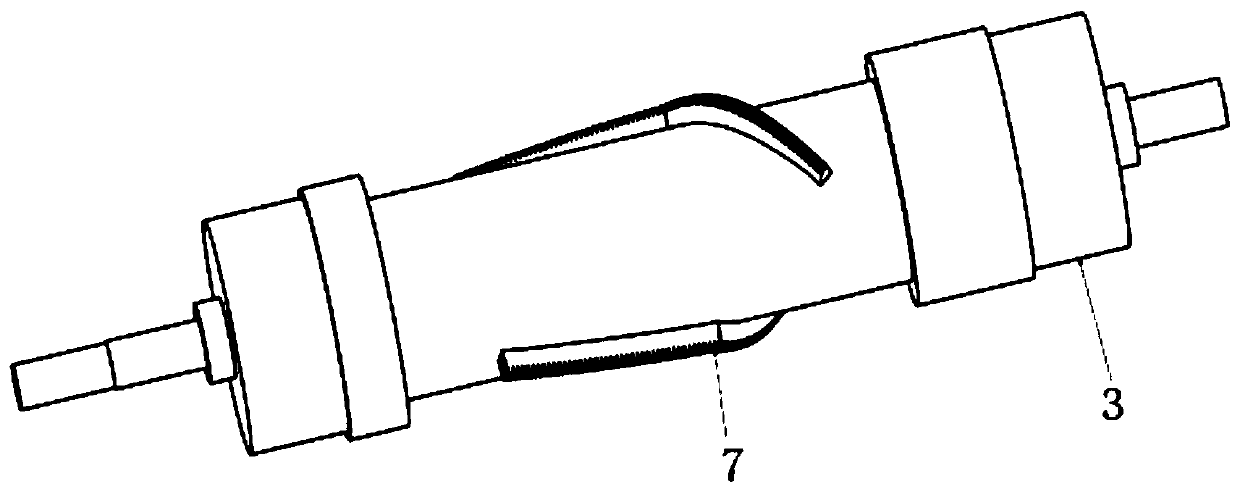

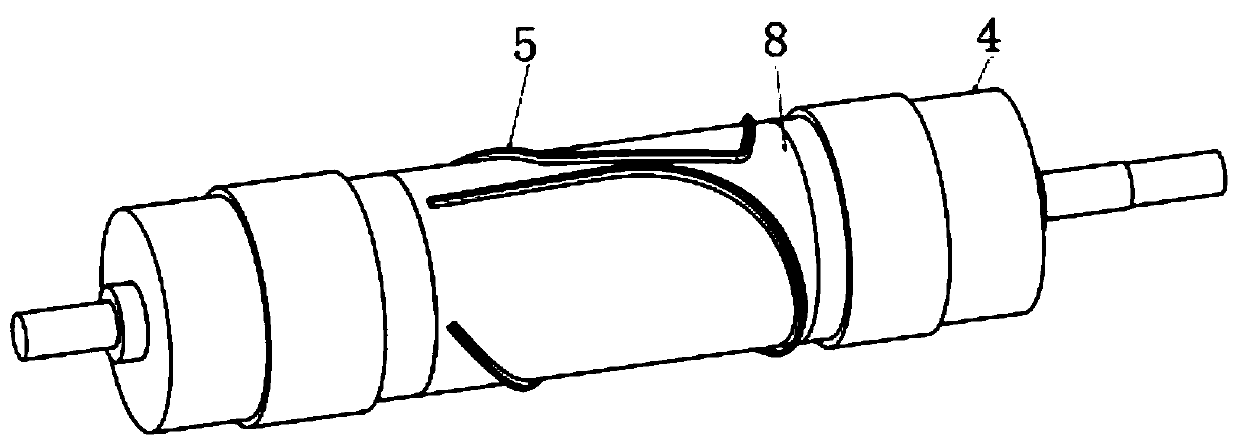

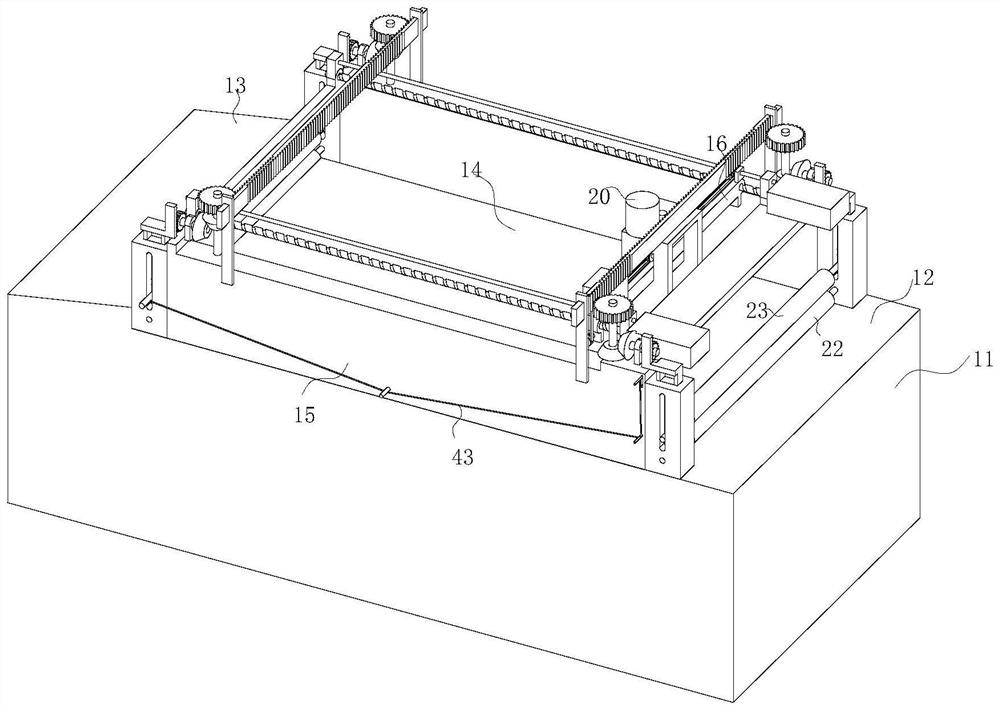

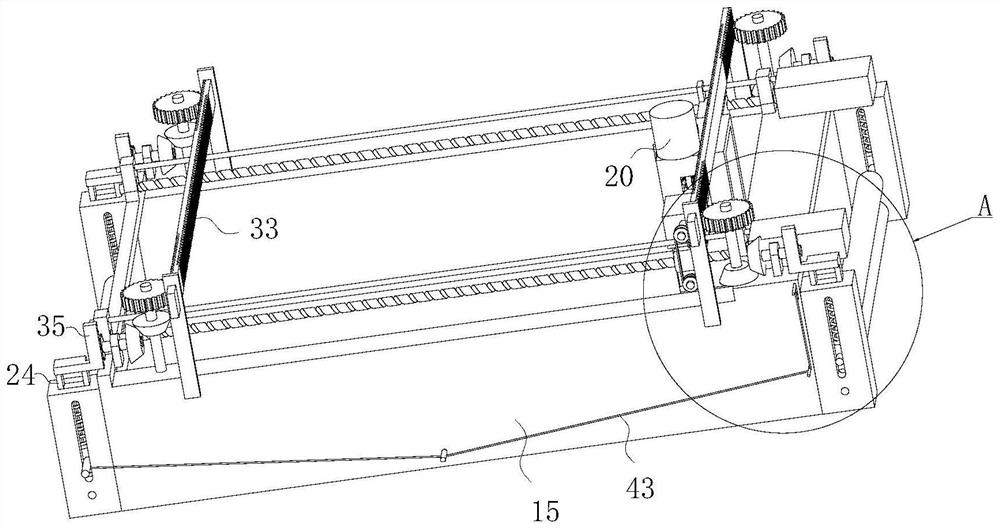

Processing and detection method for improving floating sleeve inner hole oil wedge detection efficiency

ActiveCN112710212AOil wedge depth three-position controlControl liftMechanical depth measurementsNumerical controlEngineering

The invention discloses a processing and detection method for improving floating sleeve inner hole oil wedge detection efficiency, an inner hole is a base circle, a plurality of oil wedges are uniformly distributed, and an included angle between nodes at two ends of a single oil wedge is [alpha], and the method comprises the following steps: determining an angle range beta between the oil wedge and the arc lift of the base circle within 0.001 mm according to different specifications of oil wedge lifts, and recording a width size L; aligning a base circle and a part plane of the unmachined floating sleeve, controlling the reference precision and end face bounce of the inner hole, clamping the floating sleeve, machining the floating disc inner hole oil wedge according to a set numerical control machining program, and ensuring that the width L value of the base circle of the inner hole is the same as a theoretical value after the floating disc inner hole oil wedge is actually machined; and placing a V-shaped equal-height block used for detection on a plane, then tightly attaching the end face of the floating sleeve, fixing the dial indicator on the plane, enabling a pointer of the dial indicator to extend into an oil wedge in an inner hole of the floating sleeve, and therefore, lift detection of the oil wedge of the floating sleeve can be achieved by slowly rotating the floating sleeve at a constant speed while the pointer is tightly attached to the end face of the floating sleeve.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Motor-driven bottle body painting device

PendingCN110882875AAvoid damageImprove the effect of spray paintLiquid surface applicatorsCoatingsMotor driveElectric machine

The invention relates to a motor-driven bottle body painting device. The motor-driven bottle body painting device comprises a machine body, an upper cover arranged at the top of the machine body, a motor drive mechanism, a painting structure respectively connected with the motor drive mechanism, a net frame sliding mechanism connected with the motor drive mechanism and a rotatable bottle body adjusting mechanism arranged at the bottom of the net frame sliding mechanism. The motor drive mechanism comprises a first motor and a second motor which are arranged in parallel up and down. The first motor is connected with a first lead screw, and the second motor is connected with a second lead screw. The first lead screw and the second lead screw are arranged between a first fixed plate and a second fixed plate and can rotate on the first fixed plate and the second fixed plate, wherein the first fixed plate and the second fixed plate are arranged oppositely. The first fixed plate and the second fixed plate are correspondingly provided with a first sliding block and a second sliding block in a sleeving mode, the first sliding block is fixedly connected with the painting mechanism, and the second sliding block is fixedly connected with the net frame sliding mechanism. Compared with the prior art, the motor-driven bottle body painting device has the advantages of effective dust prevention, improved processing accuracy, improved production efficiency and the like.

Owner:上海瑞姿包装材料股份有限公司

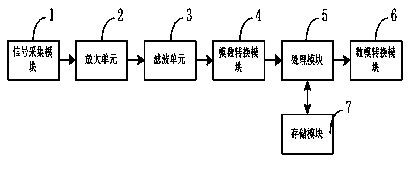

Audio signal processing method

InactiveCN103761973AGuarantee processing accuracyGuaranteed speedSpeech analysisEmbedded systemDigital conversion

The invention belongs to the field of audio signal processing methods and provides an audio signal processing method. The audio signal processing method relates to a collecting module, an amplifying module, a filtering module, an analog-to-digital conversion module, a processing module and a digital-to-analog conversion module, wherein the collecting module, the amplifying module, the filtering module, the analog-to-digital conversion module, the processing module and the digital-to-analog conversion module are connected in sequence, and the processing module is further connected with a storage module. The collecting module is used for collecting and obtaining audio signals, filtering processing is carried out on the audio signals through the filtering module after signal amplification processing is carried out on the audio signals through the amplifying module, the analog-to-digital conversion module is used for converting the audio signals input from the filtering module into digital signals, and the processing module is used for carrying out signal processing on the digital signals and sending the digital signals to the digital-to-analog conversion module to output analog signals. According to the audio signal processing method, high-quality audio messages can be obtained under a noisy environment, and the requirements of audio-visual equipment and audio equipment for high-quality audio signals under different noisy environments can be met.

Owner:南宁市公安局

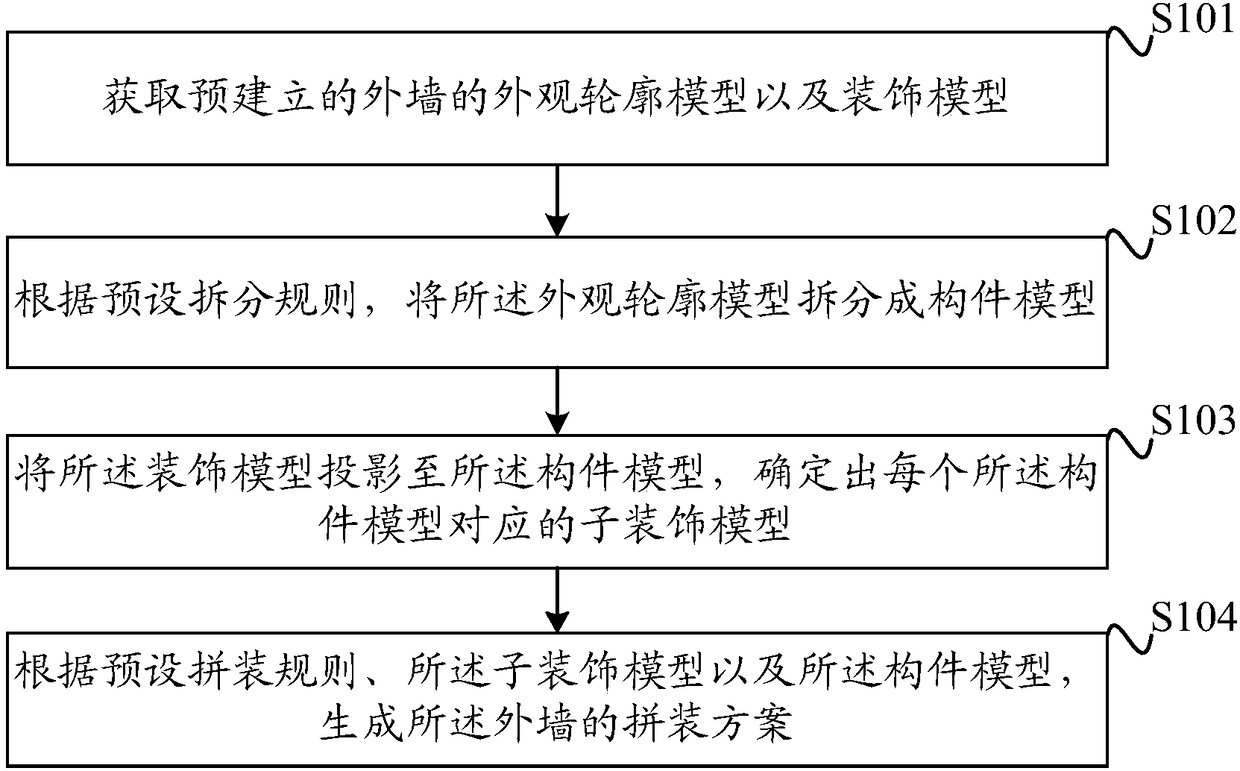

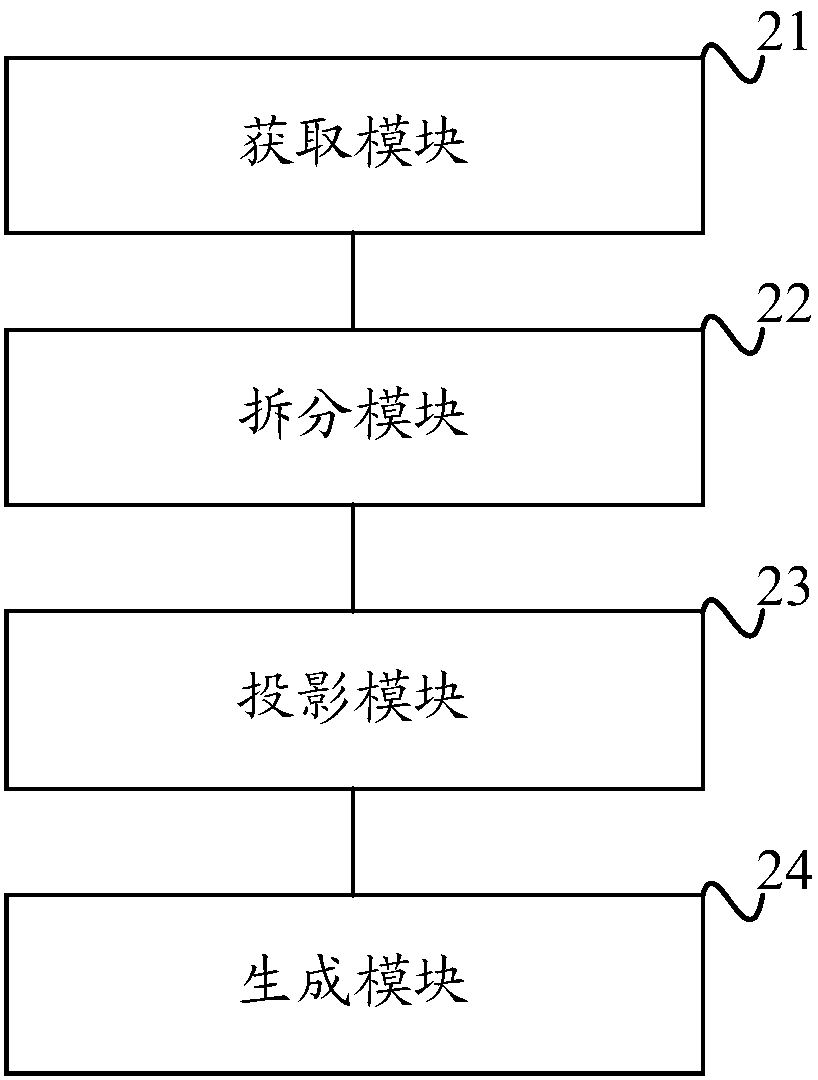

BIM-based integrated outer wall assembling scheme generation method and device

InactiveCN108427804AGuaranteed accuracyGuarantee processing accuracyGeometric CADConfiguration CADComputer science

The invention discloses a BIM-based integrated outer wall assembling scheme generation method and device. The method comprises the following steps of: obtaining a pre-established appearance contour model and a pre-established decoration model of an outer wall; splitting the appearance contour model into component models according to a preset splitting rule; projecting the decoration model to the component models so as to determine a sub-decoration model corresponding to each component model; and generating an assembling scheme of the outer wall according to a preset assembling rule, the sub-decoration models and the component models. According to the method and device, the decoration model is projected to each outer wall component so as to determine a decoration pattern on each outer wallcomponent, so that the processing correctness of each outer wall component can be ensured; and an assembling sequence and an assembling position of each outer wall component can be determined on the basis of each outer wall component and the corresponding decoration pattern. On the basis of the generated outer wall assembling scheme, the processing correctness of the outer wall components and thecorrectness of the subsequent outer wall assembling are ensured.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

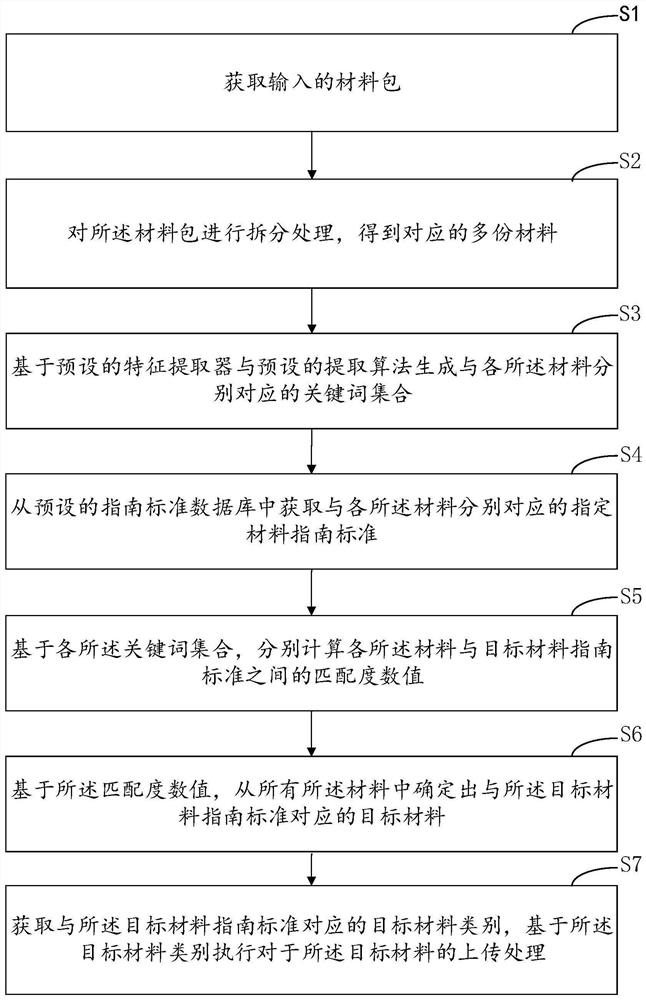

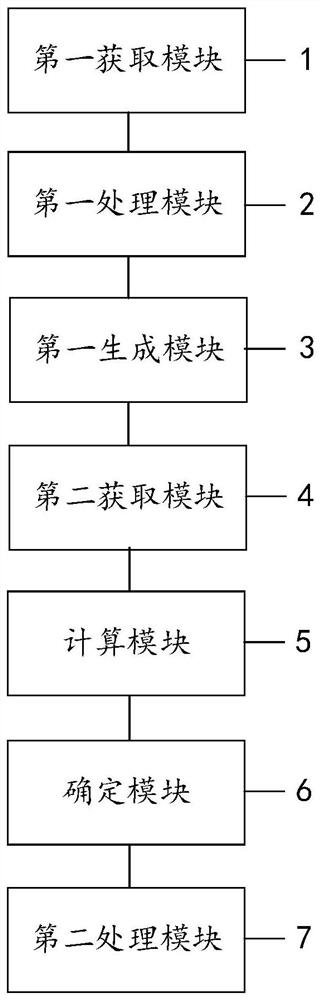

Material data processing method and device, computer equipment and storage medium

PendingCN113051372AReduce upload timeImprove processing efficiencyNatural language data processingText database queryingProcess engineeringSmart government

The invention relates to the technical field of artificial intelligence, can be applied to the field of smart government affairs, and provides a material data processing method and device, computer equipment and a storage medium.The method comprises the steps of obtaining an input material package; splitting the material bag to obtain a plurality of parts of materials; generating a keyword set corresponding to each material; acquiring a specified material guide standard corresponding to each material from a guide standard database; based on each keyword set, respectively calculating a matching degree value of each material and a target material guide standard; determining a target material corresponding to a target material guide standard from all materials based on the matching degree value; and obtaining a target material category of the target material guide standard, and executing uploading processing on the target material based on the target material category. The processing efficiency of material uploading can be improved, and the accuracy of material uploading is ensured. The method and device can also be applied to the field of block chains, and the target material can be stored on the block chain.

Owner:PINGAN INT SMART CITY TECH CO LTD

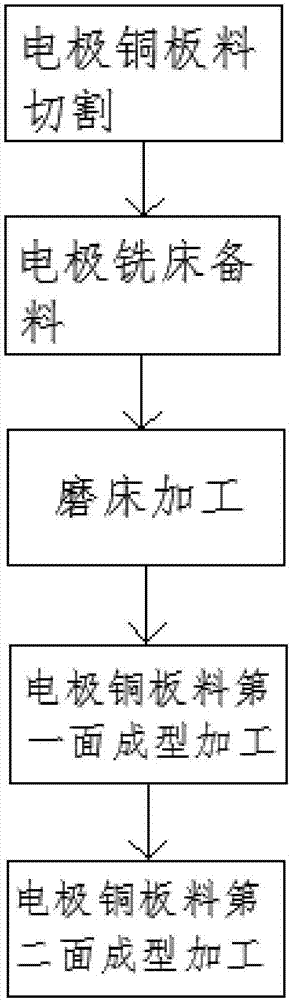

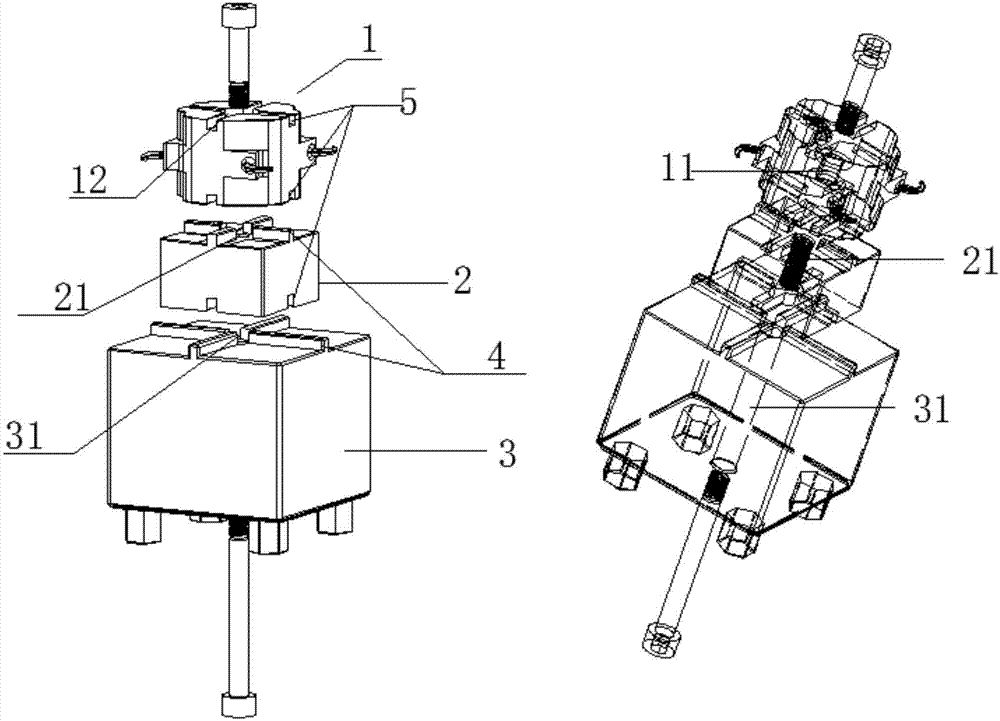

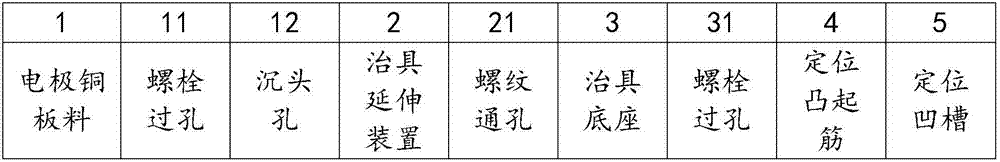

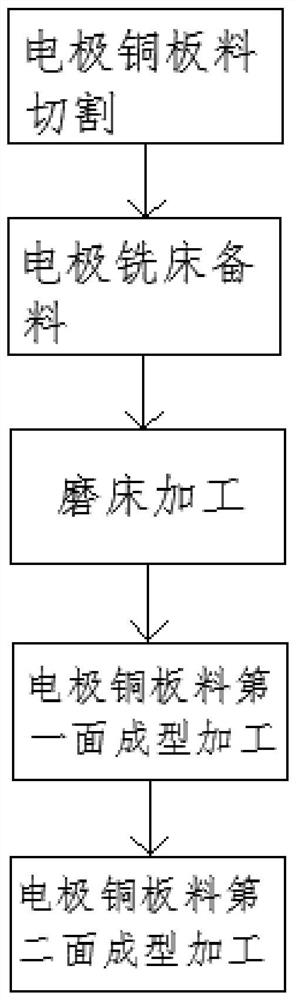

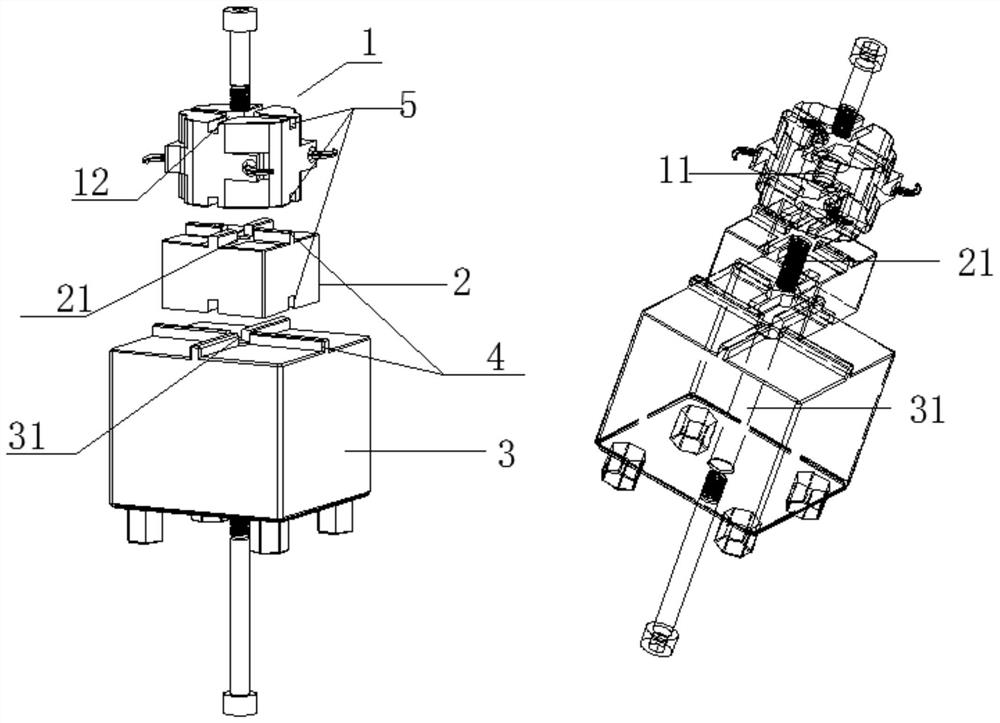

Processing method of integrated horn submarine gate electrode

ActiveCN107414427AGuaranteed coincidenceCause processing errorElectrical-based machining electrodesPositioning apparatusCopperProcessing cost

The invention provides a processing method of an integrated horn submarine gate electrode. The method comprises the following steps: cutting an electrode copper plate material, preparing materials of an electrode milling machine, processing via a grinding machine, forming and processing a first side of the electrode copper plate material and forming and processing a second side of the electrode copper plate material, wherein the step of processing via the grinding machine is characterized by processing positioning grooves used for subsequently clamping in the upper end surface and the lower end surface of the electrode copper plate material. The processing method is simple in steps, short in period and low in processing cost. A clamping fixture used in the electrode processing method comprises a fixture base and a fixture extending device, wherein the fixture base and the fixture extending device are provided with positioning convex ribs, positioning grooves and central through holes; through cooperation of the central holes and positioning structures, the electrode material to be processed is stably fixed on the clamping fixture, so that the processing accuracy is ensured. The processing method and the clamping fixture are suitable for clamping and processing various types of electrodes.

Owner:苏州沃思诺精密模具有限公司

A processing method for an integral horn submerged electrode

ActiveCN107414427BReduce the amount that can be processedSave raw materialsElectrical-based machining electrodesPositioning apparatusEngineeringMachining process

Owner:苏州沃思诺精密模具有限公司

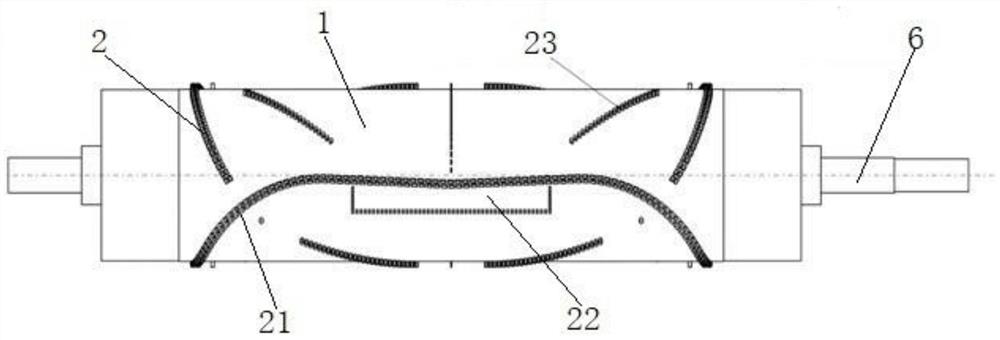

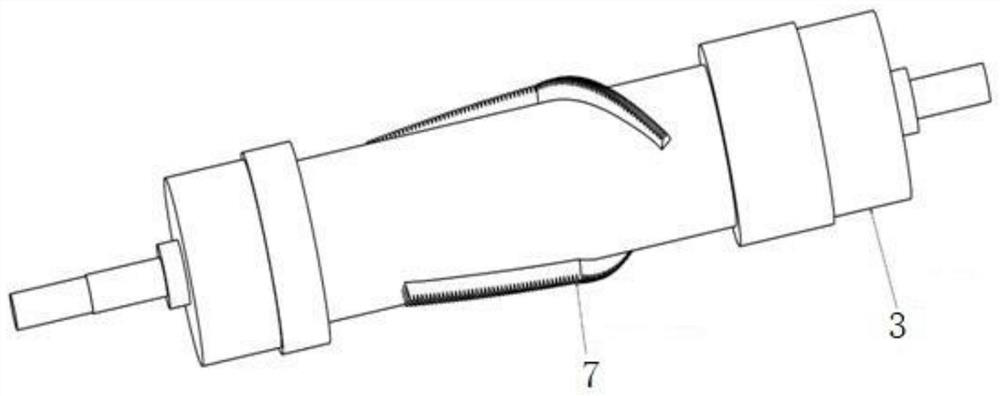

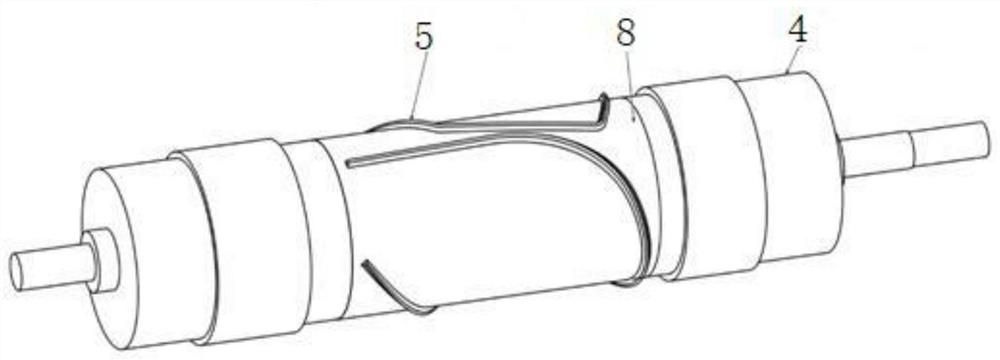

Method for machining roller by adopting nine-axis machine tool and roller produced by using method

ActiveCN111390505AHigh precisionGuaranteed machining accuracyDomestic articlesMilling equipment detailsMilling cutterCnc grinding

The invention relates to a method for machining a roller by adopting a nine-axis machine tool and the roller produced by using the method. The method comprises the following steps that S1, a round baris taken and is machined into a stepped shaft by using a lathe, and grinding is carried out on the maximum-diameter part of the stepped shaft by using a numerical control grinding machine; S2, a milling cutter in the nine-axis machine tool is used for dynamically roughing the stepped shaft to machine protruding structures, and secondary dynamic roughing is conducted on the stepped shaft to guarantee that the machining allowances reserved for finish machining of the protruding structures are uniform and consistent; S3, inner and outer side positions, shapes and inclination angles of the protruding structures on the stepped shaft are corrected by using spherical milling cutters with gradually reduced diameters in sequence so that the protruding structures can be machined and formed at a time; and S4, after machining of the protruding structures is completed, a turning tool is used for back chipping of filleted corners, milled through the spherical milling cutters, of the stepped shaft.According to the method for machining the roller by adopting the nine-axis machine tool and the roller produced by using the method, through cooperation of multi-axis linkage, dynamic roughing and themulti-diameter spherical milling cutters of the nine-axis machine tool, one-time part clamping type one-time forming for machining of the roller is achieved, the precision is improved, and the production cycle is shortened.

Owner:安徽天航机电有限公司

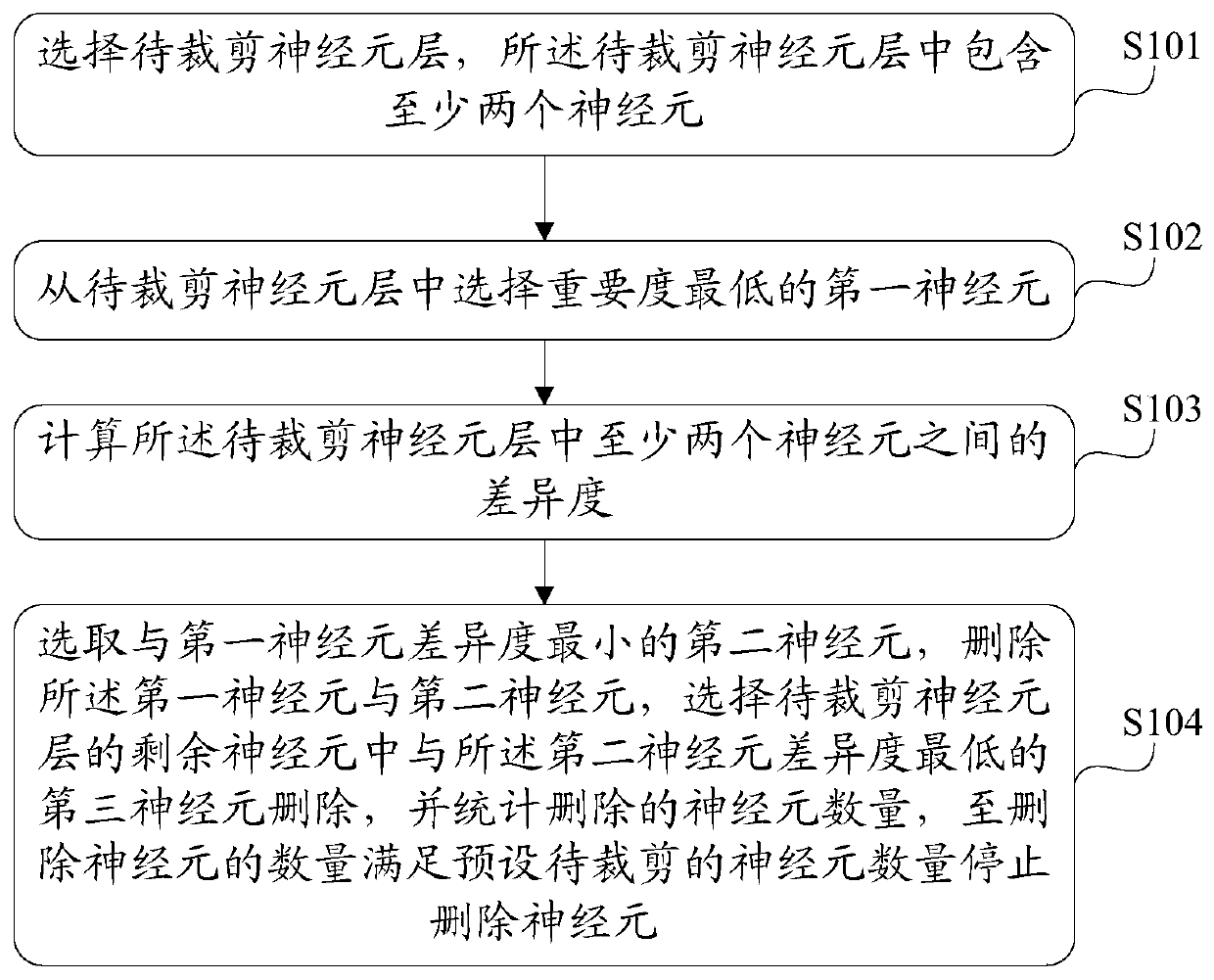

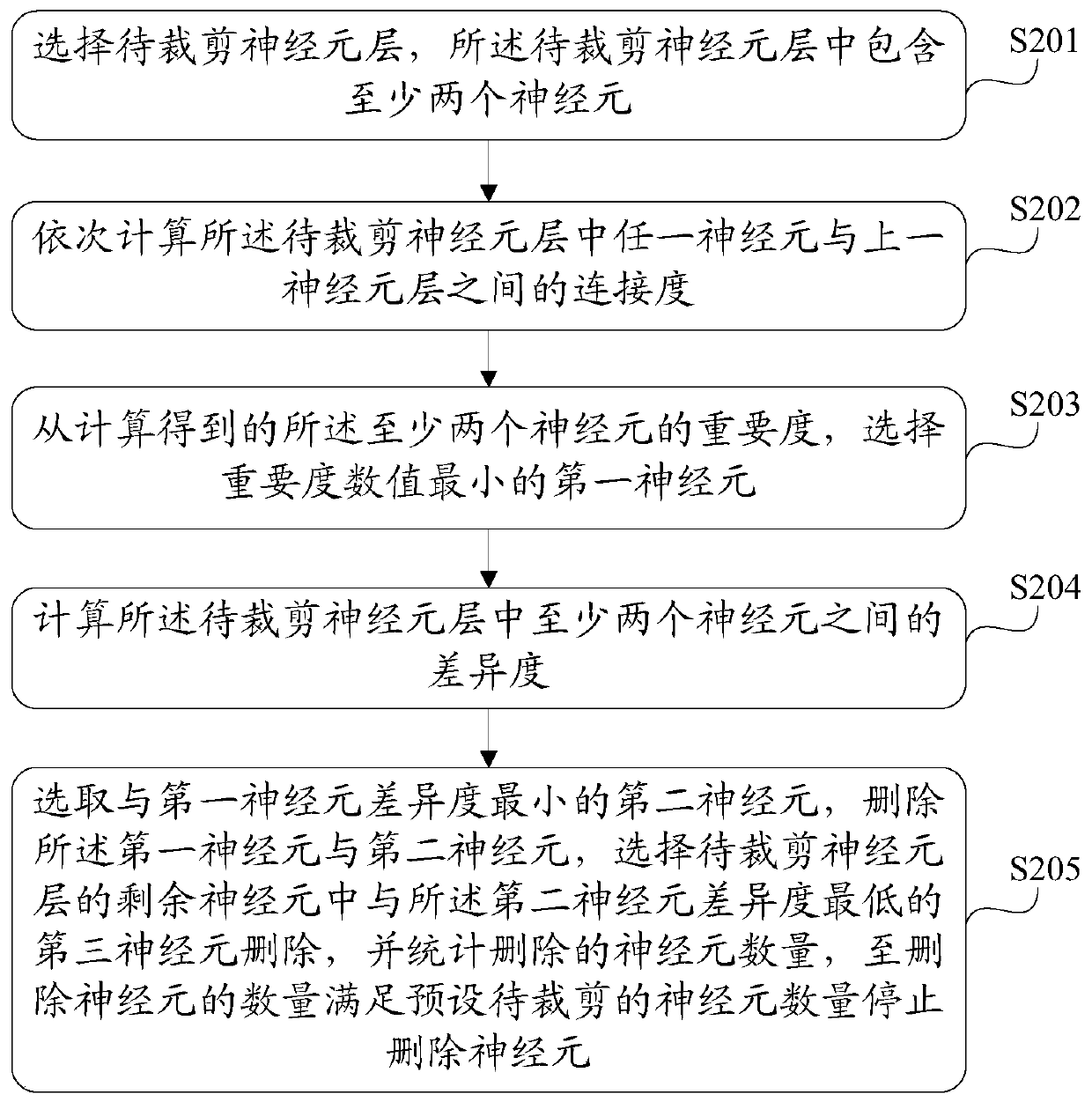

Method for cutting neural network model and electronic equipment

ActiveCN110472736AAccuracy impactGuaranteed Compression CroppingPhysical realisationNetwork modelNeuron

The invention provides a method for cutting a neural network model. The method includes: based on the lowest importance of neurons in a to-be-clipped neuron layer, determining that the first neuron isa to-be-clipped neuron, and determining the second neuron as a to-be-clipped neuron based on the minimum difference degree with the first neuron, and so on, determining the neuron with the minimum difference degree with the previous to-be-clipped neuron as a new to-be-clipped neuron until the number of clipped neurons meets the preset number of to-be-clipped neurons. The cut neurons have the lowest importance degree; the accuracy of the neural network model is not greatly influenced by the neural network model with the lowest importance degree and the neuron with the lowest difference degreefrom the neuron with the lowest importance degree, the compression cutting of the neural network model is completed on the premise of ensuring the data processing accuracy of the neural network model,and the neural network model is conveniently deployed on edge equipment.

Owner:LENOVO (BEIJING) CO LTD

Fire bending processing technology of angle steel

The invention relates to a fire-bending machining process for angle steel, which includes the following steps: (1) rough surface machining: during the machining process, a machining center is used to shovel back, cut, open half holes and grind planes on the angle steel; (2) local Heating: Local high temperature heating for the section port of the angle steel and the fire bending area of the angle steel, so that it has low deformation resistance and good plasticity at high temperatures, and can protect the metal structure from damage; (3) Opening treatment: the angle steel needs to be Open at the fire curve. After the opening is bent, it needs to be welded and then ground; (4) Correct the hole type and level the fire curve point: For the deformation of the local hole caused by the tensile curve of the steel after the fire bending of the angle steel, it is necessary to The correction is circular. At the same time, the deformation caused by the internal stress and thermal stress after the angle steel is bent during the processing needs to be leveled. At the same time, the pre-opened half hole is opened for the whole hole opening process.

Owner:江苏常峰电力科技股份有限公司

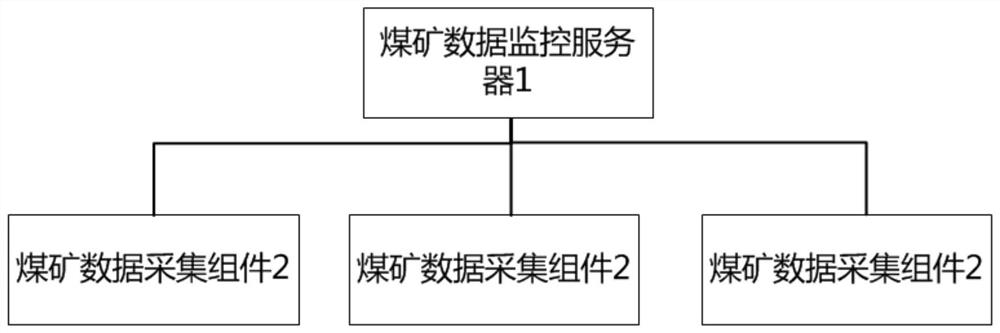

Mining process data monitoring system

ActiveCN112761727ARealize transmissionRealize automatic controlMining devicesTotal factory controlInformation processingAutomatic control

The invention provides a mining process data monitoring system. Each coal mine data acquisition assembly is in communication connection with a coal mine data monitoring server; the coal mine data acquisition assembly detects mining process data information and uploads the mining process data information to the coal mine data monitoring server; the coal mine data monitoring server compares the mining process data information with a preset threshold value, judges whether the mining process data information exceeds the threshold value or not, and gives an alarm if the mining process data information exceeds the threshold value; the mining process data information is acquired through data communication with the coal mine data acquisition assembly, so that transmission of the mining process data information and processing and analysis of the mining process data information are realized; an early warning is given according to a preset rule; a control instruction is fed back according to a mining process data information analysis result to realize automatic control; and the mining process data information can be automatically monitored, so that real-time monitoring in mining states according to different working conditions is realized, the mining operation safety is ensured, and problems can be quickly solved if the problems are encountered.

Owner:SHANDONG DONGSHAN XINYI COAL MINE CO LTD

Angle iron fire bending machining process

The invention relates to an angle iron fire bending machining process. The process includes the following steps of firstly, performing surface rough machining, wherein backing off, scarfing, half holeforming and flat surface grinding are performed on angle iron by means of a machining center in the machining process; secondly, performing local heating, wherein local high-temperature heating is performed on the section port and fire bending area of the angle iron, the resistance to deformation is low and the plasticity is high at a high temperature, and the metal structure can be protected against damage; thirdly, performing opening treatment, wherein opening needs to be performed on a fire bending cushion before fire bending is performed on the angle iron, and scarf welding and grinding are needed after opening bending; fourthly, correcting the hole type and leveling a fire bending point, wherein deformation (in an elliptical shape) happens to part of holes due to the tensile curve ofa steel material after fire bending is performed on the angle iron, so the holes need to be corrected into circular, meanwhile, in the machining process, the deformation caused by the internal stressand heat stress need to be leveled after the angle iron is bent, and meanwhile the preformed half holes are conditioner and formed.

Owner:江苏常峰电力科技股份有限公司

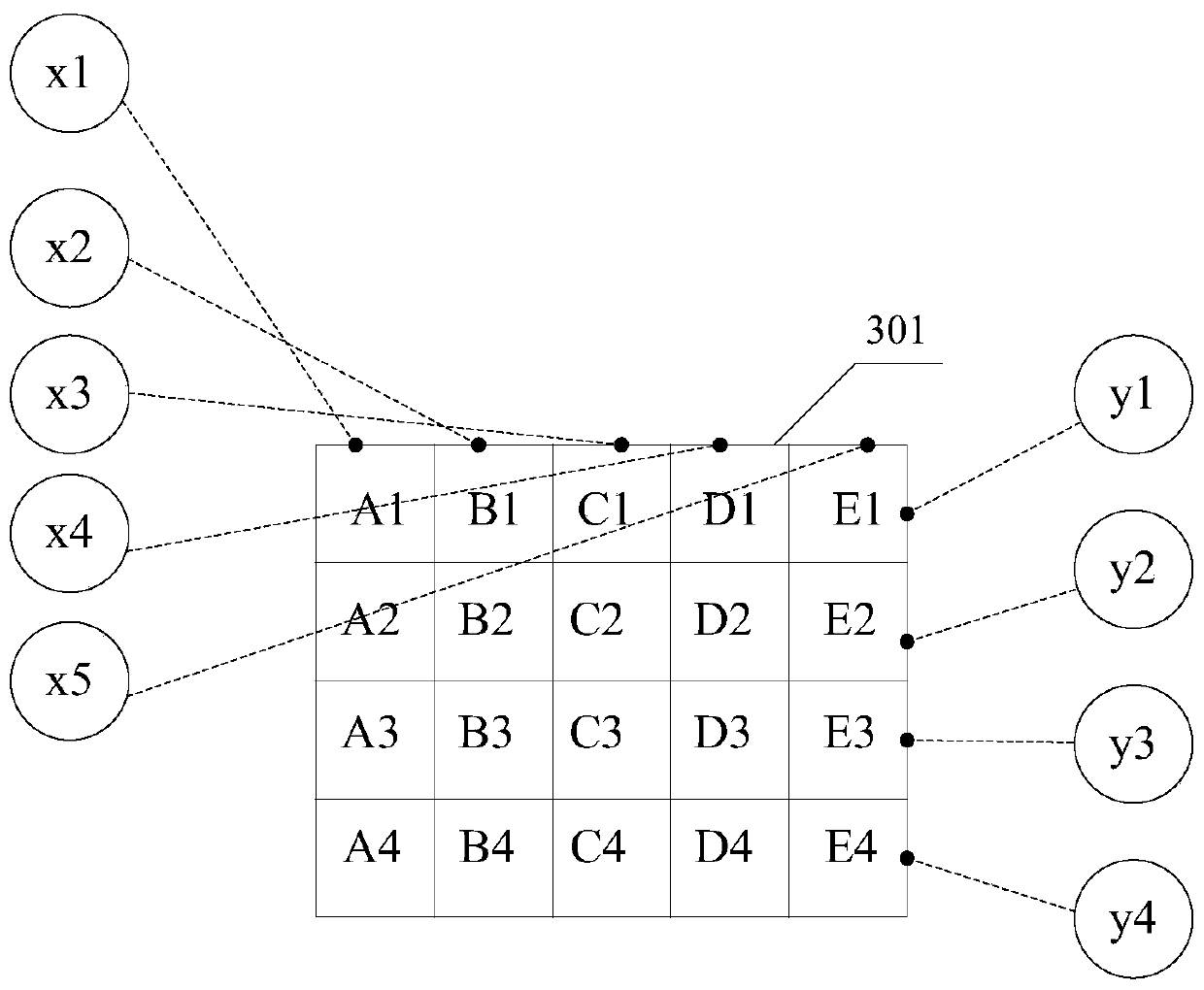

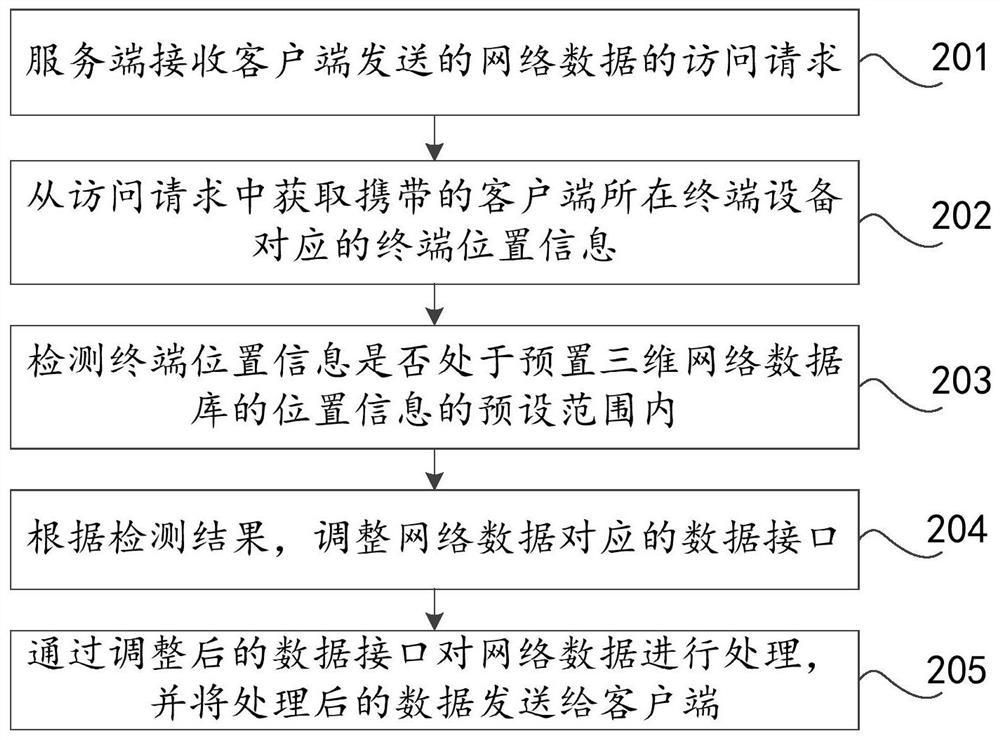

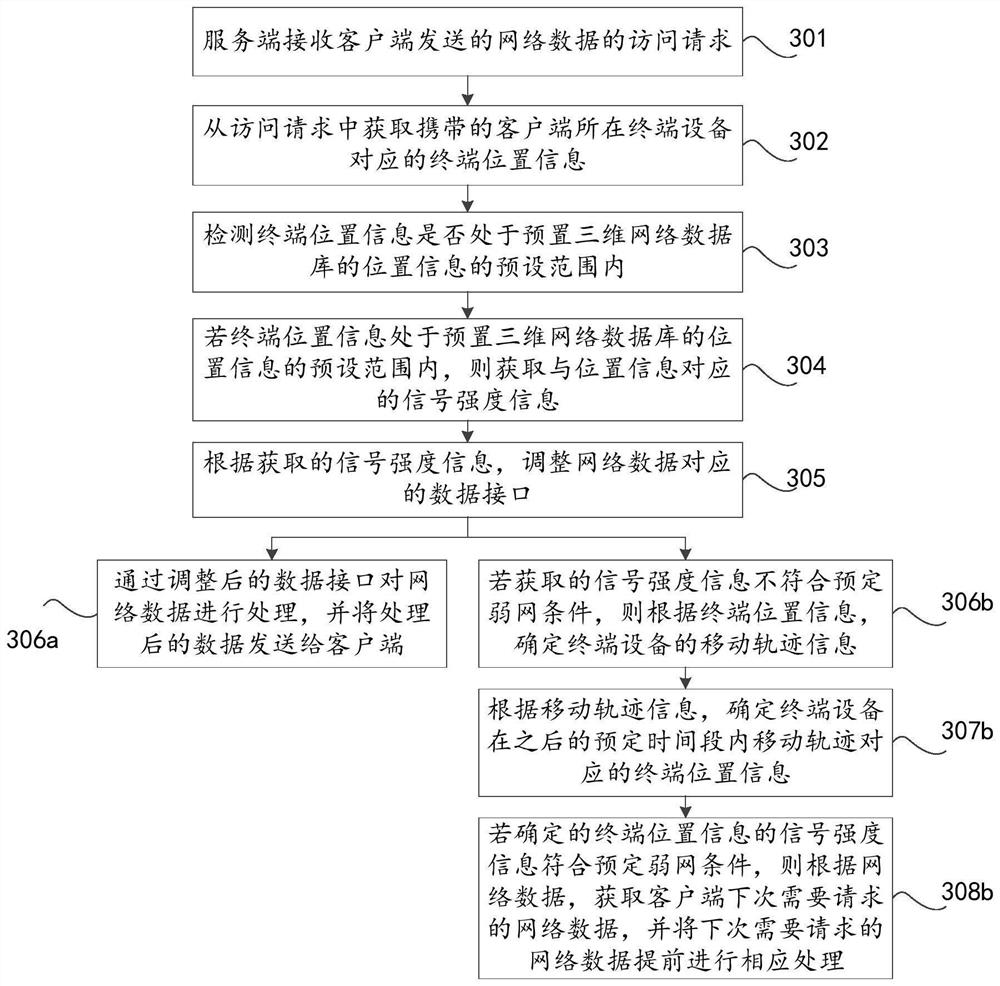

Network data processing method, three-dimensional network database construction method and system

ActiveCN108449372BTimely processingGuarantee processing accuracyGeographical information databasesTransmissionAccess networkTerminal equipment

This application discloses a method for processing network data, a method for building a three-dimensional network database and a system thereof, which relate to the field of network technology and enable users to access network data in a timely manner even in a weak network environment, and experience client applications more smoothly . The main technical solutions of this application are: receiving the network data access request sent by the client; obtaining the terminal location information corresponding to the terminal device where the client is located from the access request, and the terminal location information includes latitude and longitude information and altitude information; detecting Whether the location information of the terminal is within the preset range of the location information of the preset three-dimensional network database, different location information and signal strength information corresponding to the location information are stored in the preset three-dimensional network database; according to the detection results, adjust the network data corresponding Data interface: process the network data through the adjusted data interface, and send the processed data to the client.

Owner:ALIBABA GRP HLDG LTD

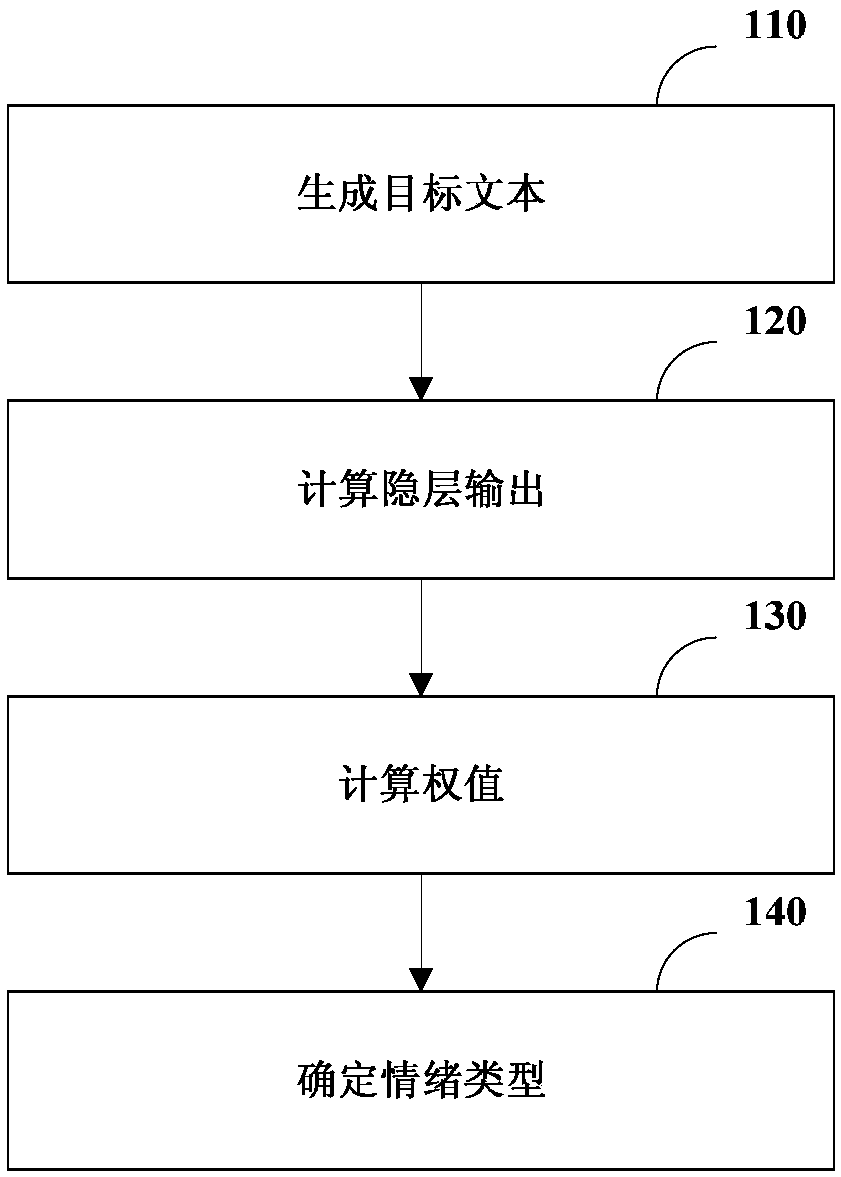

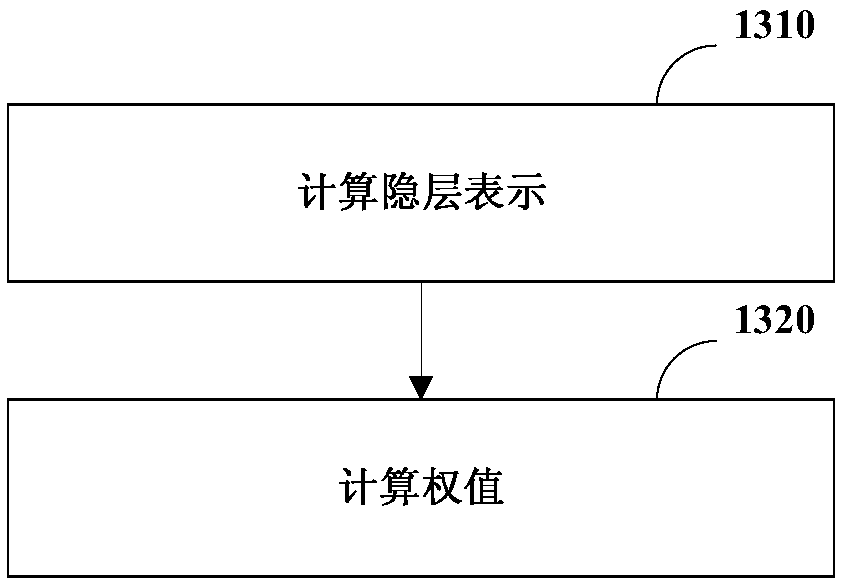

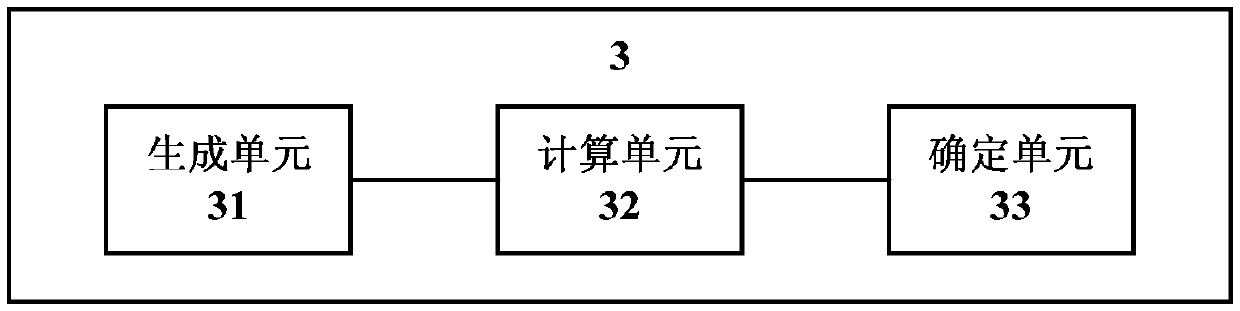

Text data processing method and device and computer readable storage medium

PendingCN111401508AGuarantee processing accuracyImprove processing efficiencyCustomer relationshipNeural architecturesHidden layerEngineering

The invention relates to a text data processing method and device and a computer readable storage medium, and relates to the technical field of artificial intelligence. The method comprises the stepsof adding one or more placeholders to a to-be-processed text to generate a target text, so that the length of the target text meets a preset text length of a deep learning model; inputting the targettext into a deep learning model, and calculating hidden layer output of each word and placeholder in the target text; calculating the weight of each word in the target text according to an attention mechanism, and setting the weight corresponding to the placeholder to be zero; and determining the emotion type of the to-be-processed text according to the weight and the hidden layer output. According to the technical scheme, the text processing efficiency can be improved on the basis of ensuring the text processing accuracy.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Method for processing rolls with nine-axis machine tool and rolls produced by the method

ActiveCN111390505BIncrease frictionHigh precisionDomestic articlesMilling equipment detailsConvex structureMilling cutter

The present invention relates to a method for processing rollers using a nine-axis machine tool and the rollers produced by the method, comprising the following steps: the first step: take a round bar, process it into a stepped shaft through a lathe, and measure the maximum diameter of the stepped shaft through a CNC grinder The second step: use the milling cutter in the nine-axis machine tool to perform dynamic roughing on the stepped shaft to process the raised structure, and perform a second dynamic roughing on the stepped shaft to ensure that it remains for the finishing of the raised structure The machining allowance is uniform; the third step: use the spherical milling cutter with gradually decreasing diameter to correct the inner and outer positions, shapes and inclination angles of the raised structure on the stepped shaft so that the raised structure can be processed at one time; the fourth step: the convex After the machining of the lifting structure is completed, use the turning tool to clean the fillet of the stepped shaft milled by the ball milling cutter. The invention utilizes the multi-axis linkage of the nine-axis machine tool, dynamic roughing and the cooperation of multi-diameter spherical milling cutters to process the rollers to realize one-time clamping and one-time molding of parts, improve precision and reduce production cycle.

Owner:安徽天航机电有限公司

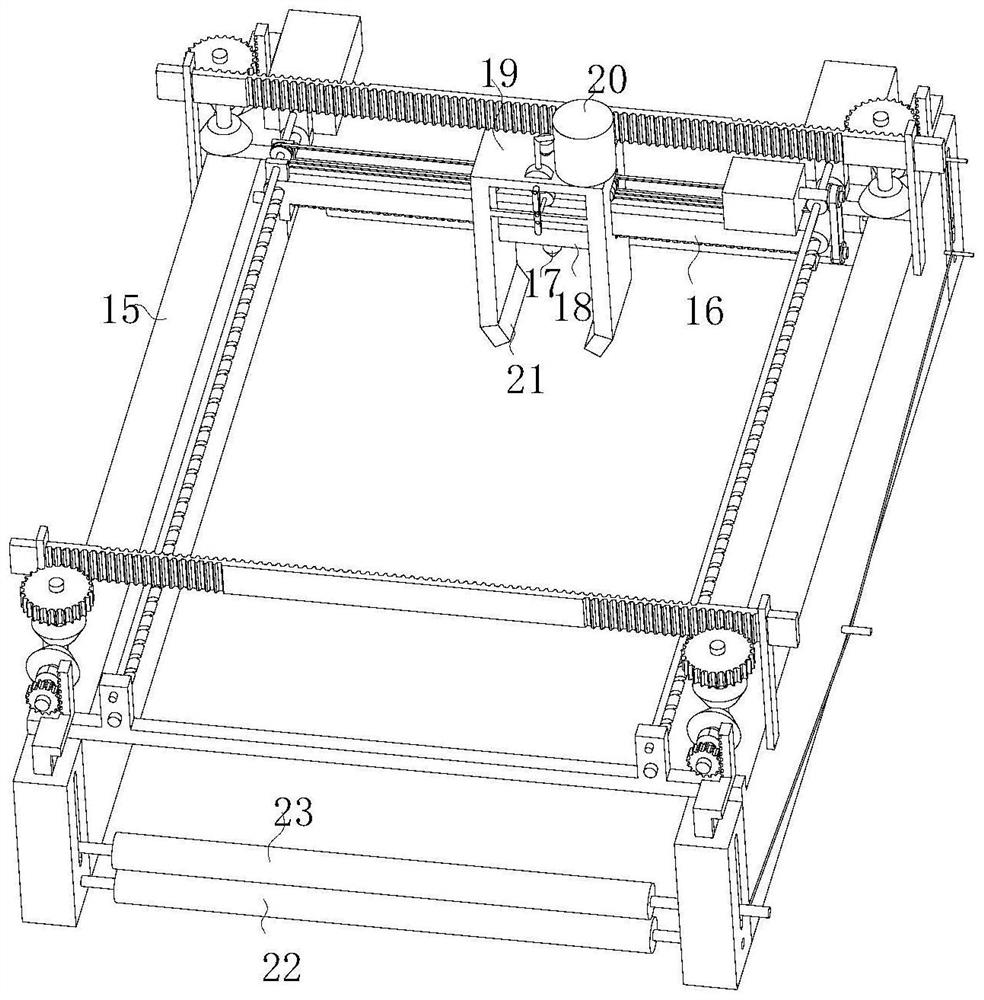

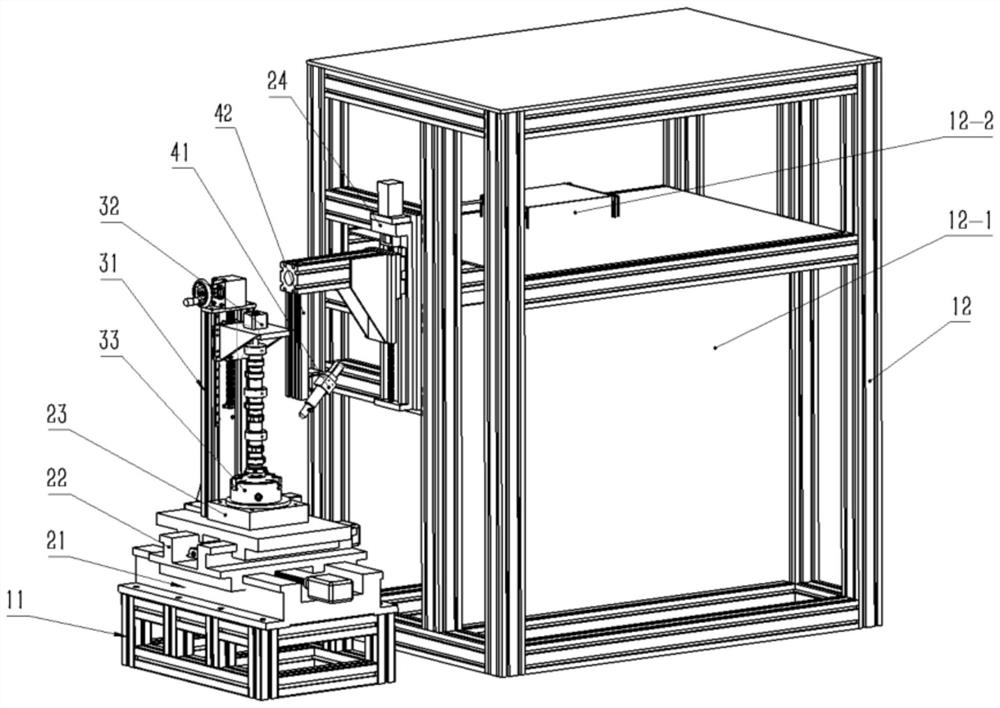

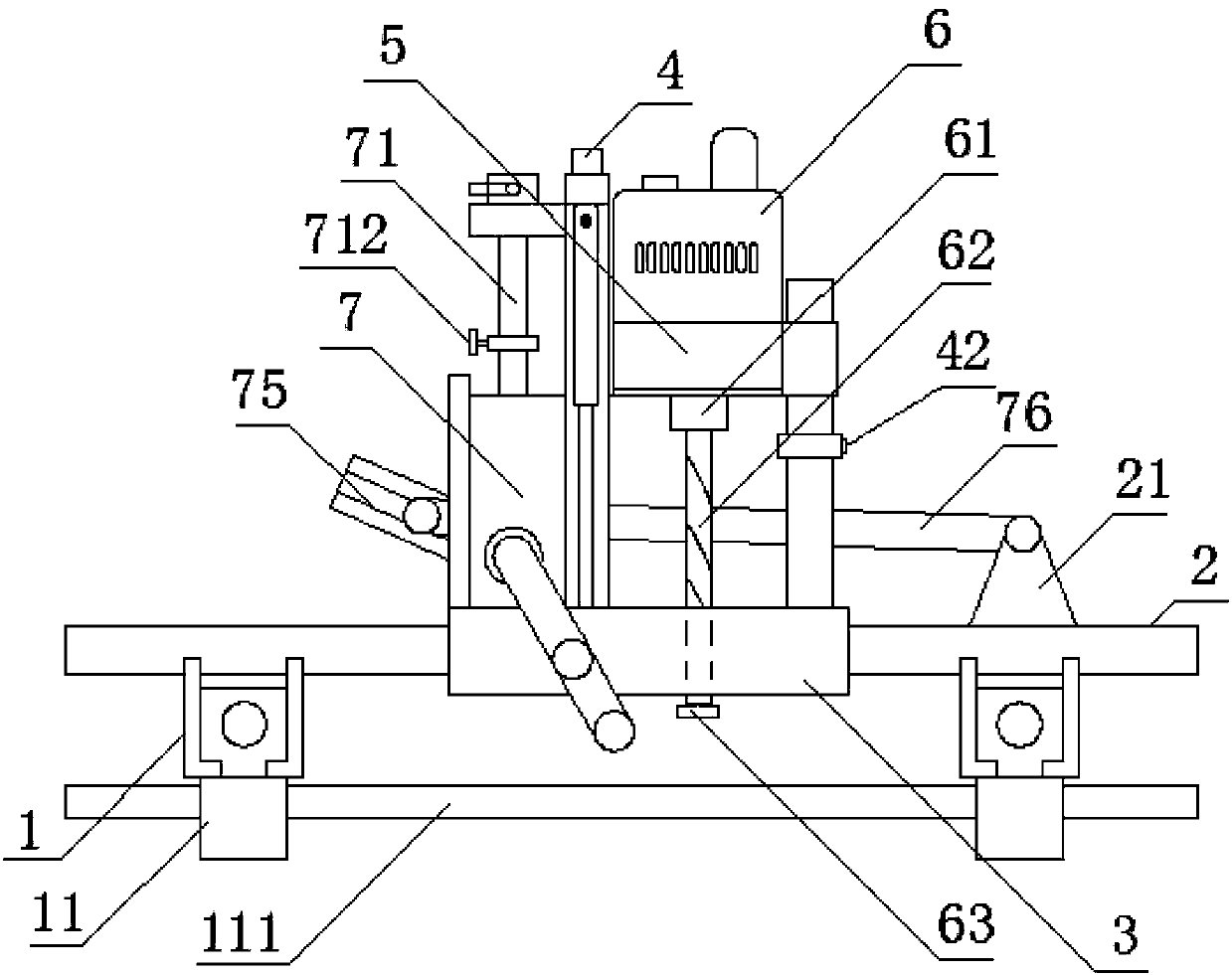

Laser parallel processing equipment

ActiveCN114799507AFree height adjustmentClear in timeLaser beam welding apparatusLaser transmitterLaser processing

The invention discloses laser parallel machining equipment in the field of laser machining. The laser parallel machining equipment comprises a transmission positioning mechanism, a dust removal mechanism and a machining center mechanism which are arranged on a workbench. The machining center comprises a complete machine bridge frame, a supporting plate and ball screw feeding units in the X direction and the Y direction, a laser transmitter connected with the ball screw feeding units is arranged on the supporting plate, and the laser transmitter is installed on the supporting plate in the Y direction in a sliding mode through a sliding base. The dust removal device comprises a dust suction unit fixedly arranged on a mounting base, and the mounting base is vertically mounted on the supporting plate in a sliding mode. The dust removal mechanism is arranged beside the laser transmitter, so that the dust removal mechanism can synchronously move along with the laser transmitter; in addition, the dust removal mechanism is arranged to be in a lifting type, the height of the dust removal mechanism can be freely adjusted, the height of the dust removal mechanism can be freely adjusted when the dust removal mechanism faces workpiece substrates with different thicknesses, the dissipation distance of dust on the workbench is reduced, and the dust removal efficiency is improved.

Owner:NANJING TRIZ INST OF LASER APPL TECH CO LTD

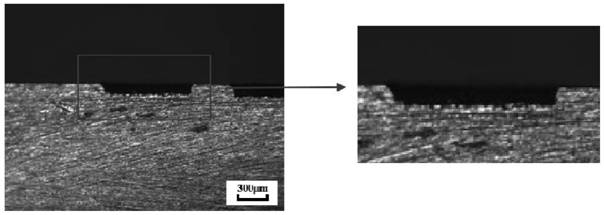

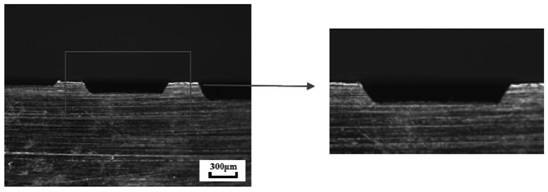

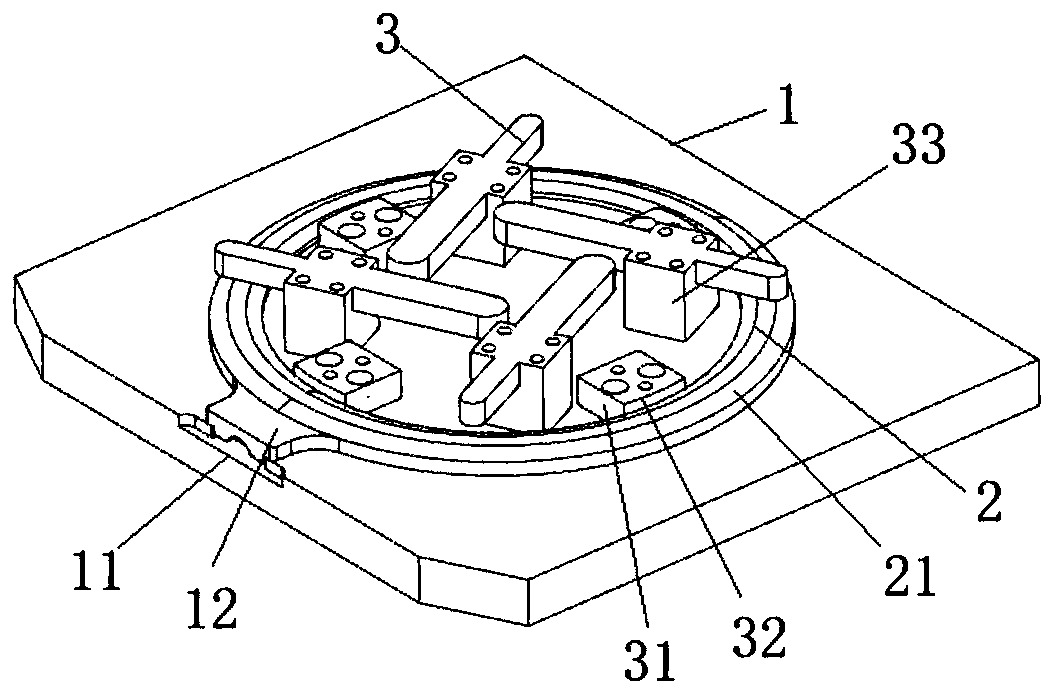

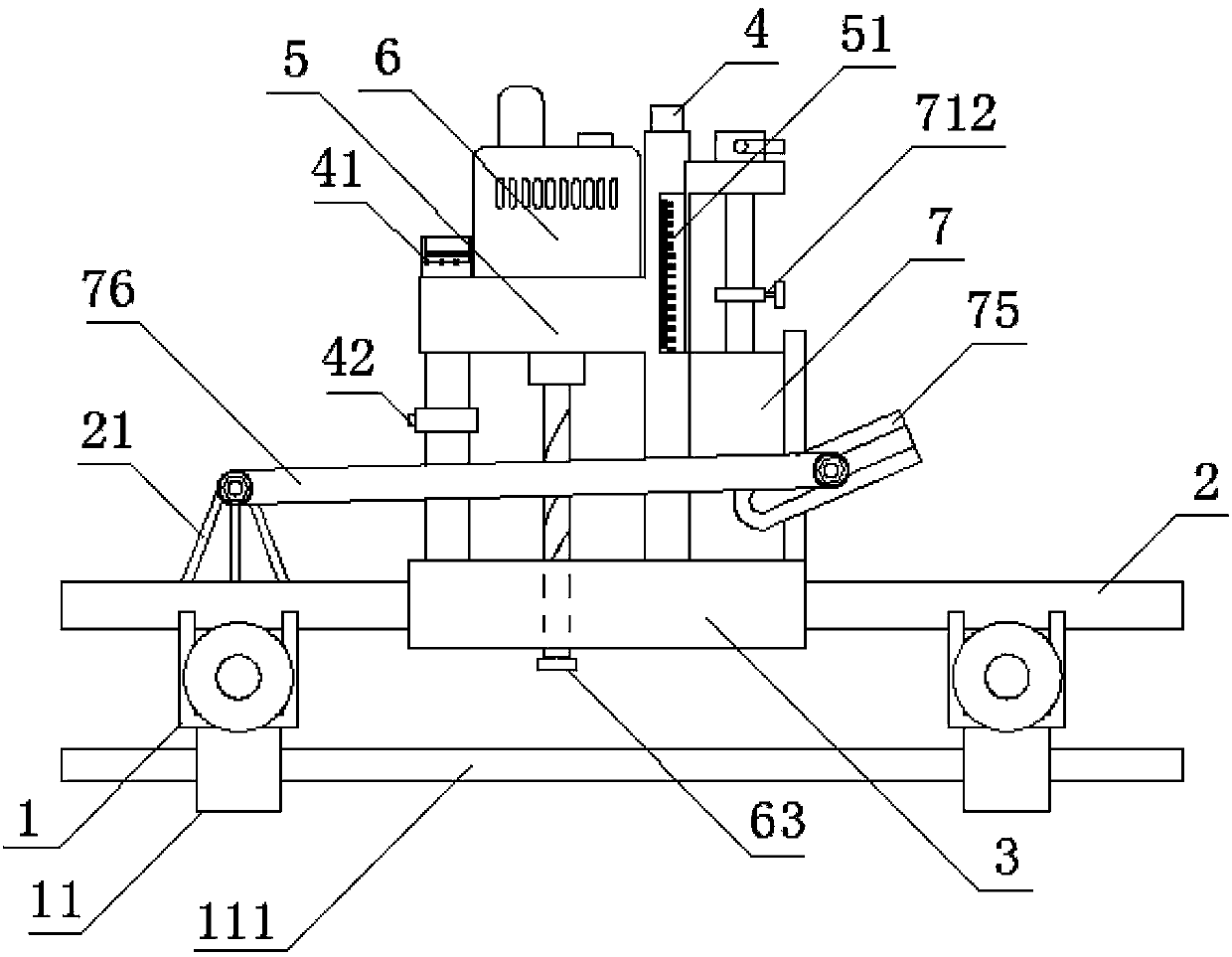

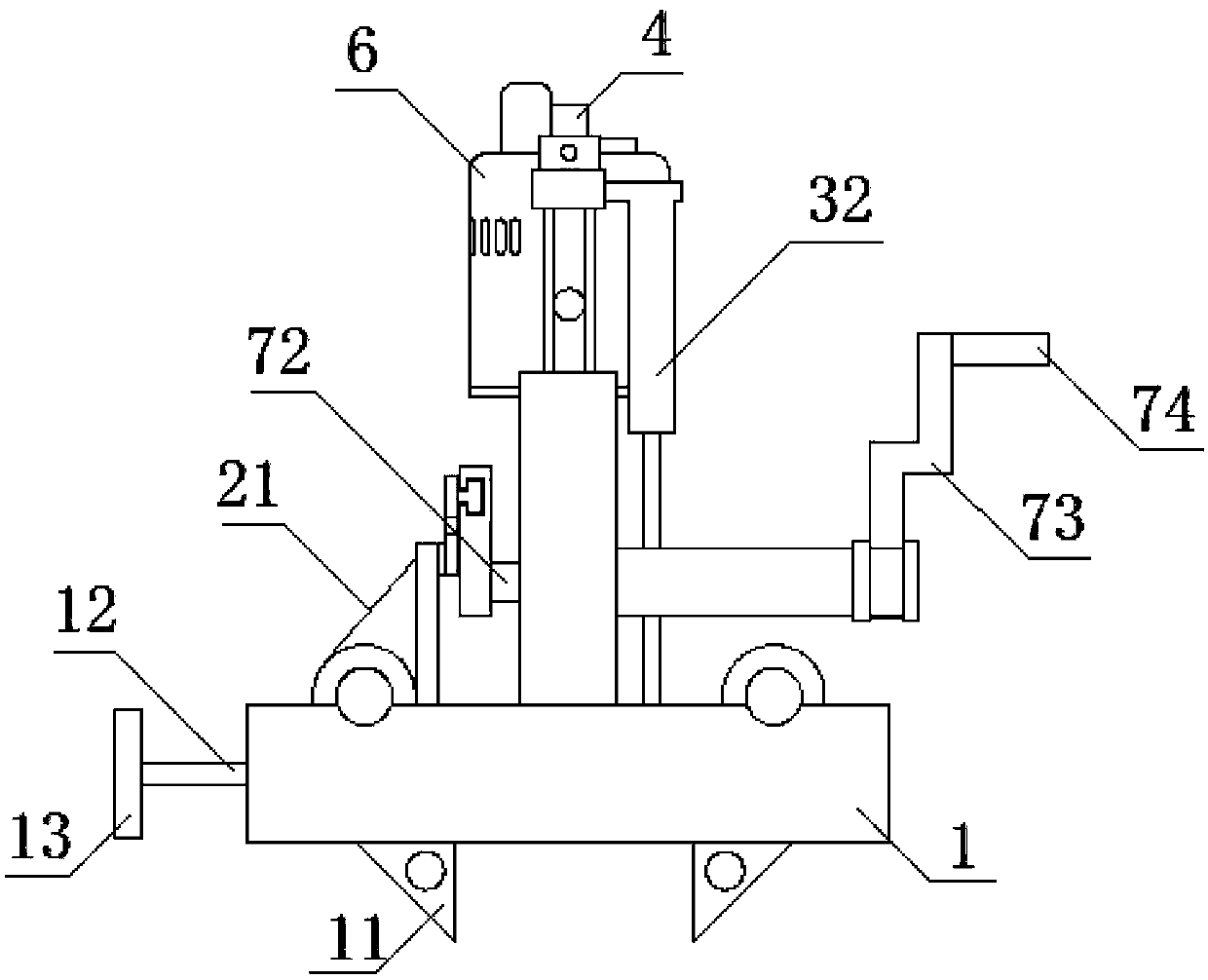

Stimulating light finishing processing equipment for edge burrs of shaft parts and method for removing burrs

ActiveCN110773873BImprove processing qualityGuarantee processing accuracyLaser beam welding apparatusPicosecond laserBeam angle

The invention discloses a device for stimulating and light-finishing the edge hairs of shaft parts and a method for removing burrs. The device includes a main body frame platform, a processing movement platform, and a tool for effectively installing and clamping shaft parts fixed on the Y-axis movement platform. The lifting fixture adjustment device, the beam angle adjustable laser processing head device installed on the suspension beam of the Z-axis motion platform, which can realize the adjustment of the laser beam angle, the motion controller in the present invention uses a 32-bit STM32 chip, and its calculation accuracy is high and the reliability is good , which can realize the coordinated control of laser and four axes. In the deburring method of the present invention, the processing equipment adopts variable focus circular scanning, changing the beam angle, high-power nanosecond laser roughing + low-power picosecond laser finishing, and uniform-speed curve track laser scanning to achieve high precision and high efficiency of burrs. It can effectively solve the problem of difficult deburring of shaft parts in practical engineering applications, and can significantly improve the quality and processing efficiency of laser finishing.

Owner:ASIMCO CAMSHAFT YIZHENG +1

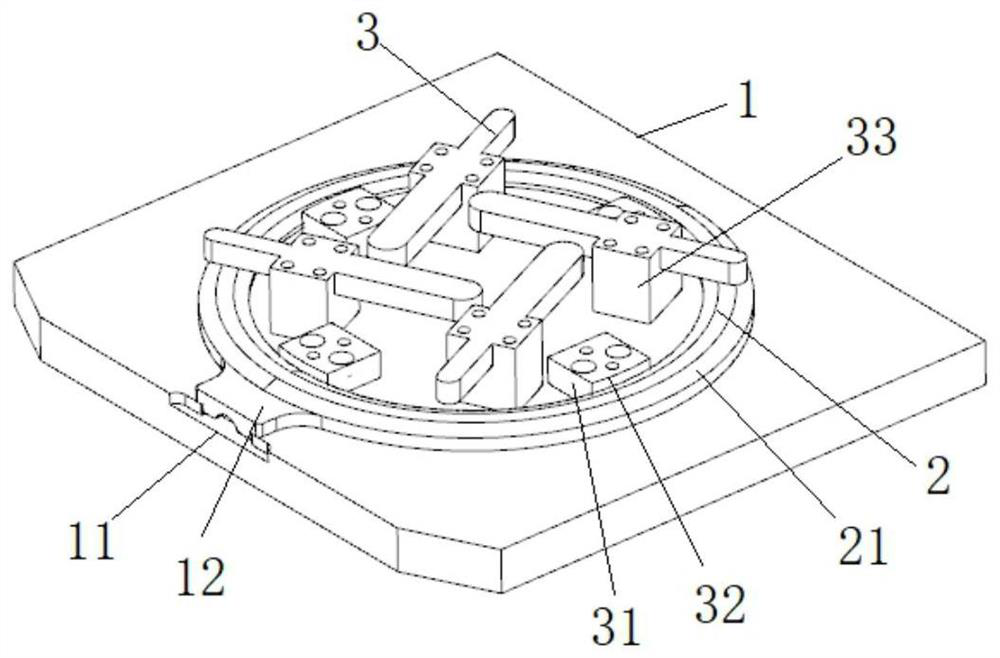

Laser-carving machining method for decoration ring of lampshade, and location jig thereof

ActiveCN110076459AGuarantee processing accuracySmooth finishWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSurface layer

The invention discloses a laser-carving machining method for a decoration ring of a lampshade. The laser-carving machining method for the decoration ring of the lampshade comprises the following steps: S1, spraying an UV colored paint layer on the surface of a housing of the decoration ring of the lampshade; S2, spraying a vacuum coating layer on the surface of the UV colored paint layer; S3, placing the decoration ring of the lampshade in the location jig; S4, removing the surface-layer paint surface of an outer ring of the decoration ring of the lampshade by a CO2 laser device, and adjustingthe focus point of the CO2 laser device through a location base point in the location jig; S5, moving the CO2 laser device along a set track, enabling the focus point of the CO2 laser device to movealong the vacuum coating layer of the outer ring of the decoration ring of the lampshade, and carrying out laser-carving machining on the vacuum coating layer to form a groove-shaped structure; and S6, cleaning the decoration ring subjected to laser-carving, of the lampshade. The laser-carving machining method for the decoration ring of the lampshade realizes the smooth and complete paint surfaceof the product.

Owner:苏州美泰利汽车部件有限公司

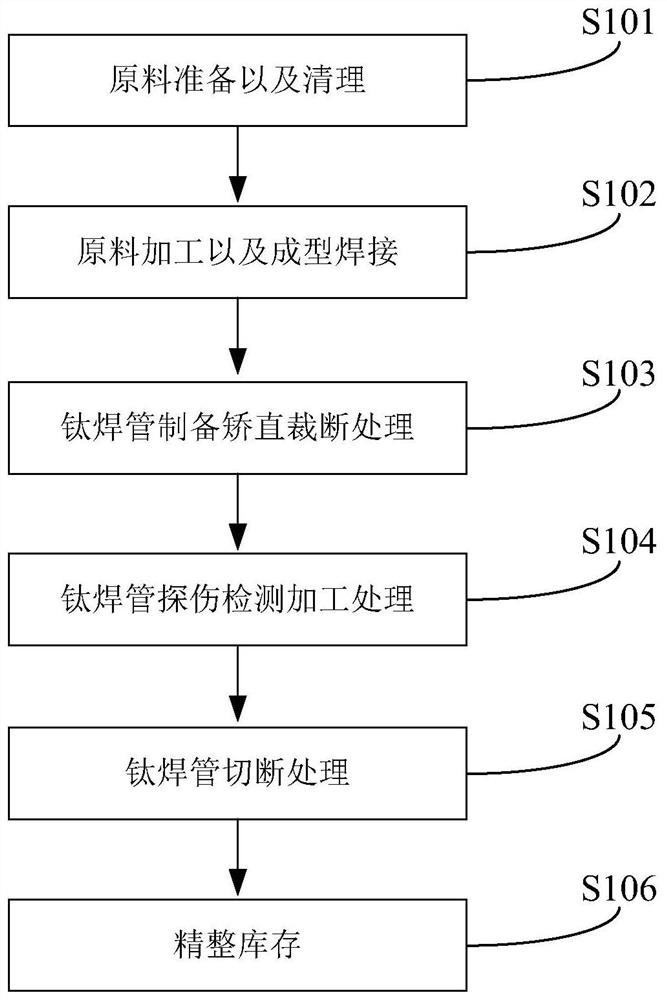

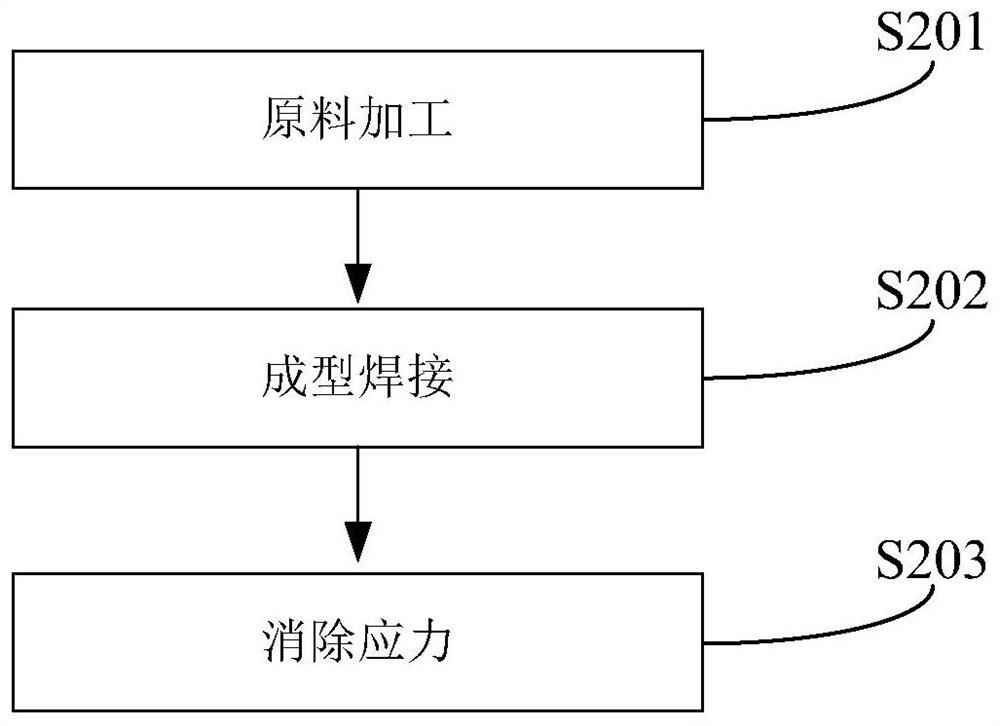

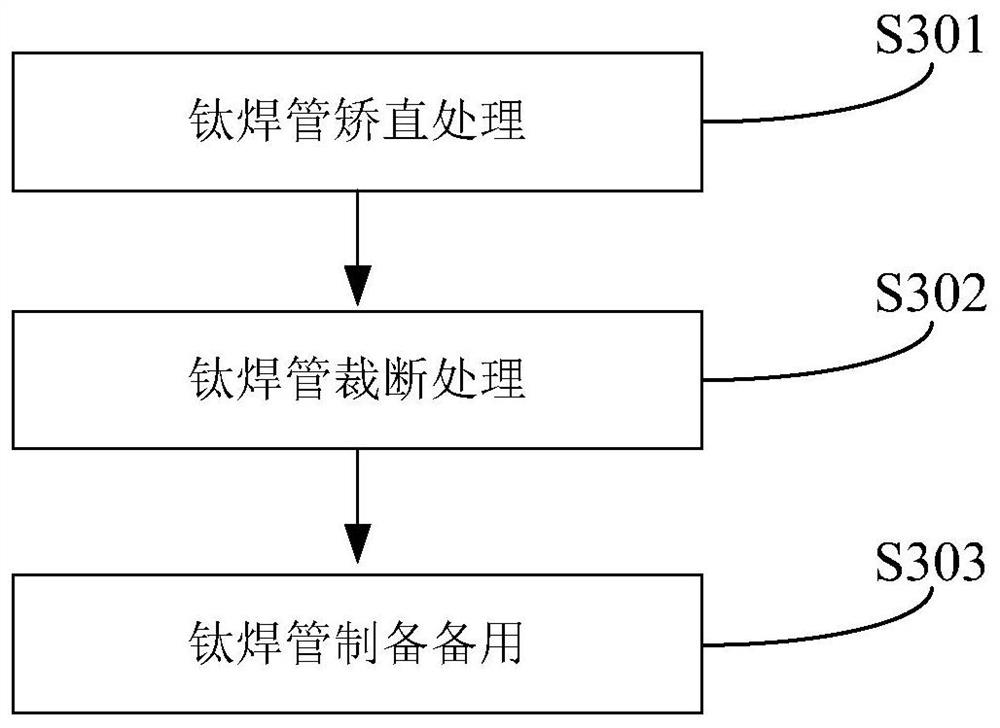

Manufacturing method for titanium welded pipe

The invention discloses a manufacturing method for a titanium welded pipe, and belongs to the field of metal processing. The manufacturing method for the titanium welded pipe comprises the following specific steps of raw material preparation and cleaning, raw material processing and forming welding, titanium welded pipe preparation and straightening and cutting treatment, titanium welded pipe flawdetection processing, titanium welded pipe cutting processing and finishing and storage. According to the method, dust, impurity and debris collection containers are added in each process, so that environmental pollution can be avoided; through multiple measurement and flaw detection marking operations, the manufactured titanium welded pipe is ensured to be accurate in size and smaller in error,and the manufacturing and processing technical processes are improved; and the processing accuracy is ensured through multiple measurements, so that the simplicity and the sequence of the processing process are ensured, and the manufacturing precision of the prepared titanium welded pipe is improved.

Owner:张家港市佳旭金属材料有限公司

Data processing method, intermediate server and system

ActiveCN104980458BAccurate operationGuarantee processing accuracyFinancePayment architectureData processing systemResource transfer

The invention discloses a data processing method. The method comprises that after an intermediate server receives a login request of a user terminal, resource transfer arrangement information of a corresponding account of the user terminal is obtained and returned to the user terminal, so that the user terminal can achieve fast and safe resource transfer while manual input of any resource transfer information is not required. The invention also discloses an intermediate server and a data processing system. According to the invention, safety of data processing is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Laser engraving processing method and positioning fixture for lampshade decorative ring

ActiveCN110076459BEasy to take outPrecise process controlWelding/cutting auxillary devicesAuxillary welding devicesLaser engravingEngineering

The invention discloses a laser engraving processing method for a lampshade decorative ring, comprising the following steps: S1, spraying a UV colored paint layer on the surface of the lampshade decorative ring; S2, spraying a vacuum coating layer on the surface of the UV colored paint layer; S3, spraying the lampshade decorative ring Place it in the positioning jig; S4, use CO 2 The laser removes the surface paint of the outer ring of the lampshade decorative ring, and adjusts the CO by the positioning base point in the positioning fixture. 2 Focus of laser; S5, CO 2 The laser moves along the set trajectory so that the CO 2 The focus point of the laser moves along the vacuum coating layer of the outer ring of the lampshade decorative ring, and it is processed by radium engraving to form a groove-like structure; S6, the lampshade decorative ring is cleaned after laser engraving. The invention realizes the smooth and complete paint surface of the product.

Owner:苏州美泰利汽车部件有限公司

Door lock mortising machine

InactiveCN103350438BPrecise positioningRapid positioningWood mortising machinesWood slotting machinesDetentOperation safety

The invention relates to a door lock mortising machine which comprises a transverse beam, a transverse guide rail, a chassis, a vertical guide rail, a fixed bracket, a motor, a rocker arm end support, a cavity, a lifting poker, a transmission shaft, a crank, a rocking bar, an oscillating arm, a rocker arm, a reducing sleeve, a tool bar, a tool bit, clamping boards, a bidirectional lead screw and a hand wheel. Compared with the prior art, the door lock mortising machine has the advantages that the door lock mortising machine can locate on a wood door accurately and move precisely, a side hole positioner is used for machining a lock hole of the wood door, the lock hole can be machined through one-step installation, positioning and puncturing instead of through a plurality steps and a plurality of machines, work efficiency is improved, the labor intensity of workers is reduced, and the door lock mortising machine is simple and convenient to use, accurate and fast in positioning, safe and reliable in operation, small in seize, convenient to carry and suitable for machining lock holes in various wood doors.

Owner:XUZHOU FENG ZHAN MACHINERY

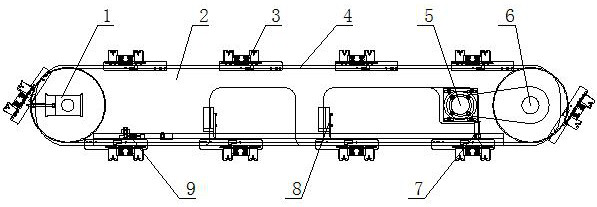

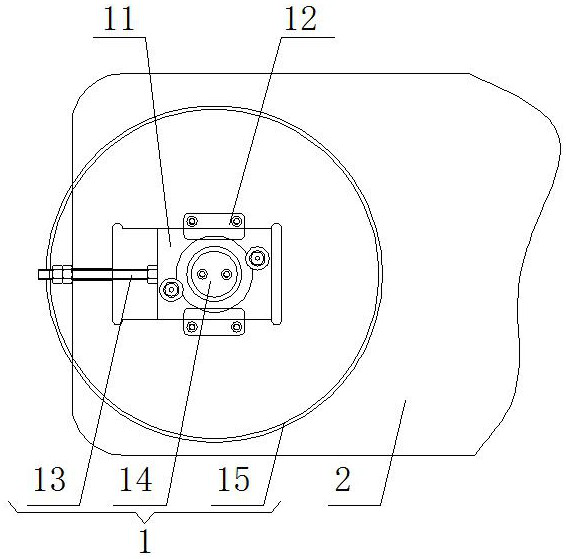

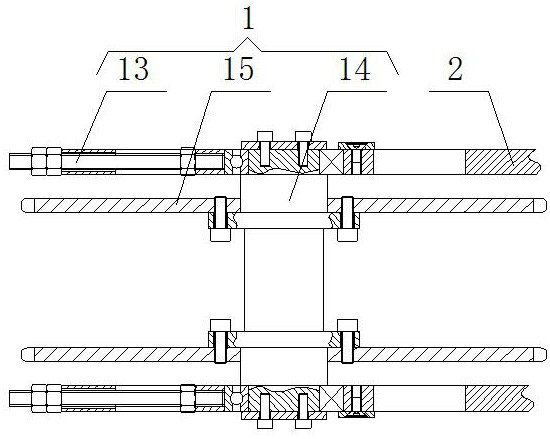

Hand bag conveying device

PendingCN114435867AGuaranteed stabilityGuaranteed reliabilityConveyorsControl engineeringProcess engineering

The invention discloses a hand bag conveying device which comprises a chain tensioning device, a rack, a clamping device, a conveying chain, a driving mechanism, a driving chain wheel, a bag clamping driving air cylinder, a station positioning device and a bag loosening driving device. A chain wheel in the chain tensioning device is connected with a driving chain wheel through a conveying chain, the driving chain wheel is connected with a synchronous belt wheel in the driving mechanism through a synchronous belt, clamping devices are arranged on the conveying chain, and a bag loosening driving device, a station positioning device and a bag clamping driving air cylinder are sequentially arranged at the lower end of the machine frame from left to right. The hand bag multi-station circulating device is ingenious in design and small in occupied space, multi-station simultaneous circulating operation of hand bags can be achieved, manual operation is avoided, the labor cost is saved, the working efficiency is greatly improved while the processing accuracy of the hand bags is guaranteed, and therefore the automatic operation level and efficiency are achieved, and development of the packaging equipment industry is facilitated.

Owner:河南新印智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com