Evaluation device and evaluation method for dynamic demulsification and dehydration characteristics of crude oil emulsion

An evaluation device and emulsion technology, applied in the direction of material inspection products, etc., can solve the problems of high consumption of crude oil emulsion, "collapsing electric field, easy blockage of pipelines, etc., and achieve effective testing services, continuous flow of dosage, and easy observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

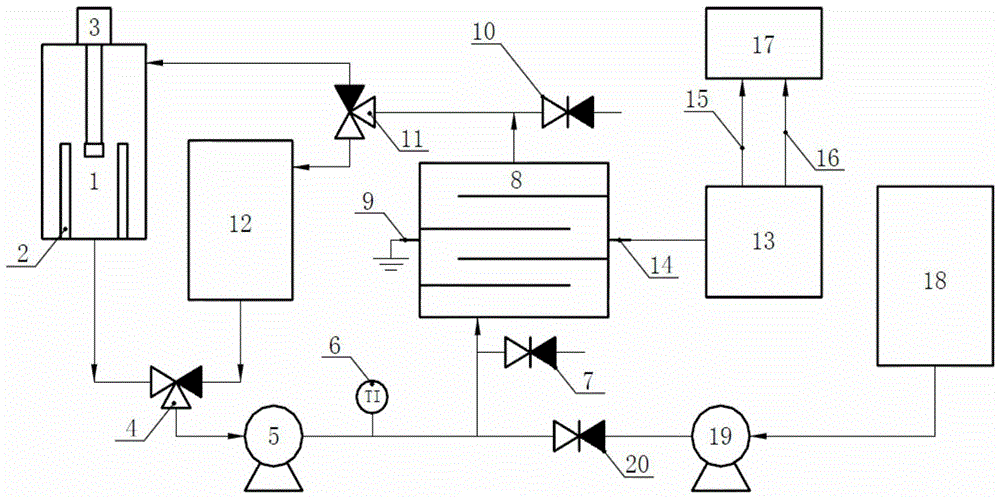

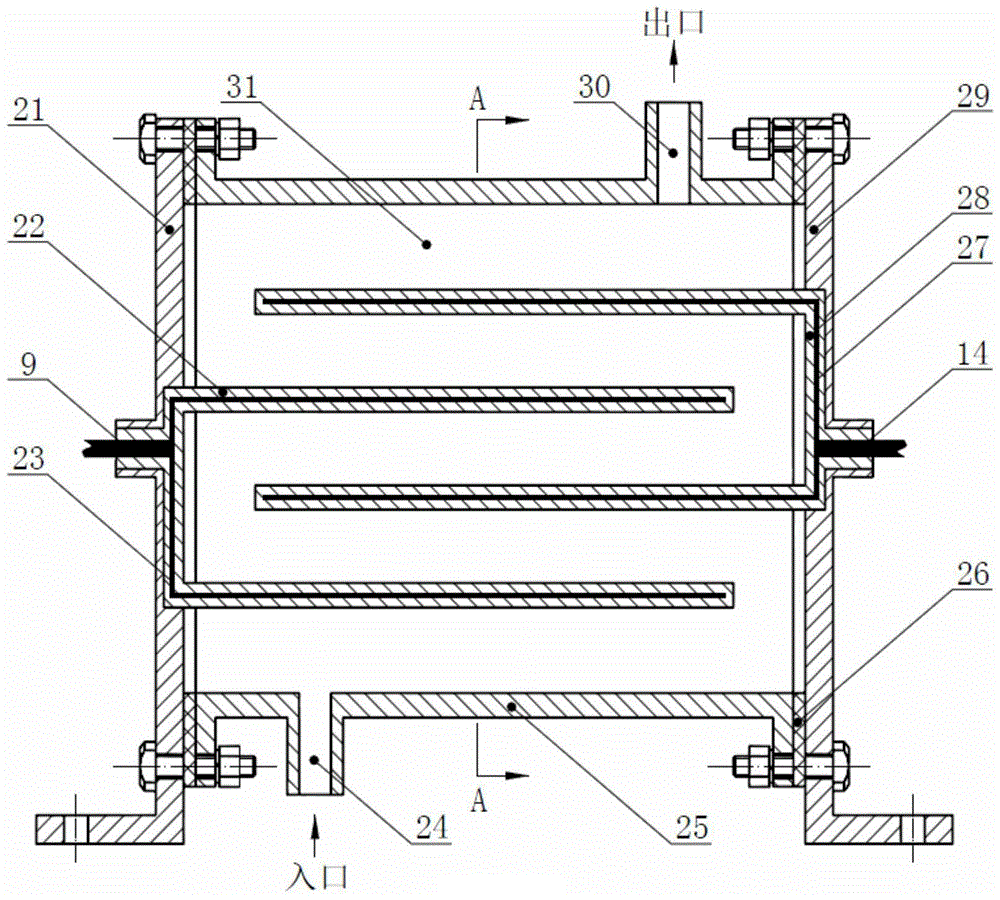

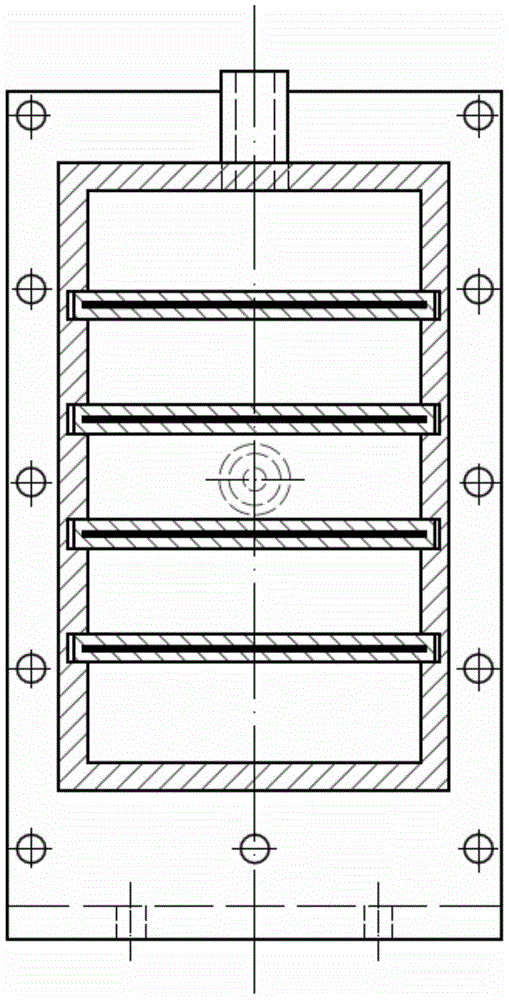

[0028] The preferred embodiment of the device for quickly evaluating the dynamic demulsification and dehydration characteristics of crude oil emulsion of the present invention is:

[0029] Including emulsion supply tank 1, electric heating equipment 2, high-speed shearing disperser 3, emulsion metering pump 5, thermometer 6, demulsification box 8, emulsion recovery tank 12, demulsifier supply tank 18, dosing pump 19. High-voltage power supply (13), oscilloscope (17);

[0030] The emulsion supply tank 1 and the emulsion recovery tank 12 are connected to the inlet of the emulsion metering pump 5 through a three-way valve 4, and the outlet of the emulsion metering pump 5 is connected to the inlet 24 of the demulsifier box. The box outlet 30 is connected to the emulsion supply tank 1 and the emulsion recovery tank 12 through a three-way valve 11;

[0031] The inlet pipeline and the outlet pipeline of the demulsifier box 8 are respectively provided with a front sampling port 7 and a rear...

Embodiment 1

[0057] Such as figure 1 , figure 2 , image 3 As shown, the rapid evaluation device for dynamic demulsification and dehydration characteristics of crude oil emulsion in this embodiment includes: an emulsion supply tank (1), an electric heating device (2), a high-speed shearing disperser (3), and an emulsion metering pump (5). ), thermometer (6), demulsifier box (8), emulsion recovery tank (12), high voltage power supply (13), oscilloscope (17), demulsifier supply tank (18), dosing pump (19), etc. . The emulsion supply tank (1) and the emulsion recovery tank (12) are connected to the inlet of the emulsion metering pump (5) through a three-way valve (4), and the outlet of the emulsion metering pump (5) is connected to the inlet (24) of the demulsifier box ), the outlet (30) of the demulsifier box is connected to the emulsion supply tank (1) and the emulsion recovery tank (12) through the three-way valve (11), and the high-voltage power supply (13) and the oscilloscope (17) are ...

Embodiment 2

[0060] The difference between this embodiment and the first embodiment is: the method of using the rapid evaluation device for the dynamic demulsification and dehydration characteristics of crude oil emulsion, the specific steps are as follows:

[0061] 1. Put the crude oil, water, and emulsifier into the emulsion supply tank (1) according to the proportion, and use the electric heating device (2) to maintain the mixture at the set temperature, and then use the high-speed shearing disperser (3) to The mixed liquid is sheared and stirred to prepare crude oil emulsions with different water content and different degrees of stability.

[0062] 2. After the preparation of the crude oil emulsion is completed, turn on the emulsion metering pump (5) to pump the crude oil emulsion into the demulsification box (8) at a set flow rate. After the crude oil emulsion flows stably in the rapid evaluation device, pass the adjustment The three-way valve (11) returns the crude oil emulsion after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com