A kind of curly keyboard preparation method

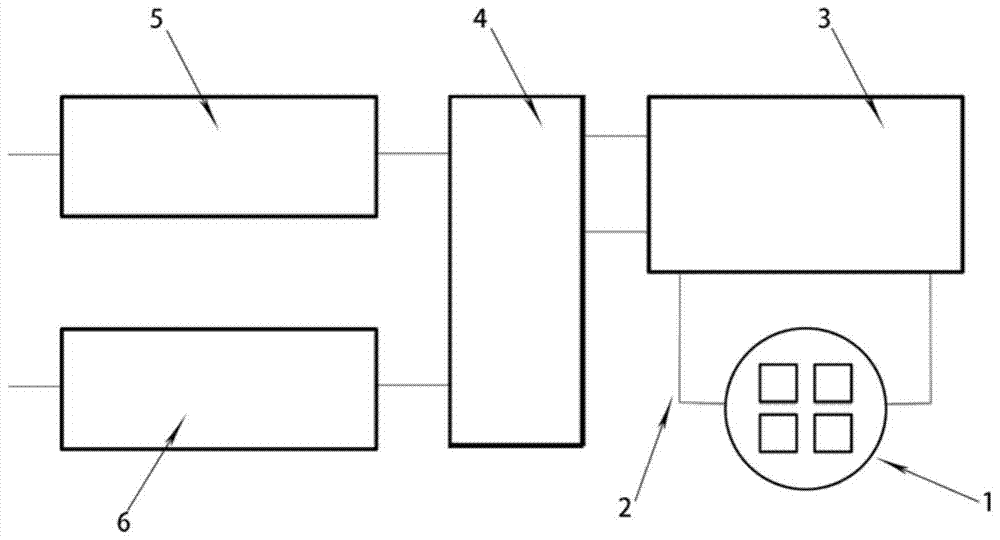

A keyboard and curling technology is applied in the field of curling keyboard preparation, which can solve the problems of high production cost, poor toughness of silica gel, unsuitable keyboard and the like, and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

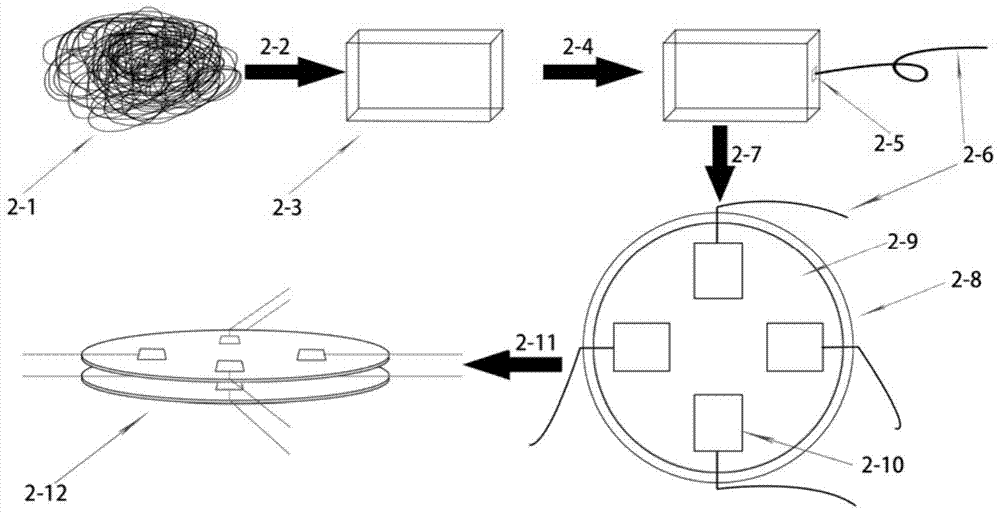

Embodiment 1

[0026] Put the cotton into a tube furnace, pass the protective gas, raise the temperature to 800°C at a rate of 2°C / min, and then perform high-temperature carbonization treatment at 800°C for several hours to obtain a whole piece of carbon fiber, and then carefully cut it with a blade Cut into 4 blocks with uniform thickness and small area difference, remove the insulation of the wire and insert it into the carbon fiber, use a conductive metal gel to make it fully contact with the carbon fiber, and then pour PDMS or PDVF base solution, do not make it submerge the carbon fiber, vacuum debubbles and then cure for 4 hours, then splice the two and a half keyboards together.

Embodiment 2

[0028] Put the vacuum-freeze-dried bacterial cellulose into a tube furnace, raise the temperature to 1000°C at a rate of 5°C / min, and then carry out high-temperature carbonization treatment at 1000°C for 2 hours to obtain a whole piece of carbon fiber, and then use a blade to Carefully cut it into 4 blocks with uniform thickness and small area difference, remove the insulation of the wire and insert it into the carbon fiber, use a conductive metal gel to make it fully contact with the carbon fiber, and then place it on a plastic of any shape The PDMS or PDVF base solution in the mold should not be covered with carbon fiber. After vacuum removal of air bubbles, cure for 3 hours, and then splice the two half-keyboards together.

Embodiment 3

[0030] Waste cotton wool such as clothes or quilts is subjected to high-temperature carbonization treatment at 900°C for 4 hours with protective gas to obtain a whole piece of carbon fiber, and then carefully cut it into 4 pieces with uniform thickness and small area difference with a blade Shape, remove the insulation of the wire and insert it into the carbon fiber, use a conductive metal gel to make it fully contact with the carbon fiber, and then pour PDMS or PDVF base solution into a plastic mold of any shape, do not let it submerge the carbon fiber, vacuum After removing air bubbles, carry out curing treatment for 5 hours, and then splice the two and a half keyboards together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com