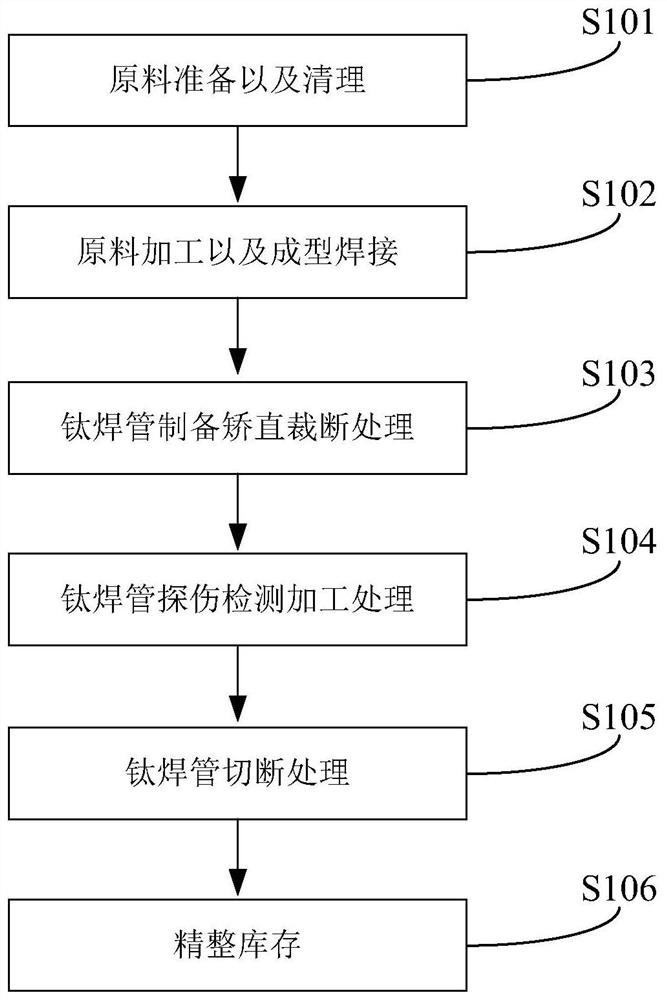

Manufacturing method for titanium welded pipe

A production method, a technology of titanium welded pipe, applied in the field of metal processing, can solve the problems of inaccurate production size, easy pollution of waste debris, backward production methods, etc., and achieve the effect of accurate size, improved production precision and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

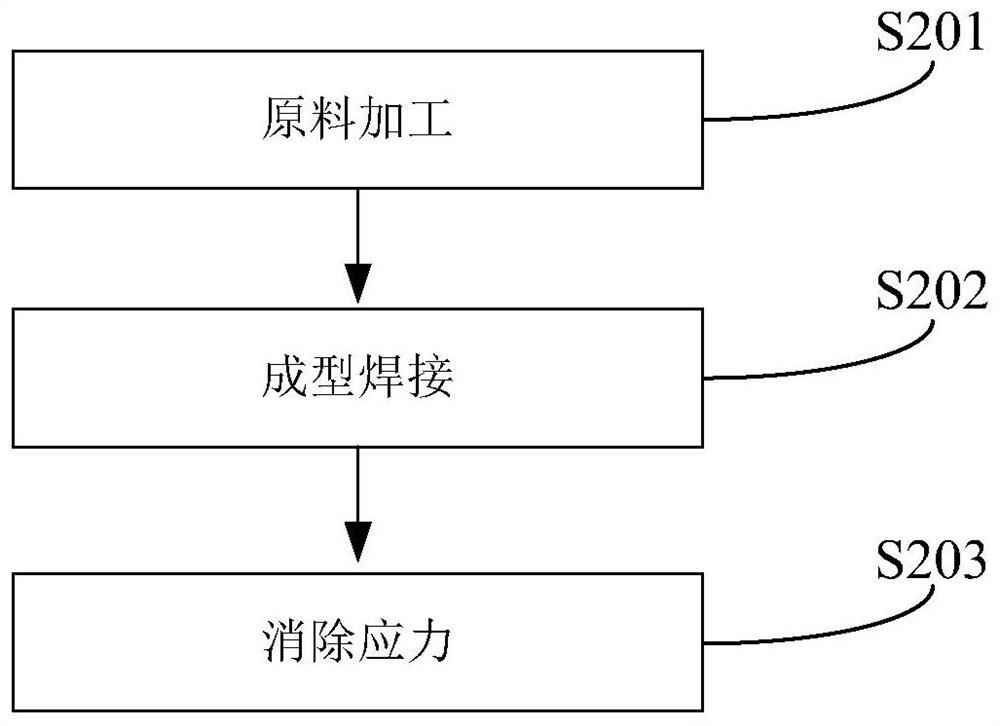

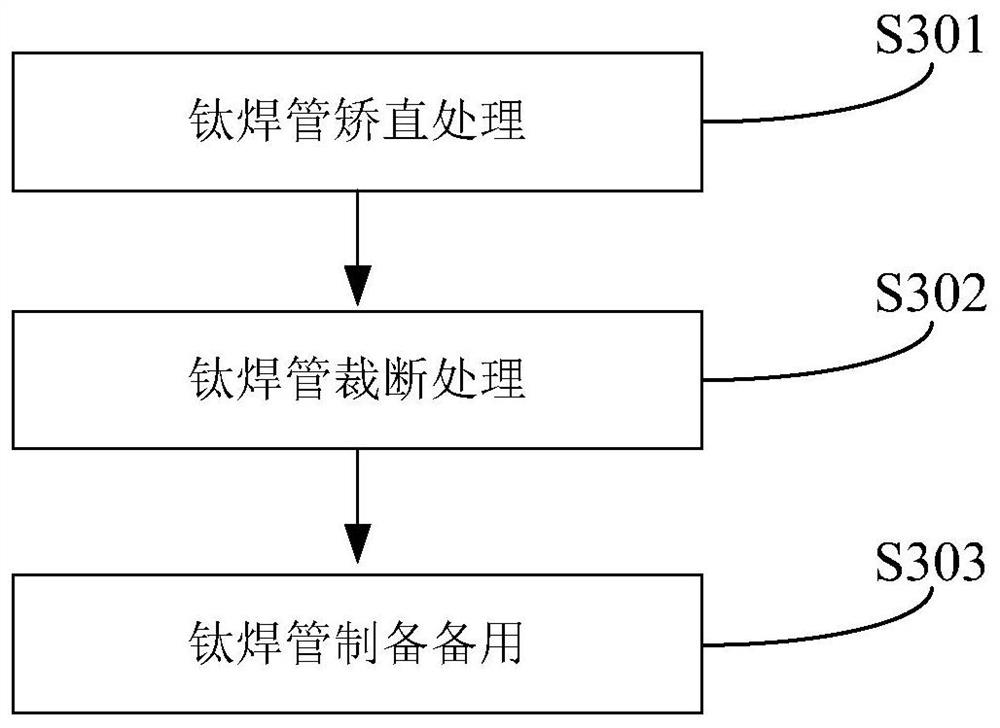

specific Embodiment 1

[0061] Prepare raw materials for processing and production, that is, a bundle of titanium strip coils, whose thickness is set to 0.8mm and width is set to 1300mm, and is weighed by a measuring scale. The dust and oxide layer on the surface of the strip coil are cleaned and removed, and then the burrs and uneven parts on the surface of the titanium strip coil are polished by a grinder to remove the burrs. After cleaning, the thickness and width of the titanium strip coil are determined by a measuring ruler. Make the cutting marks, collect the removed dust, impurities and burrs through the collection box, and clean and remove the dust through the dust collector, store them in the garbage collection area, and complete the preparation and cleaning of raw materials; The coiled material is placed in the uncoiler, uncoiled and pulled out by the uncoiler, and enters the forming machine, rolled and bent by the mold into an open tube blank, and the debris and dust generated during proces...

specific Embodiment 2

[0063] Prepare raw materials for processing and production, that is, a bundle of titanium strip coils, whose thickness is set to 1.5mm and width is set to 1500mm, and is weighed by a measuring scale. The dust and oxide layer on the surface of the strip coil are cleaned and removed, and then the burrs and uneven parts on the surface of the titanium strip coil are polished by a grinder to remove the burrs. After cleaning, the thickness and width of the titanium strip coil are determined by a measuring ruler. Make the cutting marks, collect the removed dust, impurities and burrs through the collection box, and clean and remove the dust through the dust collector, store them in the garbage collection area, and complete the preparation and cleaning of raw materials; The coiled material is placed in the uncoiler, uncoiled and pulled out by the uncoiler, and enters the forming machine, rolled and bent by the mold into an open tube blank, and the debris and dust generated during proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com