Processing method of integrated horn submarine gate electrode

A processing method and integrated technology, applied in electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the pressure loss, the two-lobed horn submersible port cannot achieve the surface quality of the product, the horn submersible port is difficult to process, etc. problems to avoid machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 2

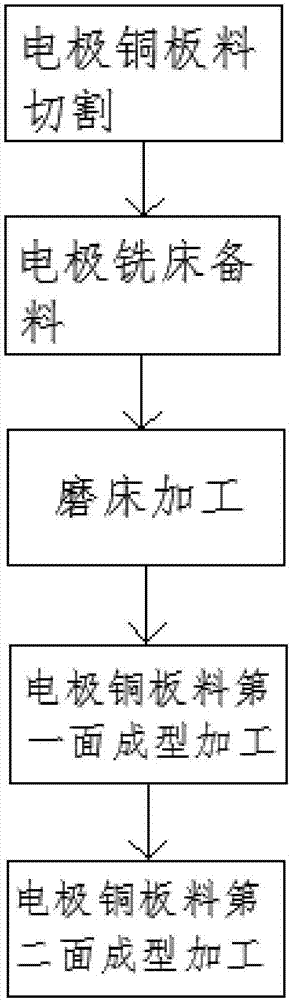

[0040] A method for processing an integral horn submerged electrode, the main steps of which include:

[0041] Electrode copper sheet cutting: After the electrode copper sheet is scribed on a flat plate, the raw material plate is sawed into a certain size rectangular electrode copper sheet 1 by water cutting equipment.

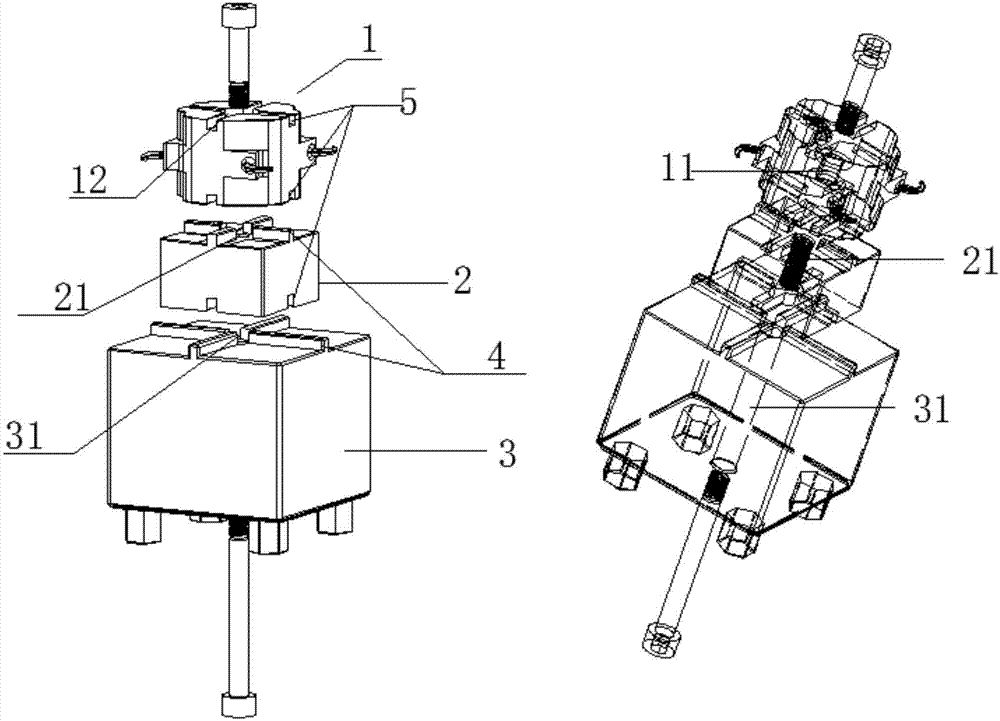

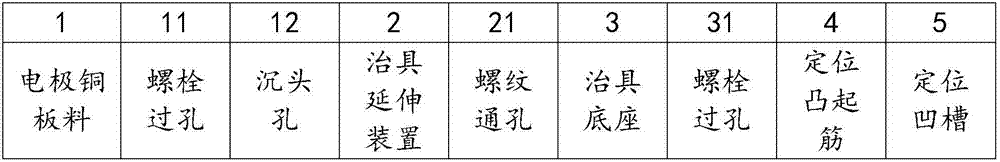

[0042] Electrode milling machine preparation: use a CNC milling machine to process countersunk holes 12 on both sides of the electrode copper sheet 1, and process bolt through holes 11 at the center of the electrode copper sheet 1. central location.

[0043] Grinding machine processing: use a CNC grinding machine to first process along the X and Y axis directions of the electrode copper sheet 1; then process the thickness direction; and finally process the "+" shaped positioning groove 5 on the end surface in place.

[0044] Forming of the first side of the electrode copper sheet: find the center of the electrode clamping jig, install the above-mentioned elec...

specific Embodiment example 3

[0049] A method for processing an integral horn submerged electrode, the main steps of which include:

[0050] Electrode copper sheet cutting: After the electrode copper sheet is scribed on a flat plate, the raw material plate is sawed into a certain size of rectangular electrode copper sheet 1 by using a water cutting device.

[0051] Electrode milling machine preparation: use a CNC milling machine to process countersunk holes 12 on both sides of the electrode copper sheet 1, and process bolt through holes 11 at the center of the electrode copper sheet 1. central location.

[0052] Grinding machine processing: use a CNC grinding machine to first process along the X and Y axis directions of the electrode copper sheet 1; then process the thickness direction; and finally process the "+" shaped positioning groove 5 on the end surface in place.

[0053] Forming of the first side of the electrode copper sheet: find the center of the electrode clamping jig, install the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com