Method for manufacturing glass for vehicle windows by applying polycarbonate-polystyrene blend alloy

A technology of polycarbonate and polystyrene, applied to windshields, windows, vehicle parts, etc., to achieve good mechanical strength, good heat insulation performance, and excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

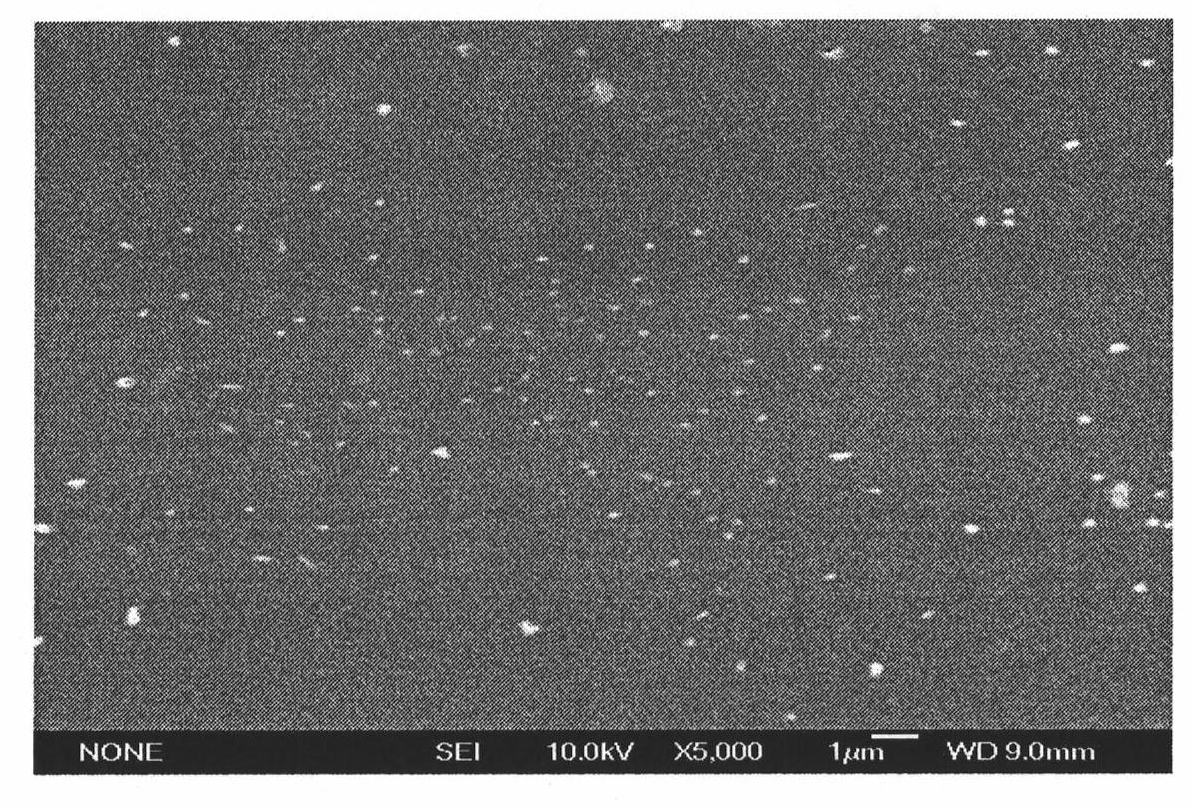

Image

Examples

Embodiment approach 1

[0051] (1) Preparation of polycarbonate PC / polystyrene PS blend

[0052] First, mix PS and PC according to the ratio of 7% by mass, take 0.35g of PS and 5g of PC, and then stir under heating and reflux, dissolve PS and PC in 30ml of tetrahydrofuran, and control the temperature between 45 and 55°C; , add 0.16g of tetraethyl orthosilicate TEOS into the dissolving solution, then stir for 10min, then add dropwise acetone and deionized water mixed solution with a pH value of 2.0 into the dissolving solution, wherein, acetone is 0.196g, deionized water It was 0.06g, and then stirred at reflux for 2h to obtain PC / PS gel. After the gel is matured, the solvent is removed; finally, it is dried at 120°C for 2 hours to obtain PC / PS / SiO 2 nanocomposites;

[0053] In the above steps, since the boiling point of tetrahydrofuran is 65.4°C, if the heating temperature is too high or too low, PC and PS will be dissolved unevenly. Therefore, the temperature between 45-55°C is the best; , when i...

Embodiment approach 2

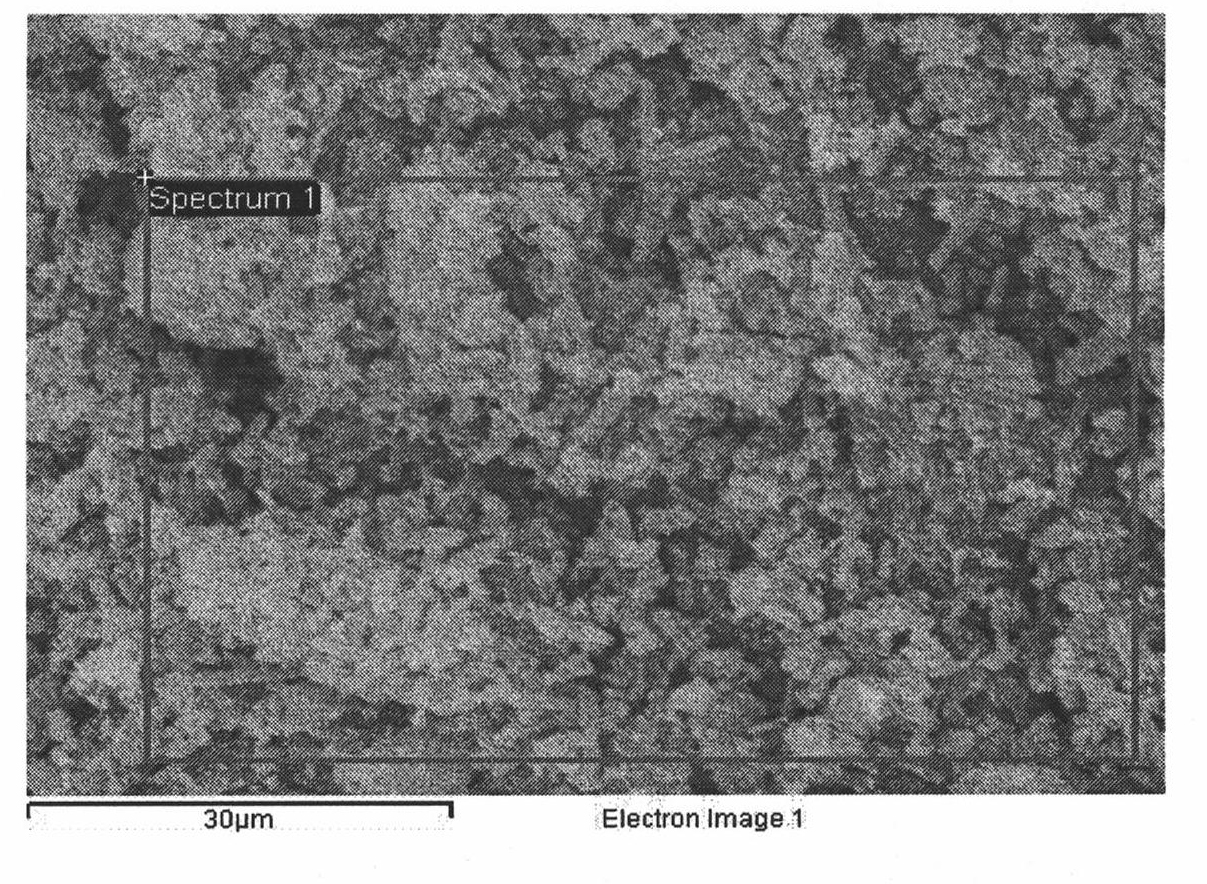

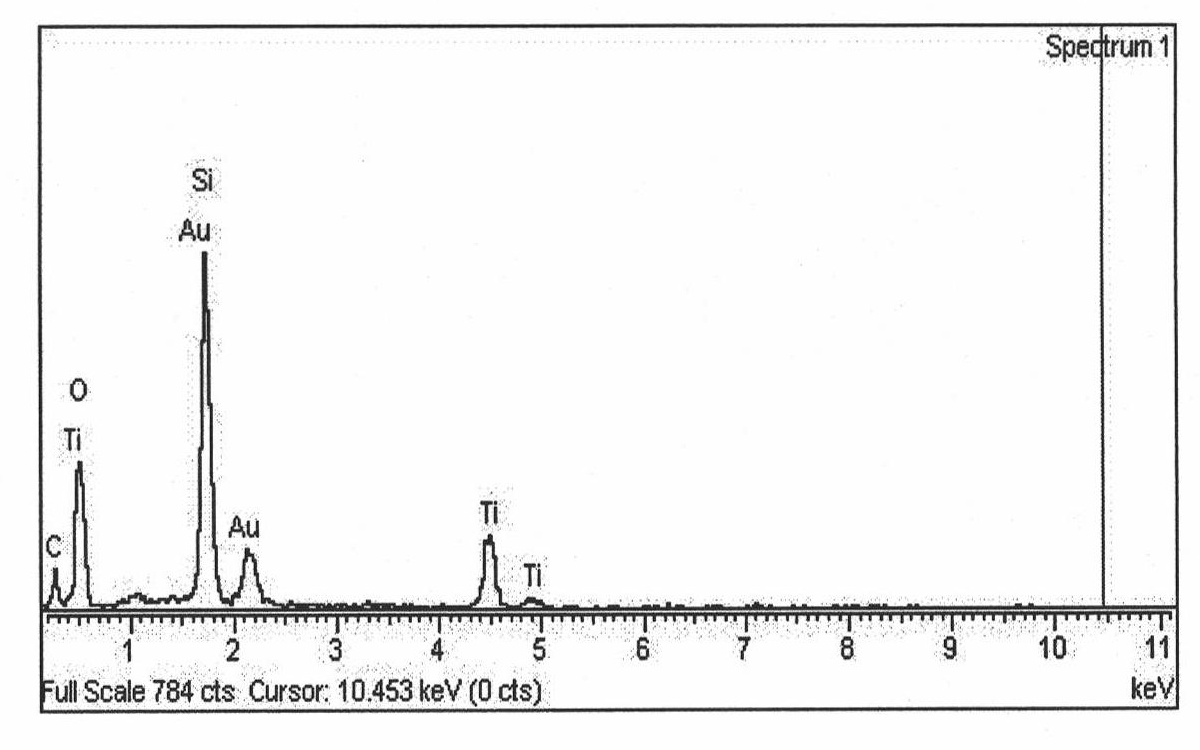

[0068] In the polymer blend alloy, the inorganic substances used as fillers account for less than ten percent. In order to improve the comprehensive performance of polycarbonate, the present invention considers adding inorganic particle nano TiO 2 and nano-SiO 2 to improve its performance. In order to study the influence of the content of inorganic particles on the performance of high polymers, the content of inorganic particles that can improve the comprehensive performance of polycarbonate is optimized by comparison. Therefore, according to the method of embodiment 1, the difference of embodiment 2 is: nano-TiO 2 / SiO 2 Powder and PC / PS / SiO 2 The content ratio of nanocomposite material is 0.5%; In this step of the preparation of polycarbonate / polystyrene blend, PS is 3% of PC, namely 0.15g, and PC is 5g; Tetraethyl silicate is 0.05% g, acetone is 0.15g, deionized water is 0.04g; in nano-TiO 2 / SiO 2 In this step of preparation, tetraethyl orthosilicate is 0.16 g, ammo...

Embodiment approach 3

[0070] According to the processing method of embodiment 1, the difference of embodiment 3 is: nano TiO 2 / SiO 2 Powder and PC / PS / SiO 2 The content ratio of the nanocomposite material is 0.5%. In the preparation step of polycarbonate / polystyrene blend, PS is 15% of PC, that is, 0.75g, PC is 5g; tetraethyl silicate is 0.25g, acetone is 0.25g, deionized water 0.08g; in nano TiO 2 / SiO 2 In this step of preparation, tetraethyl orthosilicate is 0.16 g, ammonia water is 15 ml, and KH550 is 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com