A kind of preparation method of red flag mark for deep space probe

A deep space detector and marking technology, applied in the direction of instruments, flags/flags, coatings, etc., can solve problems such as cracks and shedding, reduce degradation, improve the ability to resist electron radiation and ultraviolet radiation, The effect of suppressing the generation and propagation of microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

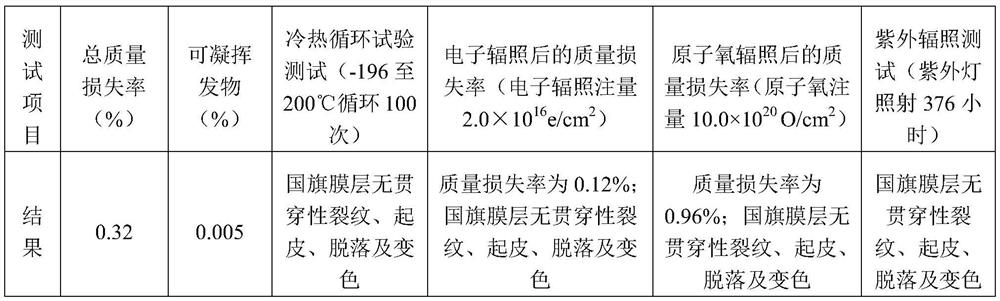

Examples

specific Embodiment approach 1

[0025] (1) Preparation of POSS-CNT-ZnO

[0026] Dissolve 10 parts by mass of octaphenyl-POSS in 50 parts by mass of tetrahydrofuran, add 2 parts by mass of carbon nanotubes (CNT) under magnetic stirring conditions, and then ultrasonically treat for 1 h. After completion, transfer the solution to a three-necked flask. Under the protection of nitrogen, reflux at 80° C. for 12 h, cool to room temperature after the reaction, filter with suction, wash with distilled water, and dry to obtain POSS-CNT.

[0027] Then put the POSS-CNT into the mortar and grind until the particle size is 50nm, put it into the deposition chamber of the atomic layer deposition instrument, and pump the deposition chamber to 5×10 -3 Torr, and then inject nitrogen gas until the chamber pressure is 0.15Torr; at the same time, keep the temperature in the deposition chamber at 150°C, perform periodic atomic layer deposition growth on the surface of POSS-CNT, and repeat 230 growth deposition cycles to obtain POS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com