A safety sunroof mechanism for automobiles

A safe, sunroof technology, applied in vehicle parts, mechanical equipment, engine components, etc., can solve the problems of sunroof anti-pinch related mechanism failure, failure, affecting the smooth sliding of sunroof glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

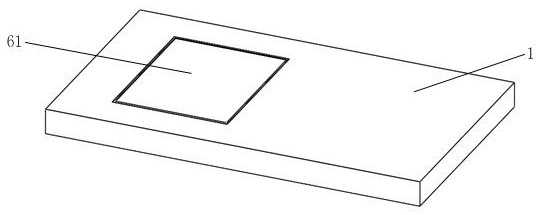

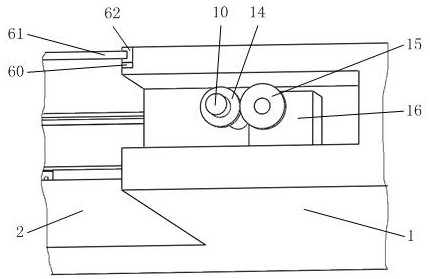

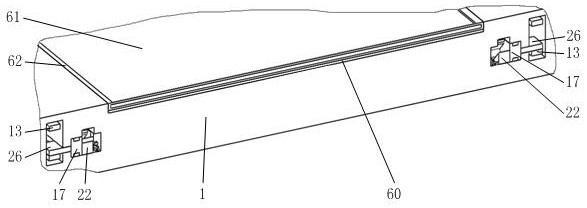

[0046] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0047] Such as figure 1 , 15 , 16, it includes mounting plate 1, transmission shaft 10, pulley A11, pulley B12, timing belt 13, electric drive module 16, slider 17, guide block A22, slider A27, slider 32, spring D34 , slant plate 35, guide block B47, spring A50, sunroof glass 61, L plate A64, sliding pin B65, sliding pin A67, wherein such as figure 1 As shown, the mounting plate 1 is installed on the top of the carriage; image 3 , 8 , 15, the two sliding bars 17 slide symmetrically in the two chute A4 in the mounting plate 1 along the moving direction of the sunroof glass 61, and the two sliding bars 17 are located on both sides of the sunroof 2; figure 2 , 5 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com