Patents

Literature

33results about How to "Material transparent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

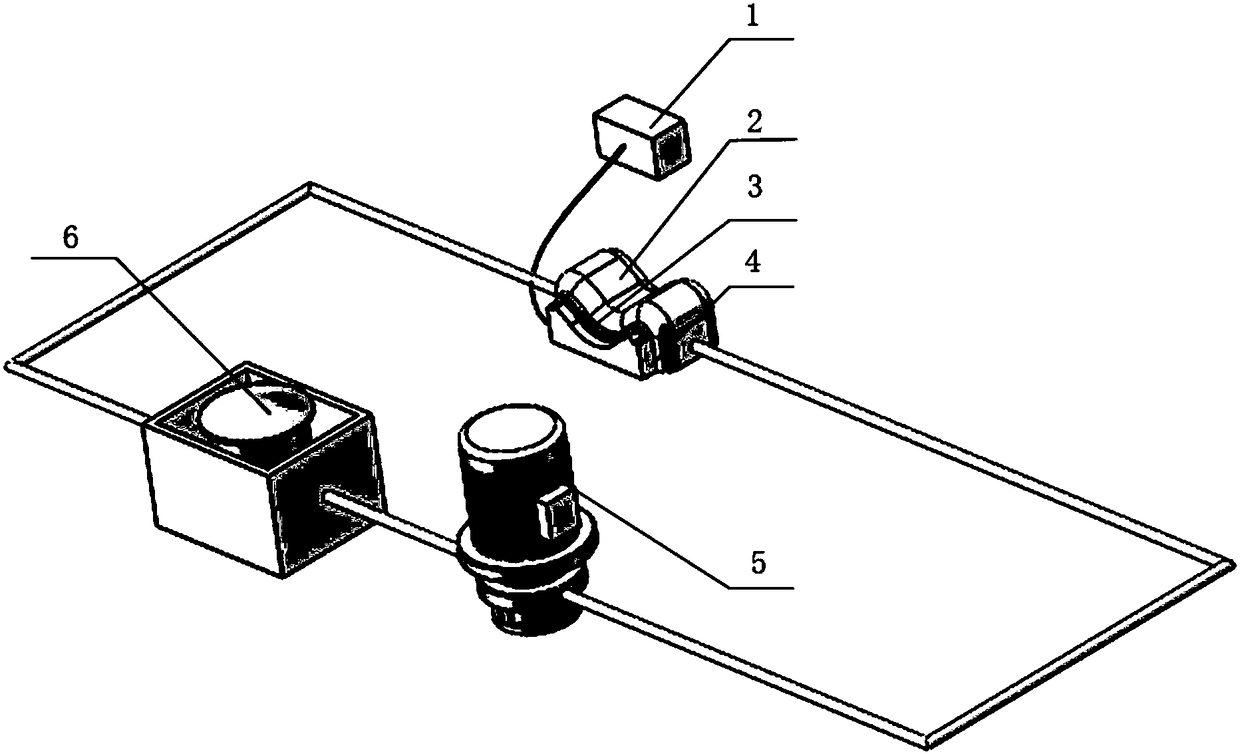

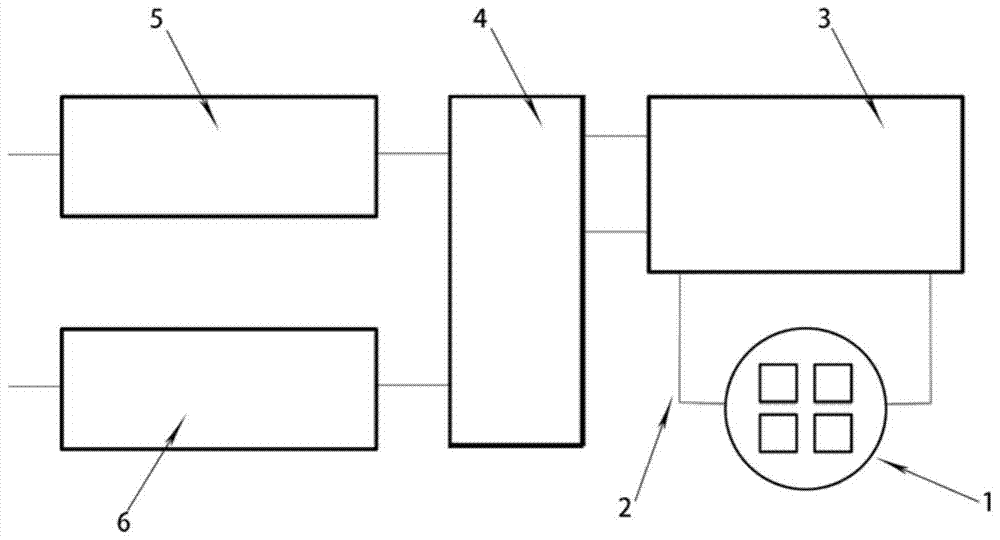

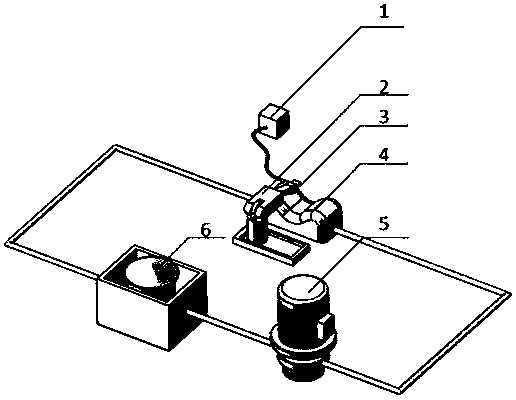

Device and method for evaluating dynamic demulsification and dehydration characteristics of crude oil emulsion

ActiveCN104807981ACompact structureReduce dosageMaterial testing goodsElectric fieldElectric heating

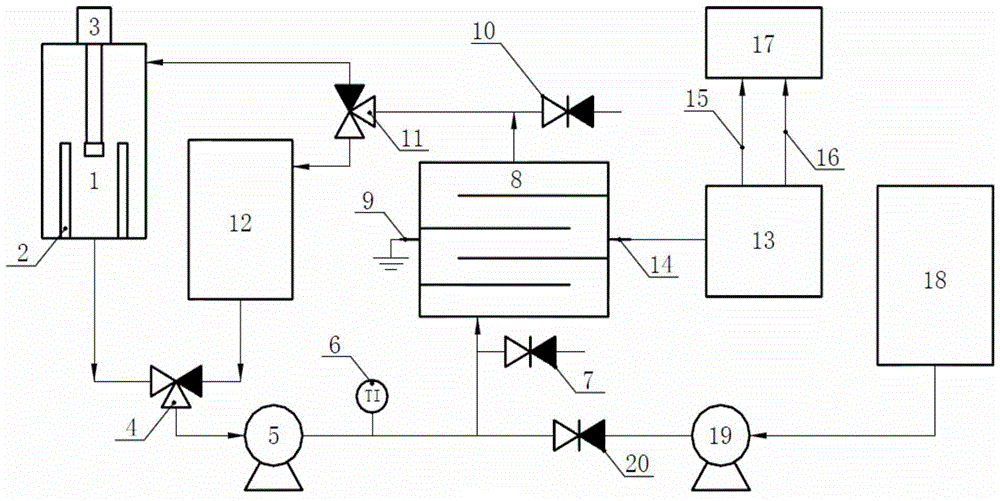

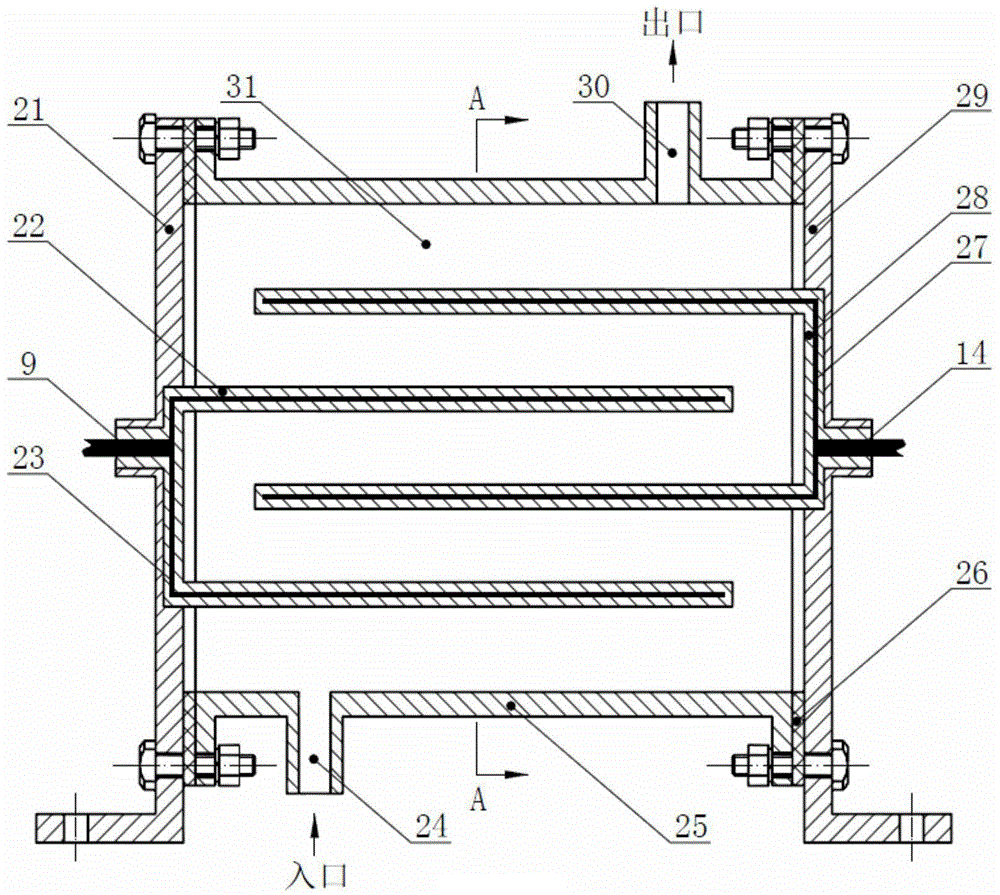

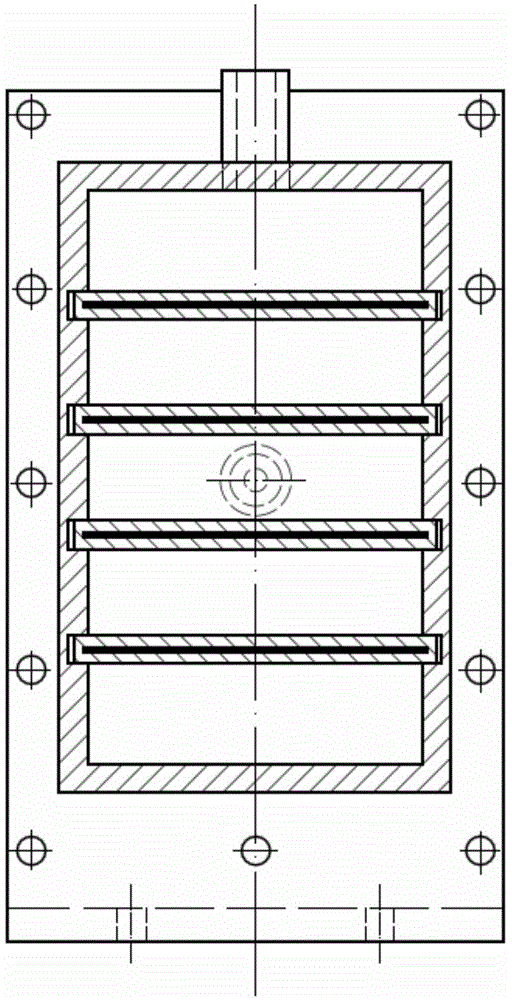

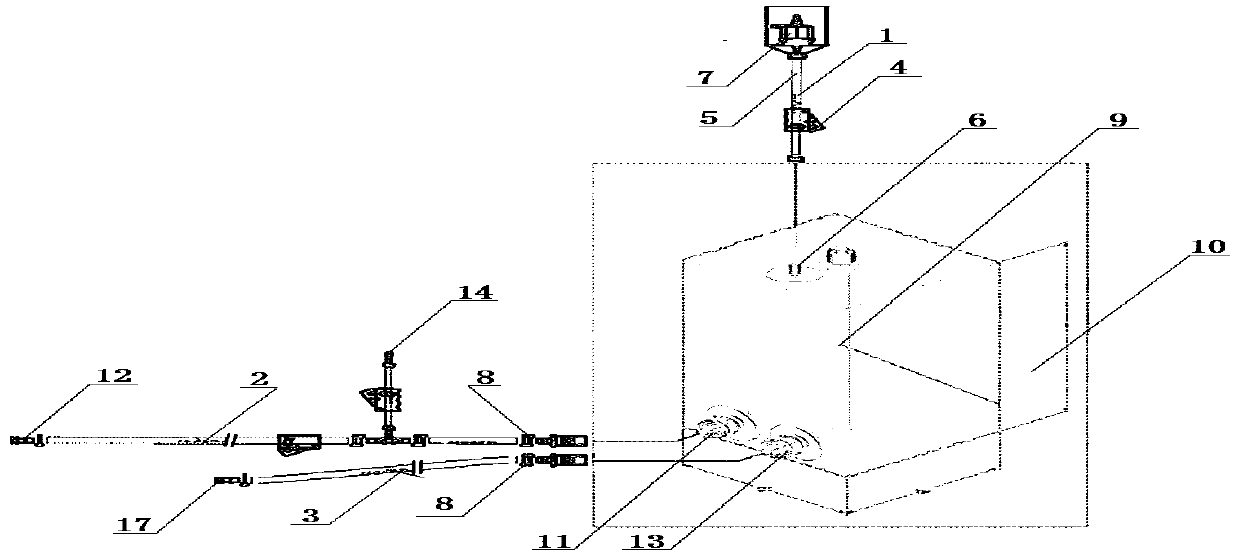

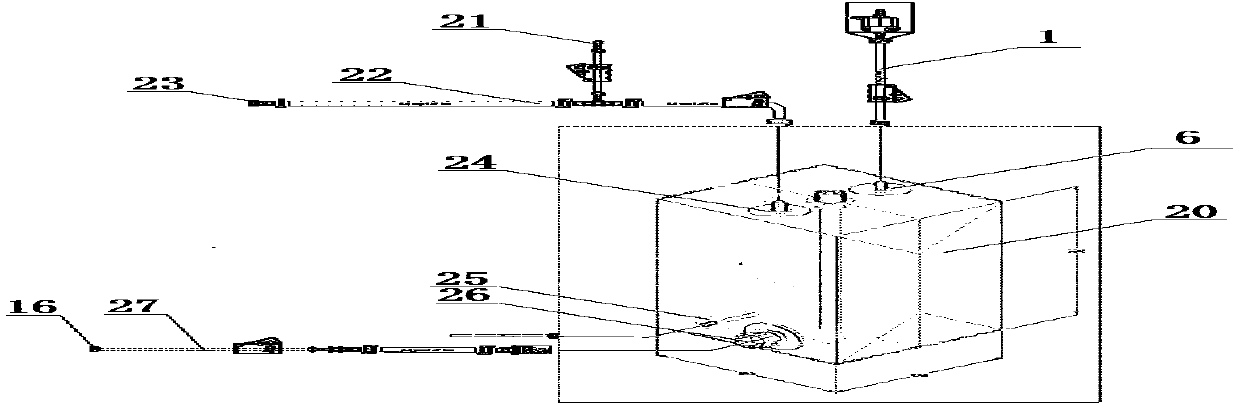

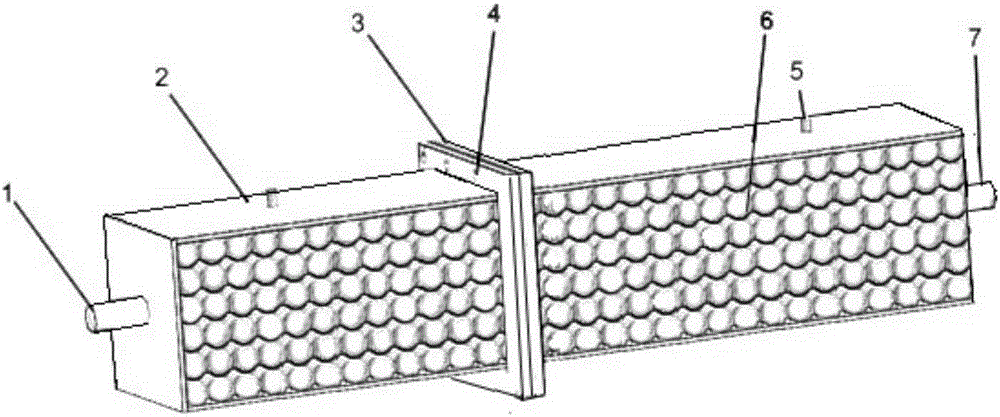

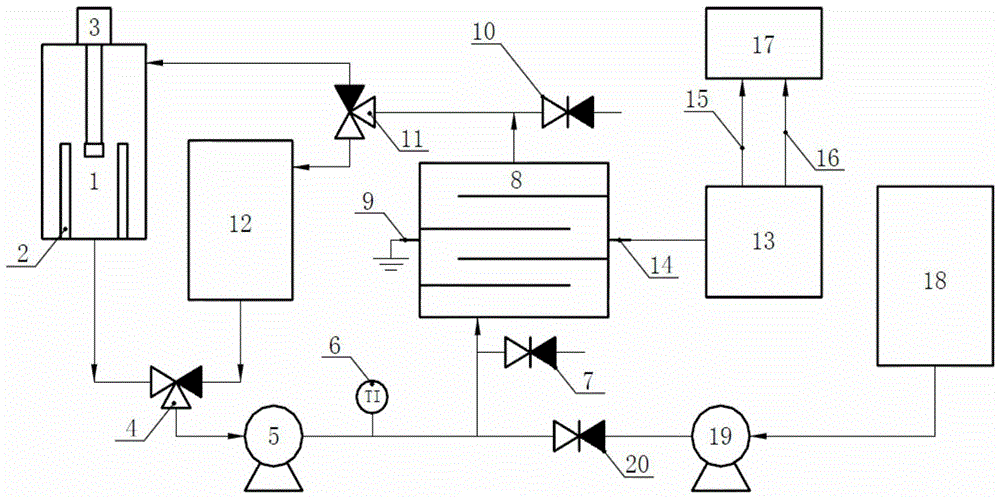

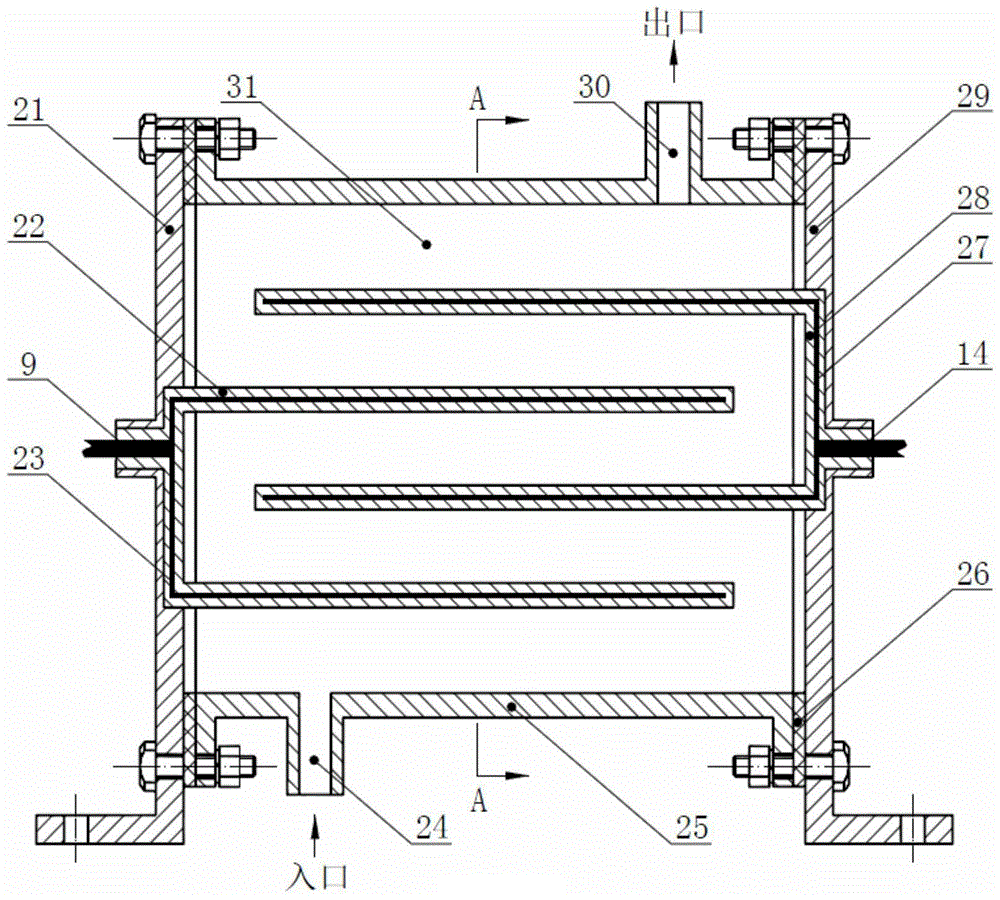

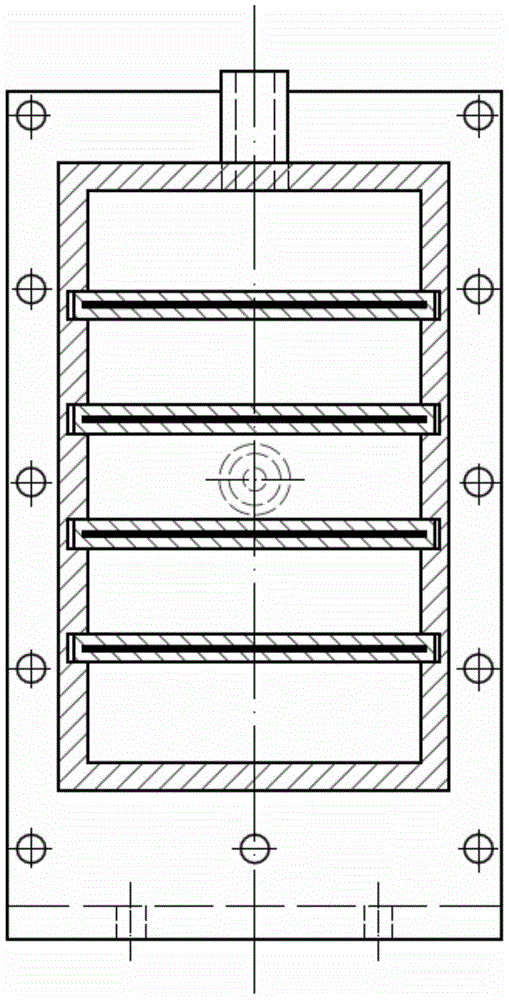

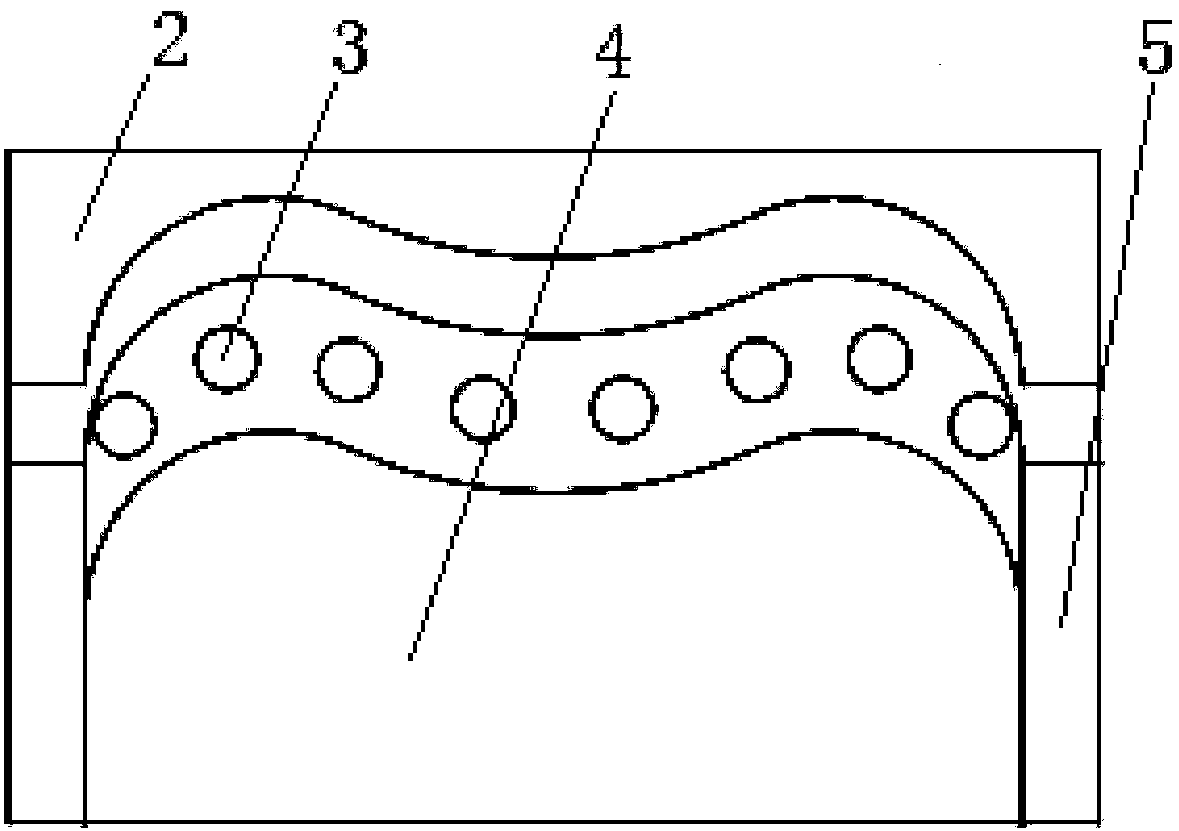

The invention discloses a device and method for evaluating dynamic demulsification and dehydration characteristics of a crude oil emulsion. The device comprises an emulsion feeding tank, electric heating devices, a high-speed shearing dispersion machine, an emulsion metering pump, a thermometer, a demulsification box, an emulsion recovery tank, a demulsifier feeding tank, a medicament feeding pump, a high-voltage power supply and an oscilloscope, wherein the emulsion feeding tank and the emulsion recovery tank are connected with an inlet of the emulsion metering pump through a three-way valve; an outlet of the emulsion metering pump is connected with an inlet of the demulsification box; an outlet of the demulsification box is connected with the emulsion feeding tank and the emulsion recovery tank through a three-way valve; a front sampling port and a rear sampling port are formed in an inlet pipeline and an outlet pipeline of the demulsification box respectively; the high-voltage power supply and the oscilloscope are sequentially connected to apply a high-voltage electric field to the demulsification box, and the demulsifier feeding tank and the medicament feeding pump are arranged on the inlet pipeline, in front of the front sampling port, of the demulsification box. The structure is compact, few crude oil emulsions are consumed, continuous flowing is realized, observation is convenient due to the fact that a box body of the demulsification box is made of a transparent material, and the device and the method can be used for quickly evaluating the dynamic demulsification and dehydration characteristics of the crude oil emulsion in a laboratory or a project site.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

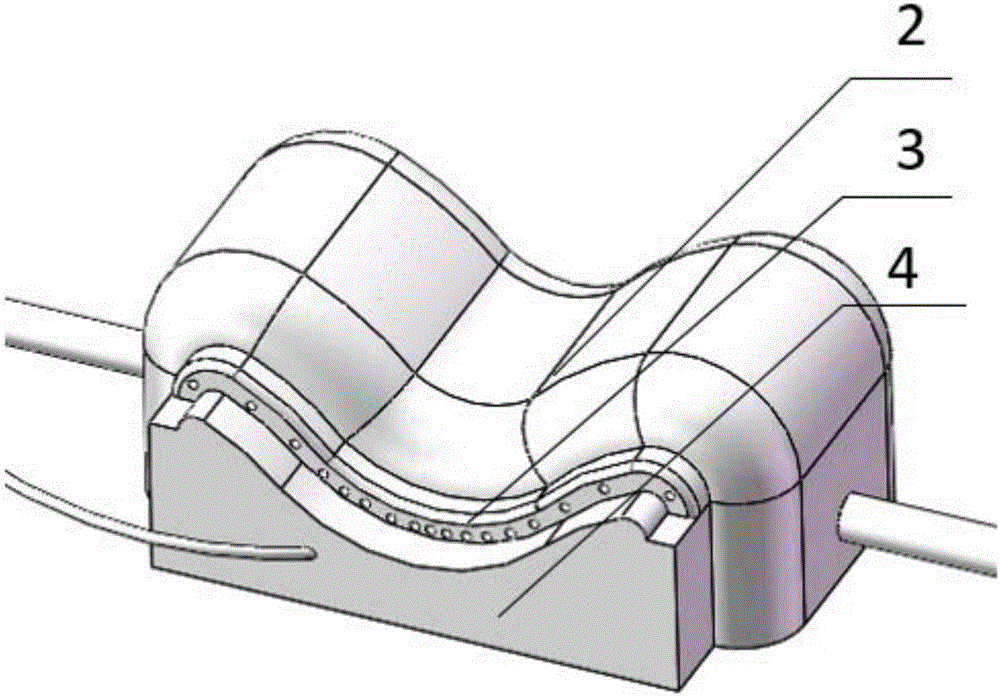

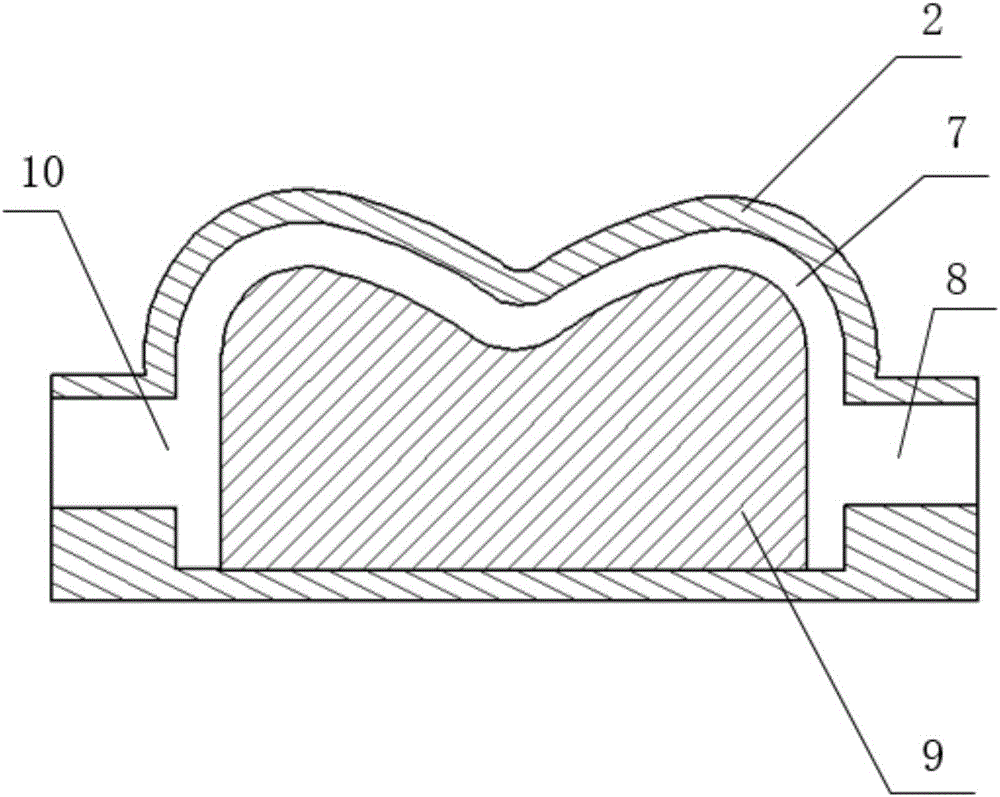

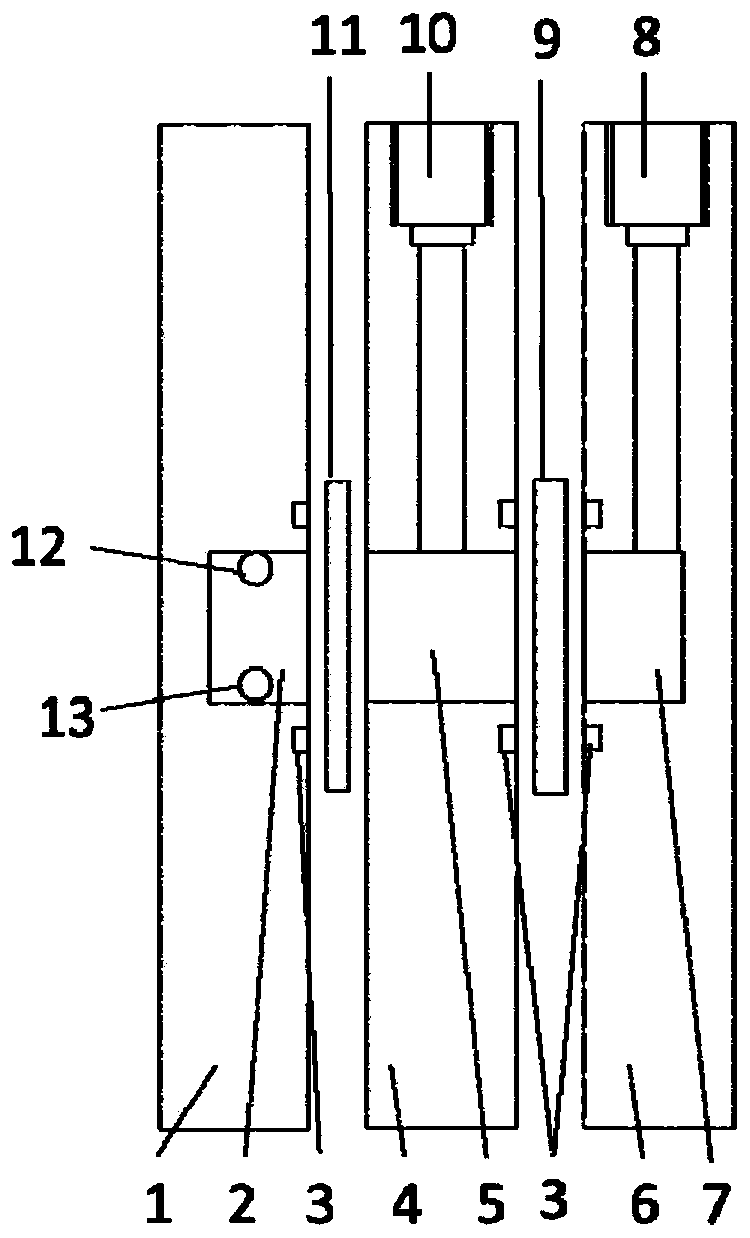

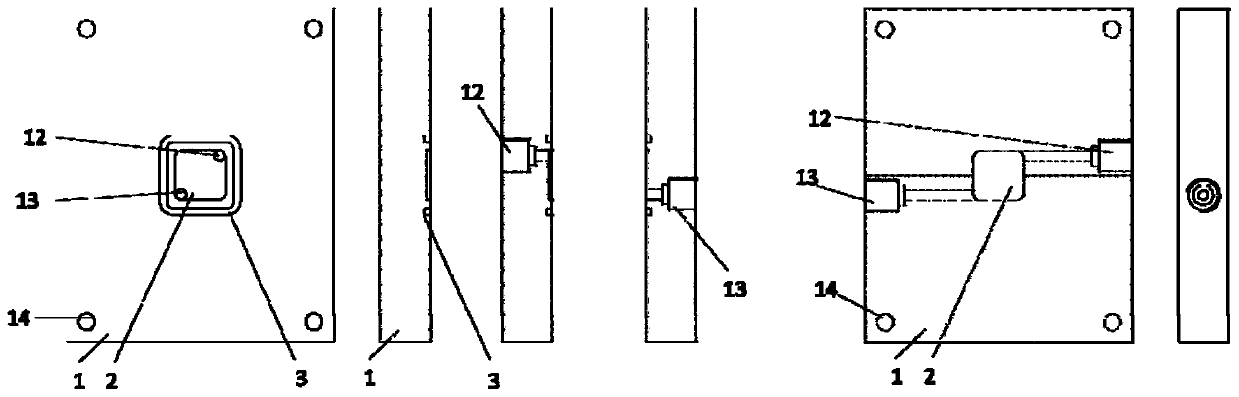

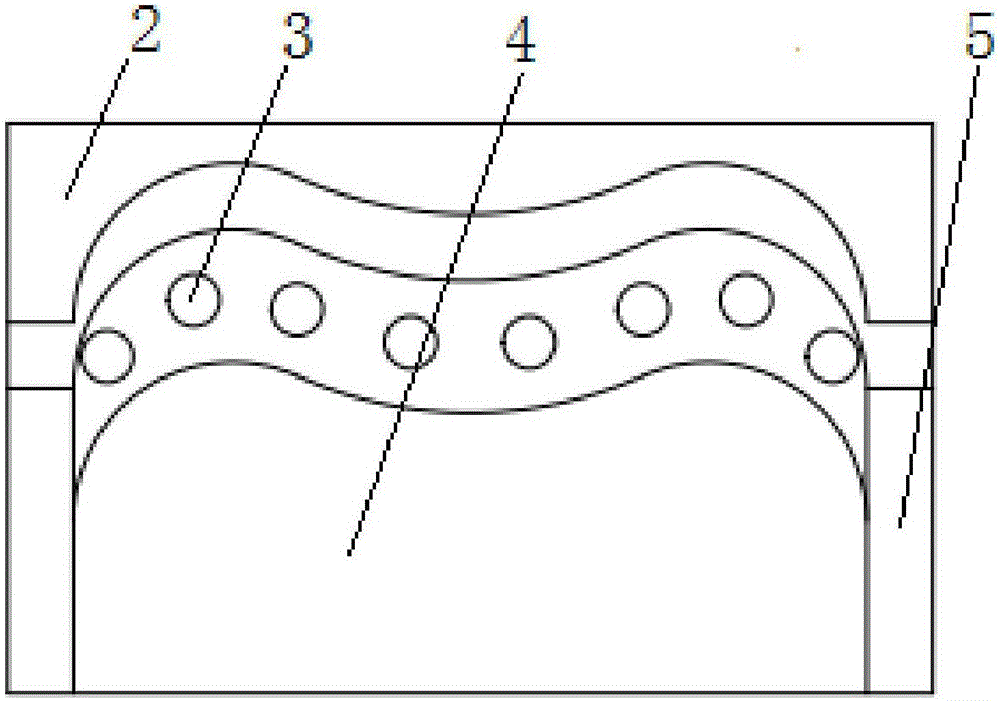

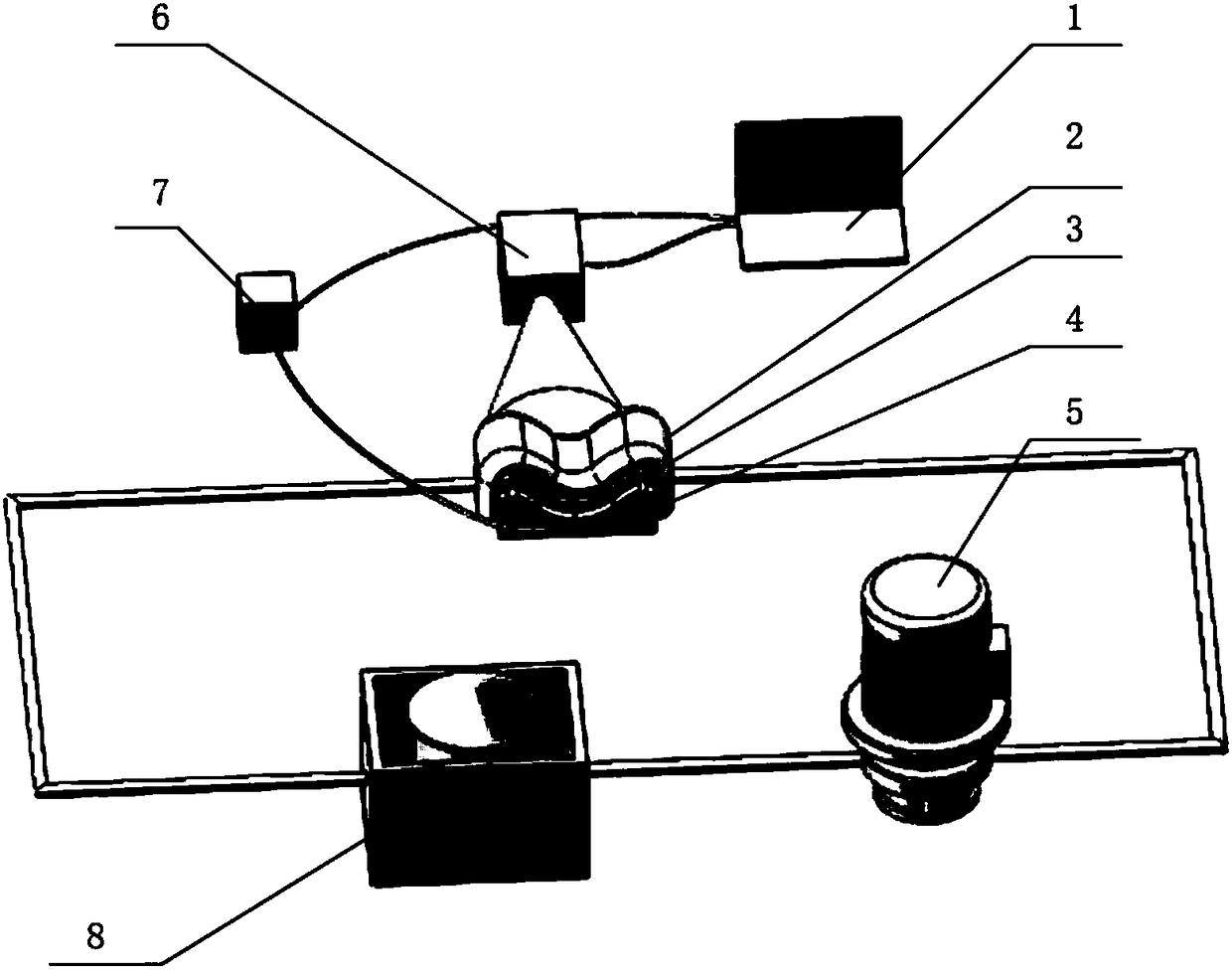

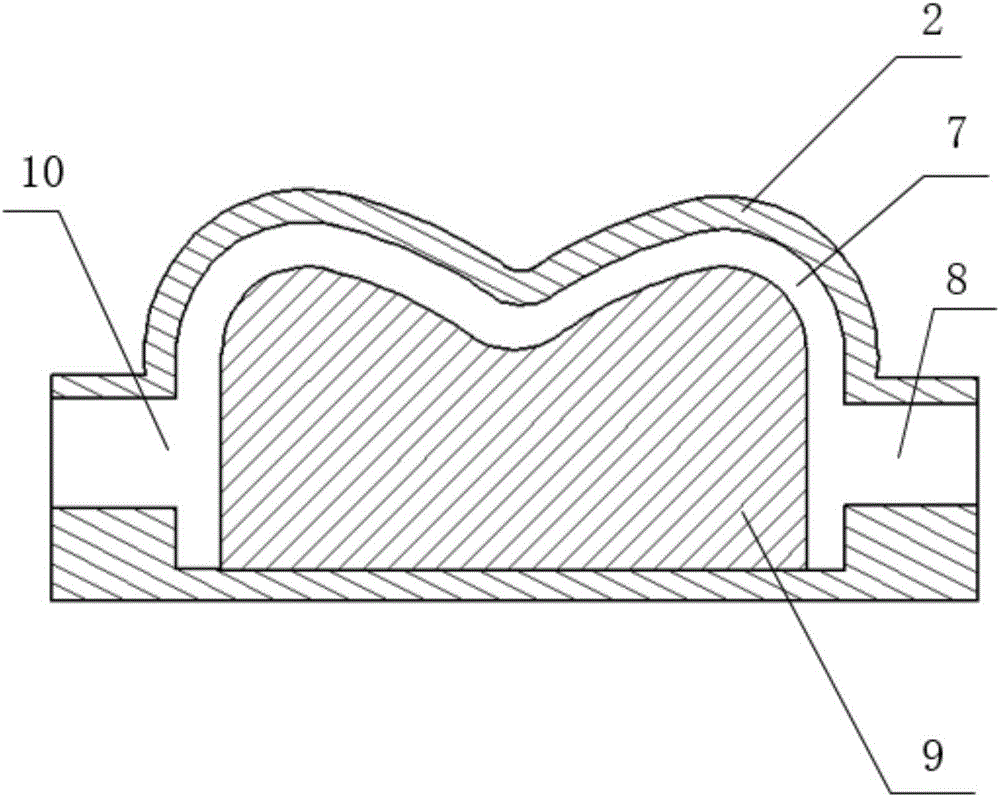

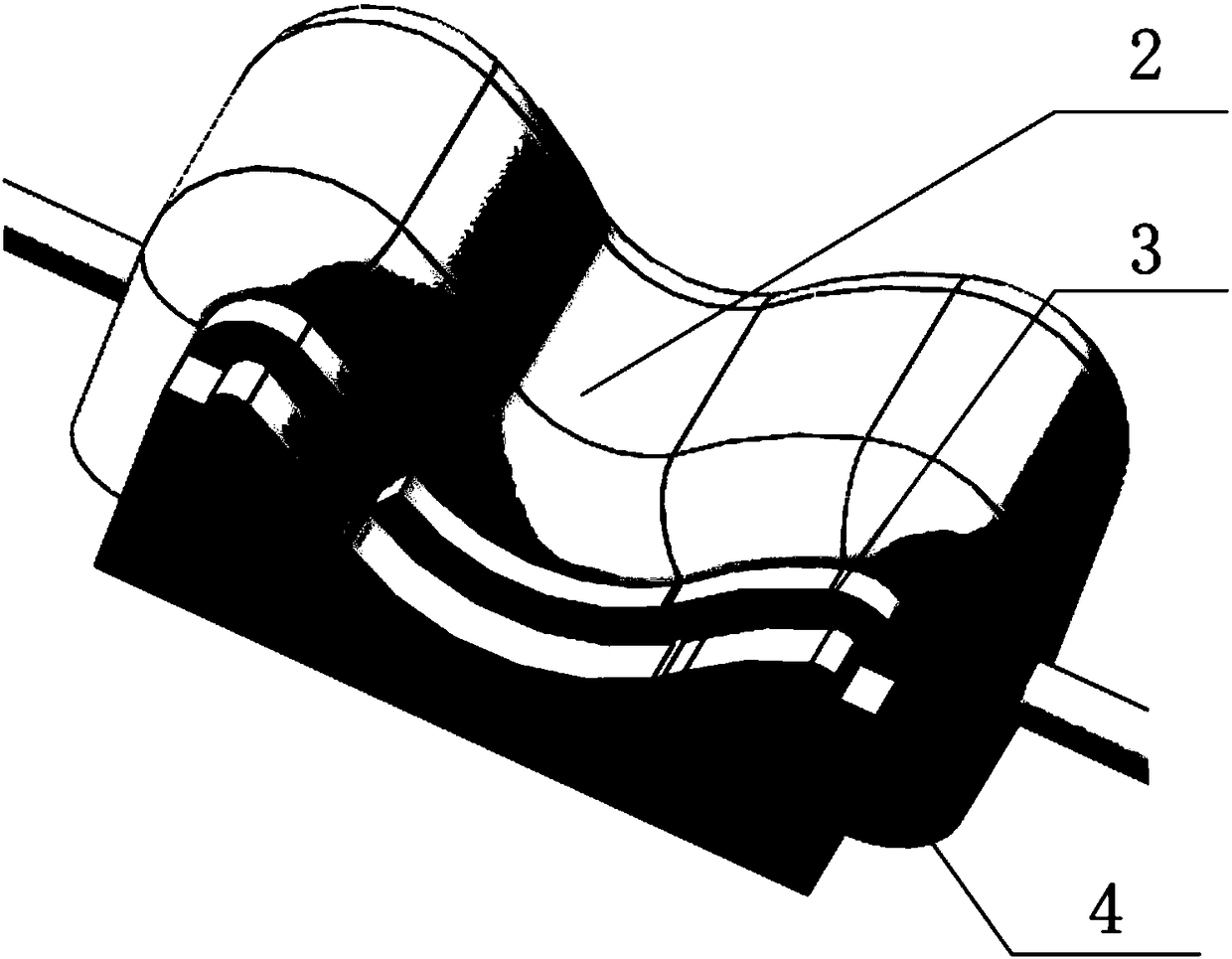

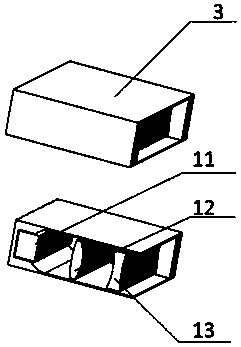

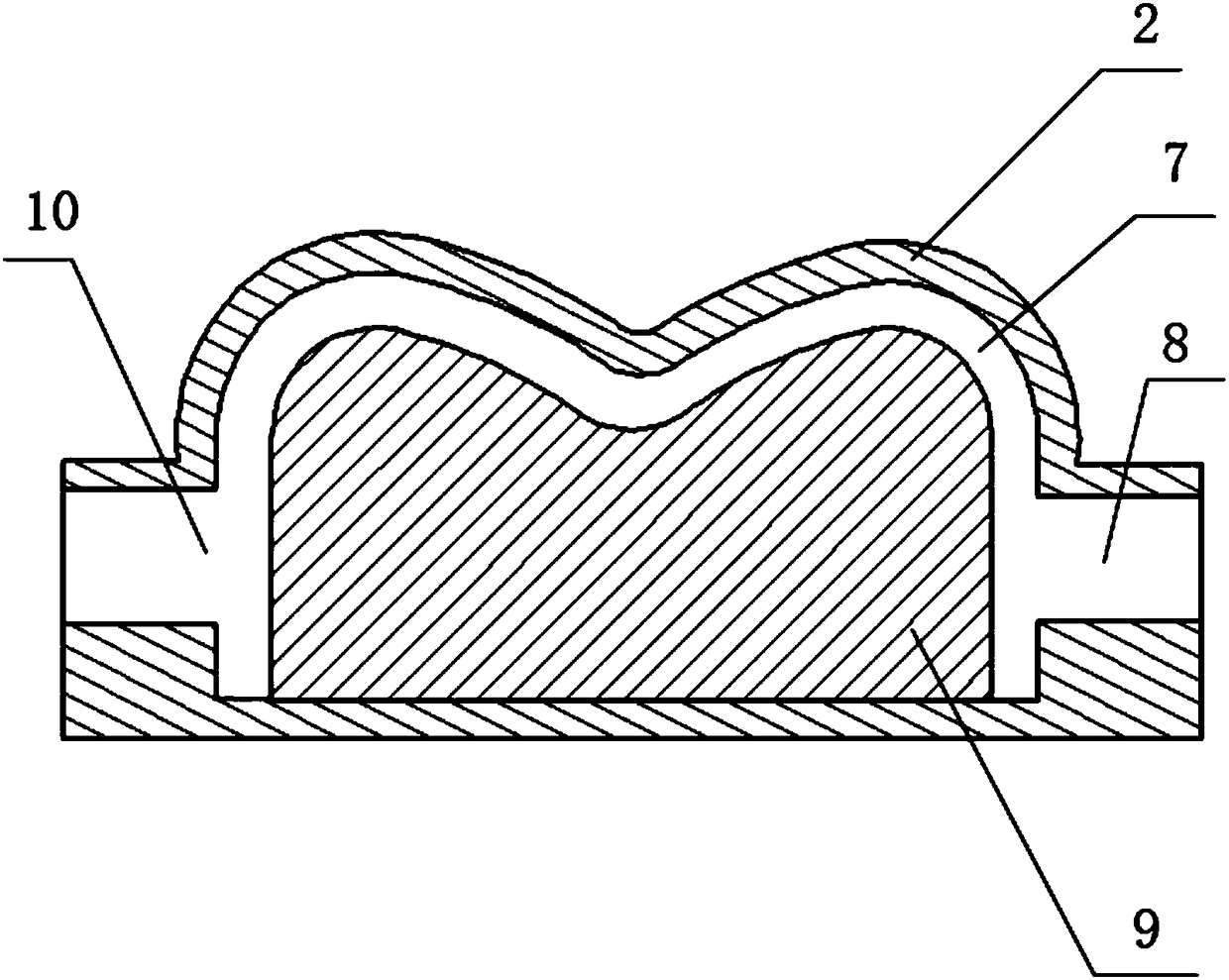

Constant temperature control device and constant temperature control of artificial joint curved surface turbulence polishing equipment

ActiveCN106475915AHigh polishing precisionIncreased turbulent kinetic energy and velocityAbrasive feedersAbrasive blasting machinesParticle flowArtificial joints

The invention discloses a constant temperature control device and a constant temperature control method of artificial joint curved surface turbulence polishing equipment. The constant temperature control device comprises a glass restriction component, an electromagnetic wave heating matrix, a supporting rack and an electromagnetic wave controller; the electromagnetic wave heating matrix is arranged on one side of the glass restriction component, and comprises a plurality of electromagnetic wave heaters; the distribution shape of the electromagnetic wave heaters is the same as the projection shape of a modeling runner on the side surface of an artificial joint; and each electromagnetic wave heater is arranged on the supporting rack, and is over against the modeling runner. The electromagnetic wave heating matrix is placed on the side surface of the glass restriction component, so that turbulence energy and a speed of an abrasive particle flow cutting fluid are increased, linear loss and head loss of an abrasive particle flow in the modeling runner are compensated, then the integral processing effect is improved, the temperature of the abrasive particle flow is kept constant in the integral processing procedure, and the surface processing quality of the artificial joint is more uniform.

Owner:ZHEJIANG UNIV OF TECH

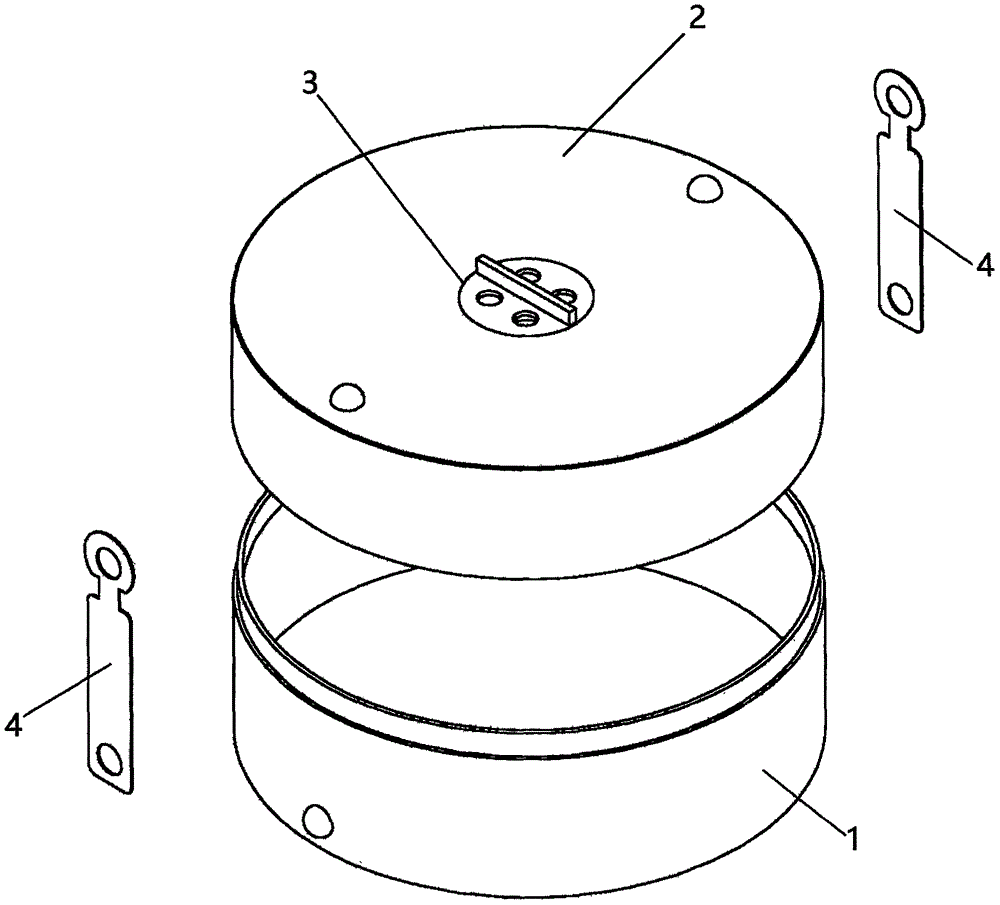

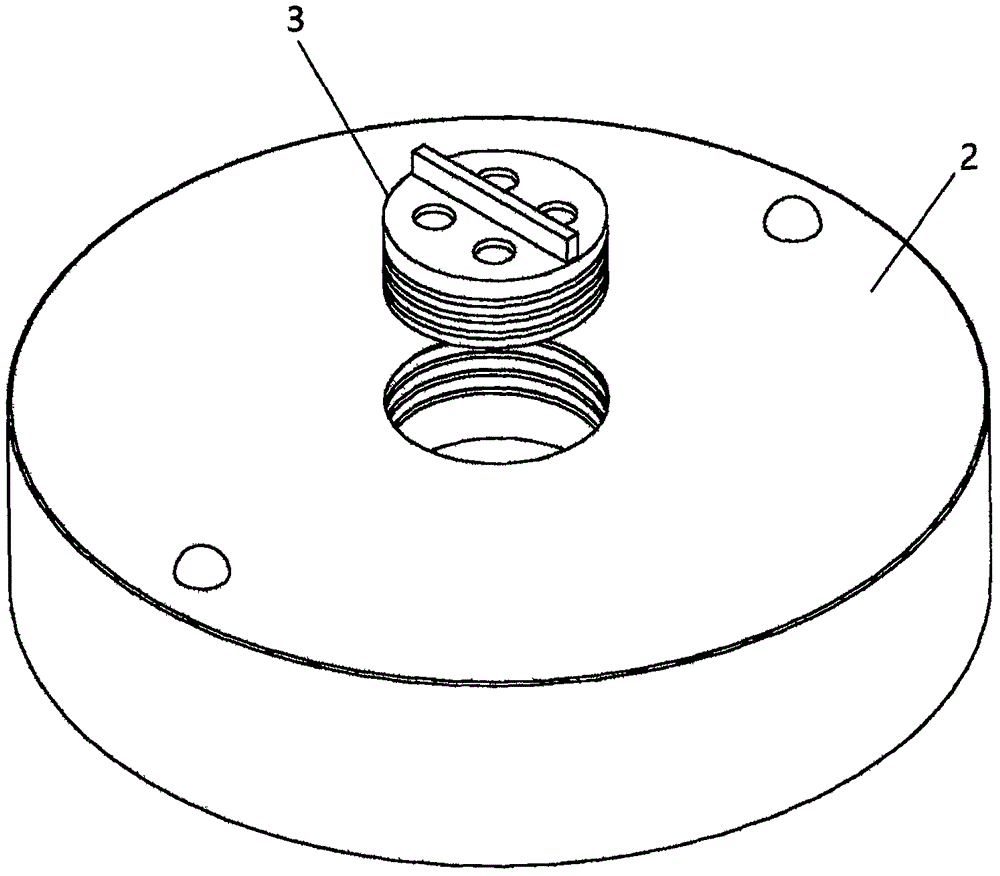

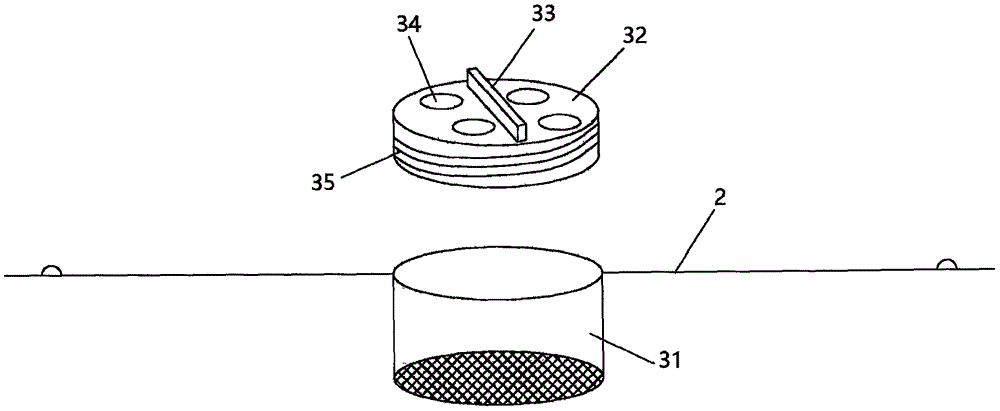

Plant callus culture utensil

PendingCN106754359APromote circulationEasy to irradiateBioreactor/fermenter combinationsBiological substance pretreatmentsPlant tissuePetri dish

The invention relates to a plant callus culture utensil which comprises a petri dish and an upper cover, wherein the petri dish is in seamless gap connection with the upper cover; a detachable recyclable connecting strip for fixation is arranged between the petri dish and the upper cover; convex points in mutual symmetry are arranged between the petri dish and the upper cover to achieve buckle type fixed connection of the petri dish and the upper cover; a columnar ventilation cavity layer is arranged right in the middle of the upper surface of the upper cover; the columnar ventilation cavity layer is provided with a cover part with small vent holes and a bottom which is integrated with the upper cover of the petri dish in an injection molding manner and is provided with a ventilation membrane; and the cover part with the small vent holes can be opened to replace degreased cotton or the ventilation membrane inside the cavity layer. The plant callus culture utensil is capable of effectively solving the defect that the cover plate and the bottom of a conventional petri dish are not stable, and is simple to process, environmentally friendly and effective, convenient to operate, beneficial to sunshine radiation, capable of effectively preventing bacterium invasion to damage plant tissue and ensuring circulation of air and moisture, and beneficial to culture of plant callus tissue.

Owner:HUZHOU TEACHERS COLLEGE

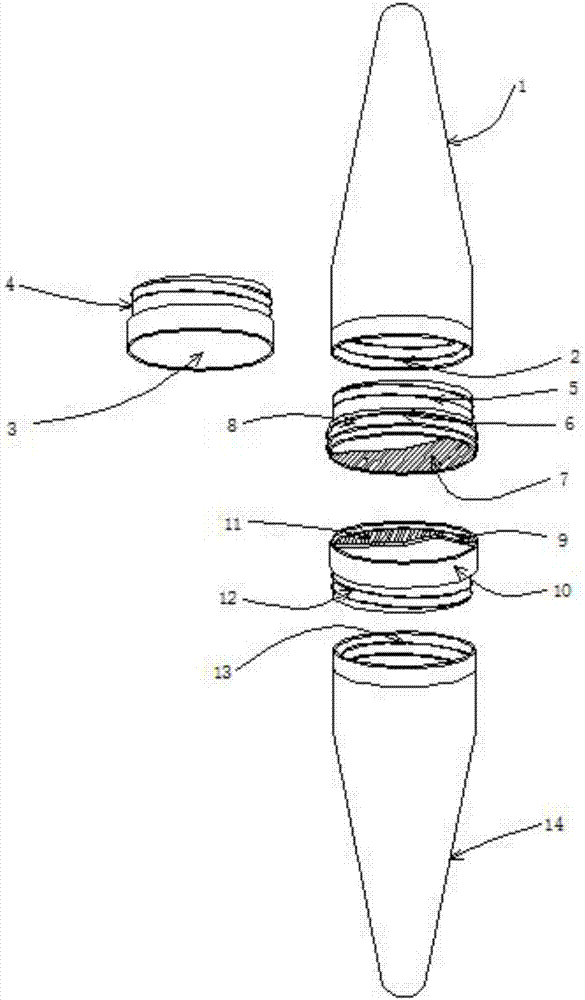

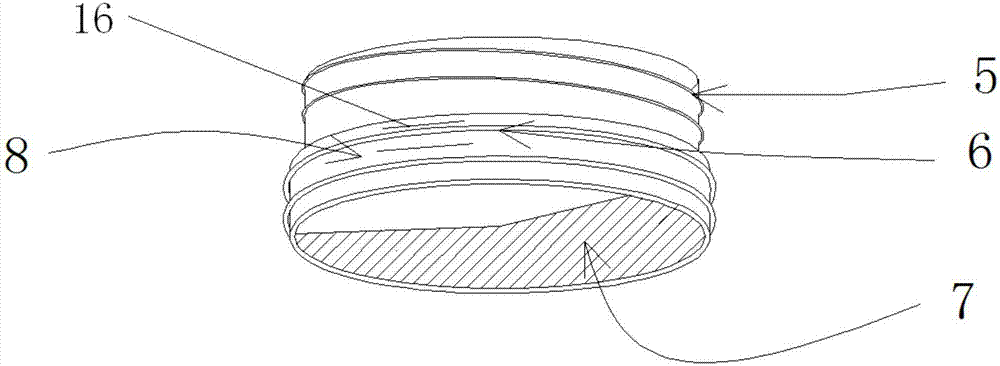

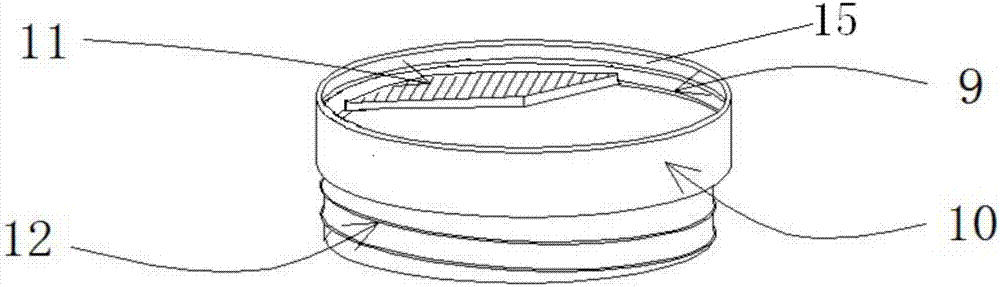

Sperm ascending device for sperm optimization

PendingCN107460116AAvoid affecting the separation effectReduce pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringStructural engineering

The invention discloses a sperm ascending device for sperm optimization. The device is characterized by comprising an ascending pipe, an upper connecting pipe, a lower connecting pipe and a sperm pipe which are detachably connected sequentially from top to bottom, wherein the upper end of the ascending pipe is sealed; the lower end of the ascending pipe is communicated with the upper connecting pipe; the lower end of the sperm pipe is sealed; the upper end of the sperm pipe is communicated with the lower connecting pipe; a first sector plate is fixedly arranged at an inner wall of the upper connecting pipe; a second sector plate complementary to the first sector plate is fixedly arranged at an inner wall of the lower connecting pipe; when the first sector plate and the second sector plate are at least overlapped partially, the upper connecting pipe is communicated with the lower connecting pipe; when the first sector plate and the second sector plate are complementary on the same horizontal plane so as to be connected into a circular shape, a closed passage is formed between the upper connecting pipe and the lower connecting pipe. The sperm ascending device for sperm optimization has the advantages of simple structure, good separating effect and high repeatability.

Owner:SUZHOU RES INST OF TONGJI UNIV

Electrochemical reactor for electrochemical reduction of carbon dioxide

ActiveCN111575726ALow costUniform structureCellsVacuum evaporation coatingElectrochemical responseElectrolytic agent

The invention provides an electrochemical reactor for an electrochemical reduction of carbon dioxide. The electrochemical reactor belongs to a three-chamber reactor and is formed by separating three transparent organic glass plates with precise-size grooves and openings by two diaphragms (namely an anionic conductive polymer film and a polypropylene film gas diffusion electrode). The three-chamberreactor comprises a gas chamber, a catholyte chamber and an anolyte chamber, wherein the gas chamber comprises one side of a polypropylene film side of the polypropylene film gas diffusion electrode;the catholyte chamber comprises one catalytic layer side of the polypropylene film gas diffusion electrode, and the catalytic layer uses a silver-based catalyst as a cathode; and the anolyte chambercomprises an anode with a mixed metal oxide catalyst. The whole electrochemical reactor is made of organic glass which is transparent in material, high in hardness and resistant to alkali and acid, and is easy for precise machining and assembling, convenient for direct monitoring and electrochemical reaction observation and free of secondary pollution in a reaction test period.

Owner:SHANGHAI TECH UNIV

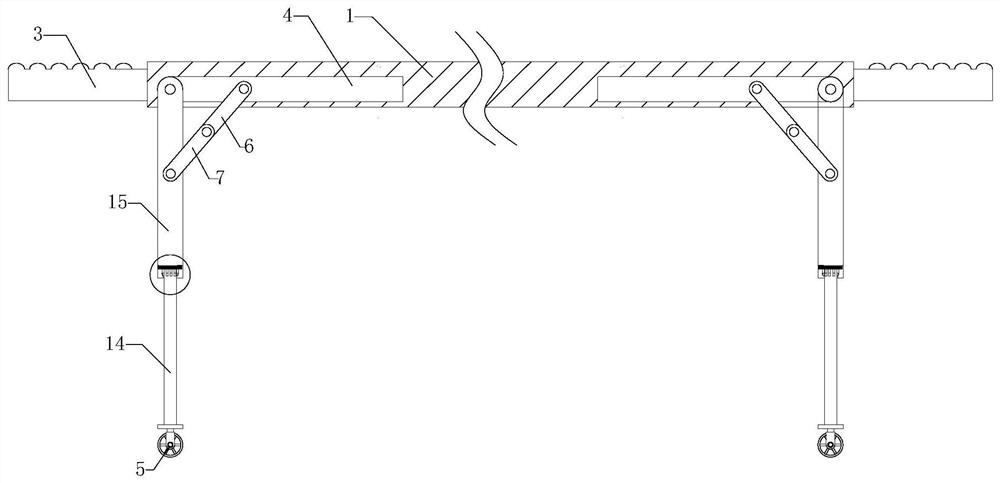

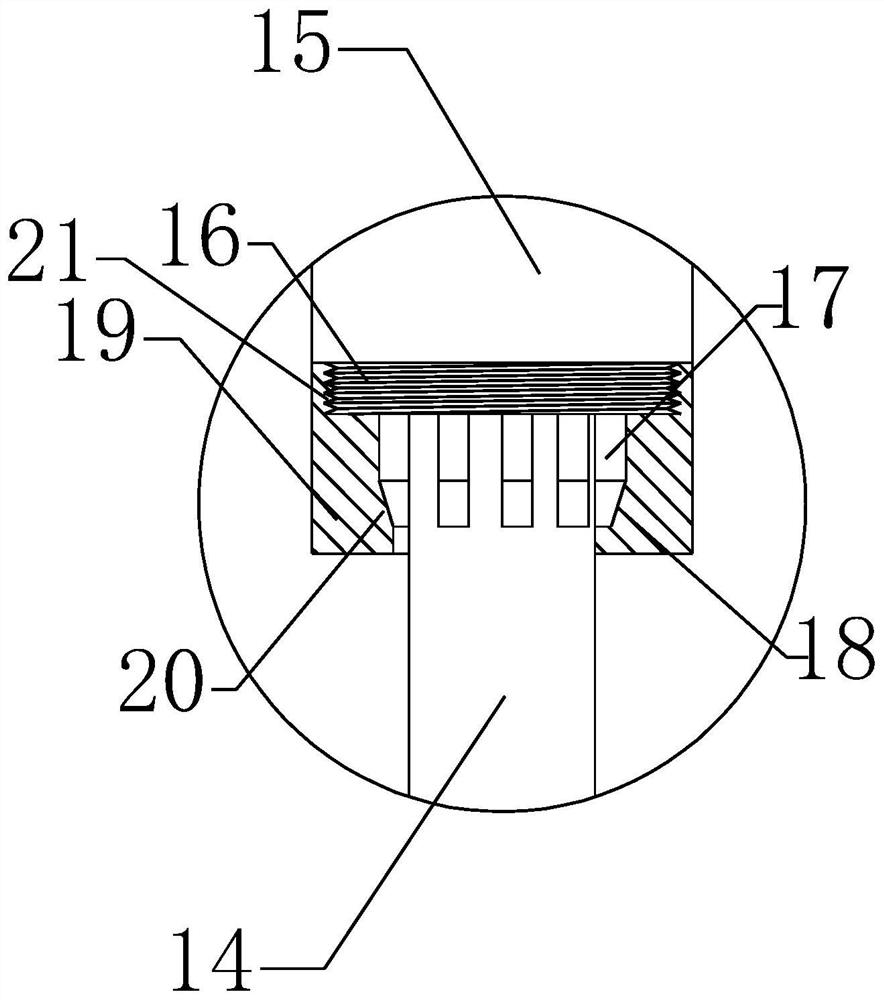

Convenient stretcher for emergency department

The invention discloses a convenient stretcher for the emergency department. The convenient stretcher comprises two stretcher rods, baffle cloth and telescopic legs, holding rods facilitating hand holding are arranged at the two ends of the stretcher rods, and stretcher cloth is fixed between the two stretcher rods. Receding grooves are further formed in the two ends of the stretcher rods, one ends of the telescopic legs are hinged to one ends of the receding grooves, moving wheels are arranged at the other ends of the telescopic legs, first connecting rods and second connecting rods are arranged between the receding grooves and the telescopic legs, wherein one ends of the first connecting rods are hinged to one ends of the second connecting rods, the other ends of the first connecting rods are hinged to the receding grooves, and the other ends of the second connecting rods are hinged to the telescopic legs. The convenient stretcher with a novel structure for the emergency department is complete in function and adapts to the requirements of different patients, the whole stretcher has a movable supporting point through opening of the telescopic legs, the stretcher is convenient to move, the patients are protected in all directions through the arrangement of supporting rods, the operation is convenient, no bolt is adopted for fixing, simpleness and rapidness are achieved, and thestretcher is integrally made of light metal or plastic, so that the overall weight is reduced while the strength is ensured.

Owner:李晓枢

Device and method for rabies virus inactivation and inactivator hydrolysis by virtue of disposable bags

ActiveCN107746797AReduced risk of inactivation failureImproved inactivation/hydrolysis methodSsRNA viruses negative-senseBioreactor/fermenter combinationsAntigenVirus inactivation

The invention provides a device and method for rabies virus inactivation and inactivator hydrolysis by virtue of disposable bags, wherein an inactivating disposable bag is provided with three connecting ports; the three connecting ports include an inflating port which is arranged at the upper side and is connected to an inflating group, and a liquid inlet and a liquid outlet which are arranged atthe bottom; the liquid inlet is connected to a liquid filling group and the liquid outlet is connected to a drainage group; a built-in stirrer is arranged in the center of the bag, wherein the inflating group is composed of a bag-type filter, a silicone tube and a pipeline clamp, and the sterile bag covers the external part of the bag-type filter; the liquid filling group is formed by sequentiallyconnecting a connector B, a silicone tube, a pipeline clamp, a tee joint and an EZD valve; and another opening of the tee joint is connected to a silicone tube, a pipeline clamp and a connector A. The device provided by the invention has the advantages that the disposable bags are transformed and reasonably used, so that a virus liquid inactivation / hydrolysis method is improved; therefore, a riskof failing in virus inactivation is reduced, antigen loss is lowered and production cost is reduced.

Owner:SHANDONG YIDU BIOTECH

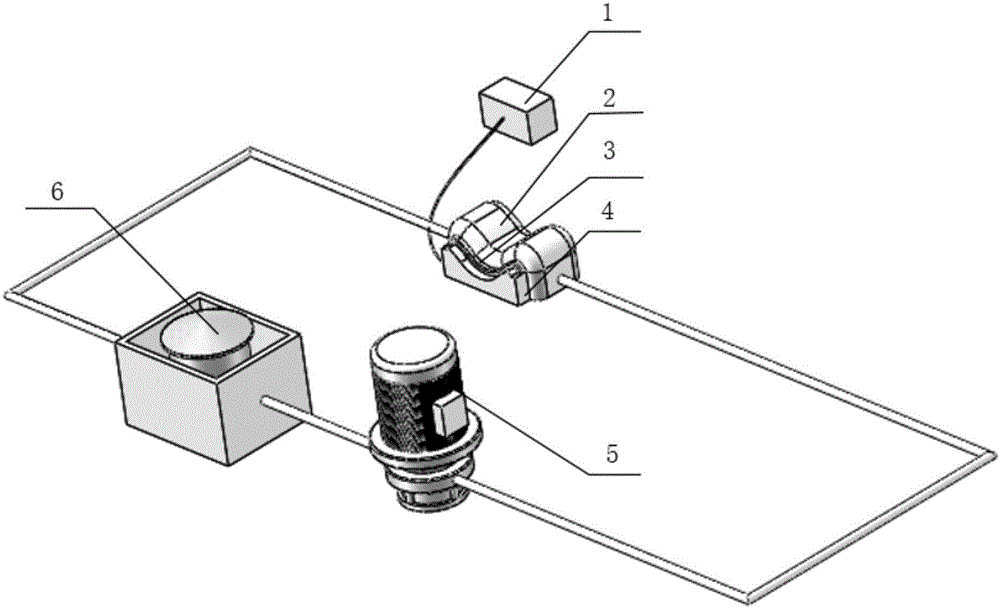

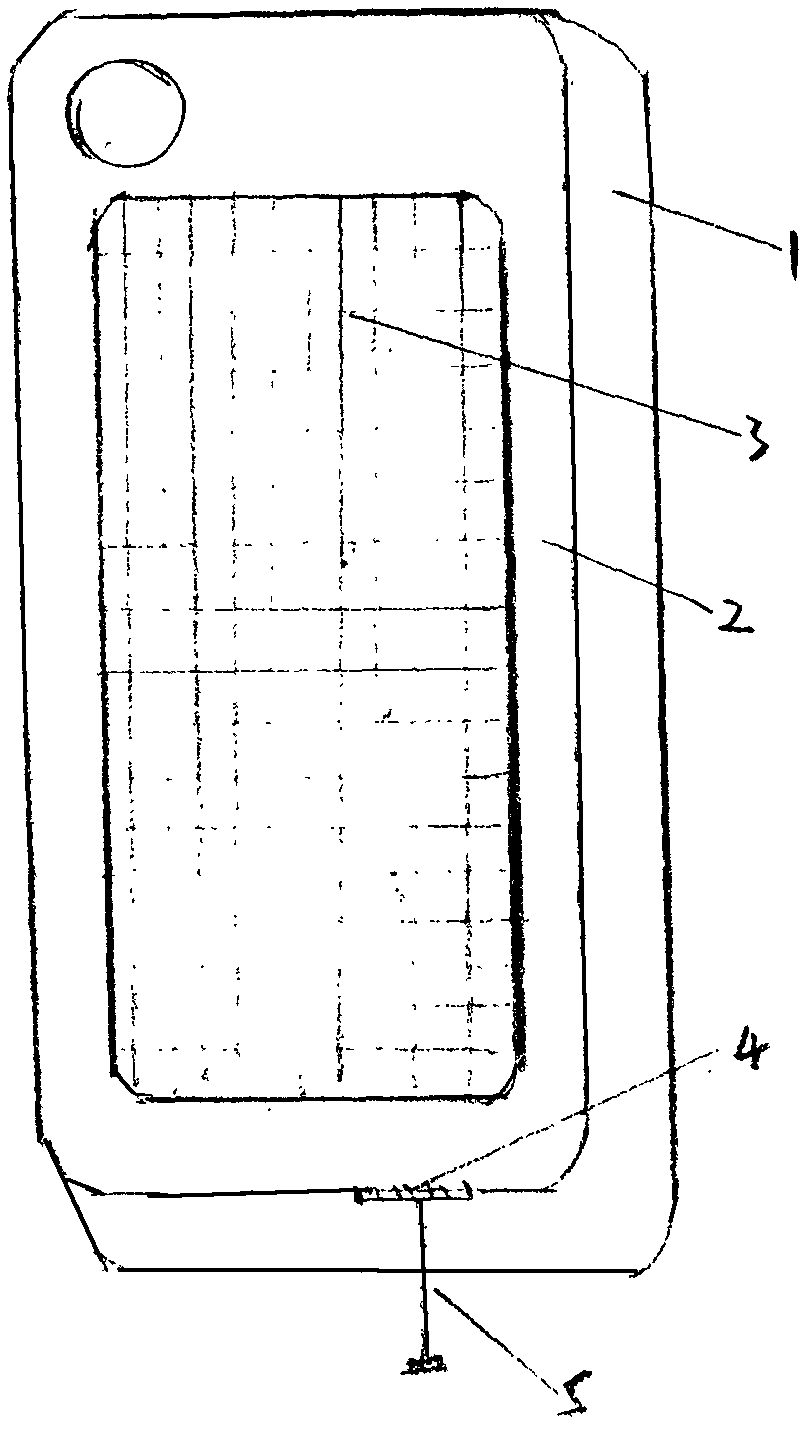

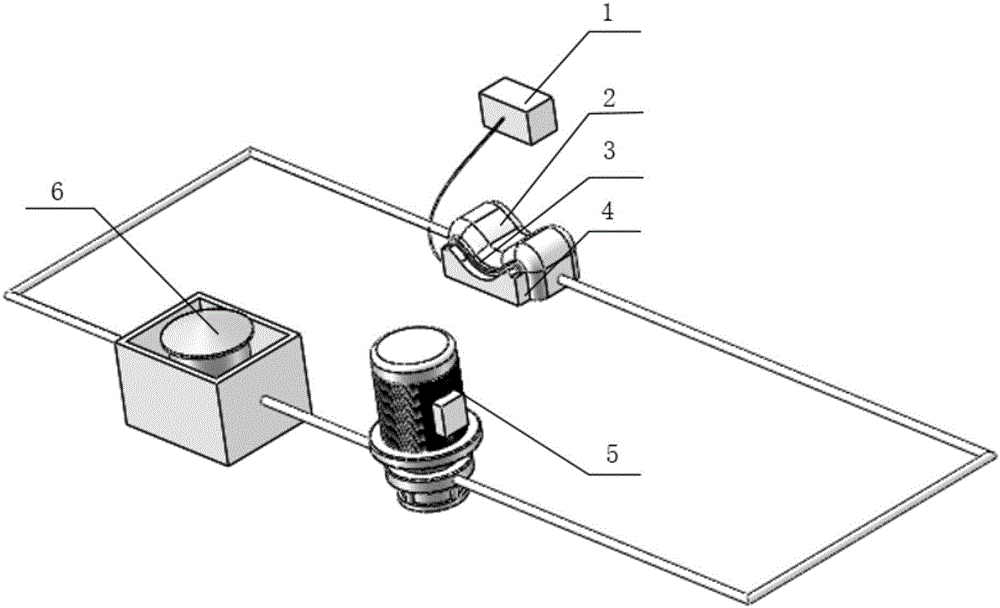

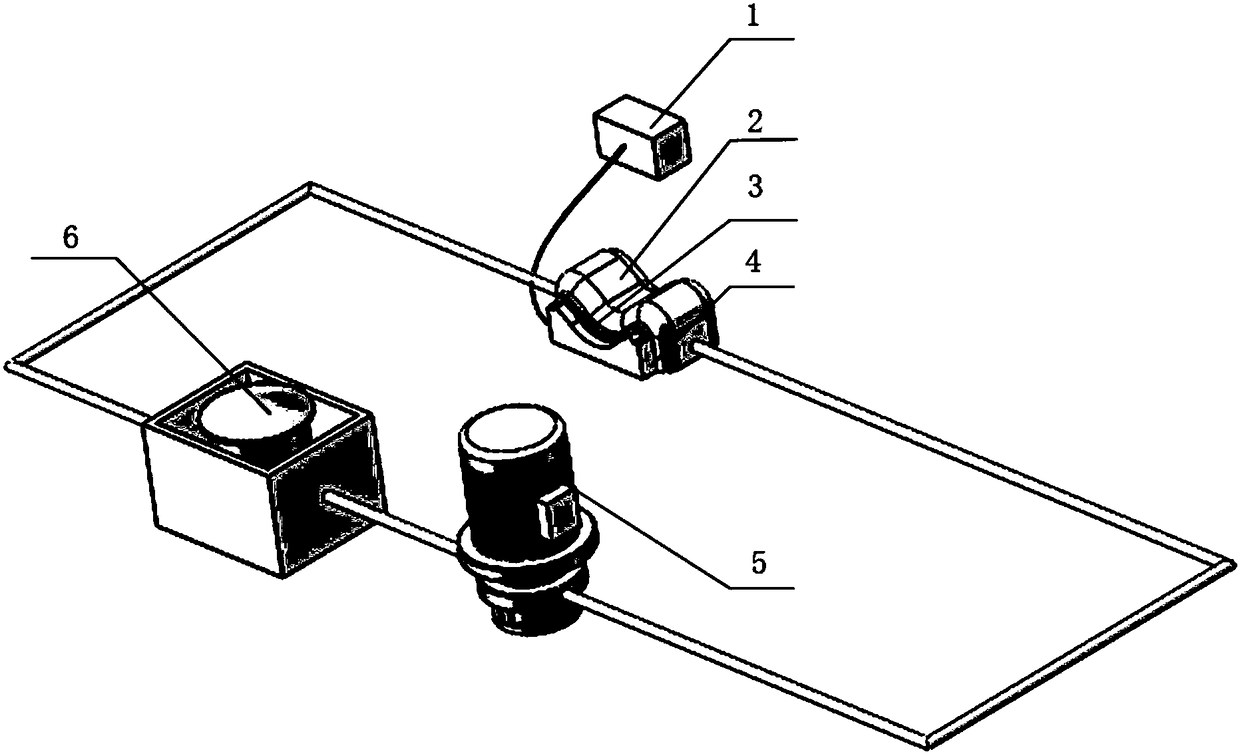

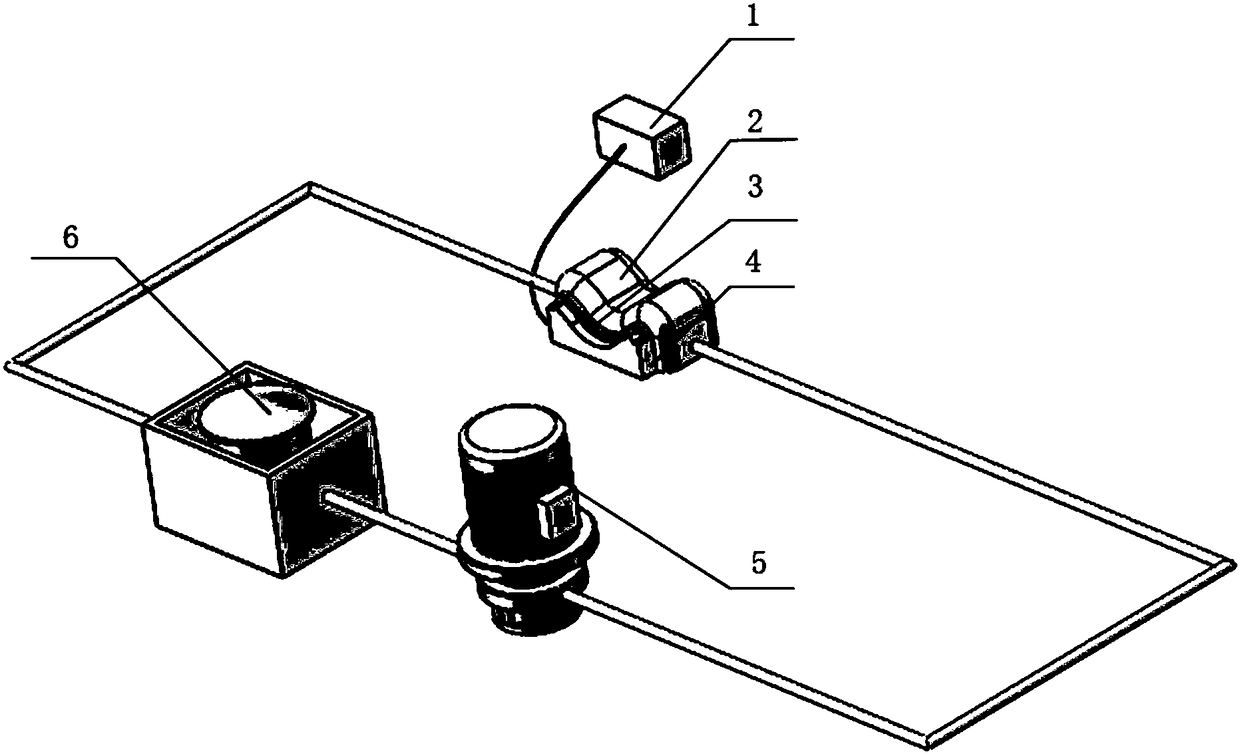

Mobile phone externally-hung flexible thin-film solar charger

InactiveCN103378627ASoft materialMaterial transparentBatteries circuit arrangementsElectric powerSilica gelMobile phone

The invention discloses a mobile phone externally-hung flexible thin-film solar charger. According to the mobile phone externally-hung flexible thin-film solar charger, solar energy can be used as a supplement power source of a mobile phone, so that carrying is convenient, and the mobile phone externally-hung flexible thin-film solar charger is also like a mobile phone sleeve and plays a role in protecting the mobile phone. The externally-hung flexible thin-film solar charger is in an externally-hung type and similar to the mobile phone sleeve. Flexible silica gel is used as a lining plate and the flexible thin-film solar cell and the silica gel are bonded together through silicone rubber binder. An adaptation interface is formed in the mobile phone externally-hung flexible thin-film solar charger. The mobile phone externally-hung flexible thin-film solar charger is connected to a mobile phone power source interface through an output line plug. The mobile phone is sleeved with the flexible silica gel lining plate firmly.

Owner:郭作超

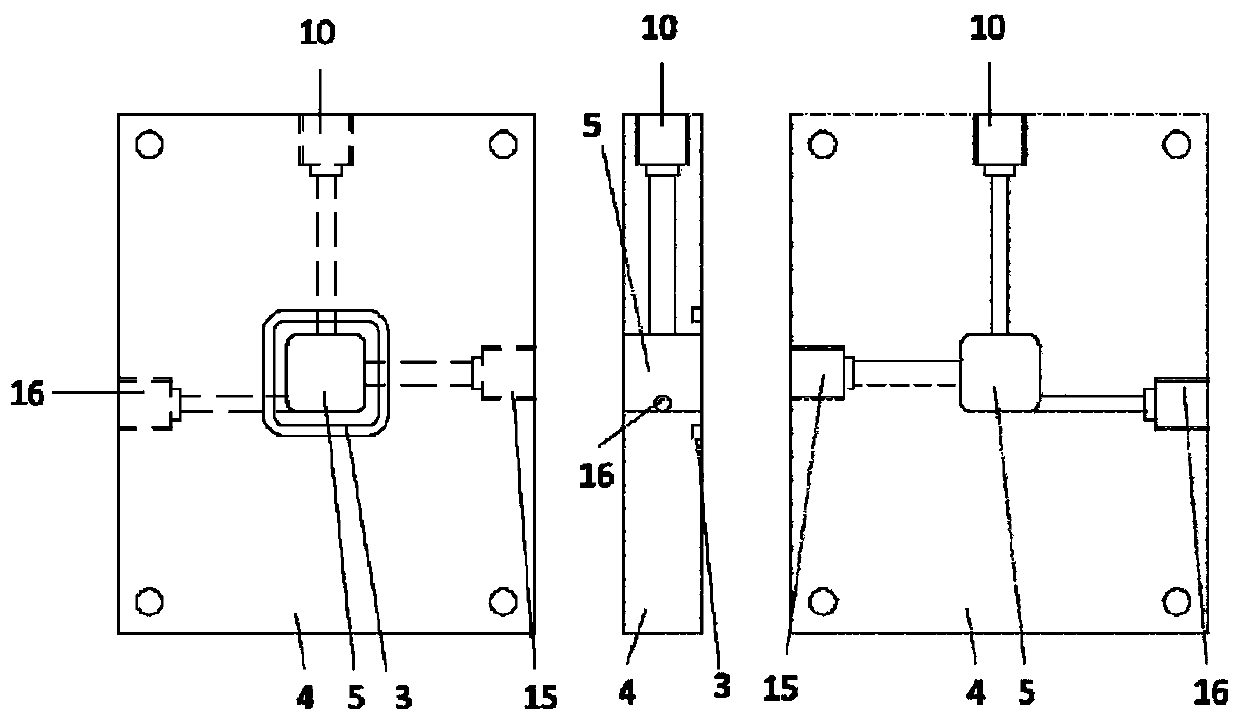

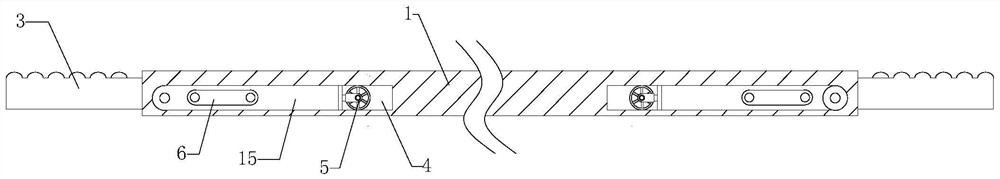

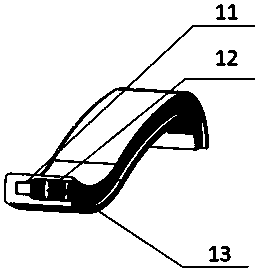

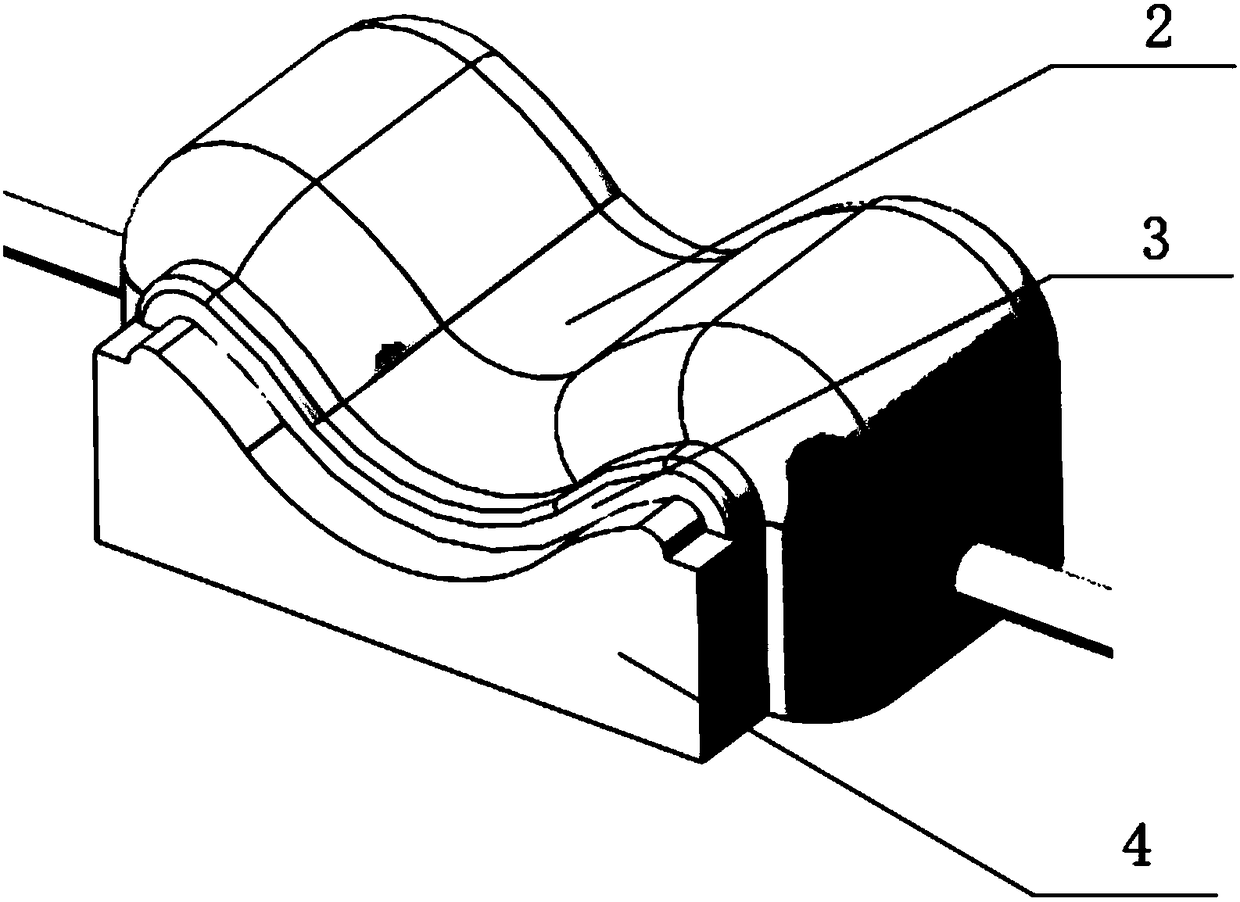

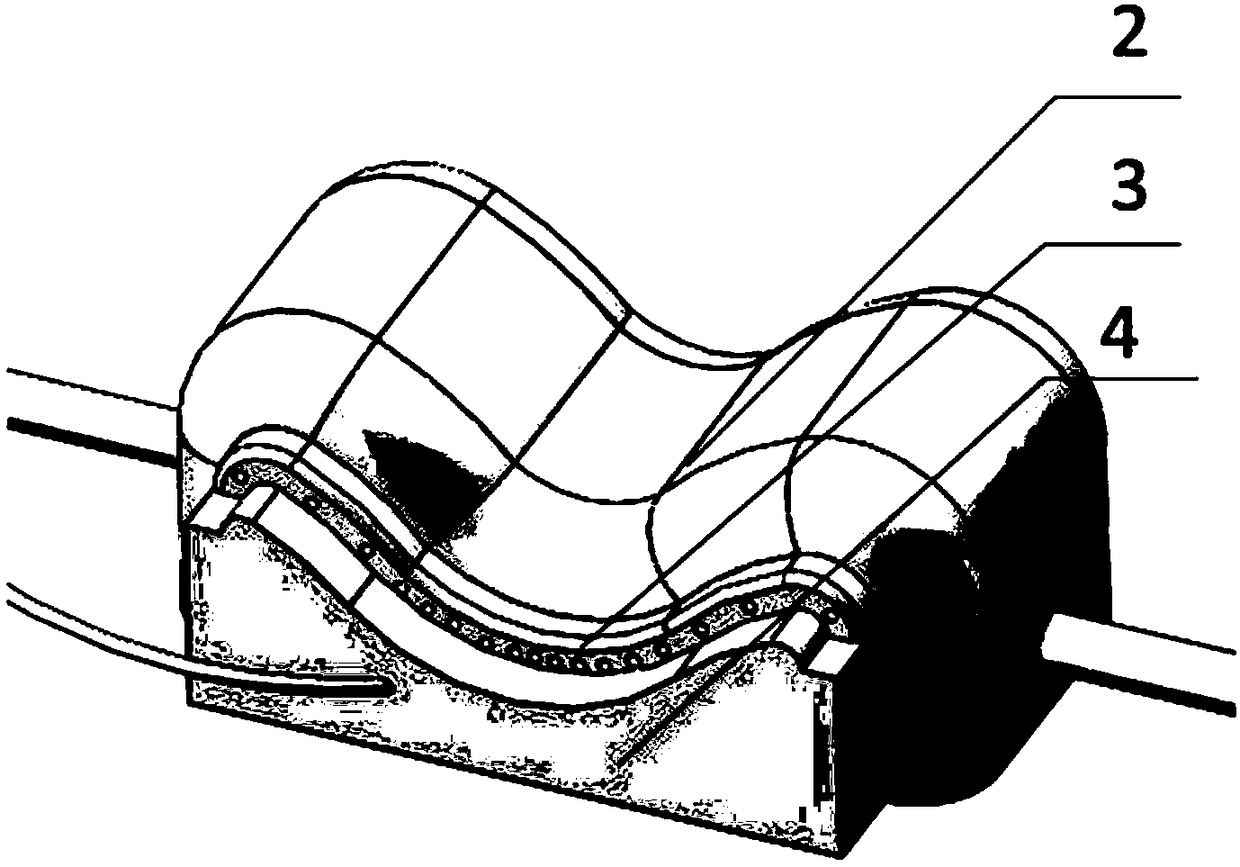

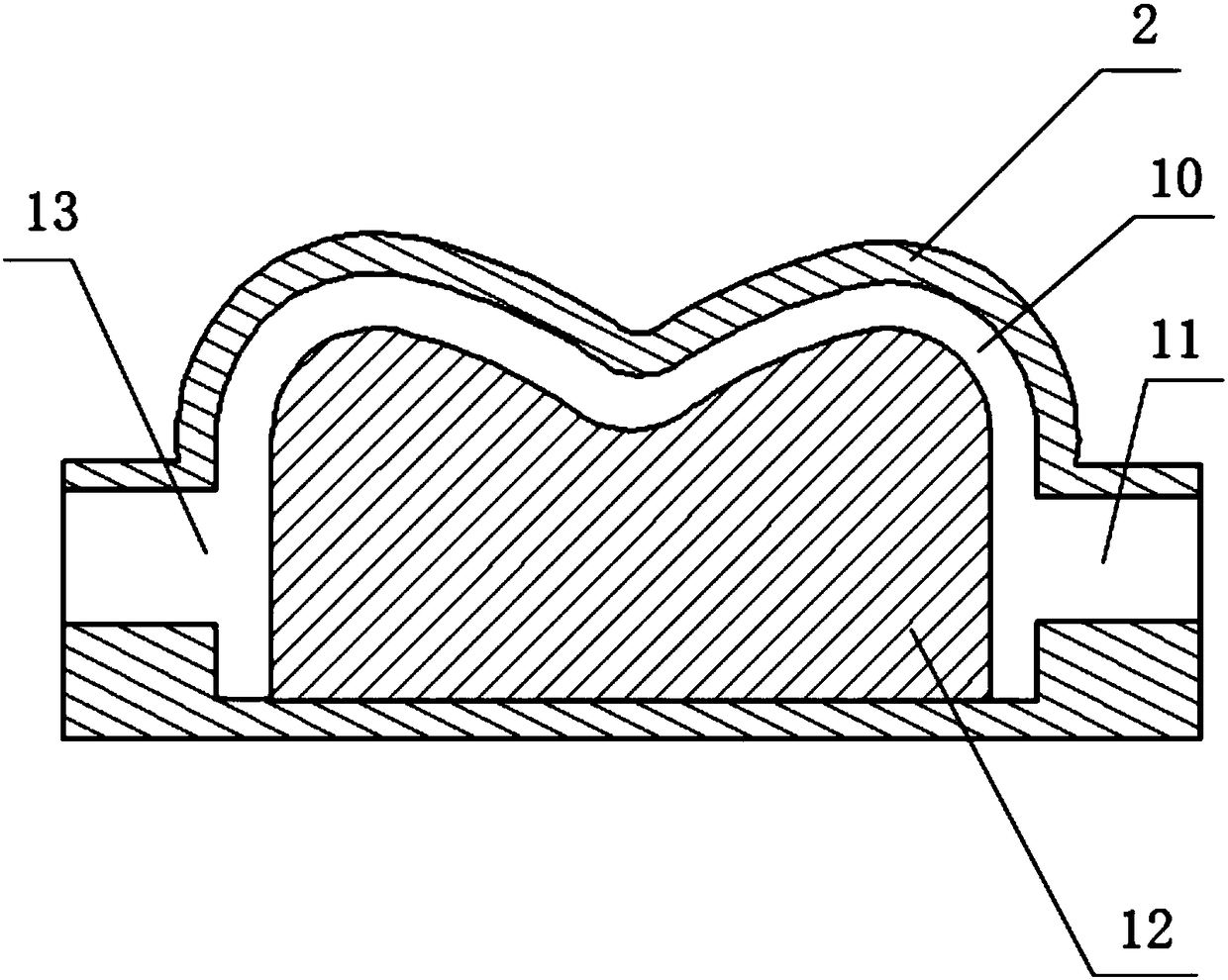

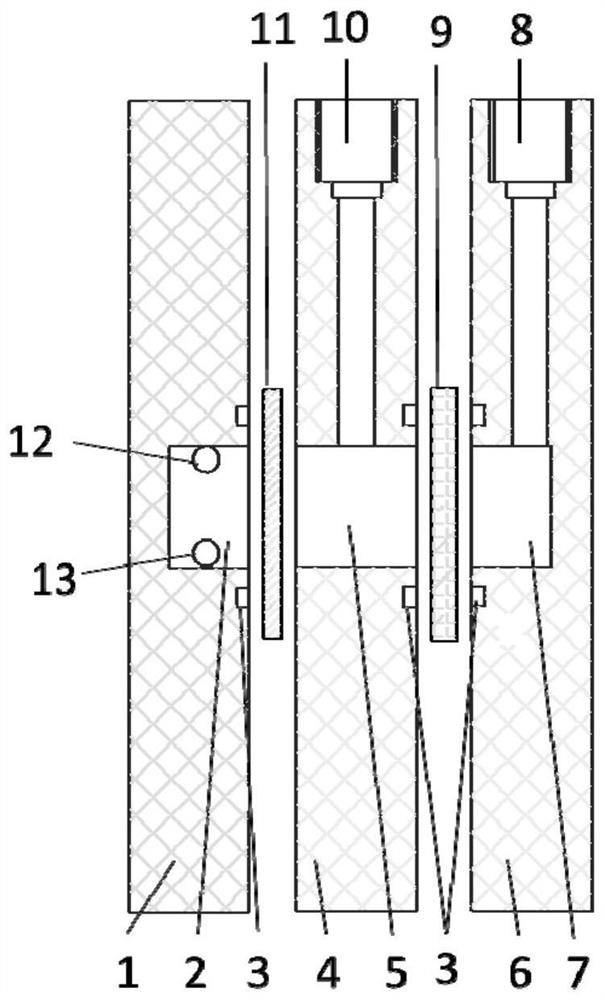

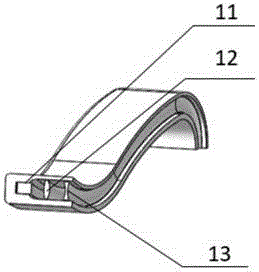

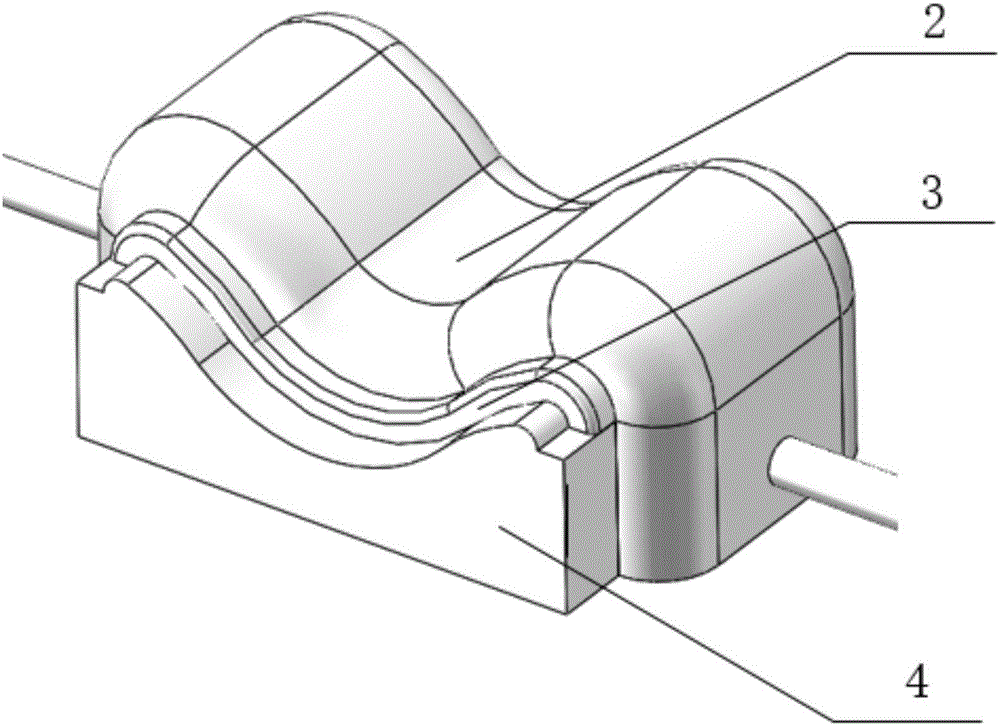

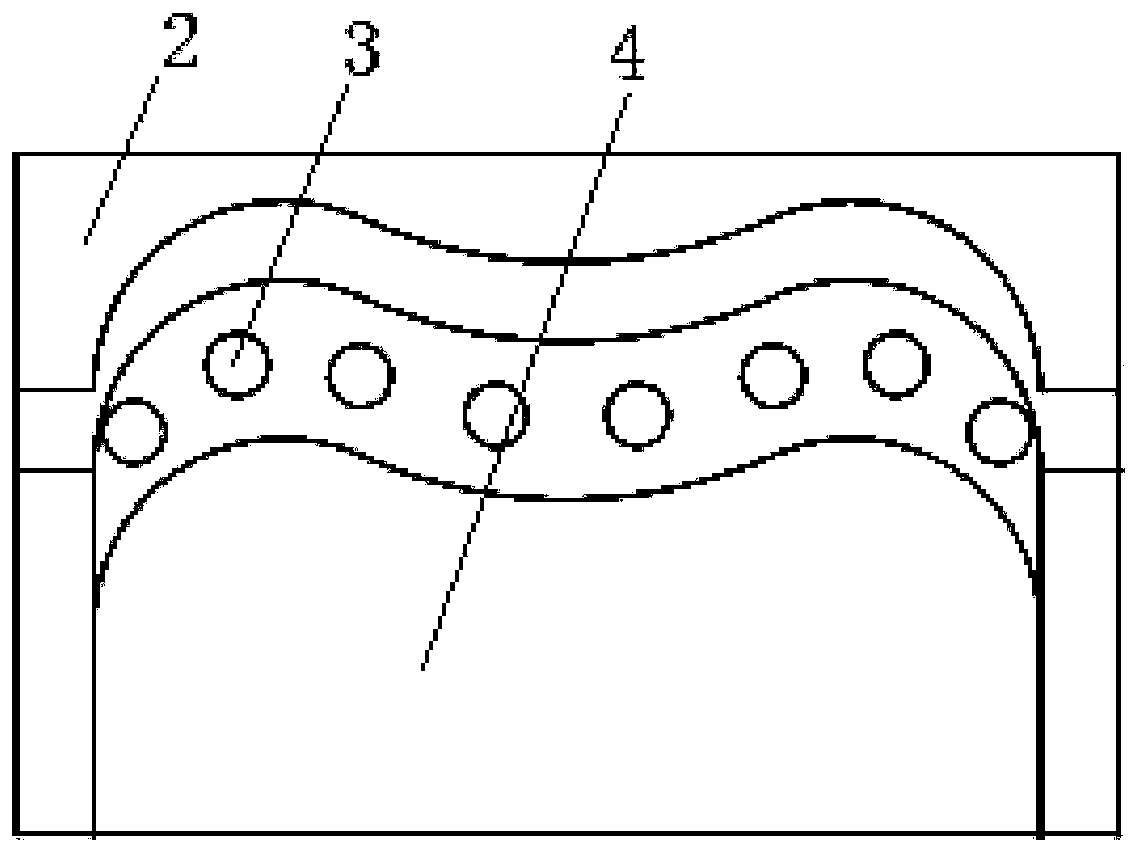

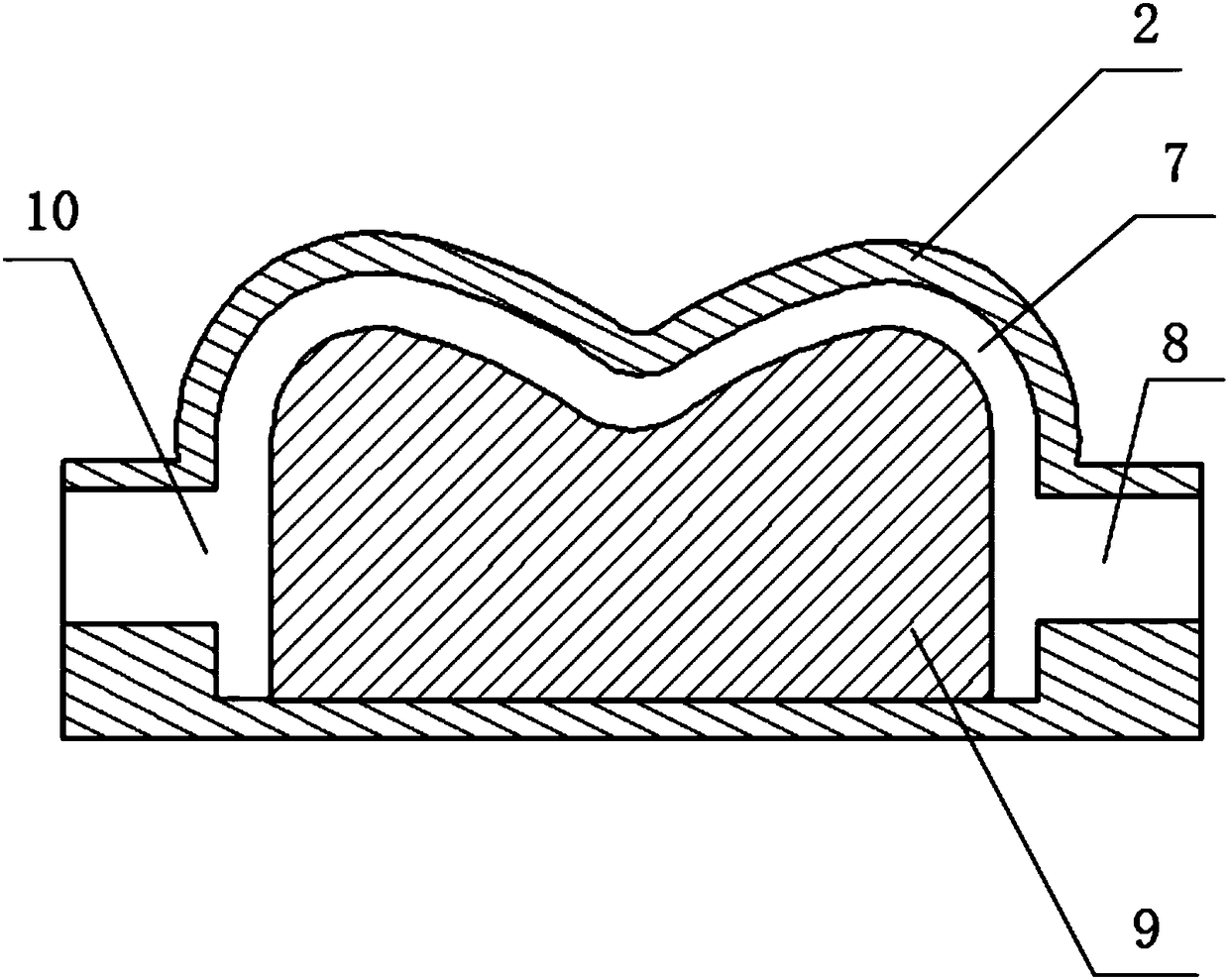

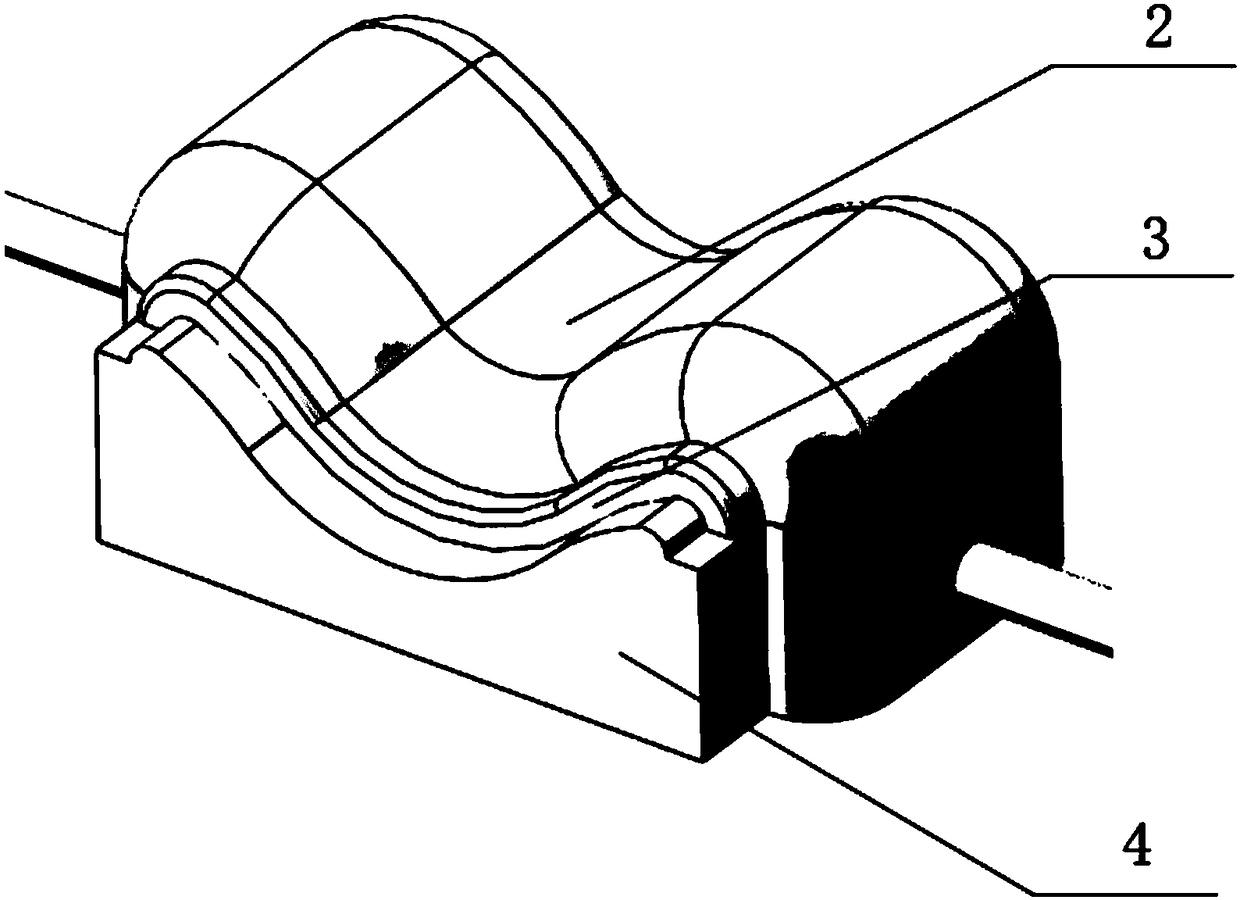

Turbulent flow simulation polishing device and method for artificial joint-like surface

ActiveCN106625277BHigh polishing precisionUniform processing qualityAbrasive machine appurtenancesAbrasive blasting machinesElectricityArtificial joints

The invention discloses an artificial joint-like piece curved surface turbulence simulating polishing device and a method thereof. The device comprises a glass constraint component, a profiling electromagnetic wave heater, a temperature detection device, a supporting frame and an electromagnetic wave controller, wherein the glass constraint component is arranged outside an artificial joint-like piece in a sleeving way; the inner surface of the glass constraint component and the curved surface of the artificial joint-like piece form a profiling runner with uniform thickness; the profiling electromagnetic wave heater is arranged on one side of the glass constraint component; the profiling electromagnetic wave heater comprises an outer cover, heating sources, a concave lens and a convex lens; and each heating source of the profiling electromagnetic wave heater is electrically connected with the electromagnetic wave controller and is independently controlled by the electromagnetic wave controller. One heating source is placed on the side surface of the glass constraint component, the turbulence energy and the speed of abrasive flow cutting fluid are increased, and the linear loss and the head loss of the abrasive flow in the profiling runner are compensated, so that the whole processing effect is improved and the surface processing quality of the artificial joint-like piece is more uniform.

Owner:ZHEJIANG UNIV OF TECH

A device and method for inactivating rabies virus and hydrolyzing an inactivating agent using a disposable bag

ActiveCN107746797BReduced risk of inactivation failureImproved inactivation/hydrolysis methodSsRNA viruses negative-senseBioreactor/fermenter combinationsAntigenVirus inactivation

The invention provides a device and method for rabies virus inactivation and inactivator hydrolysis by virtue of disposable bags, wherein an inactivating disposable bag is provided with three connecting ports; the three connecting ports include an inflating port which is arranged at the upper side and is connected to an inflating group, and a liquid inlet and a liquid outlet which are arranged atthe bottom; the liquid inlet is connected to a liquid filling group and the liquid outlet is connected to a drainage group; a built-in stirrer is arranged in the center of the bag, wherein the inflating group is composed of a bag-type filter, a silicone tube and a pipeline clamp, and the sterile bag covers the external part of the bag-type filter; the liquid filling group is formed by sequentiallyconnecting a connector B, a silicone tube, a pipeline clamp, a tee joint and an EZD valve; and another opening of the tee joint is connected to a silicone tube, a pipeline clamp and a connector A. The device provided by the invention has the advantages that the disposable bags are transformed and reasonably used, so that a virus liquid inactivation / hydrolysis method is improved; therefore, a riskof failing in virus inactivation is reduced, antigen loss is lowered and production cost is reduced.

Owner:SHANDONG YIDU BIOTECH

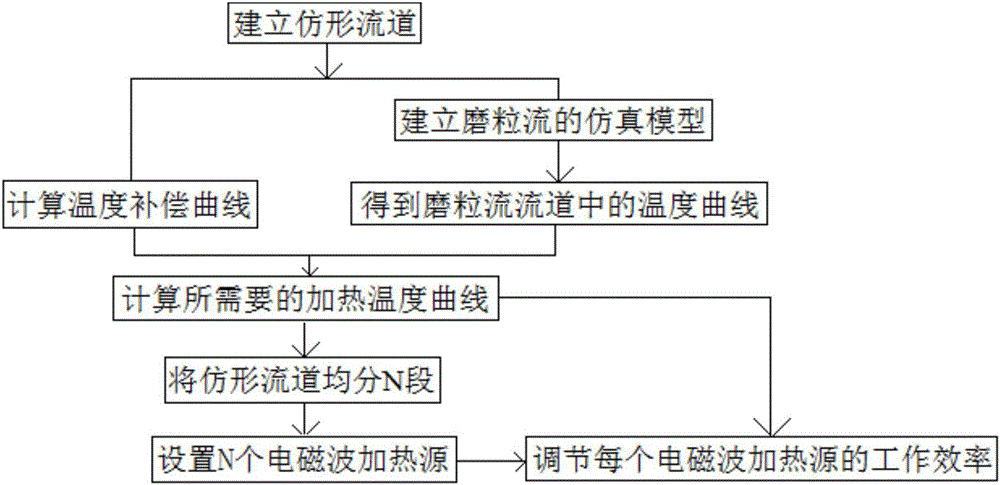

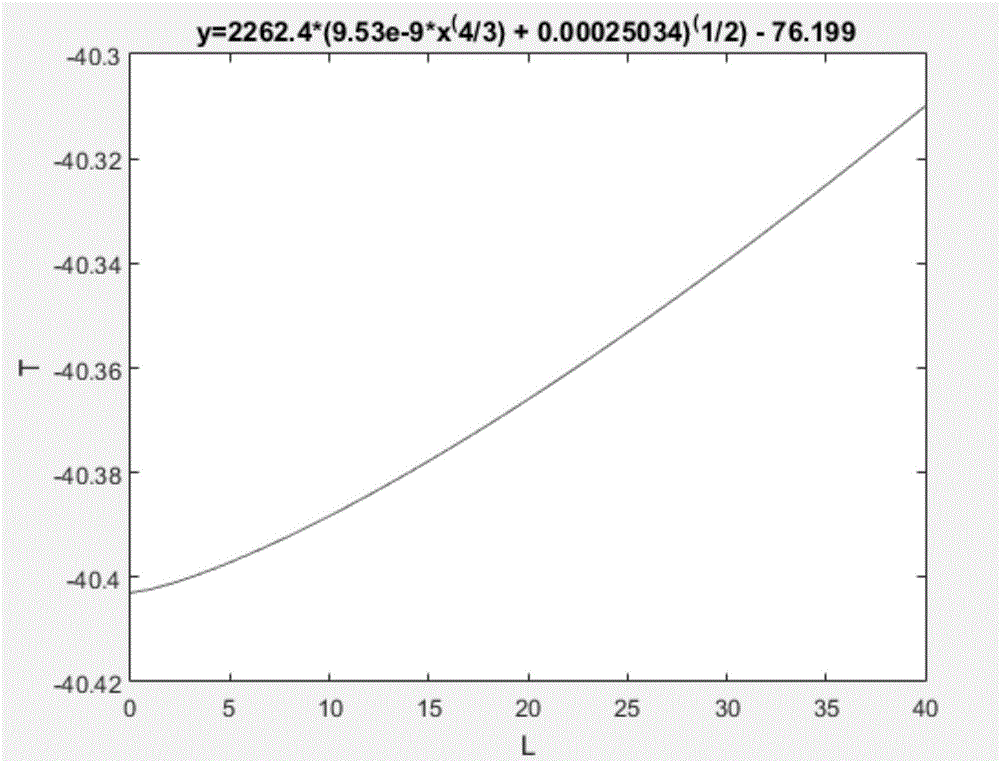

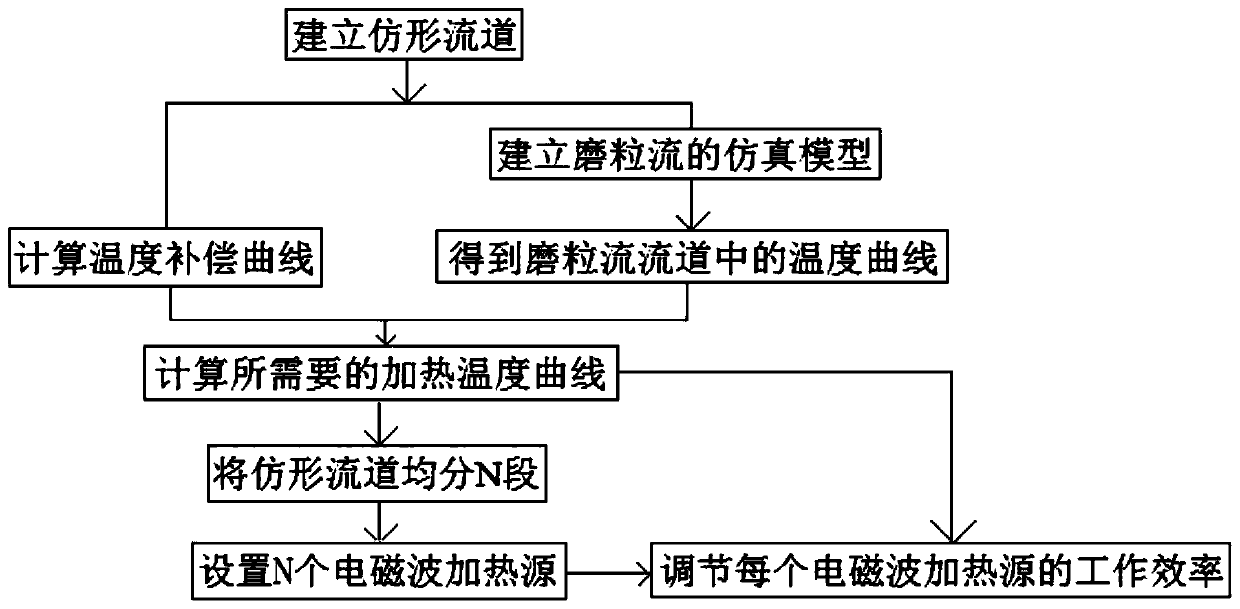

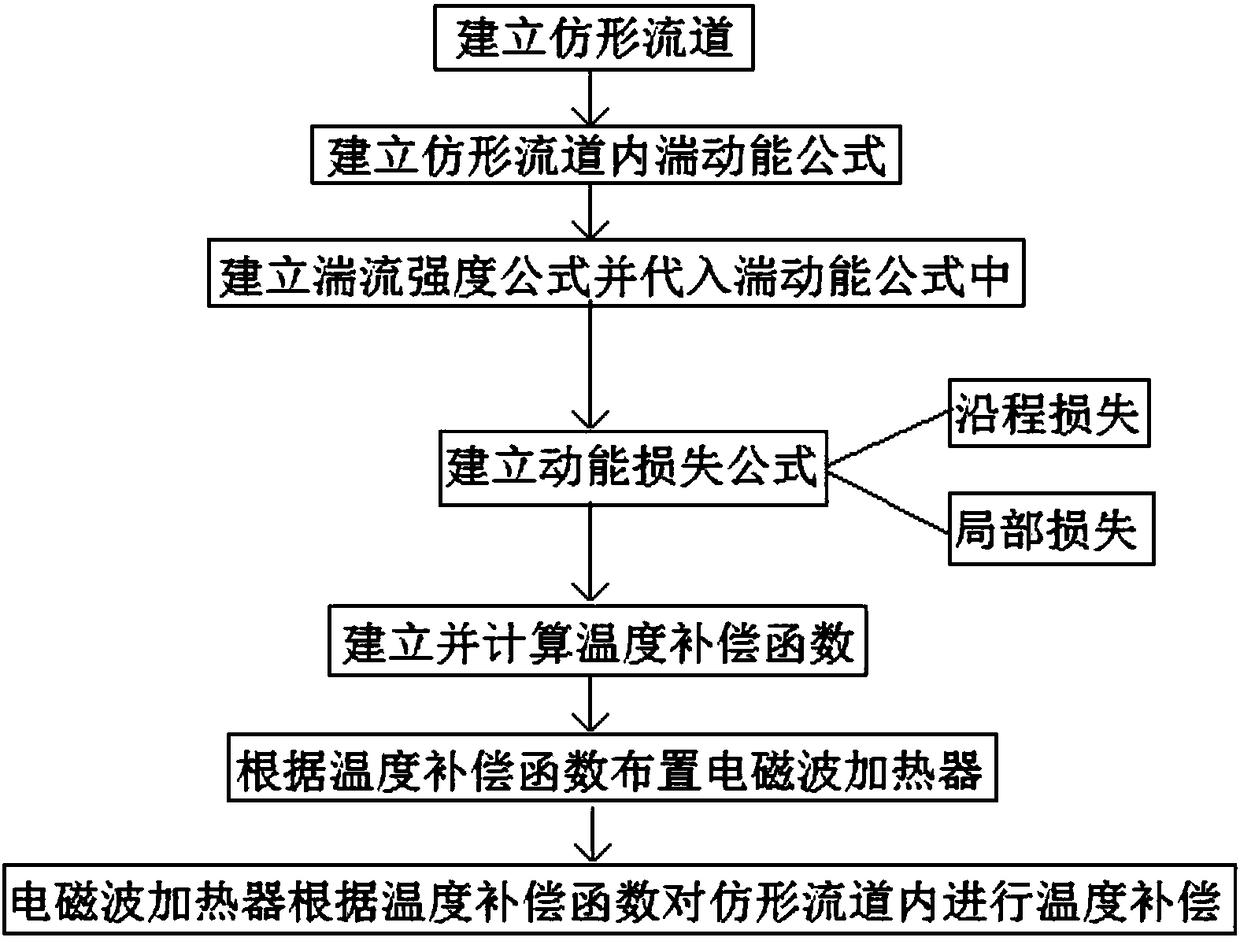

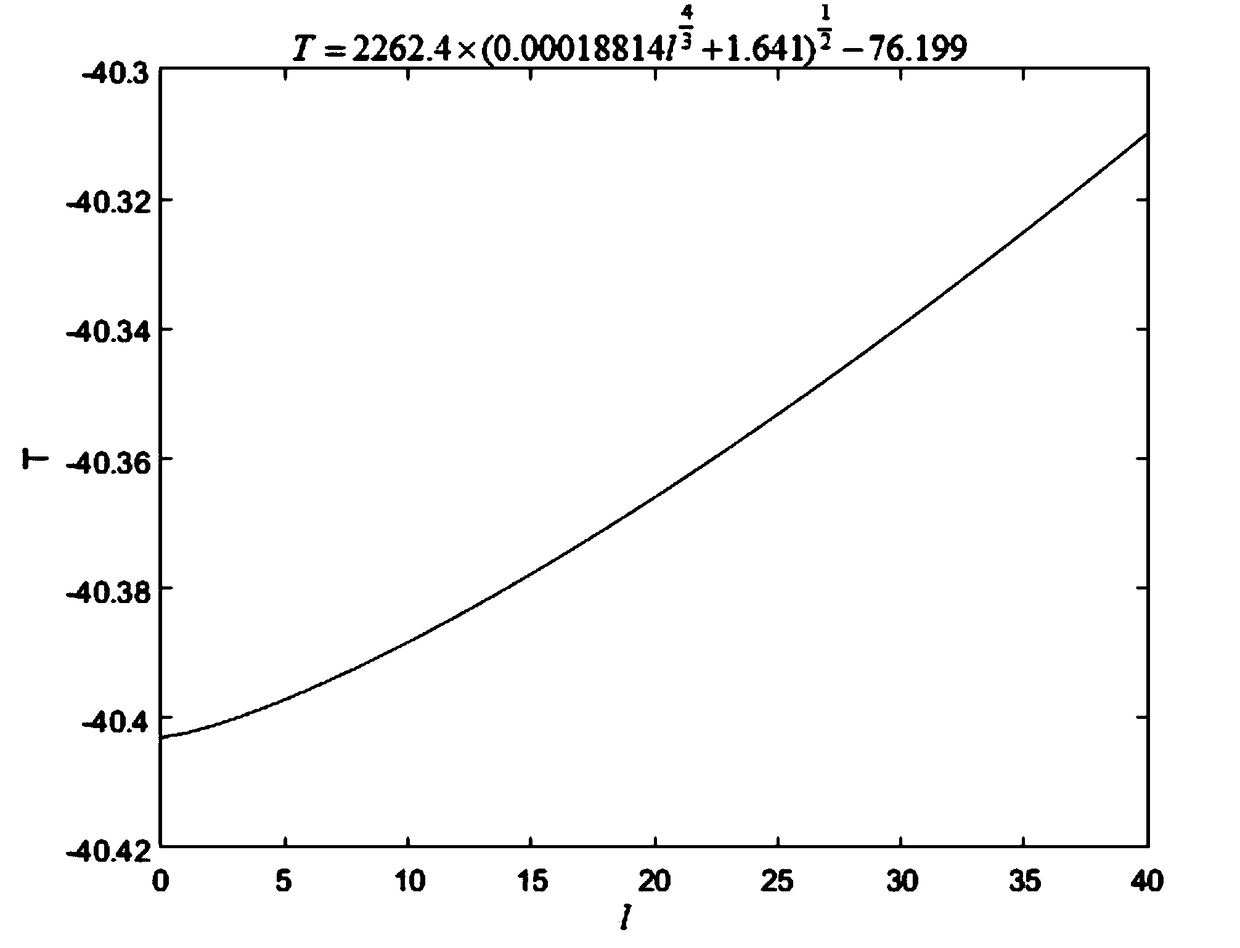

Method for heating abrasive flow in turbulent flow processing of similar-artificial joint

ActiveCN106425875ASimple structureEasy to produceAbrasive machine appurtenancesSpecial data processing applicationsArtificial jointsLinear loss

The invention discloses a method for heating abrasive flow in turbulent flow processing of a similar-artificial joint. The method comprises the following steps: (1) establishing a profiling flow channel; (2) establishing a simulating model of the abrasive flow; (3) calculating a temperature compensation curve required for the profiling flow channel on the basis of tubulence energy of the abrasive flow and linear loss and local loss of the tubulence energy; (4) obtaining a temperature curve in the flow channel of the abrasive flow on the basis of the simulating model; (5) calculating a heating temperature curve; (6) equally dividing the profiling flow channel into N sections, wherein N ranges from 10 to 30; (7) mounting N electromagnetic wave heating sources on a side surface of the profiling flow channel; and (8) adjusting the working efficiency corresponding to each electromagnetic wave heating source 3 according to the heating temperature curve in the step (5). The fluid simulating model is established to obtain the heating temperature curve, temperature change of the abrasive flow in the profiling flow channel is visually reflected in real time, the electromagnetic heating sources are accurately controlled by the heating temperature curve, and therefore, uniformity of processing is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

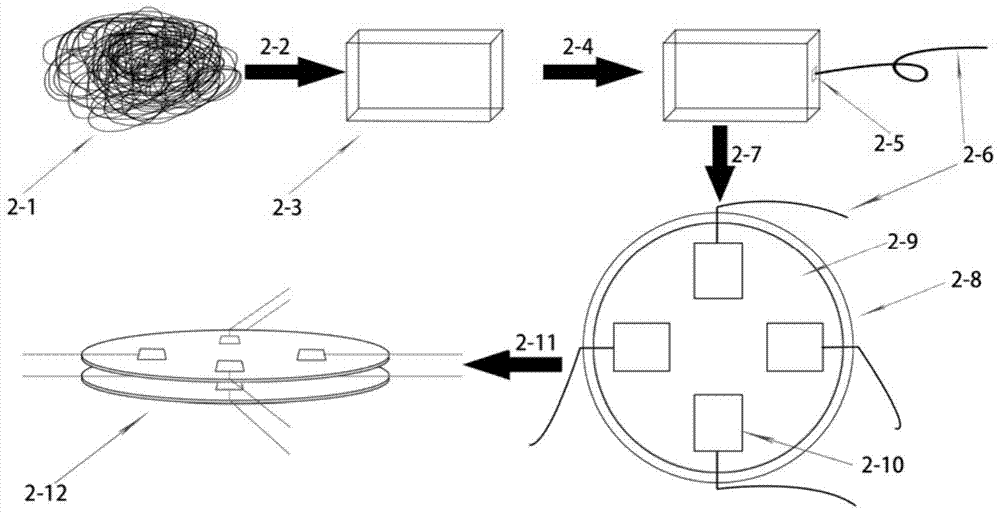

A kind of curly keyboard preparation method

ActiveCN103902052BSimple structureThin structureInput/output for user-computer interactionMicrocontrollerFiber

The invention discloses a method for preparing a curly keyboard. Firstly, carbon fiber is carbonized at high temperature, connected with an electrode, put into a plastic mold of any shape, then poured into a PDMS or PDVF base solution, debubbled and solidified in a vacuum, and connected with a single-chip microcomputer as the core. keying circuit. The invention utilizes the excellent elastic characteristics and electrical conductivity of the elastic conductor to produce a keyboard with a simple structure, light and thin, no mechanical loading device, the keyboard base material is transparent, can be twisted arbitrarily, and has excellent waterproof, fireproof, high temperature resistance, etc., surpassing the traditional keyboard. characteristics, so that it can be used in aerospace, marine exploration and other fields.

Owner:UNIV OF SCI & TECH OF CHINA

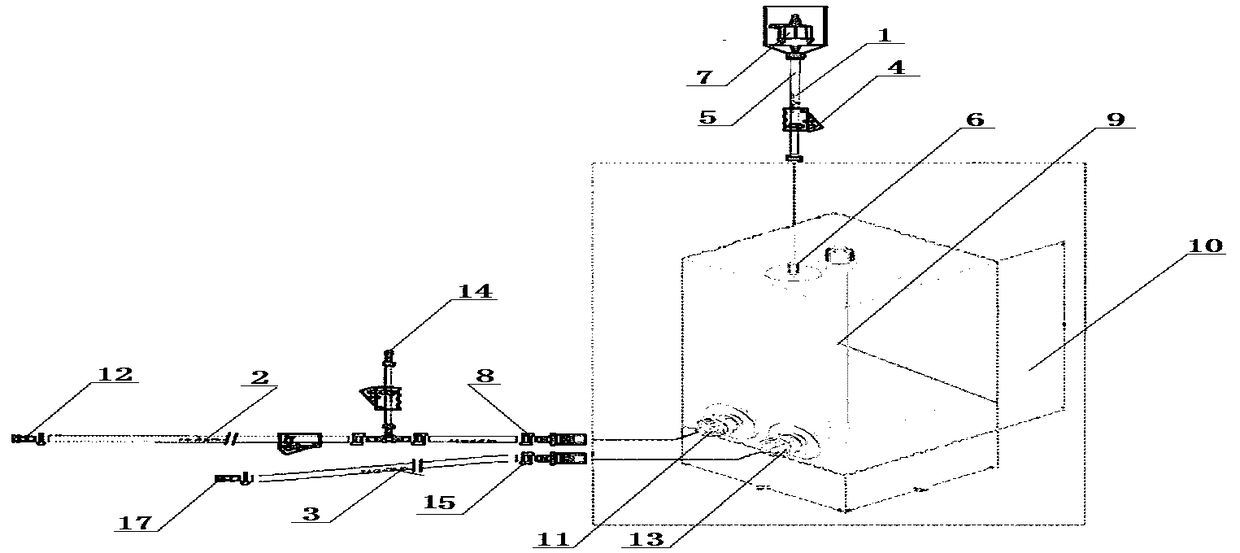

A temperature -controlled grinding granular flow of arthric joint surface turbulence machining device and method

ActiveCN106363537BHigh polishing precisionHigh viscosityAbrasive machine appurtenancesAbrasive blasting machinesParticle flowTemperature control

The invention discloses a temperature-control abrasive particle flow humanoid artificial joint part curved surface turbulent machining device and method. The temperature-control abrasive particle flow humanoid artificial joint part curved surface turbulent machining device comprises a glass constraint component, an infrared window, a computer, an infrared temperature detector, an electromagnetic wave heating matrix, a stirrer, a gas membrane pump, a supporting frame and an electromagnetic wave controller, wherein a uniform-thickness profile flow channel is formed between the inner surface of the glass constraint component and the curved surface of a humanoid artificial joint part; the inlet of the profile flow channel is connected with the gas membrane pump, the stirrer and the outlet of the profile flow channel sequentially through a pipeline; the profile flow channel is exposed to the infrared temperature detector through the infrared window; and the electromagnetic wave heating matrix is mounted on the other side of the glass constraint component. The temperature-control abrasive particle flow humanoid artificial joint part curved surface turbulent machining device disclosed by the invention has the advantages that through arrangement of the electromagnetic wave heating matrix on one side of the glass constraint component, the turbulent energy and velocity of an abrasive particle flow cutting fluid are increased, so that the entire machining effect can be improved, the temperature of abrasive particle flow during an entire machining process can be kept constant, and the surface machining quality of the humanoid artificial joint part can be more uniform.

Owner:ZHEJIANG UNIV OF TECH

An electrochemical reactor for the electrochemical reduction of carbon dioxide

ActiveCN111575726BLow costUniform structureCellsVacuum evaporation coatingElectrochemical responseElectrolytic agent

The invention provides an electrochemical reactor for the electrochemical reduction of carbon dioxide, the device belongs to a three-chamber reactor, and three diaphragms are separated by two kinds of diaphragms (i.e., an anion-conducting polymer film and a polypropylene film gas diffusion electrode). It is made of transparent plexiglass plate with precision-sized grooves and openings; the three-chamber reactor includes: a gas chamber, a catholyte chamber and an anolyte chamber. The gas chamber includes one side of the polypropylene film gas diffusion electrode polypropylene film, and the catholyte chamber includes one side of the polypropylene film gas diffusion electrode catalyst layer with a silver-based catalyst as the cathode, and the anolyte chamber includes Anode with mixed metal oxide catalyst. The electrochemical reaction device of the present invention adopts organic glass with transparent material, high hardness, alkali resistance and acid resistance as a whole, which is easy for precise processing and assembly, convenient for direct monitoring and observation of electrochemical reaction, and no secondary pollution during the reaction test .

Owner:SHANGHAI TECH UNIV

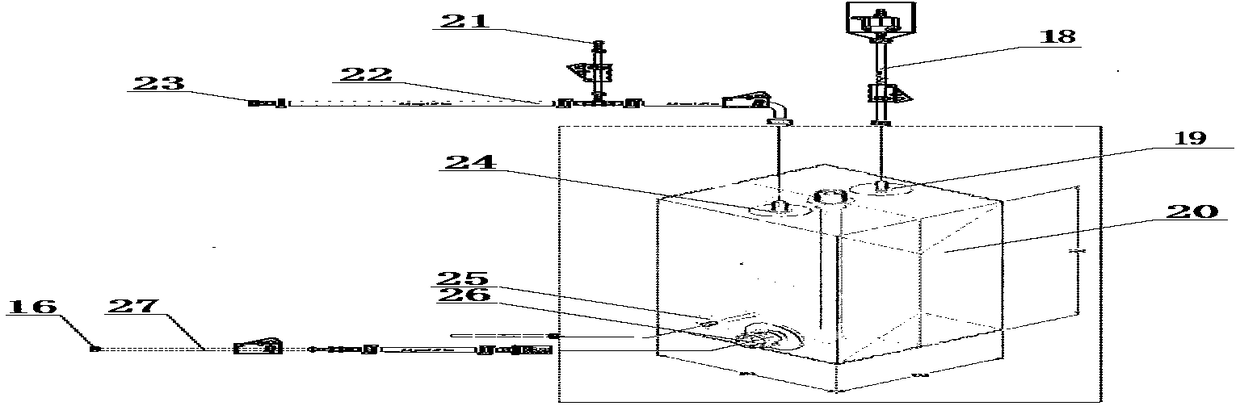

Temperature control device of pseudo artificial joint part abrasive flow turbulence polishing equipment temperature control device and method thereof

ActiveCN106625278AHigh polishing precisionUniform processing qualityTemperature control using electric meansAbrasive machine appurtenancesEquipment temperatureTemperature control

The invention discloses a temperature control device of pseudo artificial joint part abrasive flow turbulence polishing equipment temperature control device and a method thereof. The temperature control device comprises a glass constraint component, a temperature detection device, a three-freedom-degree moving device, an electromagnetic wave heater, a support frame, a gas membrane pump, a stirring device and an electromagnetic wave controller; the inner surface of the glass constraint component and the curve surface of the pseudo artificial joint part form a profiling flow passage with the uniform thickness; the profiling flow passage, the gas membrane pump and the stirrer form an abrasive flow circulation system through a pipeline; the temperature detection device is right aligned with the profiling flow passage; the three-freedom-degree moving device drives the electromagnetic wave heater to freely move in the three-dimensional space above the glass constraint component. Through the electromagnetic wave heater capable of moving along the three-freedom degree moving device which is arranged on the glass constraint component and is used for heating any position in the profiling flow passage; the turbulence kinetic energy and the speed of the abrasive flow cutting fluid in the corresponding heating position are respectively increased and accelerated, so that the integral processing effect is improved; the surface processing quality of the pseudo artificial joint part is more uniform.

Owner:ZHEJIANG UNIV OF TECH

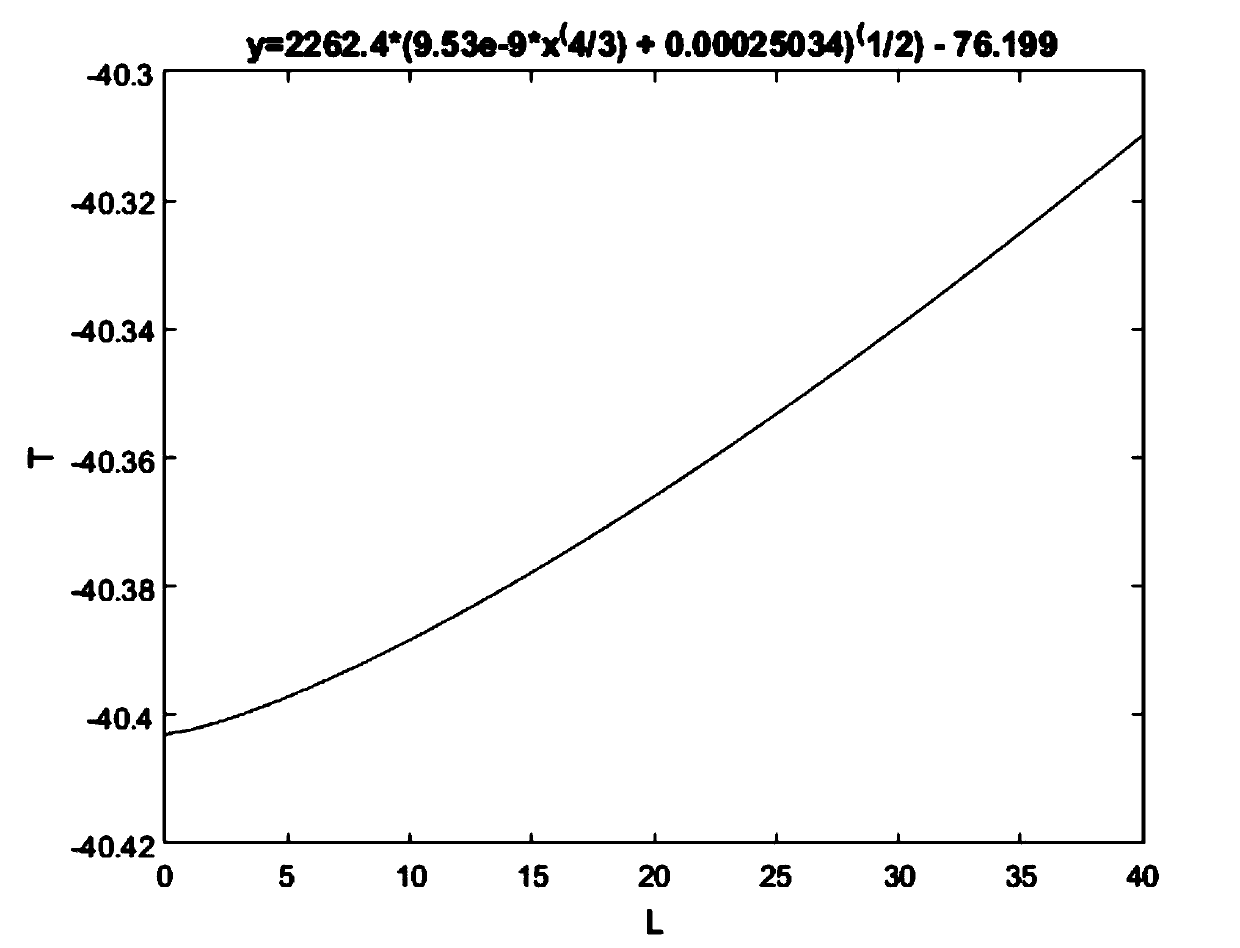

Temperature compensation method for machined workpiece in turbulent flow machining process of artificial joint piece

ActiveCN106553129ASimple structureEasy to produceAbrasive machine appurtenancesAbrasive blasting machinesArtificial jointsAbrasive flow machining

The invention discloses a temperature compensation method for a machined workpiece in the turbulent flow machining process of an artificial joint piece. The method includes the following steps that (1) an artificial joint abrasive flow machining profiling flow channel is established; (2) the turbulence energy function of abrasive flow in the profiling flow channel is established; (3) the kinetic energy loss formula of the abrasive flow is established; (4) the relational expression of the temperature and machining path is established; (5) profiling electromagnetic wave heaters are arranged; and (6) after the whole device works stably, all the positions in the profiling flow channel are subjected to temperature compensation by independently adjusting a heating source of each profiling electromagnetic wave heater, and the abrasive flow is used for continuously machining the artificial joint piece till the complete machining process is completed. By means of the temperature compensation method, the temperature compensation function is established, temperature variation of the abrasive flow in the profiling flow channel is visually reflected in real time by establishing the temperature compensation function, and therefore temperature compensation of all the positions in the profiling flow channel is facilitated, the heating sources of the electromagnetic wave heaters can be accurately controlled conveniently, and homogeneity in the machining process is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

Chitosan material and preparation method thereof

The invention discloses a chitosan material and a preparation method thereof. The chitosan material is mainly composed of chitosan hydrogel, and has extremely high water absorbability. The chitosan material is prepared from a cheap and easily available chitosan reactant through a radiation cross-linking technology. The preparation method has the advantages of simple process, suitableness for industrial mass production, low cost, and basically no environmental protection.

Owner:NANJING YIHE CULTURE CREATIVE CO LTD

Hydroponics of woody plants

ActiveCN103891589BGrow vigorouslyGrow neatlyCultivating equipmentsSoilless cultivationFiberWoody plant

The invention relates to the field of plant cultivating, and particularly discloses a water culture method of a woody plant. The water culture method of the woody plant comprises the following steps of cleaning, root pruning, disinfecting, water controlling, primary root promoting, field planting, secondary root promoting and conservation. According to the water culture method, growth conditions of the woody plant are fully considered, twice root promoting is conducted on the woody plant, and therefore less damage is caused to root fibers of the plant, and the survival rate of the woody plant is increased effectively. According to the water culture method, the woody plant has access to the market by being used as an ornamental plant bonsai in a water culture mode, and the situations that during soil culture, fertilization is conducted frequently, and the environment is affected because bacteria and peculiar smell are produced during soil replacement and watering are avoided. The woody plant cultured with the water culture method grows robustly and trimly, has deep green leaf colors and is bright in color, more large flowers are produced, the flowering period is long, and the ornamental effect and artistic value of the bonsai are greatly improved.

Owner:黄山市徽州区花之韵花卉科技有限公司

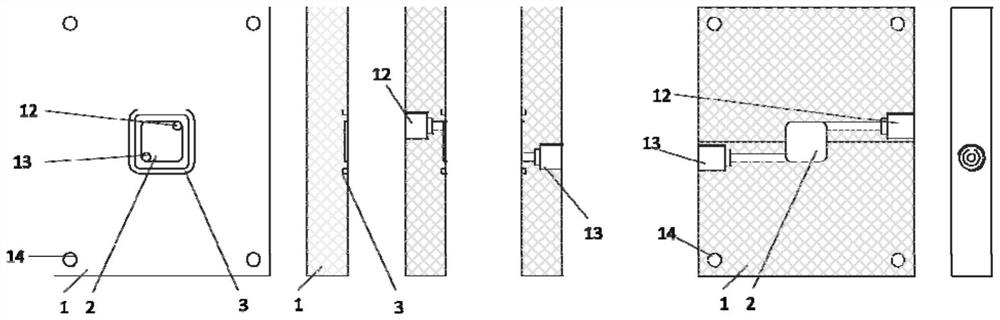

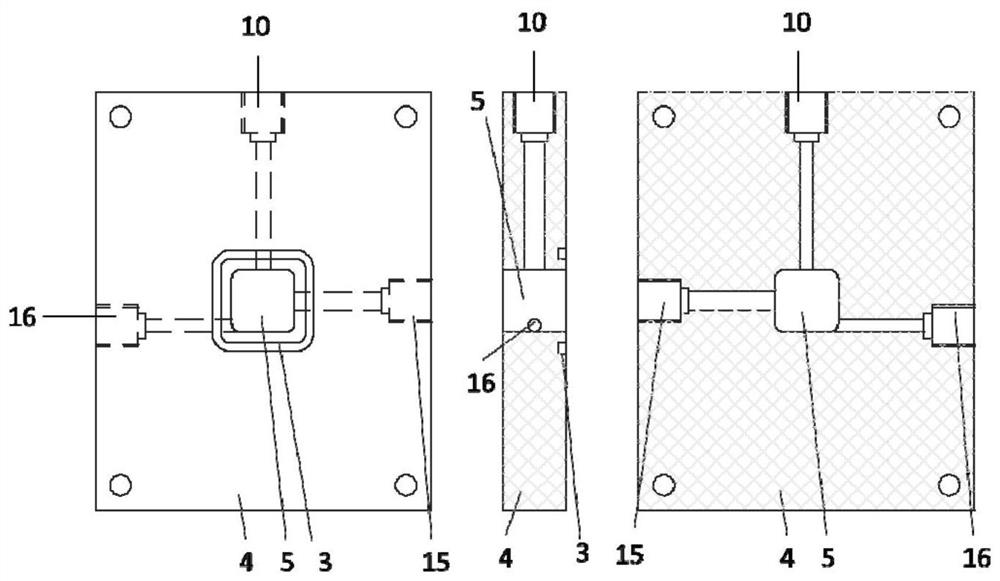

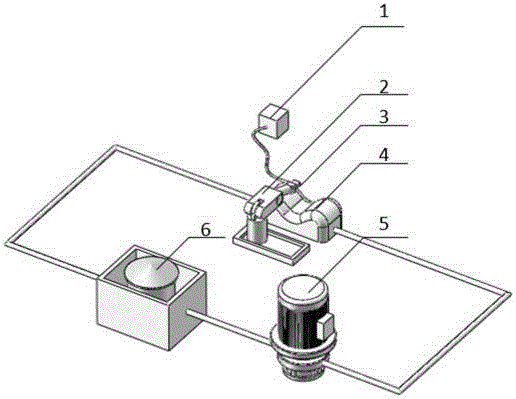

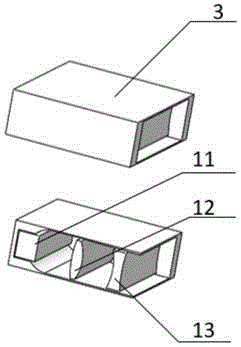

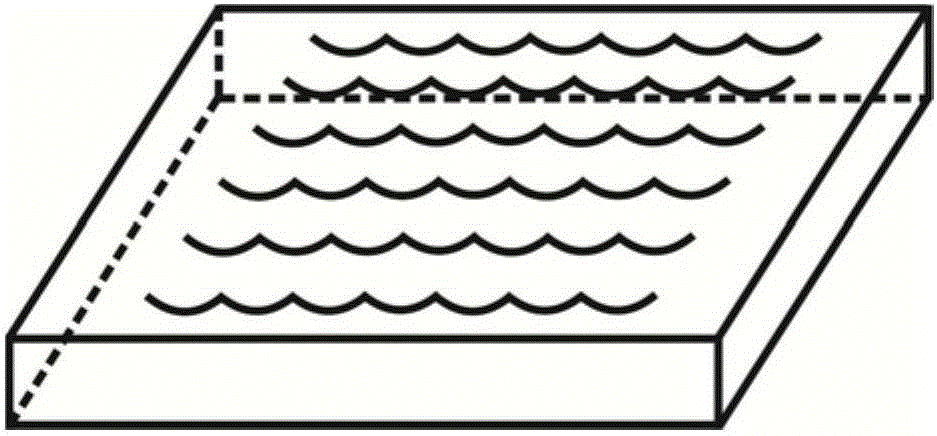

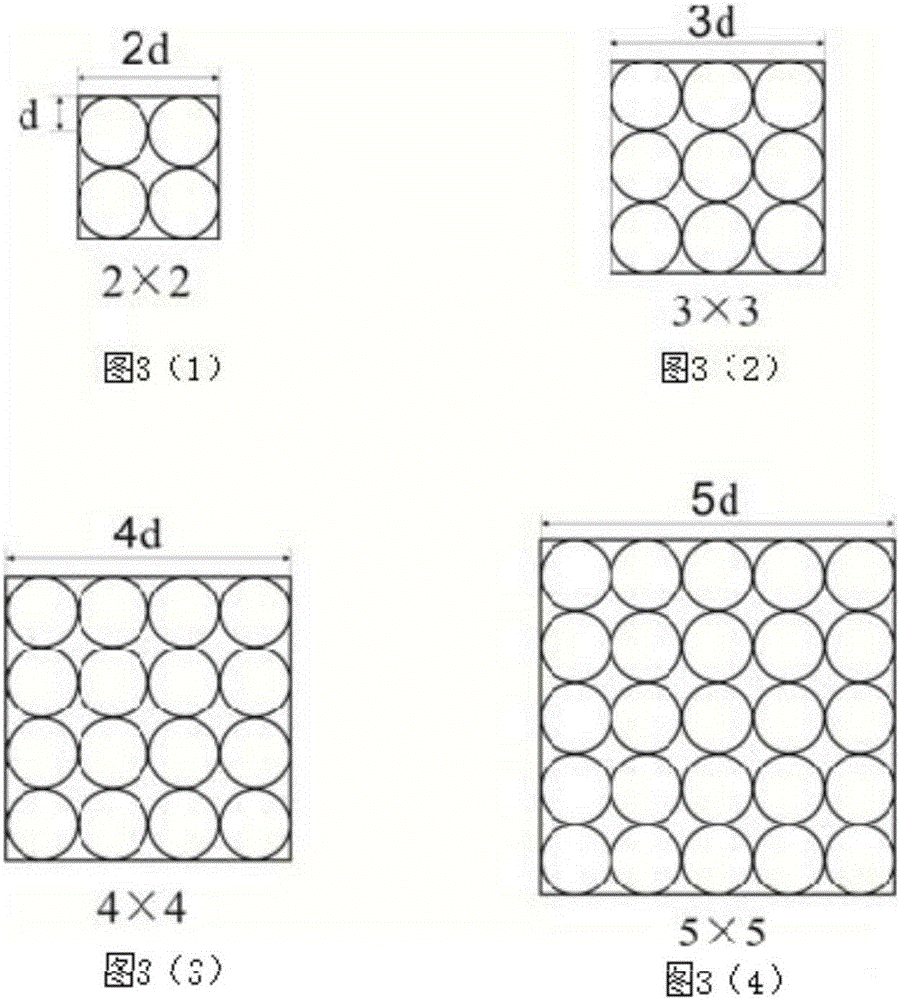

Percolation experiment method and die in pore medium

InactiveCN105225583AEliminate the effects ofMaterial transparentEducational modelsMechanical engineeringMechanics

The invention relates to a percolation experiment method and a die in a pore medium, which are used for solving the basic equation parameters of pore medium percolation by utilizing a cuboid tube filled with cubic units formed by adhering N*N*N equal-particle-size spherulites. By using the percolation experiment method and the die in a pore medium, disclosed by the invention, the influence of additional resistance caused by tube wall to an experiment is small and even can be neglected, so that a typical unit model capable of reflecting the percolation resistance characteristics of a pore medium model in cubic arrangement can be obtained, and the influence of the resistance of the tube wall to the experiment result can be eliminated.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Evaluation device and evaluation method for dynamic demulsification and dehydration characteristics of crude oil emulsion

The invention discloses a device and method for evaluating dynamic demulsification and dehydration characteristics of a crude oil emulsion. The device comprises an emulsion feeding tank, electric heating devices, a high-speed shearing dispersion machine, an emulsion metering pump, a thermometer, a demulsification box, an emulsion recovery tank, a demulsifier feeding tank, a medicament feeding pump, a high-voltage power supply and an oscilloscope, wherein the emulsion feeding tank and the emulsion recovery tank are connected with an inlet of the emulsion metering pump through a three-way valve; an outlet of the emulsion metering pump is connected with an inlet of the demulsification box; an outlet of the demulsification box is connected with the emulsion feeding tank and the emulsion recovery tank through a three-way valve; a front sampling port and a rear sampling port are formed in an inlet pipeline and an outlet pipeline of the demulsification box respectively; the high-voltage power supply and the oscilloscope are sequentially connected to apply a high-voltage electric field to the demulsification box, and the demulsifier feeding tank and the medicament feeding pump are arranged on the inlet pipeline, in front of the front sampling port, of the demulsification box. The structure is compact, few crude oil emulsions are consumed, continuous flowing is realized, observation is convenient due to the fact that a box body of the demulsification box is made of a transparent material, and the device and the method can be used for quickly evaluating the dynamic demulsification and dehydration characteristics of the crude oil emulsion in a laboratory or a project site.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

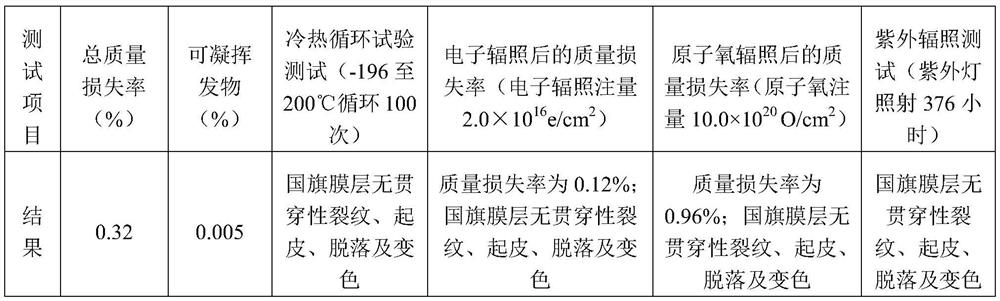

A kind of preparation method of red flag mark for deep space probe

ActiveCN111073499BReduce degradationDoes not affect colorFlags/bannersCoatingsCrazingElectron radiation

Owner:HARBIN INST OF TECH

A segmented heating type artificial joint-like turbulent precision machining device and method thereof

ActiveCN106425876BHigh polishing precisionUniform processing qualityAbrasive machine appurtenancesAbrasive blasting machinesArtificial jointsWear particle

Owner:ZHEJIANG UNIV OF TECH

Glue film solar cell packaging method

InactiveCN104022177AReduced agglomeration quenchingReduce interactionFinal product manufacturePhotovoltaic energy generationPhotovoltaic industryHigh energy

The invention discloses a glue film solar cell packaging method; a sun concentrator is employed to convert high energy sunlight responding to no silicon cell into spectrum responding to the silicon cell, thereby promoting photovoltaic industry development in our country; an excellent base hot melt glue film is developed through molecule system design, screening and preparation of nanometer rare earth transition material, and research of surface modification and optical performance; the method can improve processing technology performance of the glue film solar cell packaging material, improves service life of the solar cell, reduces usage cost, and satisfy solar cell packaging needs in our country.

Owner:王也

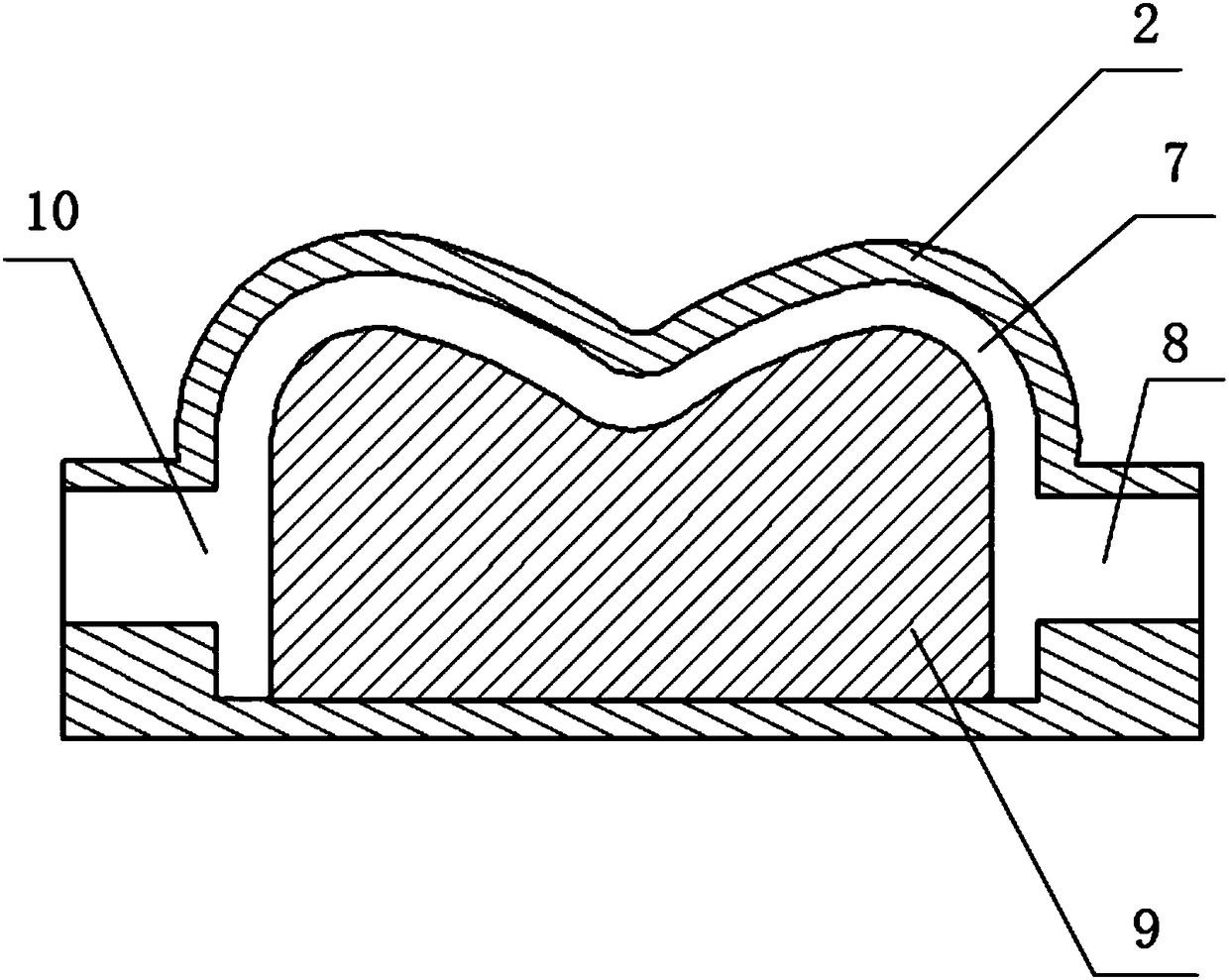

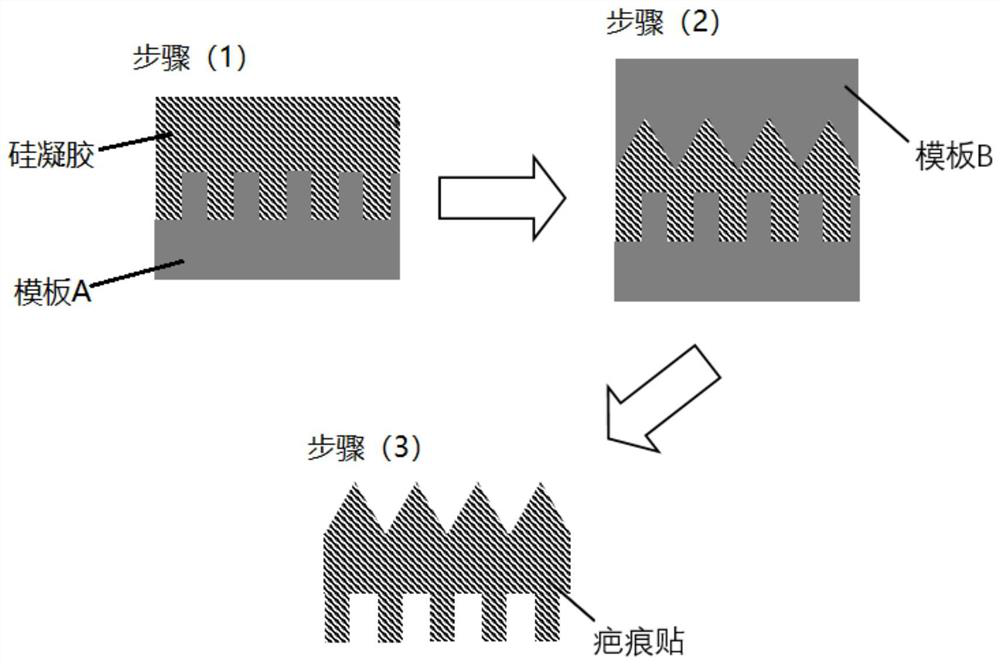

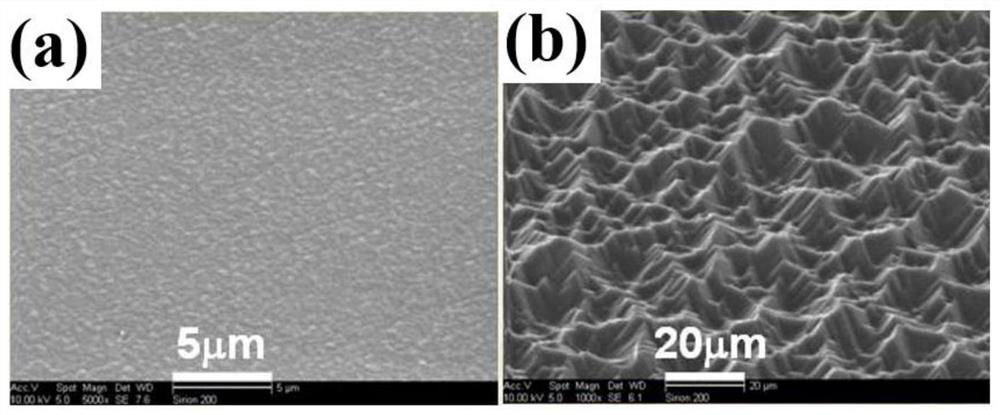

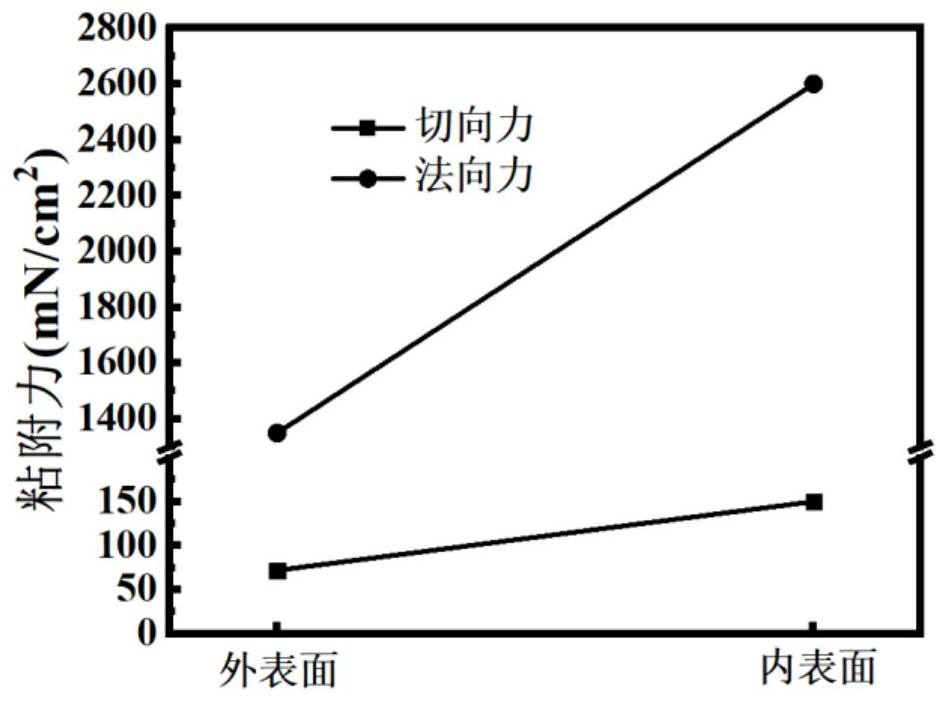

Viscosity-adjustable silica gel scar patch and preparation method thereof

InactiveCN113332231AViscosity high precision controlSimple methodAerosol deliveryOintment deliverySilicone GelsSilica gel

The invention discloses a viscosity-adjustable silica gel scar patch and a preparation method thereof, and belongs to the technical field of medical cosmetology, and the preparation method of the viscosity-adjustable silica gel scar patch comprises the following steps: step (1) preparing semi-cured silica gel; step (2) preparing a silica gel film with two side surfaces having different viscosities; and step (3) preparing the silica gel scar patch. In order to solve the technical problem that the viscosity difference of the inner surface and the outer surface of silica gel is difficult to coordinate in the prior art, the viscosity of the silica gel scar patch is controlled by regulating micro-nano bulges on the surface of the silica gel scar patch, so that the viscosity difference of the inner surface and the outer surface of the silica gel is controlled; the control method is that: transferring micro-nano-level structures on different surfaces of the template A and the template B to the inner surface and the outer surface of the silica gel; no solution participates in the transfer printing process, no residual silica gel treatment process exists, the operation is easy and fast, and the cost-effectiveness is high.

Owner:安徽猛犸数据科技有限公司

A method for raising the temperature of abrasive particle flow in turbulent flow machining of similar artificial joints

ActiveCN106425875BSimple structureEasy to produceAbrasive machine appurtenancesAbrasive blasting machinesLinear lossArtificial joints

The invention discloses a method for heating abrasive flow in turbulent flow processing of a similar-artificial joint. The method comprises the following steps: (1) establishing a profiling flow channel; (2) establishing a simulating model of the abrasive flow; (3) calculating a temperature compensation curve required for the profiling flow channel on the basis of tubulence energy of the abrasive flow and linear loss and local loss of the tubulence energy; (4) obtaining a temperature curve in the flow channel of the abrasive flow on the basis of the simulating model; (5) calculating a heating temperature curve; (6) equally dividing the profiling flow channel into N sections, wherein N ranges from 10 to 30; (7) mounting N electromagnetic wave heating sources on a side surface of the profiling flow channel; and (8) adjusting the working efficiency corresponding to each electromagnetic wave heating source 3 according to the heating temperature curve in the step (5). The fluid simulating model is established to obtain the heating temperature curve, temperature change of the abrasive flow in the profiling flow channel is visually reflected in real time, the electromagnetic heating sources are accurately controlled by the heating temperature curve, and therefore, uniformity of processing is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

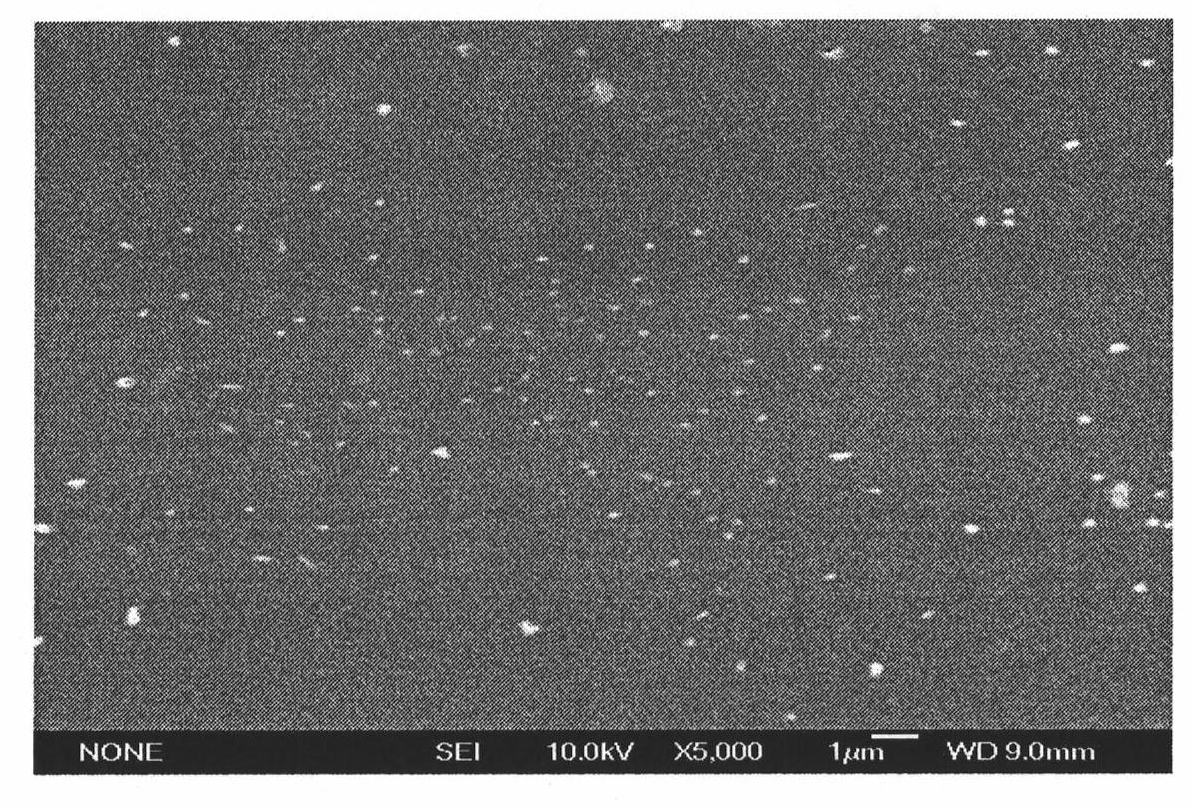

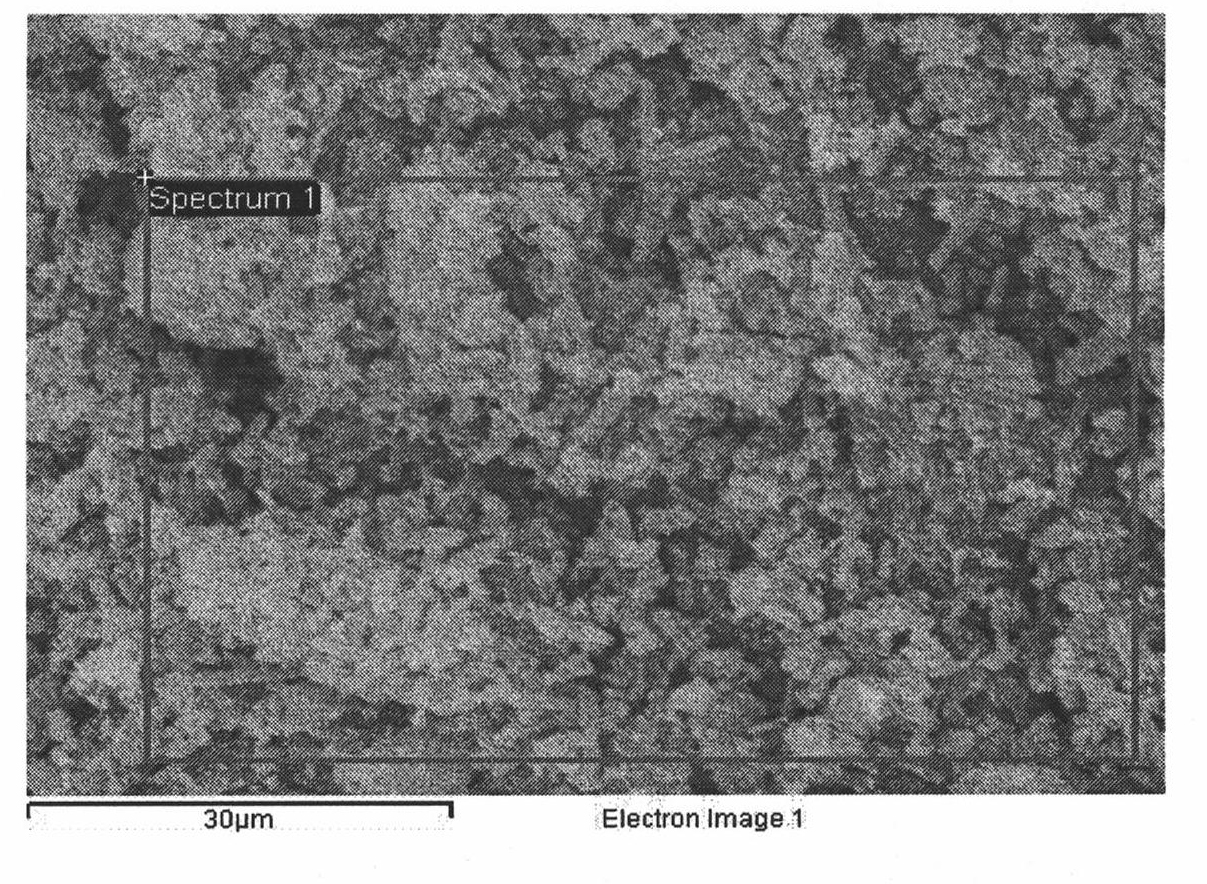

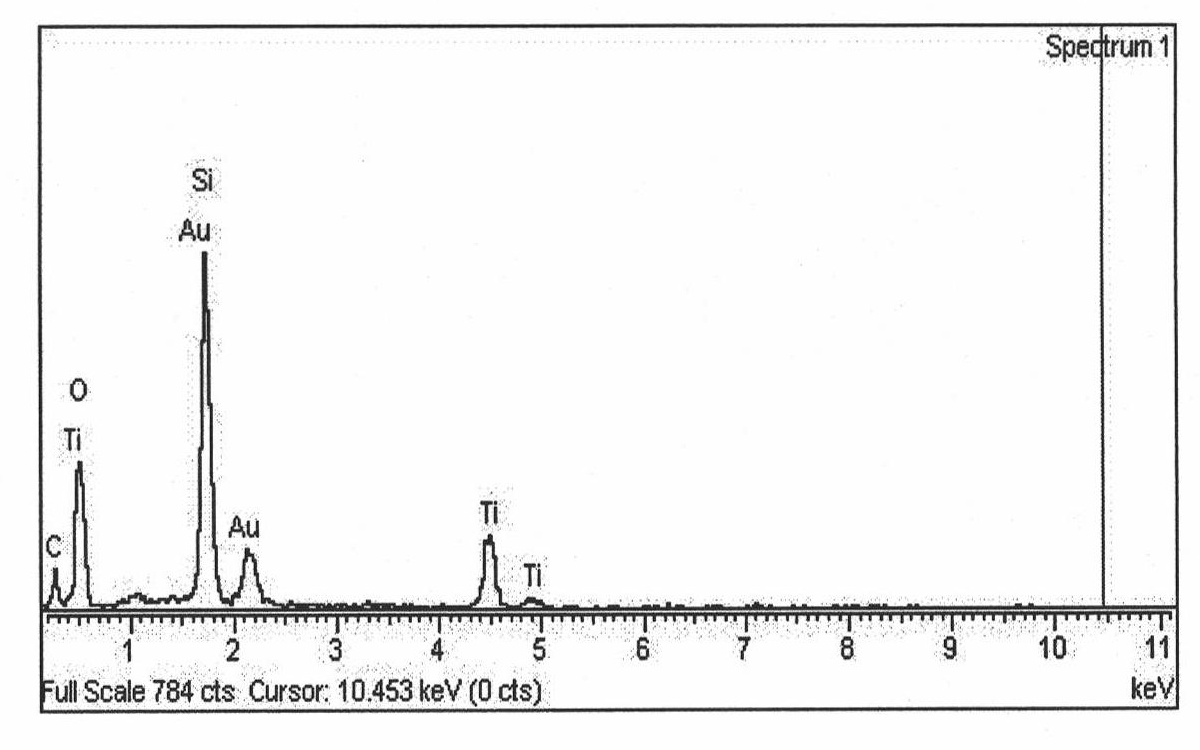

Method for manufacturing glass for vehicle windows by applying polycarbonate-polystyrene blend alloy

ActiveCN101537781BImprove mechanical propertiesExcellent dielectric propertiesWindowsWindscreensMulti materialInorganic particle

The invention relates to a method for manufacturing glass for vehicle windows by applying polycarbonate-polystyrene blend alloy. The method comprises the following steps: the PC, the PS and the SiO2 are clad to obtain a high polymer, then the TiO2 is clad with the SiO2 to obtain inorganic particles, then the high polymer is fused with the inorganic particles to obtain polycarbonate-polystyrene blend alloy by injection molding, and the polycarbonate-polystyrene blend alloy is applied to manufacturing the glass for vehicle windows and has better ultraviolet resistance, wear resistance and weatherability. The invention is simple and convenient in process, is easy for operational realization and short in period and enables the PC plastic glass for the vehicle windows to be possible in multi-material combination, multi-fitting compounding, multi-color combination and light weighting.

Owner:TAIYUAN UNIV OF TECH

Hydroponics for herbs

ActiveCN103891590BGrow vigorouslyGrow neatlyCultivating equipmentsSoilless cultivationNutrient solutionObserved Survival

The invention relates to the field of plant culture, and particularly discloses a water culture method for a herbaceous plant. The water culture method includes the following steps of cleaning, root pruning, disinfecting, water controlling, primary root forcing, field planting, secondary root forcing and maintaining. Root forcing of the herbaceous plant is performed in twice, in this way, root fibers of the herbaceous plant are damaged little, the water culture survival rate of the herbaceous plant is effectively improved, meanwhile, the herbaceous plant sends forth an aquatic root system through culture and thereby survives easily, the defect that in the prior art, water culture of the plant completely depends on a nutrient solution is overcome, after sending forth the aquatic root system, the herbaceous plant can be cultured with common clear water, and therefore the water culture cost of the plant is effectively reduced.

Owner:黄山市徽州区花之韵花卉科技有限公司

Temperature control device and method for abrasive particle flow turbulent flow polishing equipment for similar artificial joints

ActiveCN106625278BHigh polishing precisionUniform processing qualityTemperature control using electric meansAbrasive machine appurtenancesTemperature controlEquipment temperature

Owner:ZHEJIANG UNIV OF TECH

A kind of artificial joint parts abrasive flow turbulent flow polishing variable temperature processing method

ActiveCN106625279BSimple structureEasy to produceDesign optimisation/simulationAbrasive machine appurtenancesLinear lossUltimate tensile strength

The invention discloses a joint prosthesis part abrasive flow turbulence polishing varying-temperature processing method, which comprises the following steps of (1) building a profiling runner; (2) establishing a relational expression of tubulence energy h and turbulence intensity I of an abrasive flow in the profiling runner; (3) establishing a kinetic energy loss formula of the abrasive flow; (4) combining a computational formula of the tubulence energy and a computational formula of linear loss and local loss so as to establish a relation expression of temperature and a processing route; (5) setting multiple electromagnetic wave heating sources along the side face of the profiling runner according to a temperature compensation function T; and (6) carrying out temperature compensation on each position in the profiling runner through independently adjusting each electromagnetic wave heating source. According to the joint prosthesis part abrasive flow turbulence polishing varying-temperature processing method provided by the invention, the temperature variation of the abrasive flow in the profiling runner is intuitively reflected in real time through establishing the temperature compensation function, so that the temperature compensation is carried out conveniently on each position in the profiling runner, the electromagnetic wave heating sources are accurately controlled conveniently, and the homogeneity in a processing process is ensured.

Owner:ZHEJIANG UNIV OF TECH

Temperature Compensation Method of Machining Workpieces During Turbulent Flow Machining of Similar Artificial Joints

ActiveCN106553129BSimple structureEasy to produceAbrasive machine appurtenancesAbrasive blasting machinesArtificial jointsAbrasive flow machining

The invention discloses a temperature compensation method for a machined workpiece in the turbulent flow machining process of an artificial joint piece. The method includes the following steps that (1) an artificial joint abrasive flow machining profiling flow channel is established; (2) the turbulence energy function of abrasive flow in the profiling flow channel is established; (3) the kinetic energy loss formula of the abrasive flow is established; (4) the relational expression of the temperature and machining path is established; (5) profiling electromagnetic wave heaters are arranged; and (6) after the whole device works stably, all the positions in the profiling flow channel are subjected to temperature compensation by independently adjusting a heating source of each profiling electromagnetic wave heater, and the abrasive flow is used for continuously machining the artificial joint piece till the complete machining process is completed. By means of the temperature compensation method, the temperature compensation function is established, temperature variation of the abrasive flow in the profiling flow channel is visually reflected in real time by establishing the temperature compensation function, and therefore temperature compensation of all the positions in the profiling flow channel is facilitated, the heating sources of the electromagnetic wave heaters can be accurately controlled conveniently, and homogeneity in the machining process is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com