Laser engraving processing method and positioning fixture for lampshade decorative ring

A processing method and positioning fixture technology, applied in the field of laser engraving, can solve problems such as unstable silk screen printing process, decreased yield rate, and increased cost, and achieve the effect of simple operation, high flexibility, and guaranteed processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

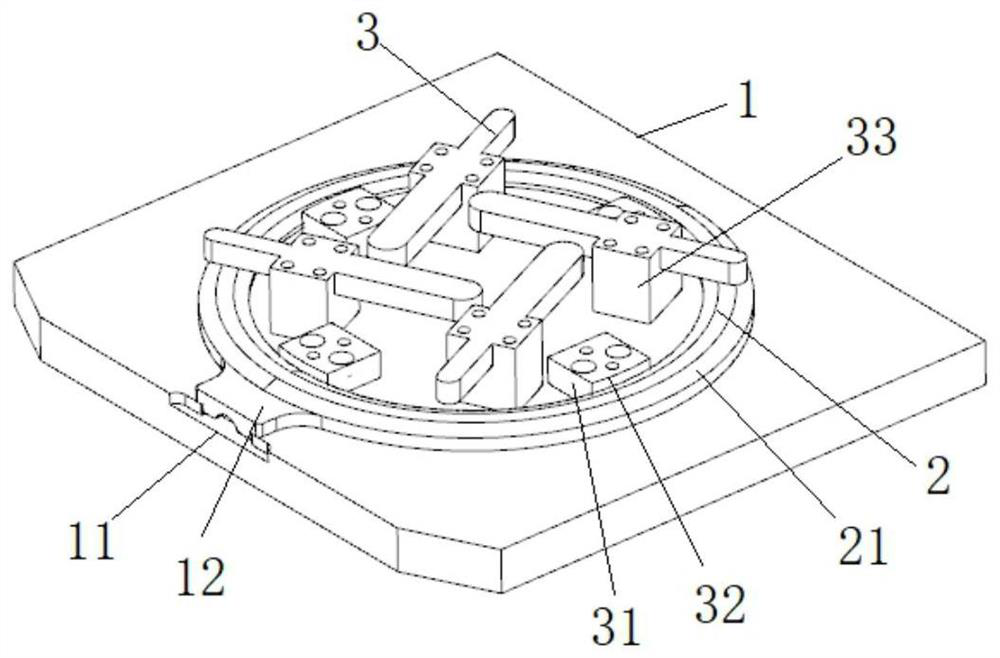

[0026] refer to figure 1 As shown, this embodiment is a fixture for positioning lampshade decorative rings, including a base plate 1, an annular groove (not marked in the figure) disposed in the base plate 1, and several positioning components disposed inside the annular groove.

[0027] In this embodiment, the bottom plate is a plate-shaped structure, and one side of the annular groove communicates with the side of the bottom plate 1 and is provided with a positioning groove 11 . There is a decorative ring corresponding to it in the annular groove, and the outer side of the decorative ring is provided with a joint part 12, and the joint part 12 is matched with the positioning groove 11. The two sides of the positioning groove 11 clamp the two sides of the joint part 12, and the positioning The depth of the groove 11 is greater than the thickness of the joint portion 12 . There is a gap between the bottom of the joint part 12 and the bottom of the positioning groove 11 .

[...

Embodiment 2

[0031] This embodiment is a laser engraving processing method for a decorative ring of a lampshade, which includes the following steps:

[0032] S1. Spray the surface of the lampshade decorative ring with a UV color paint layer. The thickness of the UV color paint layer is 20 μm. The UV color paint layer is mixed with UV transparent electroplating primer and UV solvent according to the color paste ratio. The product is sprayed and passed through an oven. After baking and leveling, it is cured by UV light;

[0033] S2, spray the vacuum coating layer on the surface of the UV color paint layer, the thickness of the vacuum coating layer is 8 μm, place the lampshade decorative ring after coating the UV color paint layer in a vacuum electroplating furnace, put the target material, and extract the air in the furnace to reach Evaporation and electroplating of target material after preset vacuum value;

[0034] S3. Place the lampshade decorative ring in the positioning jig, remove the...

Embodiment 3

[0039] This embodiment is a laser engraving processing method for a decorative ring of a lampshade, which includes the following steps:

[0040] S1. Spray the surface of the lampshade decorative ring with a UV color paint layer. The thickness of the UV color paint layer is 35 μm. The UV color paint layer is mixed with UV transparent electroplating primer and UV solvent according to the color paste ratio. The product is sprayed and passed through an oven. After baking and leveling, it is cured by UV light;

[0041] S2, spray the vacuum coating layer on the surface of the UV color paint layer, the thickness of the vacuum coating layer is 4 μm, place the lampshade decorative ring after coating the UV color paint layer in a vacuum electroplating furnace, put the target material, and extract the air in the furnace to reach Evaporation and electroplating of target material after preset vacuum value;

[0042] S3. Place the lampshade decorative ring in the positioning jig, remove the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com