Viscosity-adjustable silica gel scar patch and preparation method thereof

A technology of silicone gel and scar sticker, applied in the field of medical beauty, can solve the problems of difficulty in coordination of differences in viscosity, and achieve the effects of preventing adhesion, good viscoelasticity and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

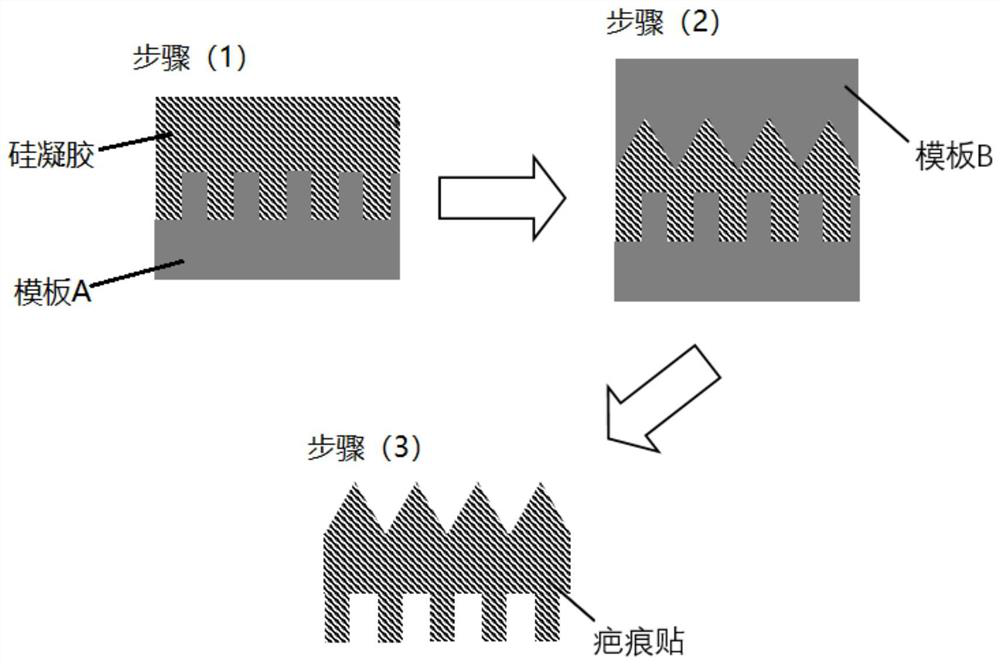

[0033] Such as figure 1 As shown, a preparation method of a silicone gel scar patch with adjustable viscosity comprises the following steps:

[0034] Step (1), preparation of semi-cured silicone gel: evenly coat the silicone gel on the template A, let it stand at room temperature 25°C until the bubbles are completely precipitated, and then heat the template A to half of the silicone gel. solidified state, then stop heating and cool to obtain semi-cured silicone gel;

[0035] Step (2), preparation of silicone gel films with different viscosities on both sides: positively press the template B brushed with a release agent on the semi-cured silicone gel after step (1), heat until it is completely cured, and remove the template A and template B, the reverse structure of the micro-nano array structure prepared on the template can be transferred to the colloidal film to obtain a silicone gel film with different viscosities on both sides;

[0036] Step (3), preparation of silicone g...

Embodiment 2

[0038] Determination of curing time and temperature of silicone gel with fixed ratio:

[0039] Coat the silicone gel evenly mixed according to a certain ratio (polymethylsiloxane: curing agent = 3:1) on the common template, and let it stand at room temperature 25°C for 2 hours until the bubbles are separated and distributed. After uniformity, put the ordinary template on the heating plate and heat it at a temperature of 40°C until the silicone gel is completely cured, and measure the time required for complete curing.

[0040] The measured results showed that the curing time was 8 hours.

Embodiment 3

[0042] Determination of curing time and temperature of silicone gel with fixed ratio:

[0043] Coat the silicone gel evenly mixed according to a certain ratio (polymethylsiloxane: curing agent = 9:1) on the common template, and let it stand at room temperature for 2 hours at 25°C until the bubbles are separated and distributed. After uniformity, put the ordinary template on the heating plate and heat it at a temperature of 100°C until the silicone gel is completely cured, and measure the time required for complete curing.

[0044] The measured results show that the curing time is 30min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com