Stimulating light finishing processing equipment for edge burrs of shaft parts and method for removing burrs

A finishing and deburring technology, applied in metal processing equipment, laser welding equipment, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

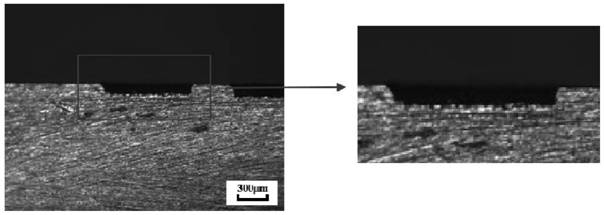

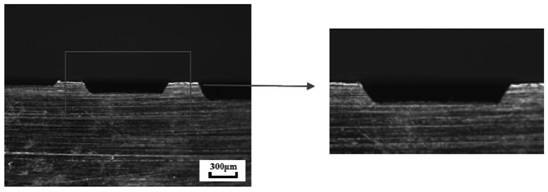

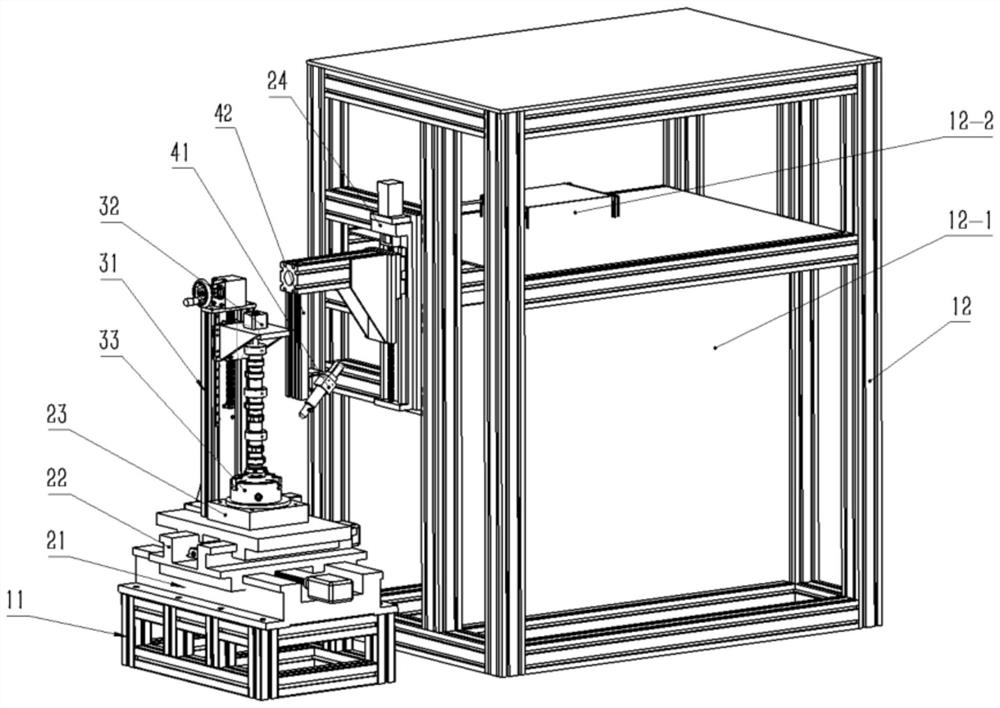

[0051] An embodiment of the present invention provides a shaft-like piece edge burr stimulating light finishing processing equipment and a burr removal method thereof, such as Figure 1-6 As shown, the laser finishing equipment is used for laser finishing of edge burrs of shafts, including a main frame platform processing platform base 11, a cabinet for placing a laser 12-2, a motion controller, and an electrical installation panel 12-1 12. The X-axis motion platform 21, Y-axis motion platform 22, θ-axis motion platform 23, and Z-axis motion platform 24 installed on the main frame platform, and fixed on the Y-axis motion platform 22 for effective installation and clamping Lifting fixture adjustment device for shaft parts. This elevating fixture adjusting device comprises elevating frame mechanism 31, movable thimble device 32, three-jaw chuck 33. The laser finishing equipment also includes a beam angle adjustable laser processing head device installed on the suspension beam 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com