Patents

Literature

53results about How to "Affect the processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

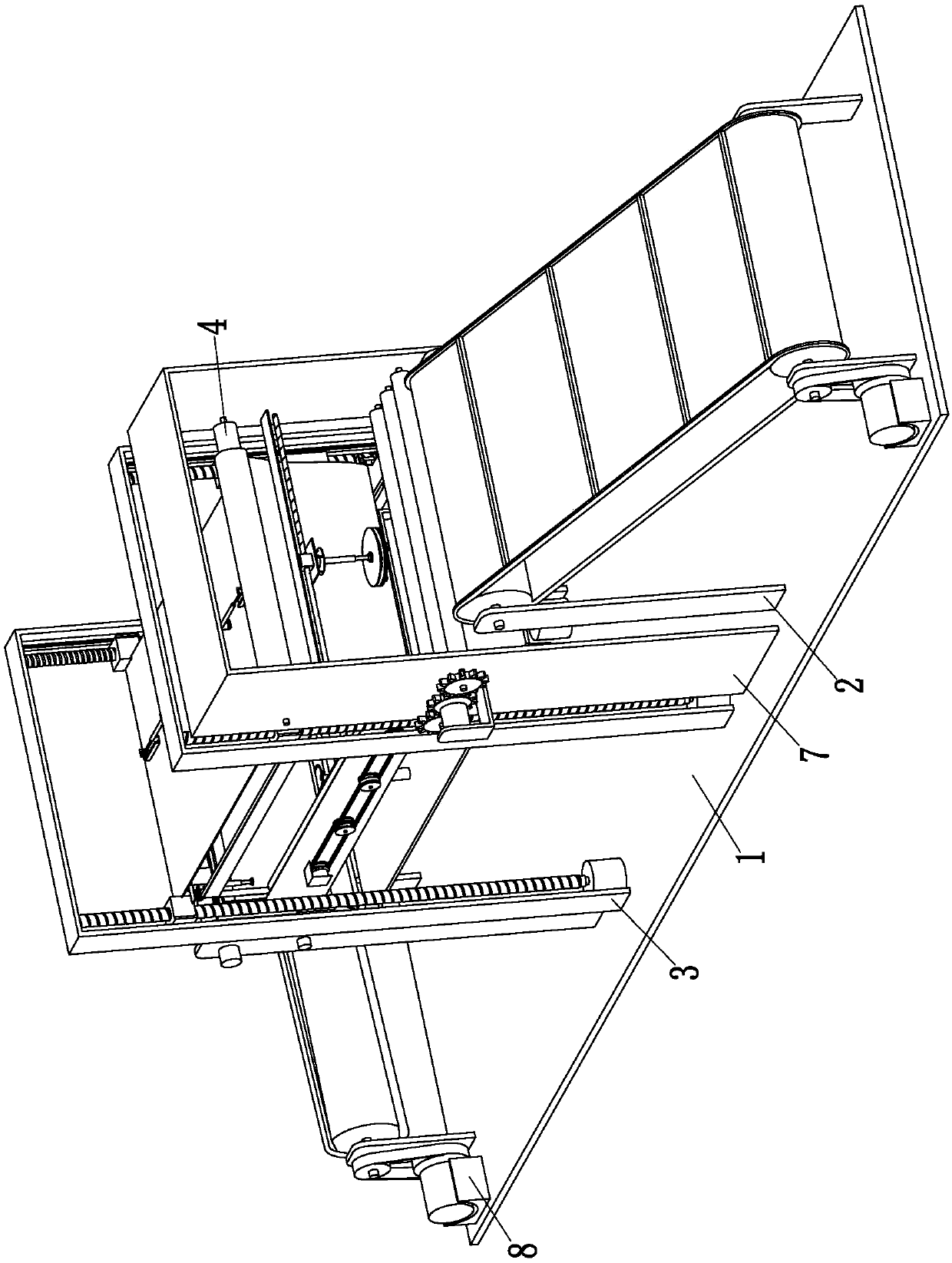

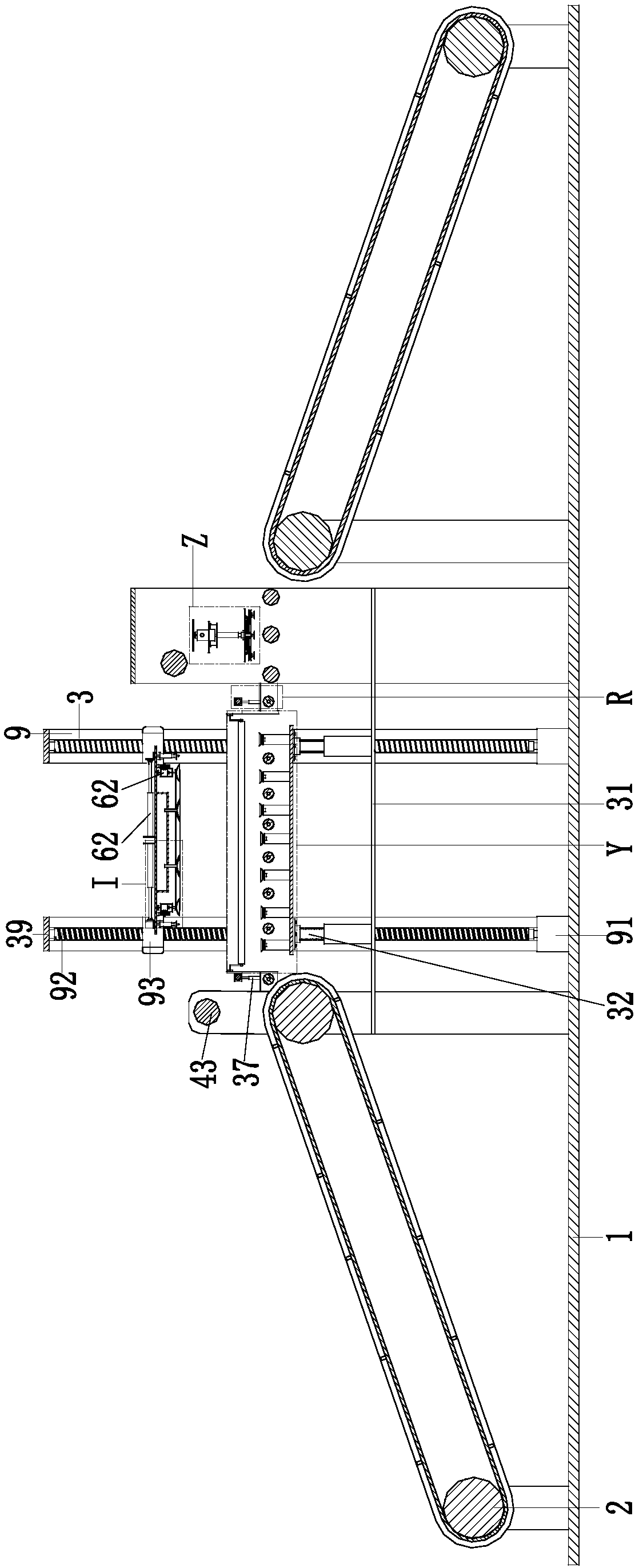

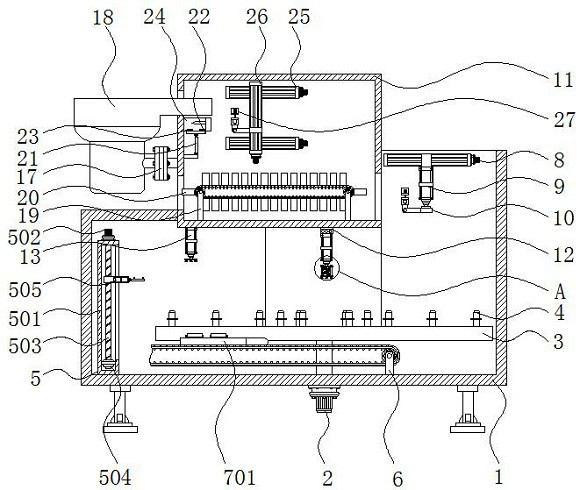

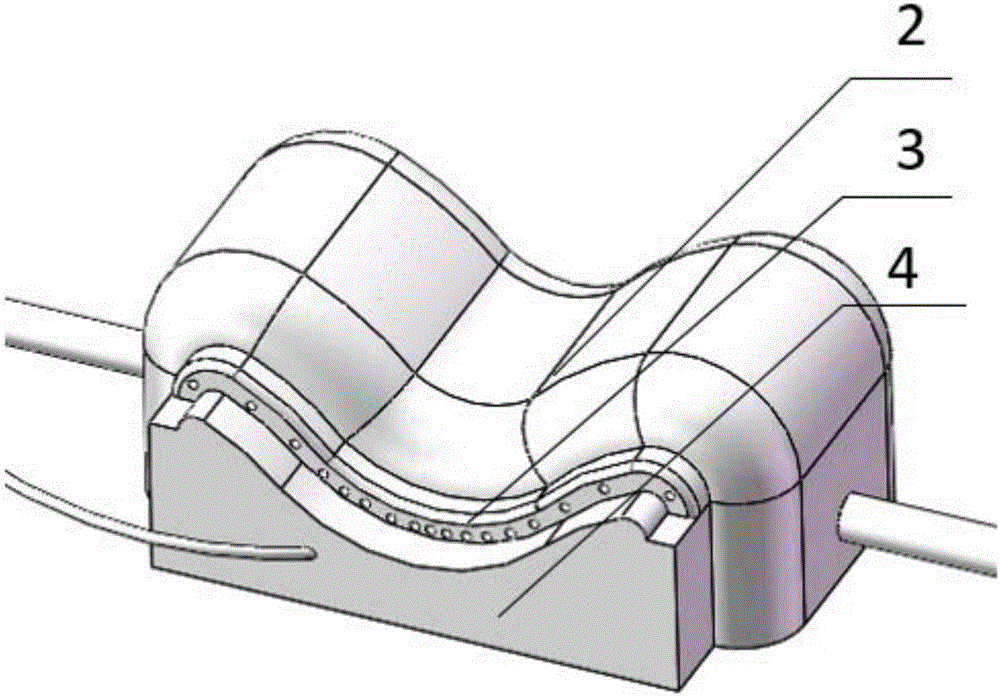

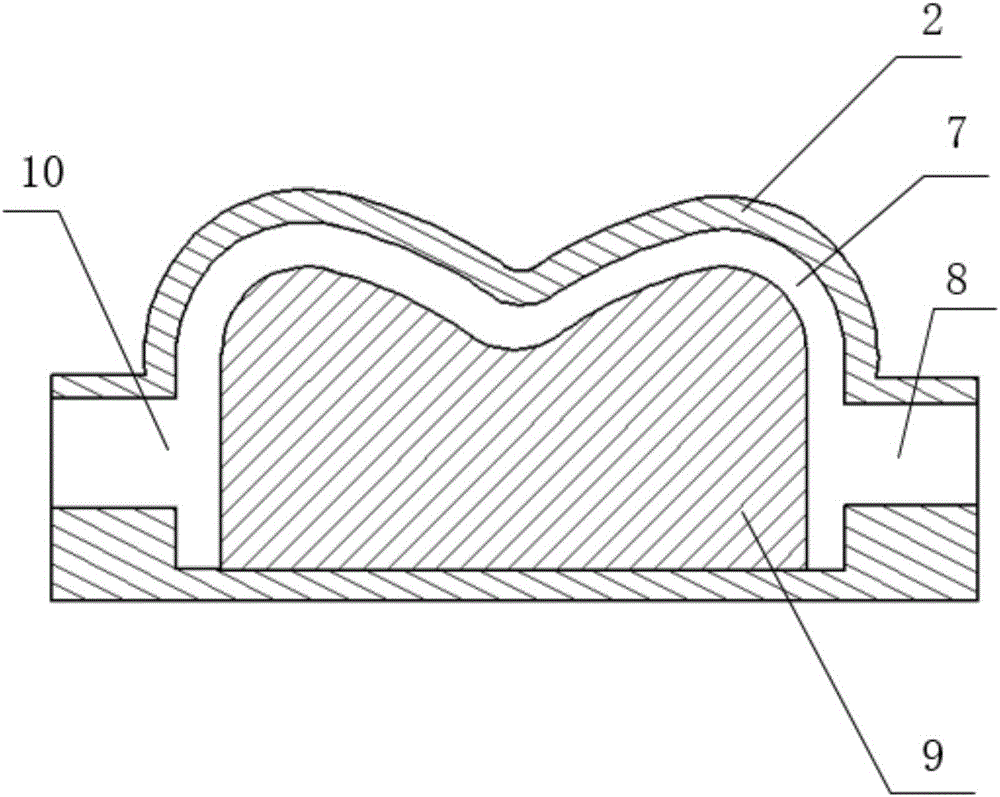

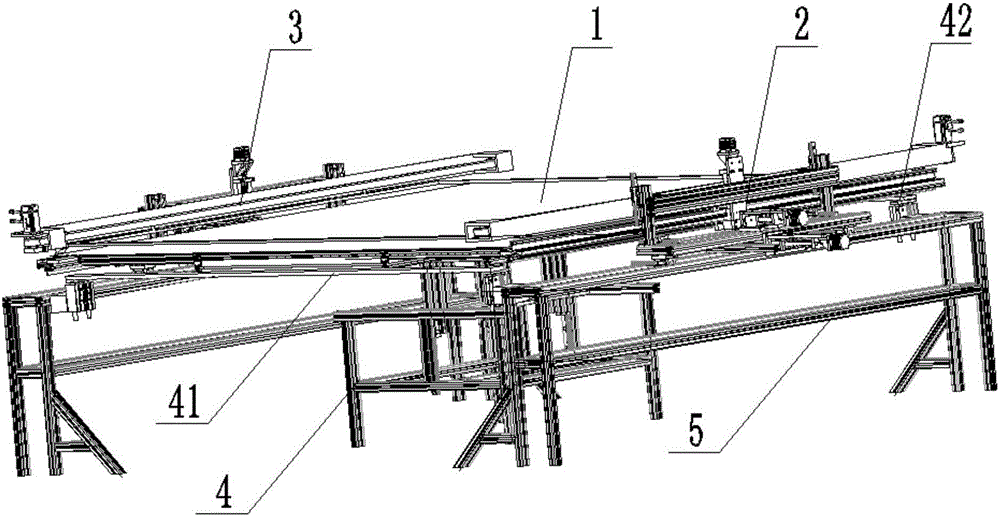

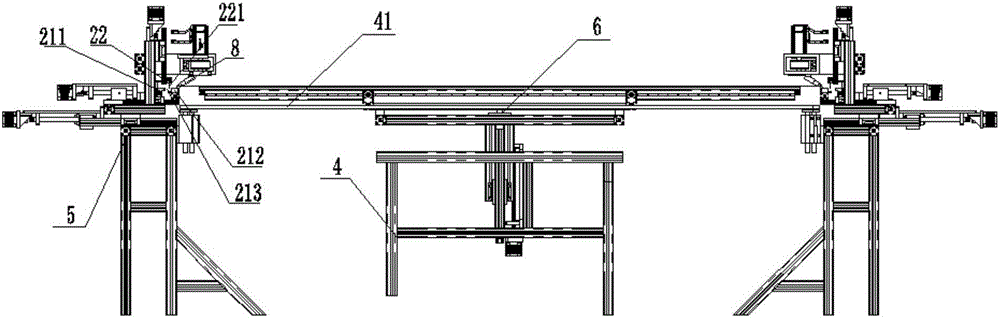

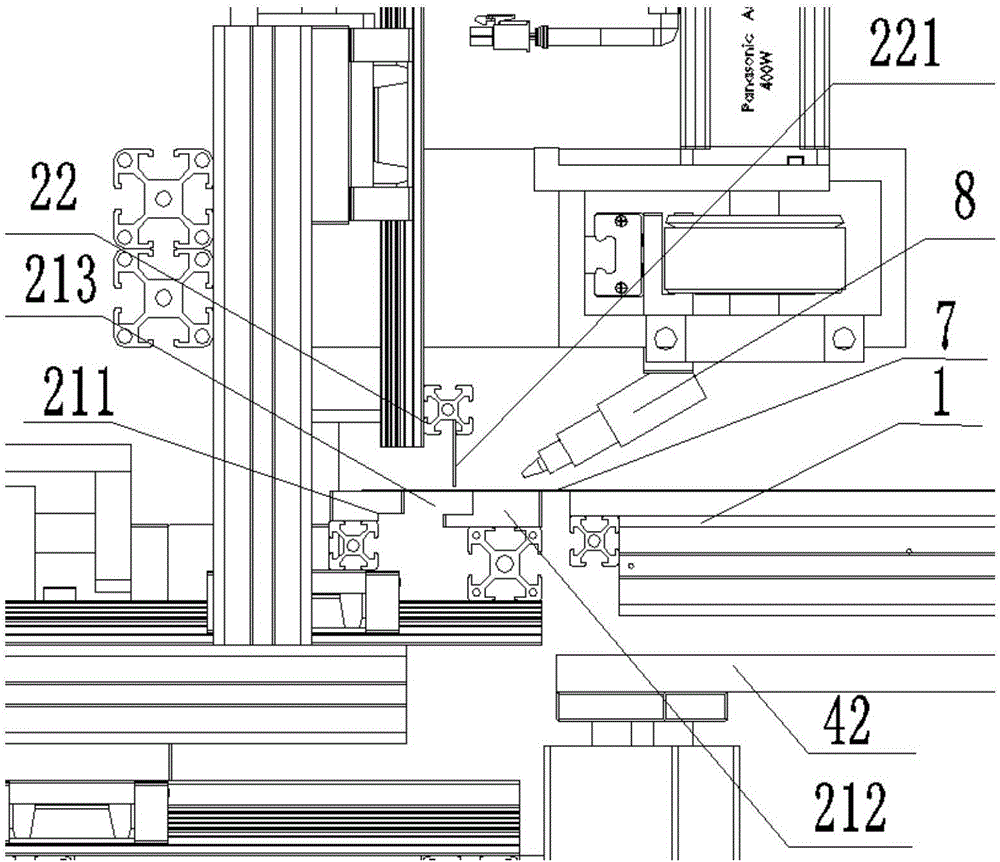

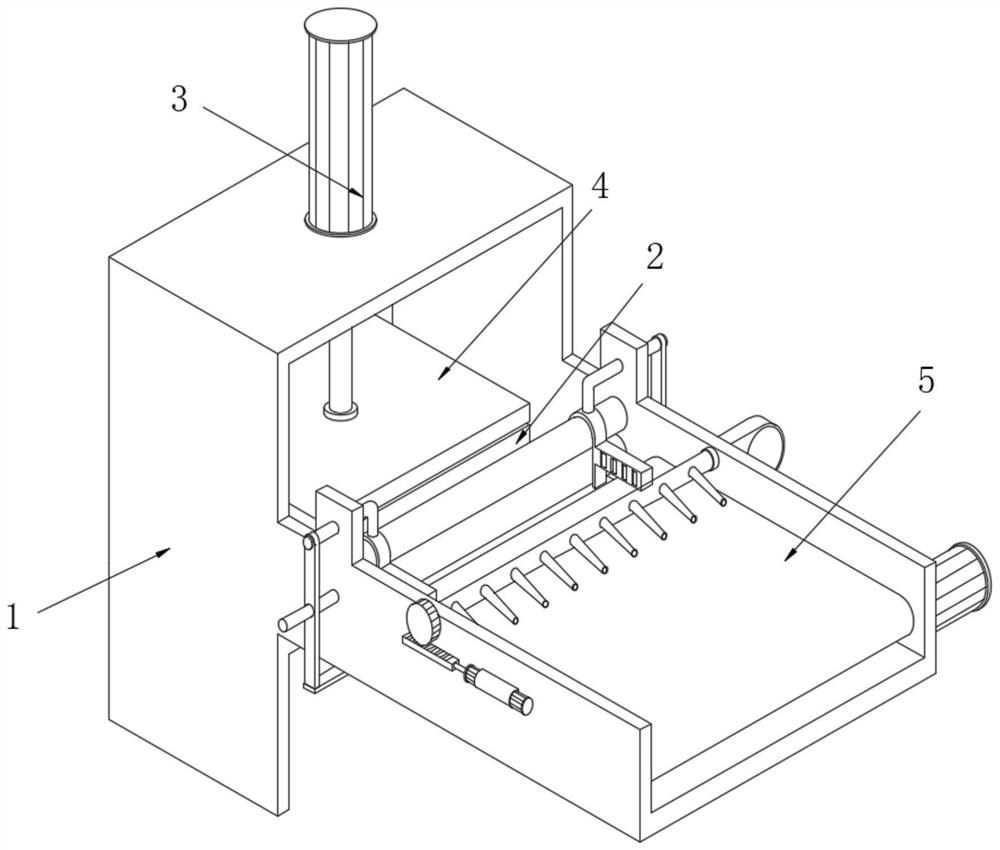

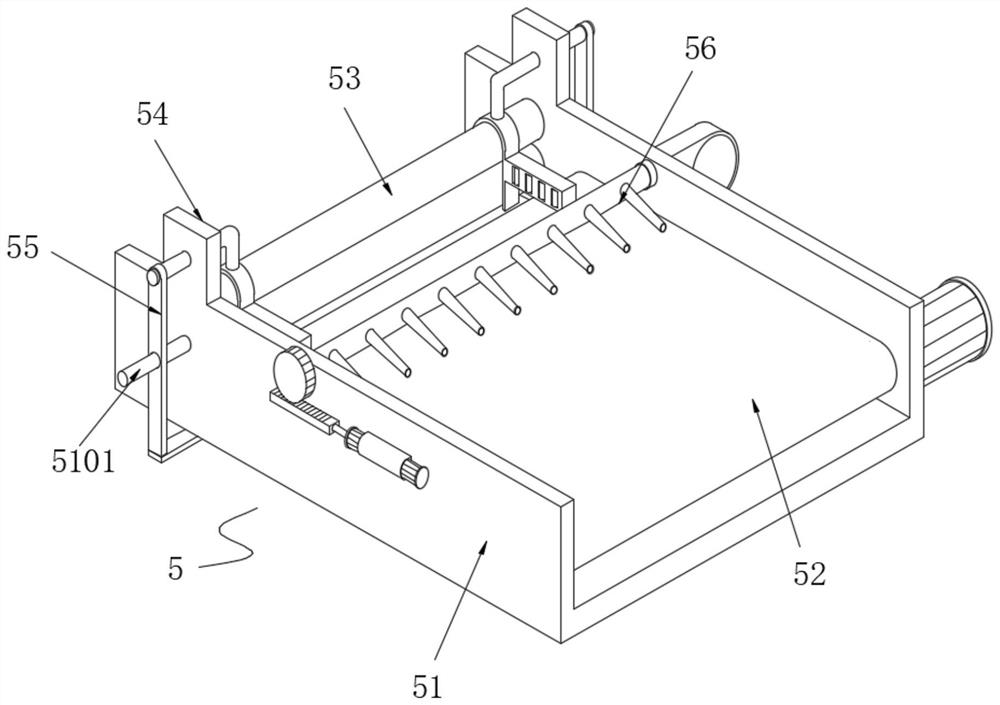

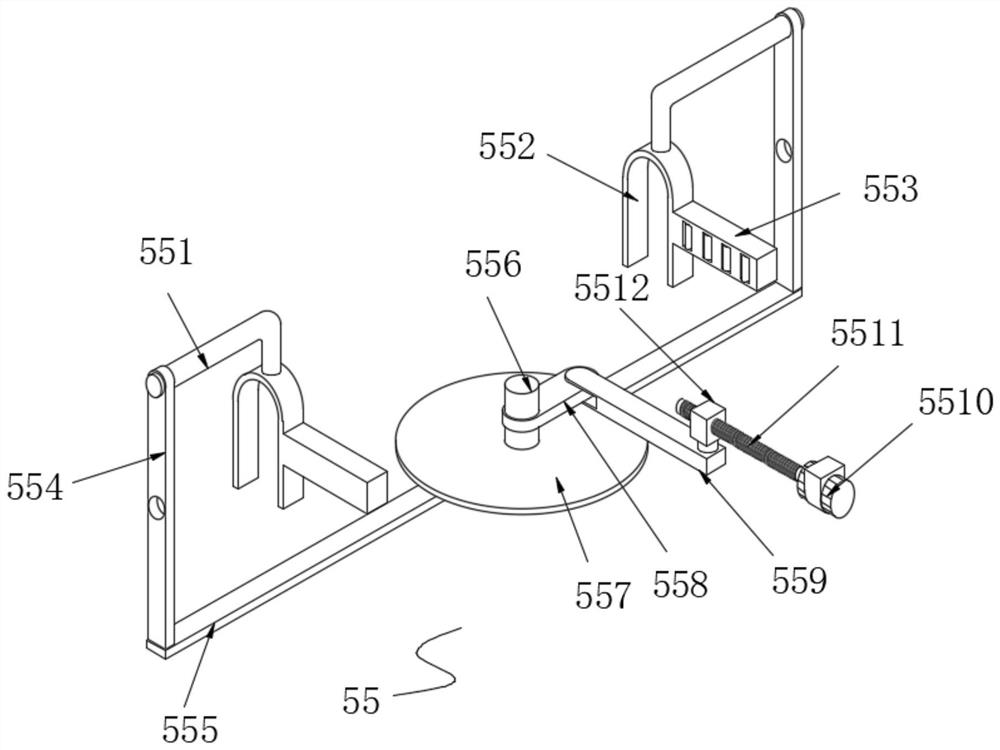

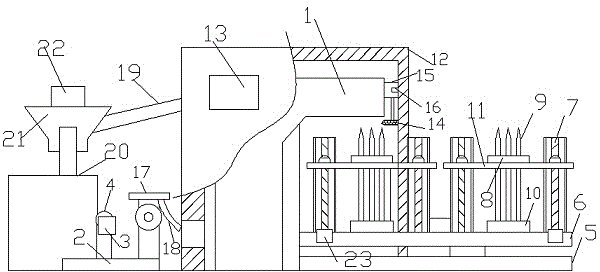

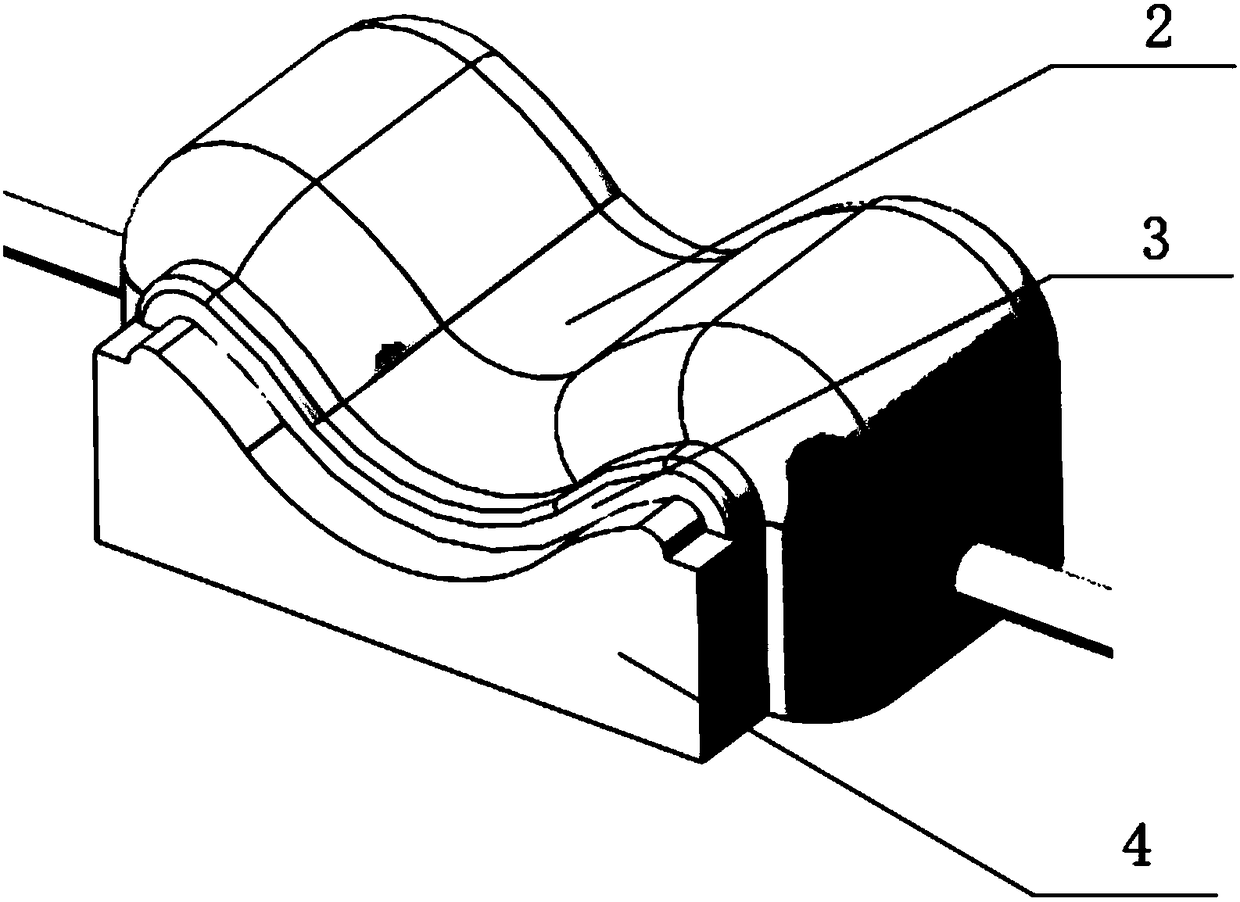

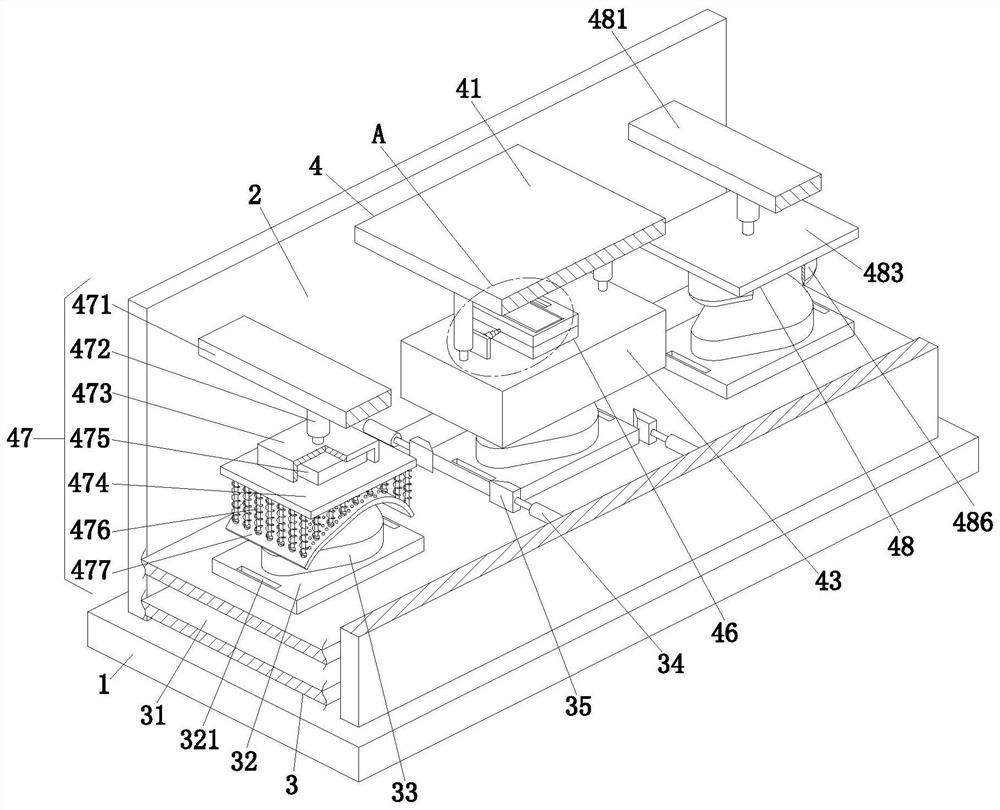

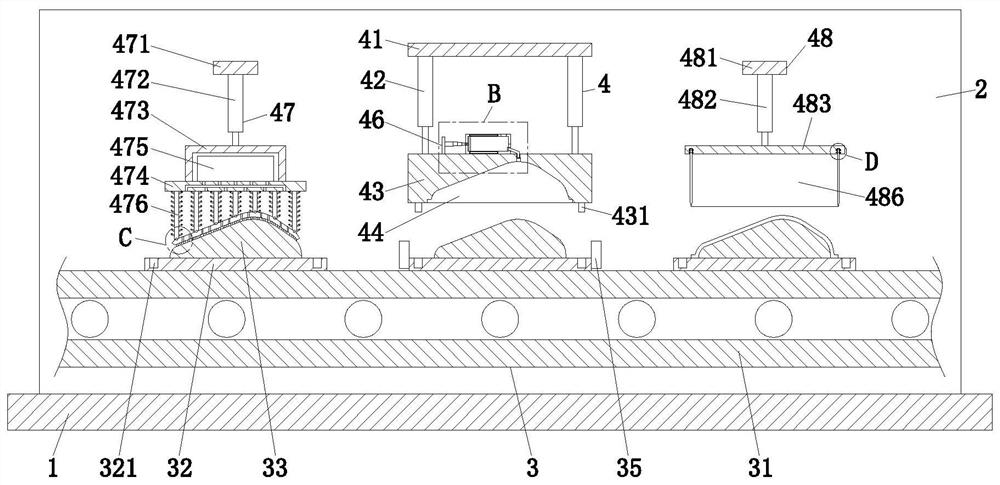

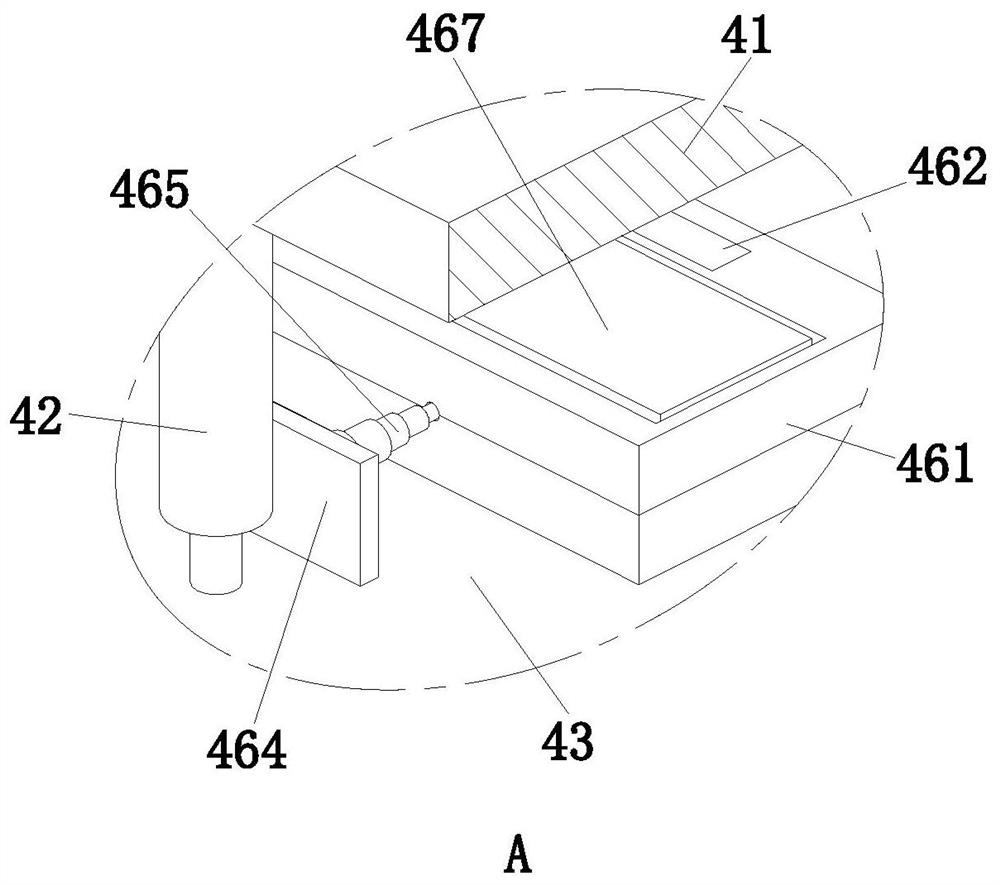

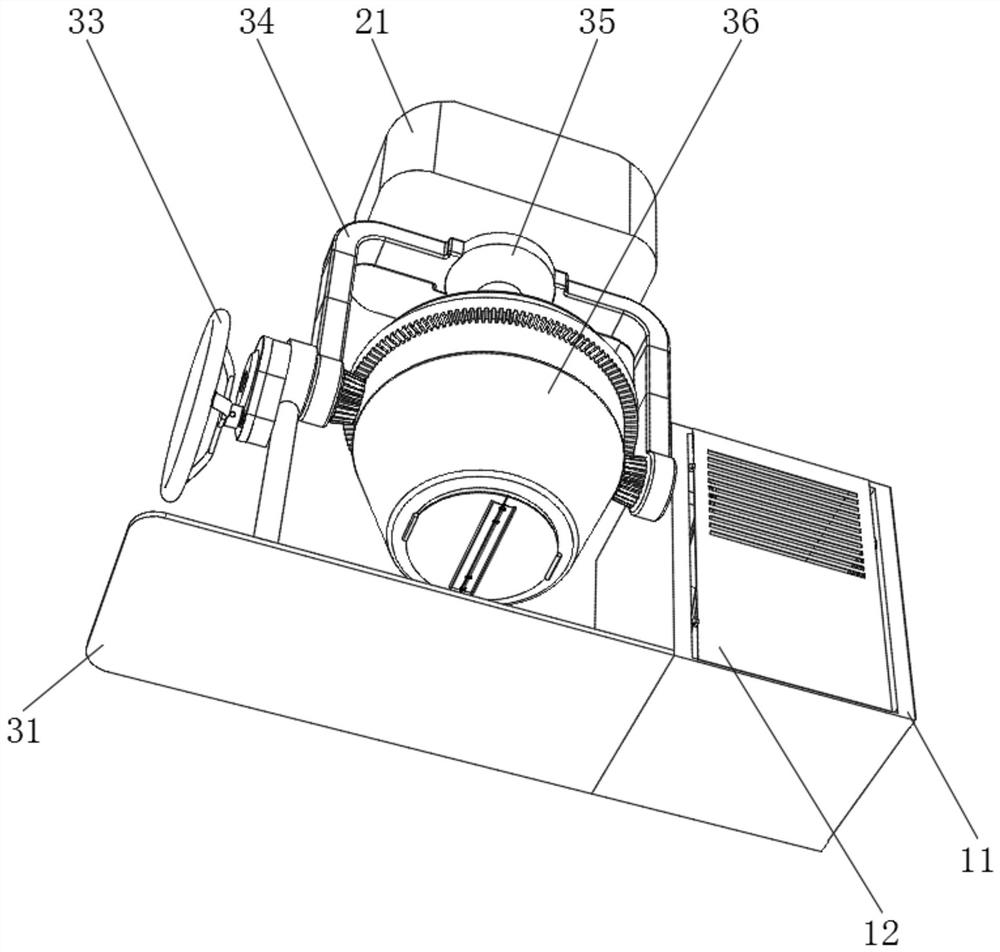

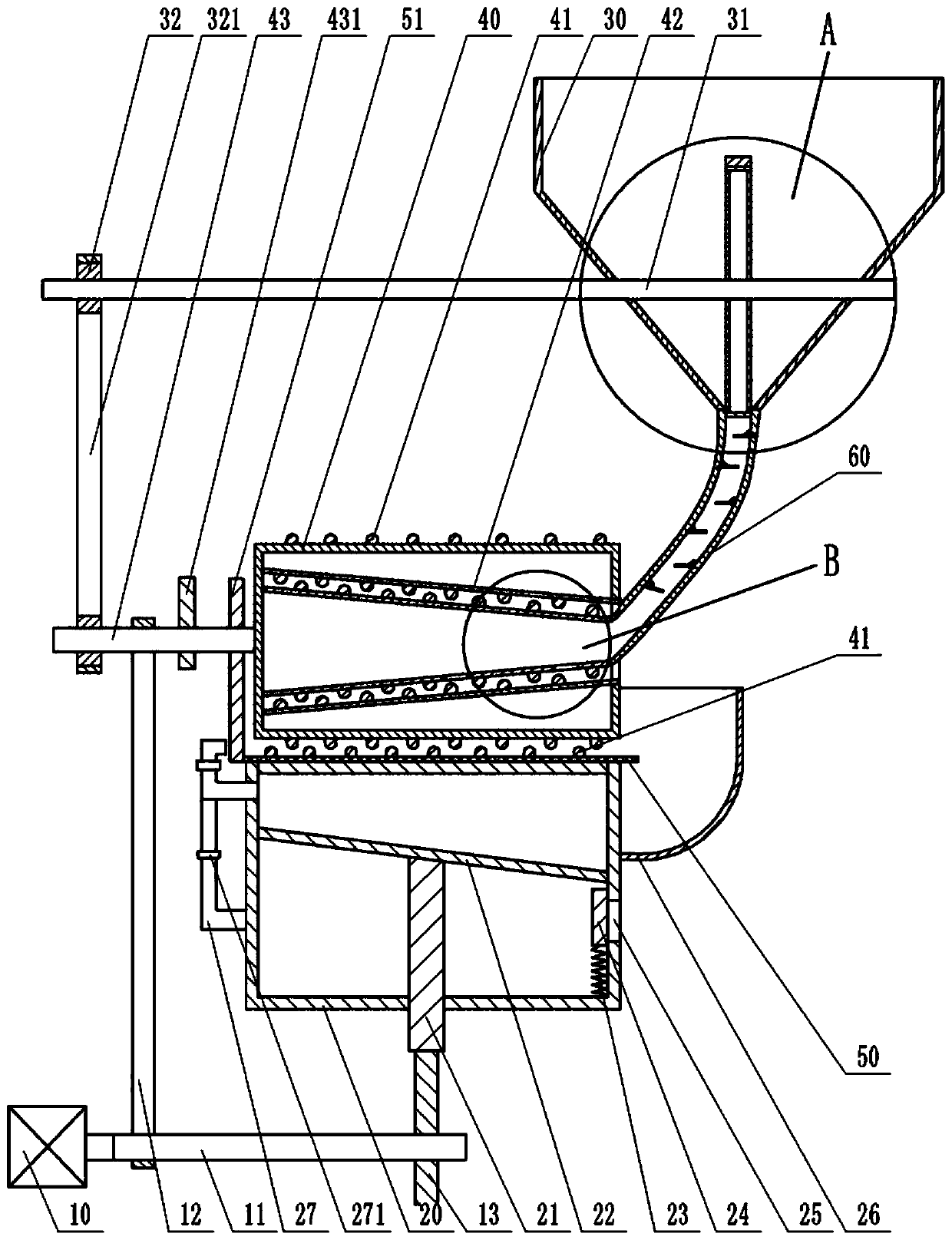

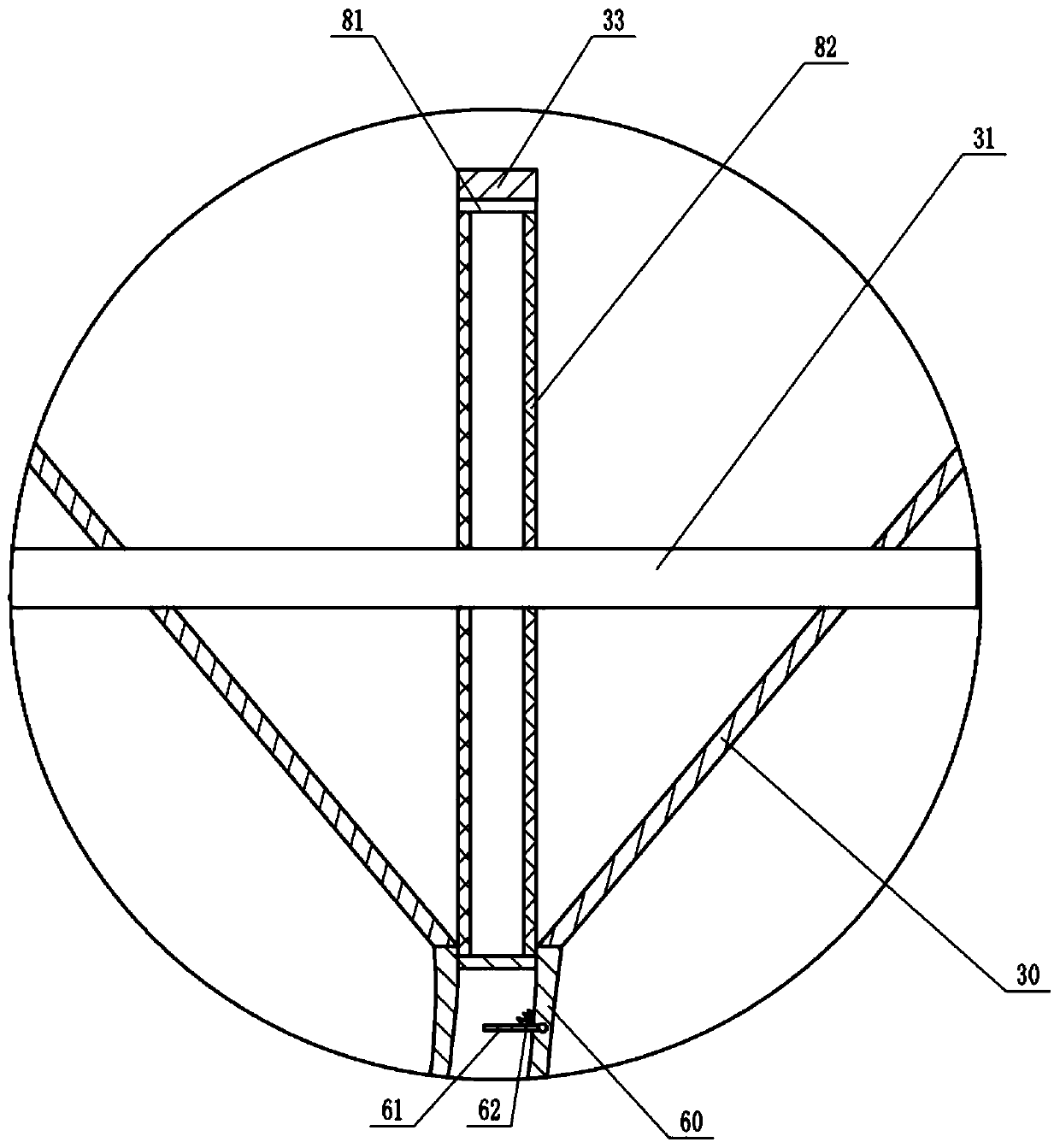

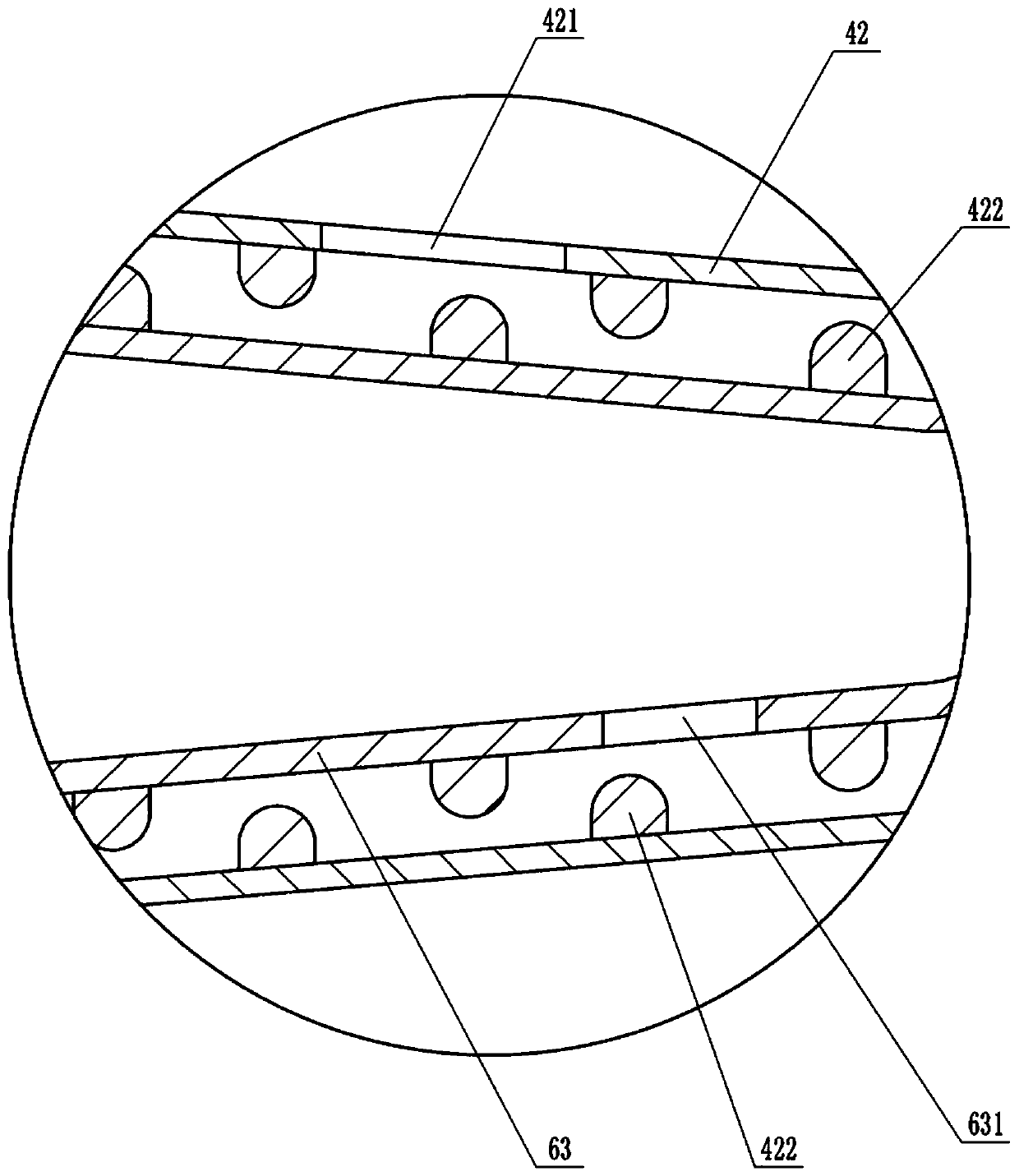

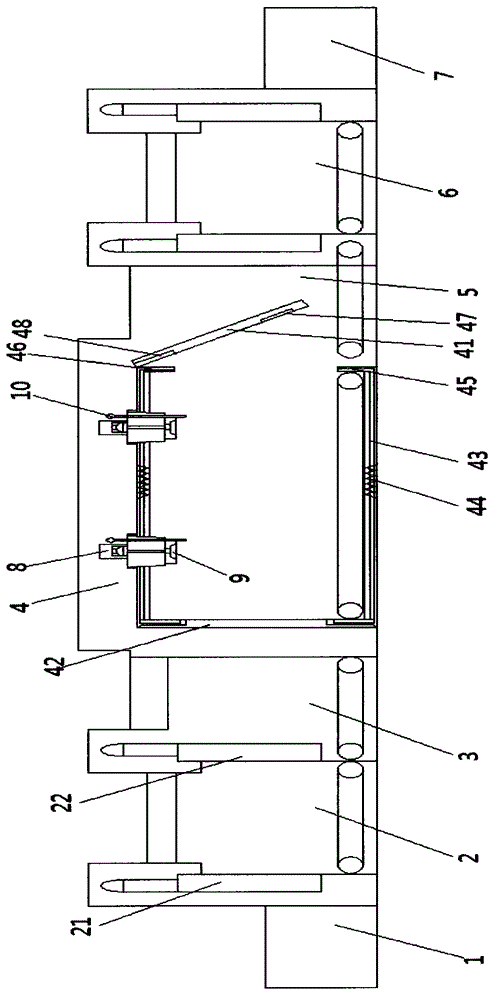

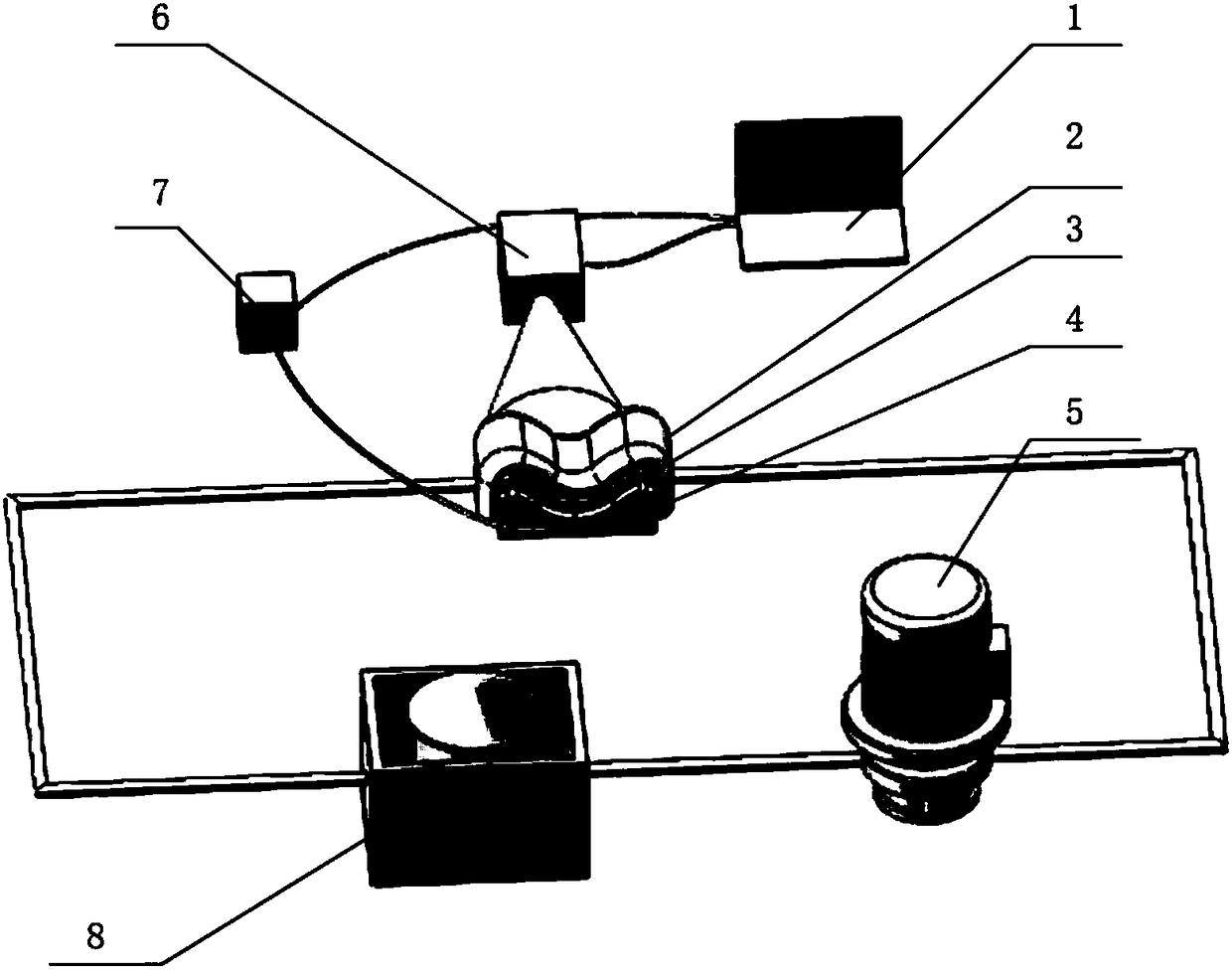

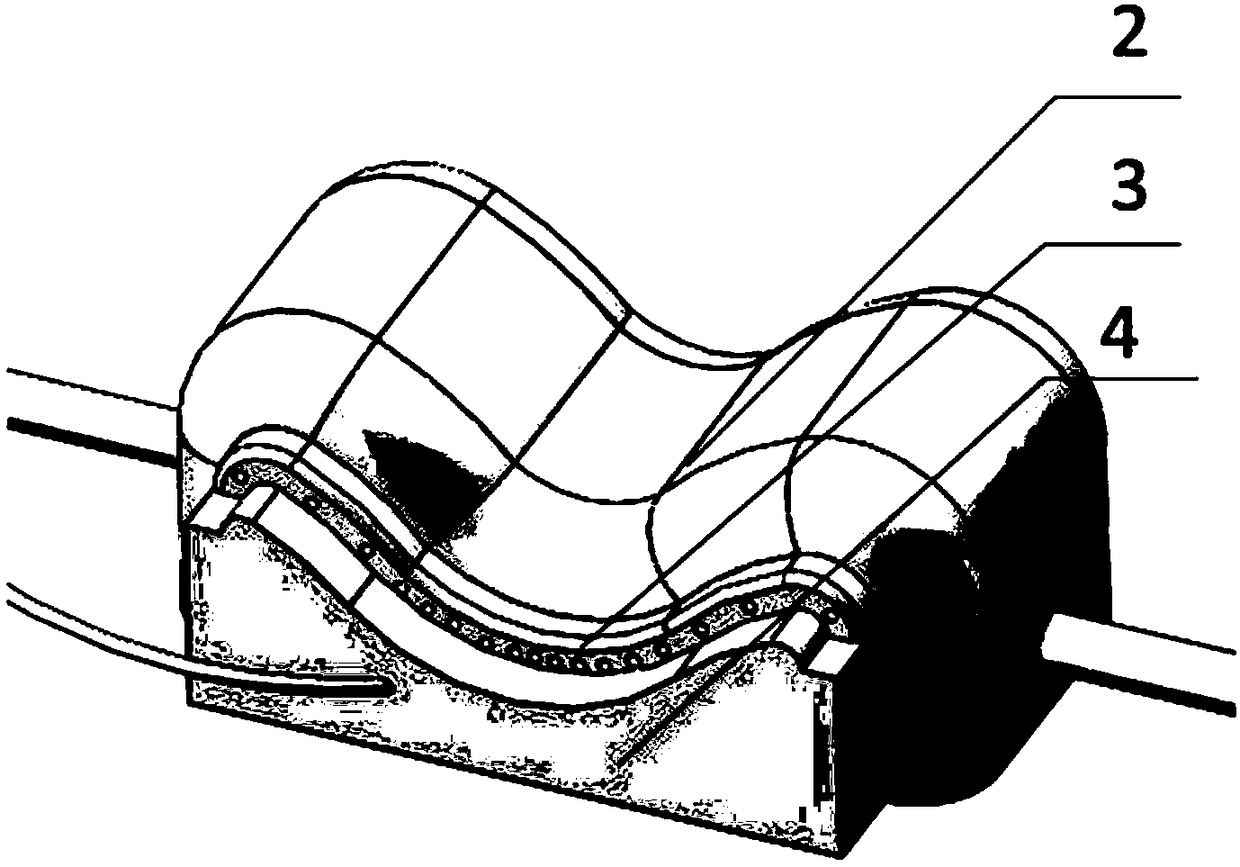

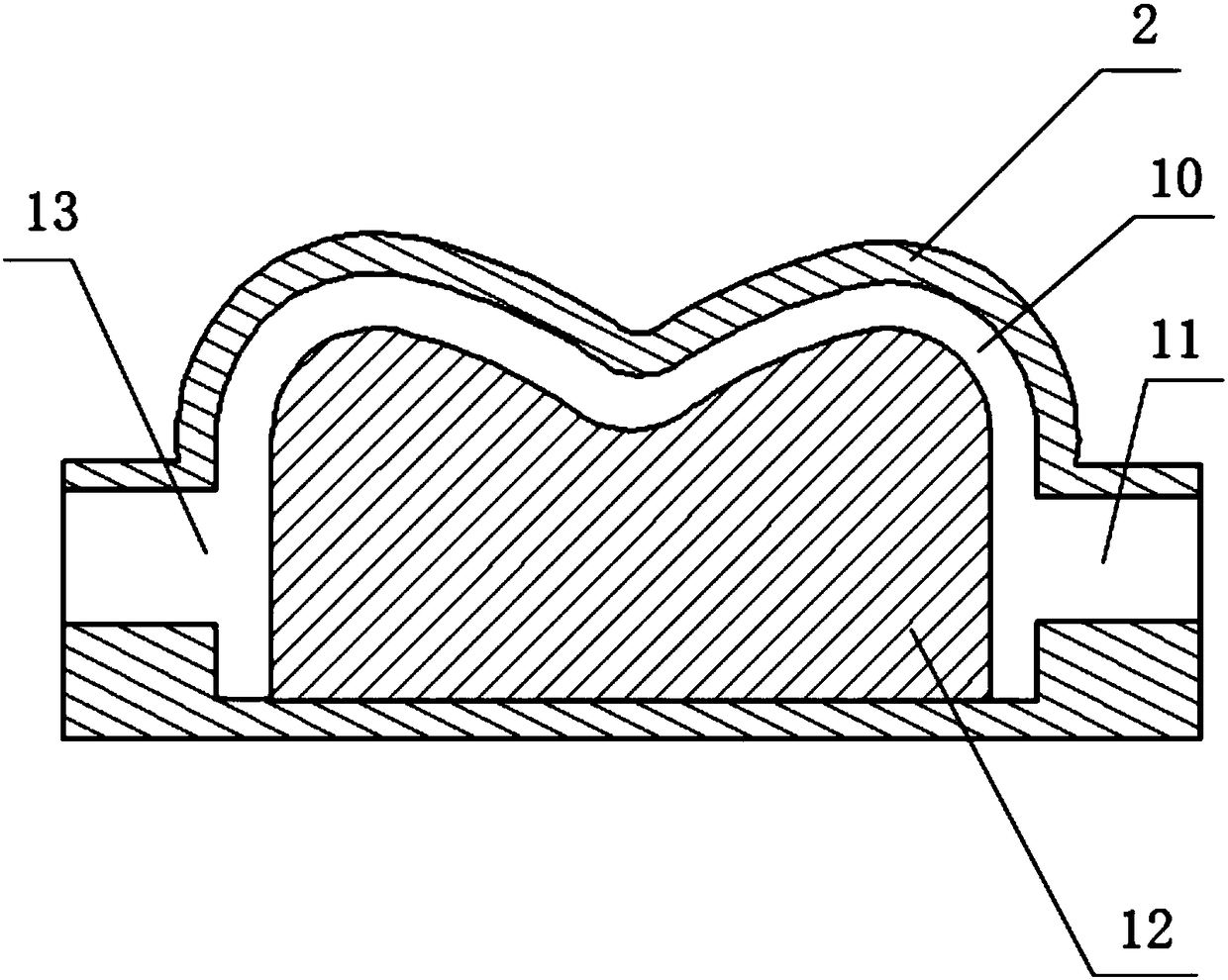

Automatic laminating apparatus special for color steel corrugated sheets of portable houses

ActiveCN107696662ARealize the function of automatic laminationInconsistent processing directionLaminationLamination apparatusEngineeringUltimate tensile strength

The invention relates to an automatic laminating apparatus special for color steel corrugated sheets of portable houses, comprising a bottom plate. A first conveyer, an adjusting device, a conveying laminating device and a second conveyer are arranged on the bottom plate sequentially from front to rear; a winding device is mounted between the adjusting device and the second conveyer; automatic laminating process of color steel corrugated sheets is achieved through the cooperation of the first conveyer, the adjusting device, the winding device, the conveying laminating device, a conveying rolling device and the second conveyer. By using the automatic laminating apparatus, the problems are solved: for instance, processing directions used in the existing laminating process of color steel corrugated sheets are non-uniform; the surface of the color steel corrugated sheets is uneven; since rolling dies in the existing laminating equipment to roll between film and color steel corrugated sheets are simple, manually changing and adjusting concave-convex depth of color steel corrugated sheets is required, and high labor intensity and low working efficiency are caused. The automatic laminating apparatus can provide automatic laminating for color steel corrugated sheets of portable houses.

Owner:重庆远海建筑装配技术开发有限公司

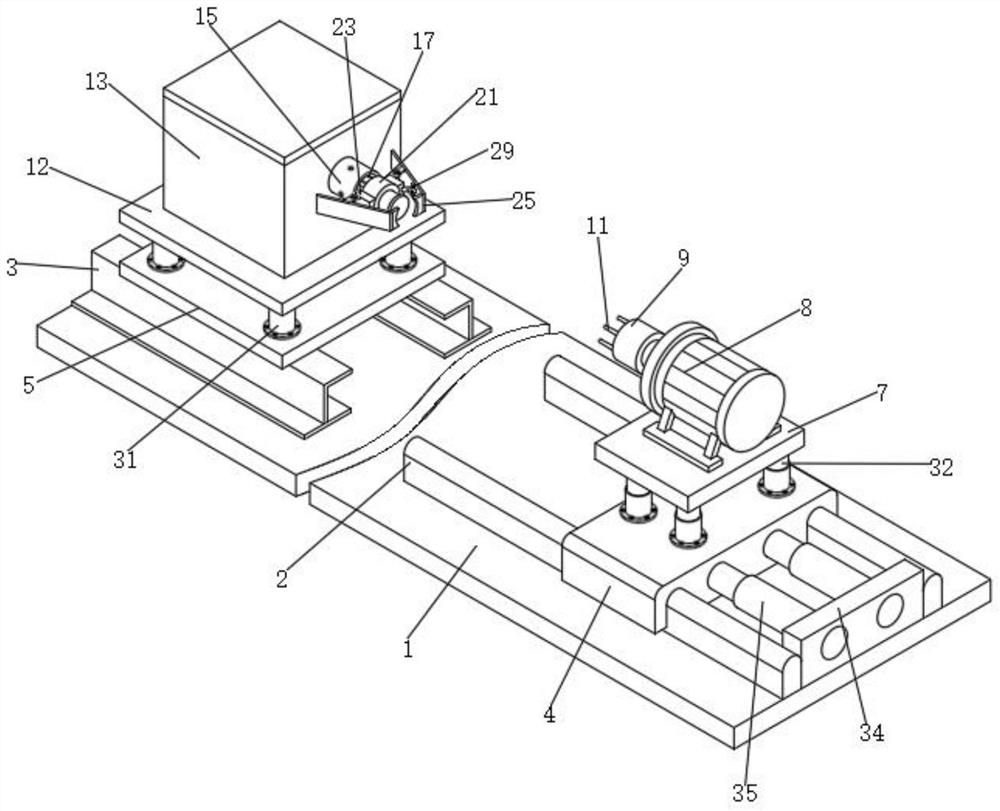

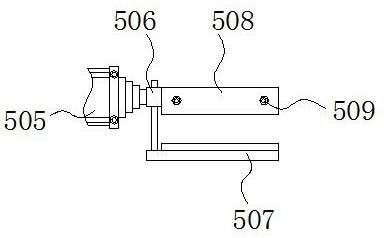

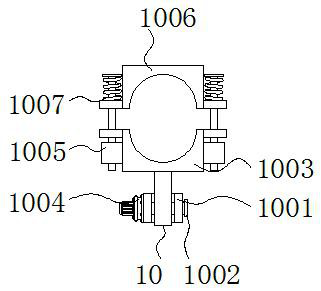

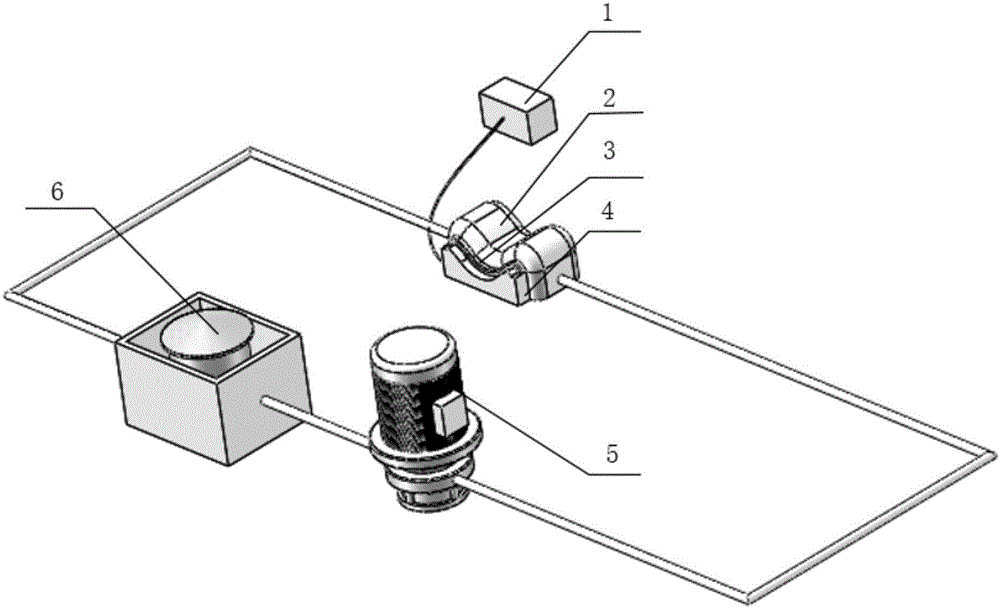

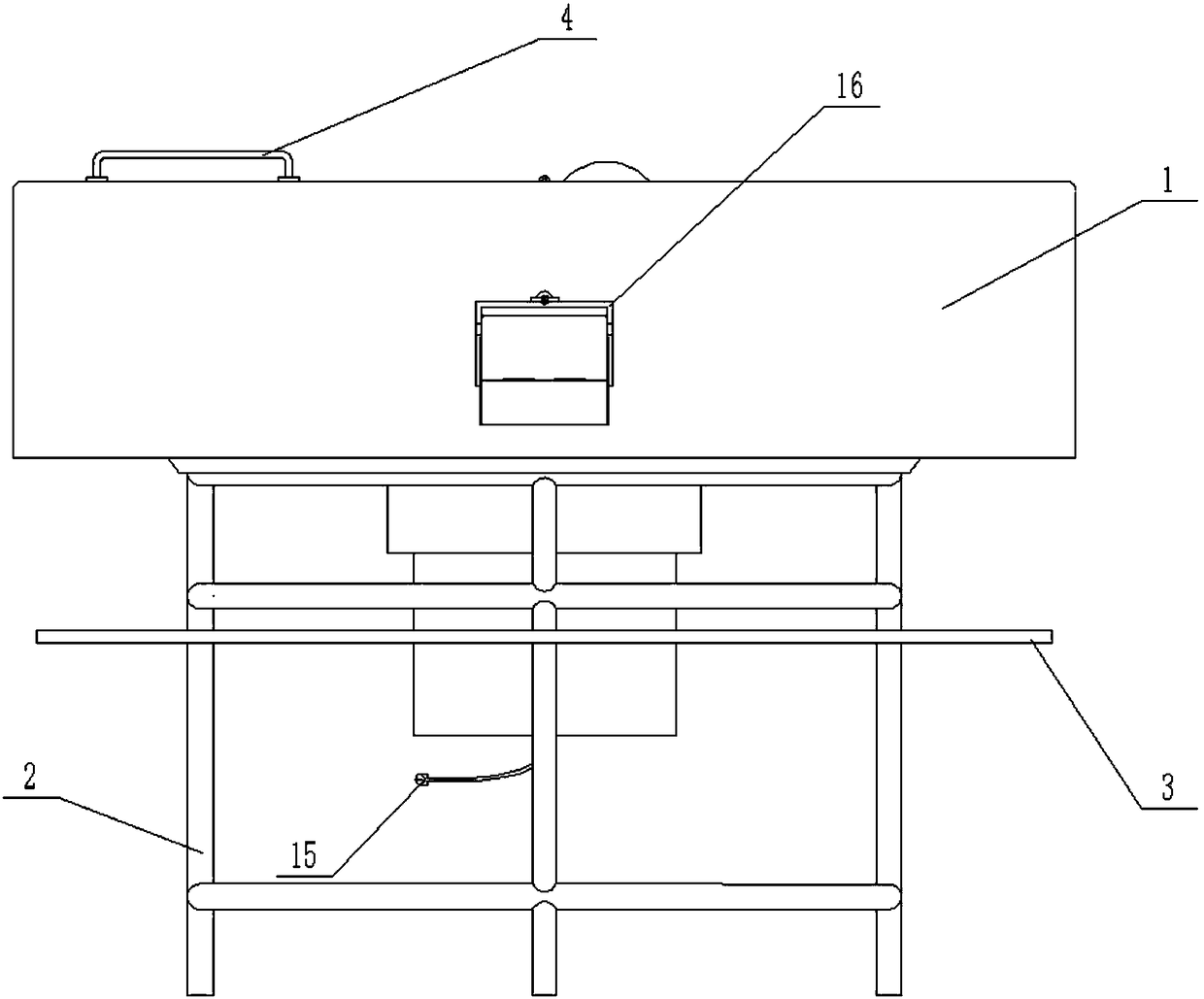

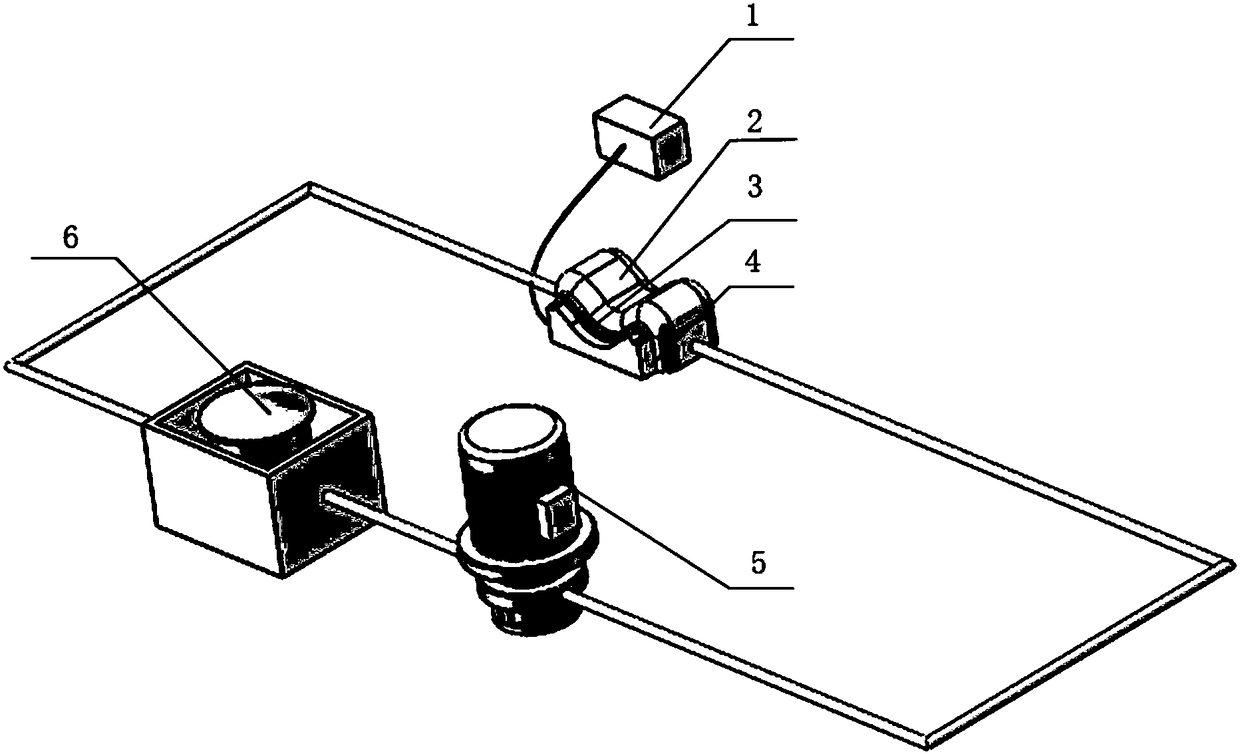

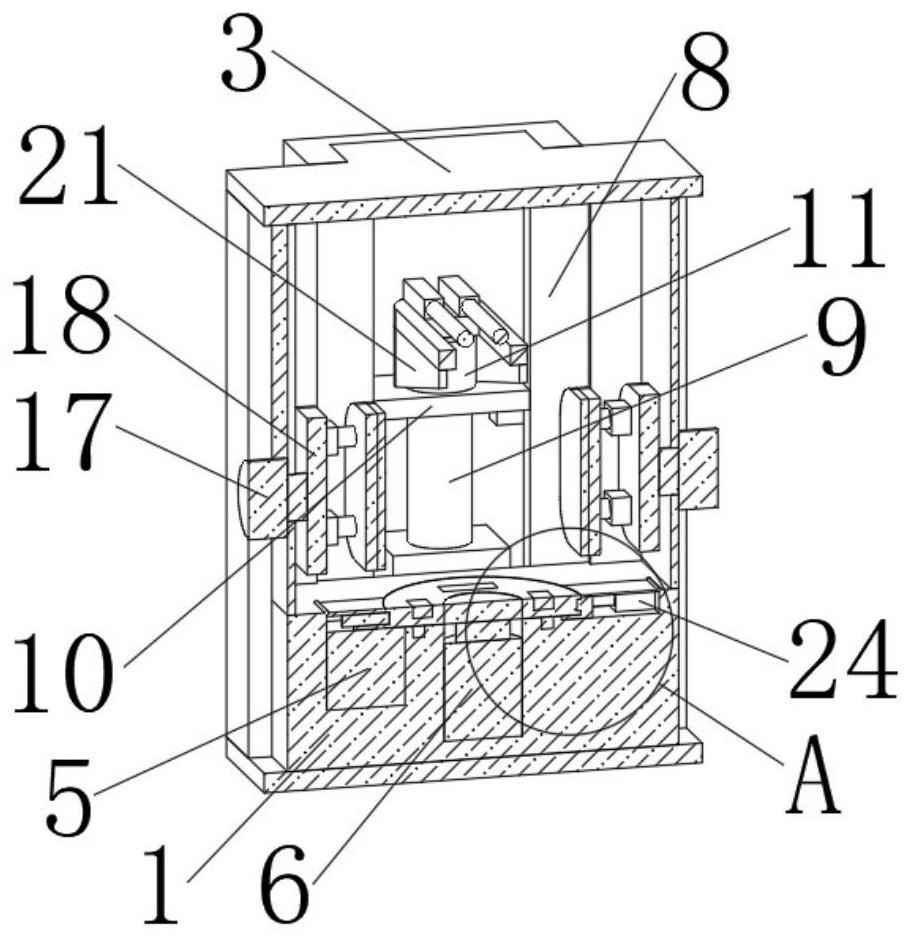

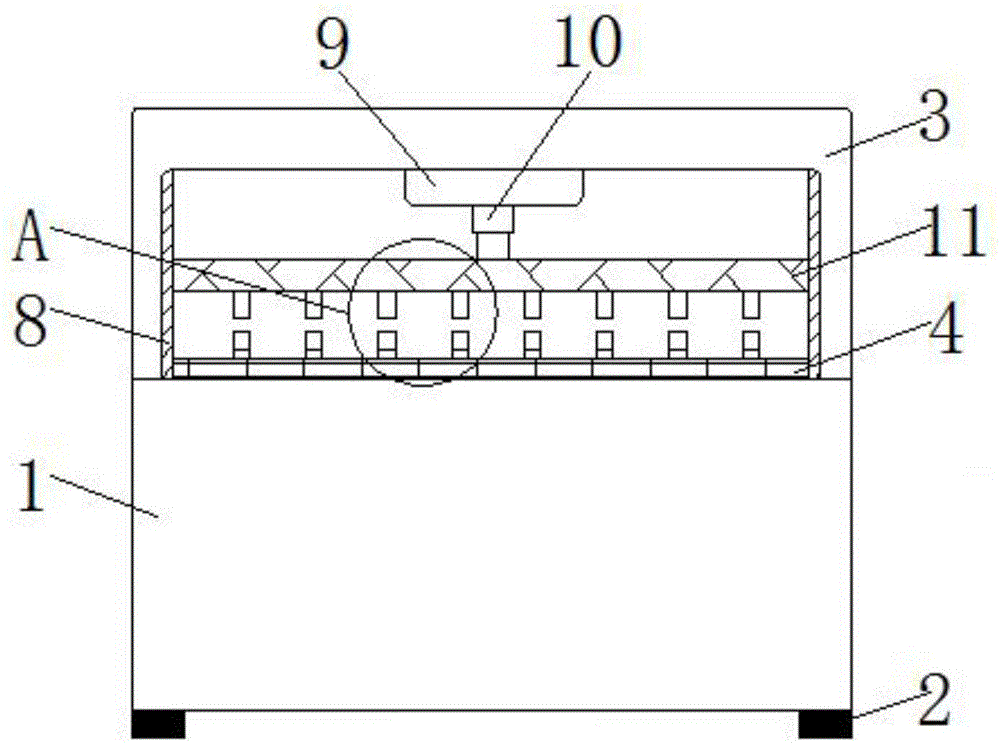

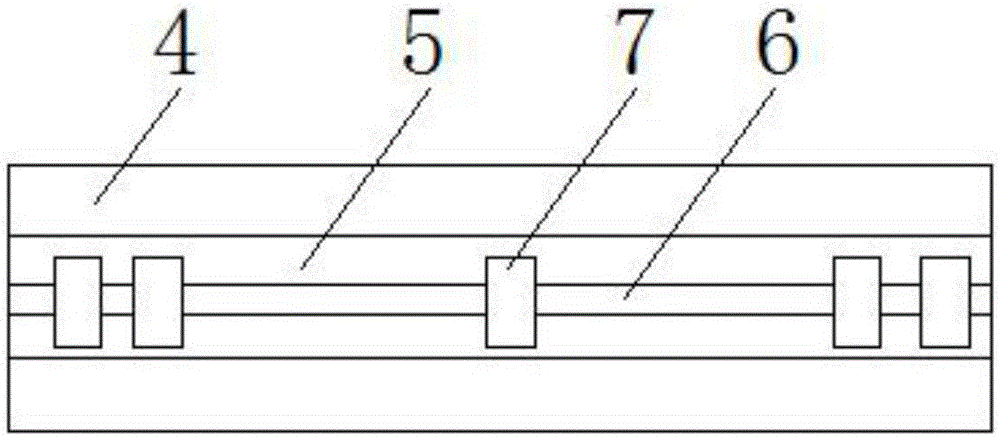

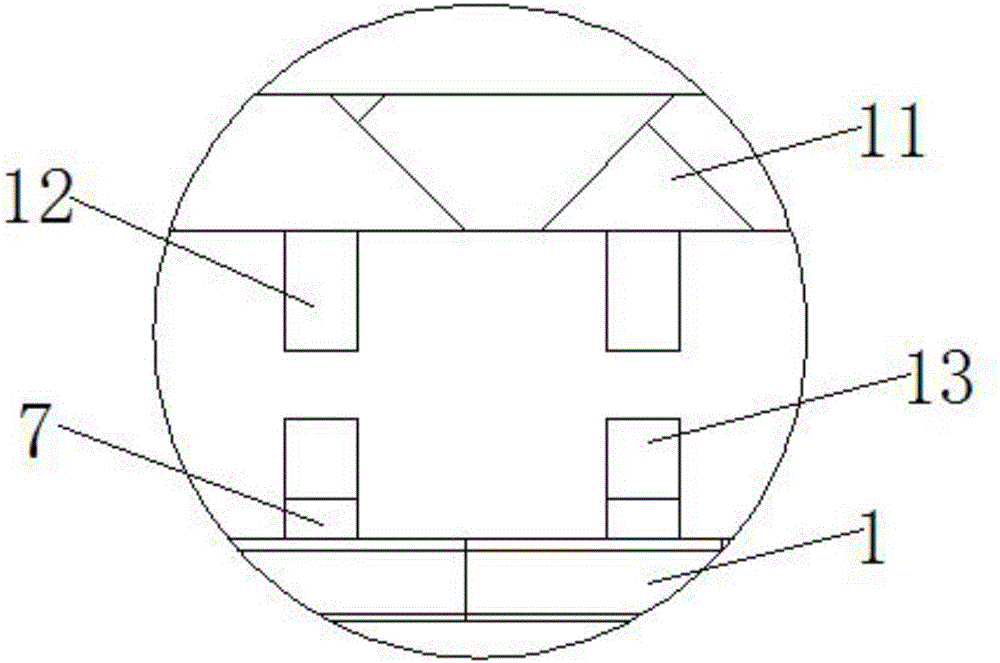

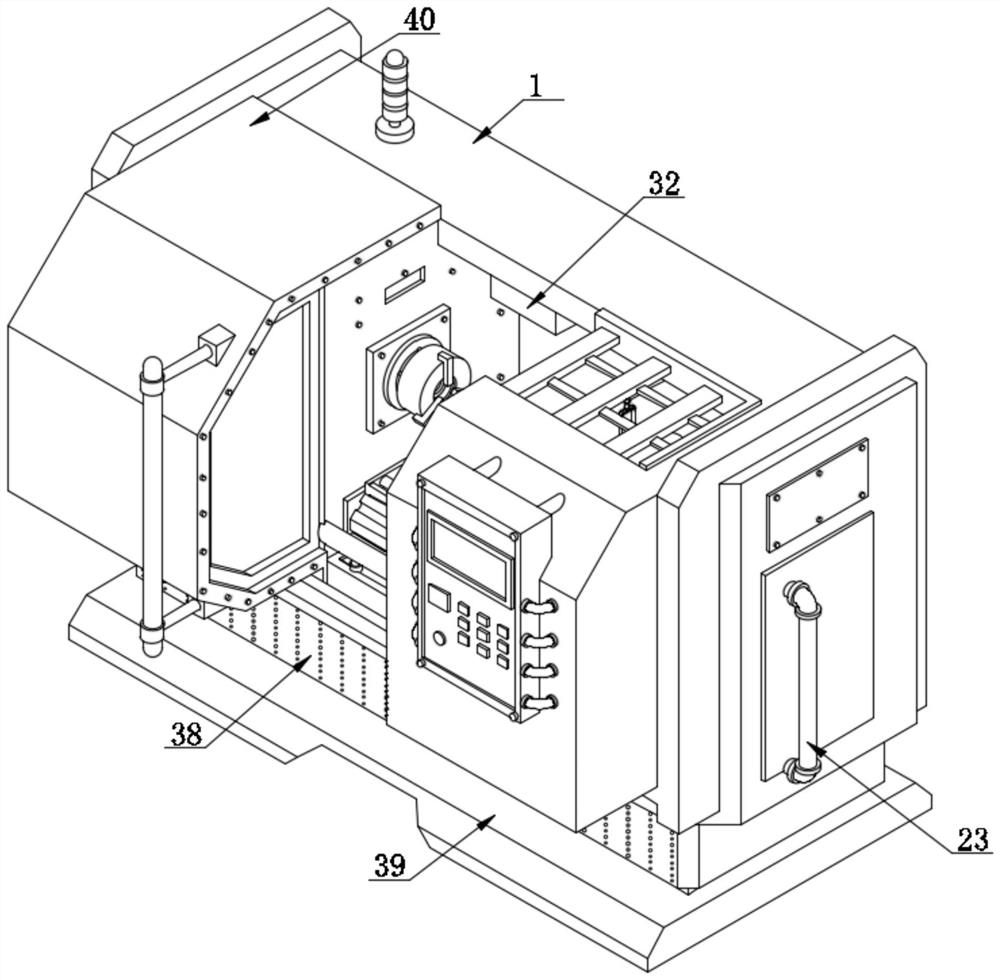

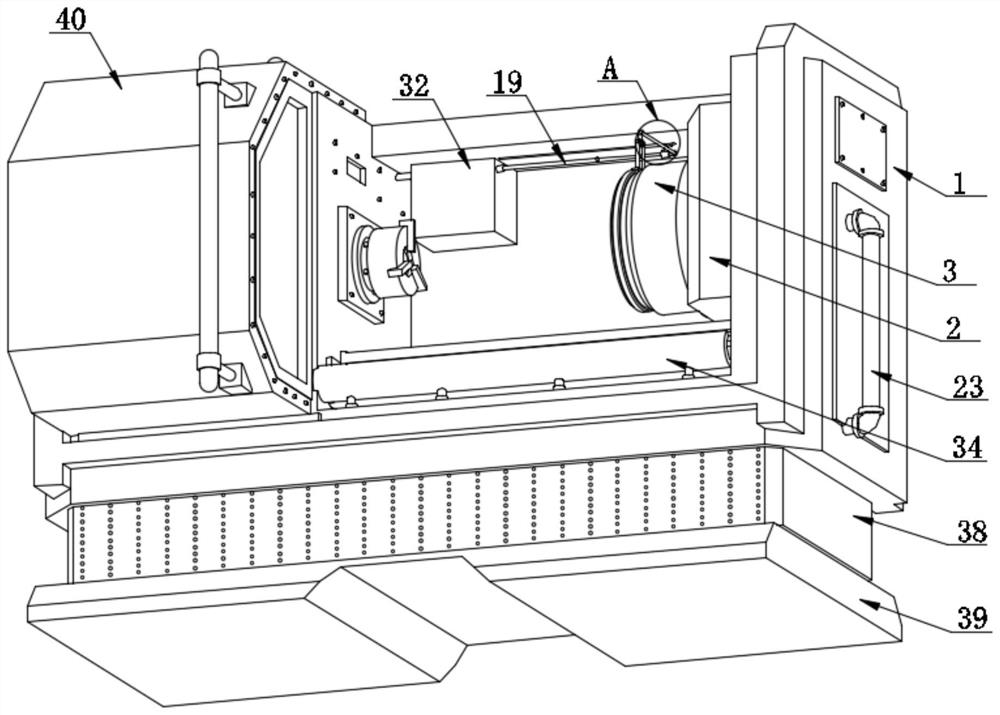

Log centering device with good centering effect for log processing

PendingCN113601623AAffect the processing effectDetachableMulti-purpose machinesGrinding machinesElectric machinerySlide plate

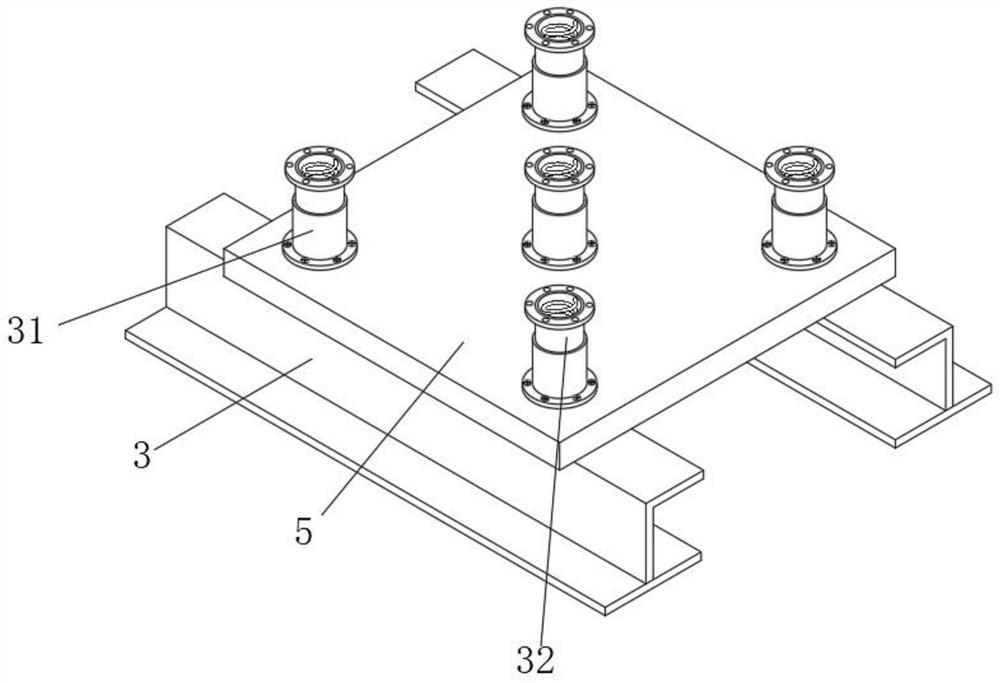

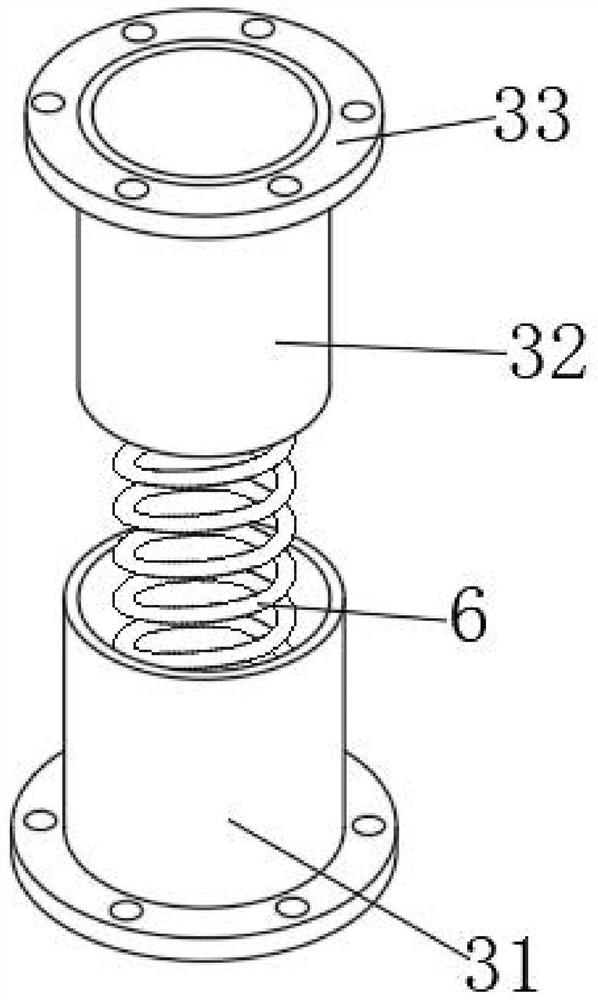

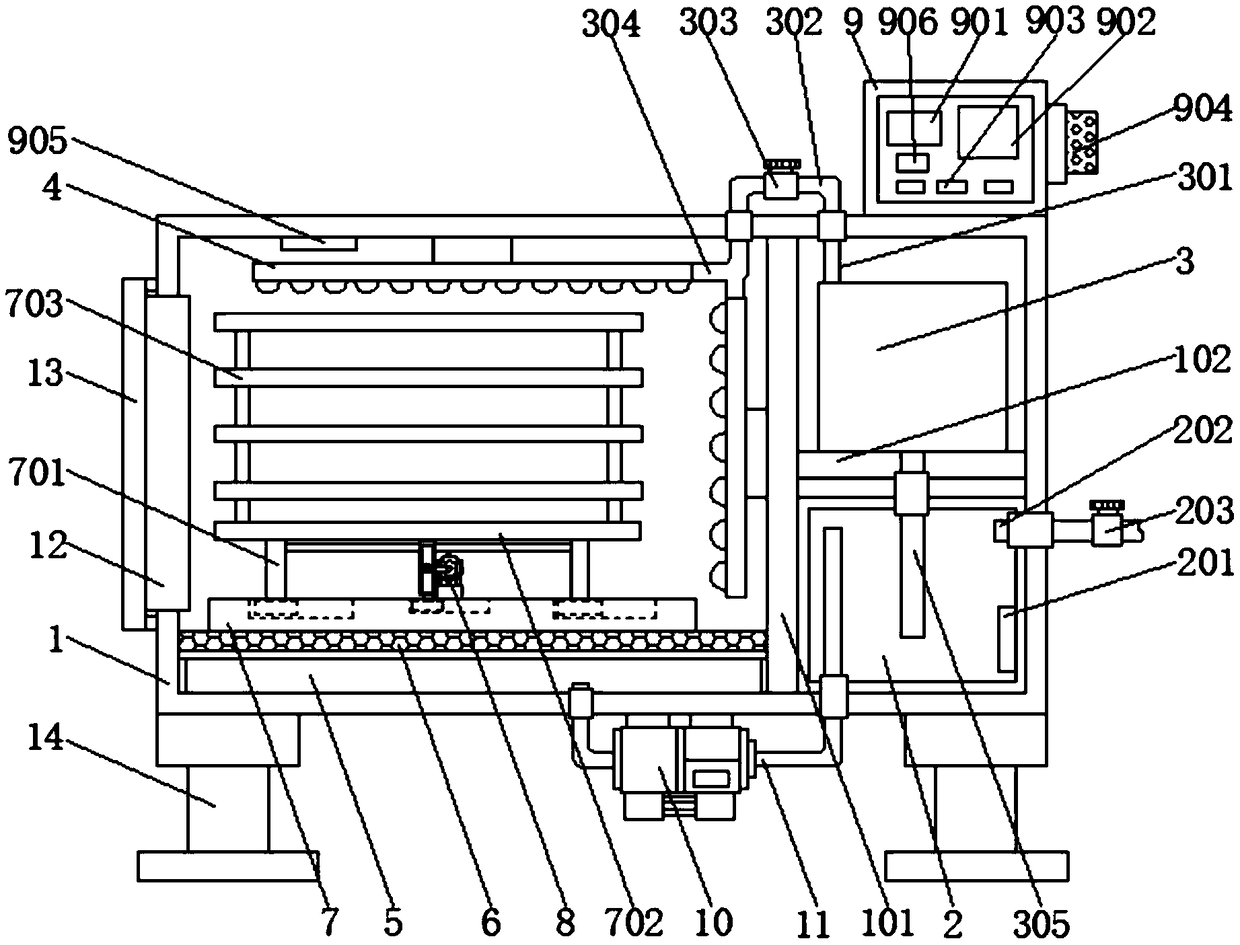

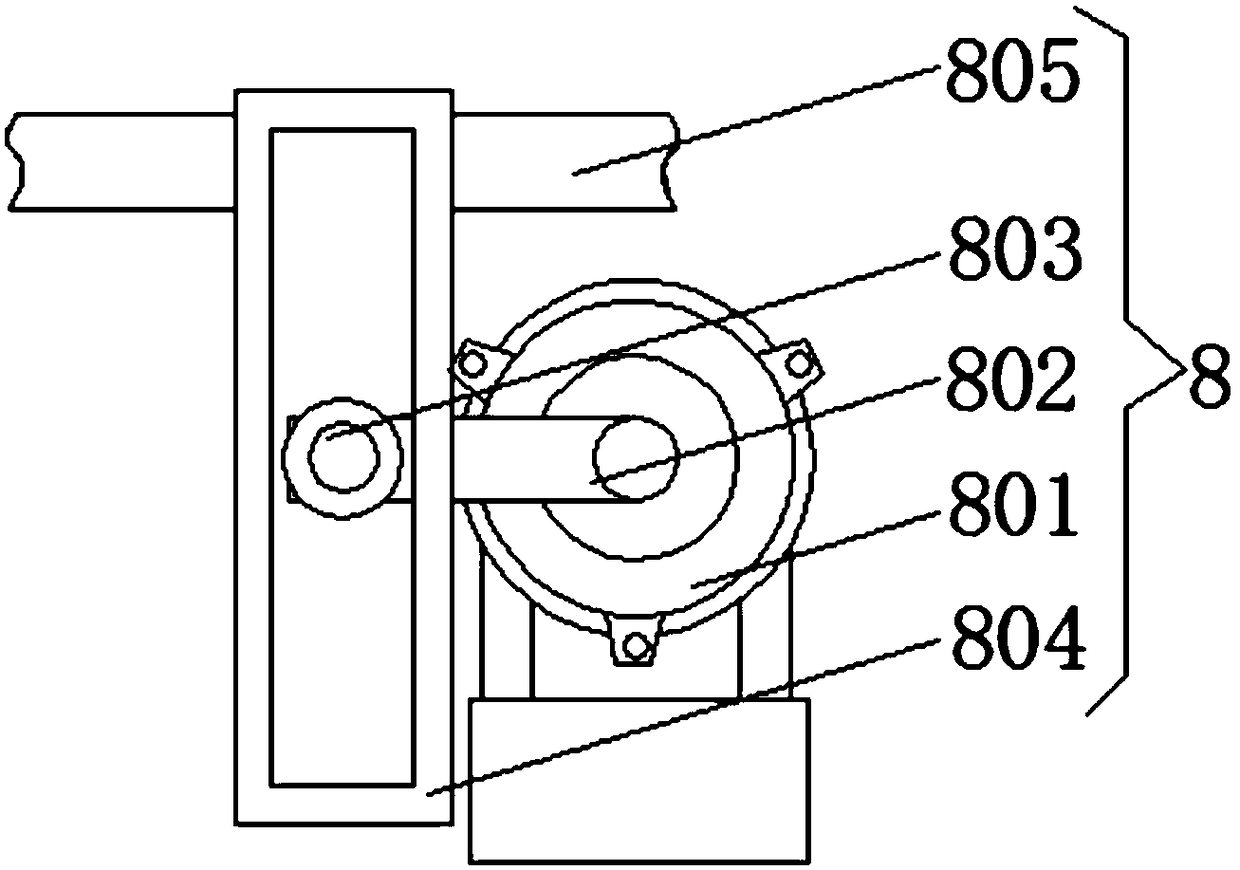

The invention discloses a log centering device with a good centering effect for log processing. The log centering device comprises a bottom plate, sliding rods and folding pieces, the two sets of sliding rods arranged front and back are installed at the top of the bottom plate, and the folding pieces are installed at the top of the bottom plate. Sliding plates are installed on the outer surfaces of the two sets of sliding rods correspondingly, a fixing plate is installed at the tops of the two sets of folding pieces, and multiple sets of telescopic springs are installed at the top of the fixing plate and the tops of the sliding plates correspondingly. A storage plate is installed at the tops of four sets of telescopic springs, and a servo motor is installed at the top of the storage plate. According to the log centering device, one end of a log can be fixed through steel needles, meanwhile, the other end of the log can be attached to the outer wall of a rubber sleeve through pushing force generated when electric telescopic rods extend outwards, the other end of the log is doubly fixed, and thus the situation that the log is thrown out of the device under driving of rotating force is avoided; parts for fixing in the device are detachable, and thus size replacement is facilitated; and vibration can be counteracted through the springs when two sets of motors in the device operate.

Owner:JIANGSU JIANGHAI MACHINE TOOLS GROUP

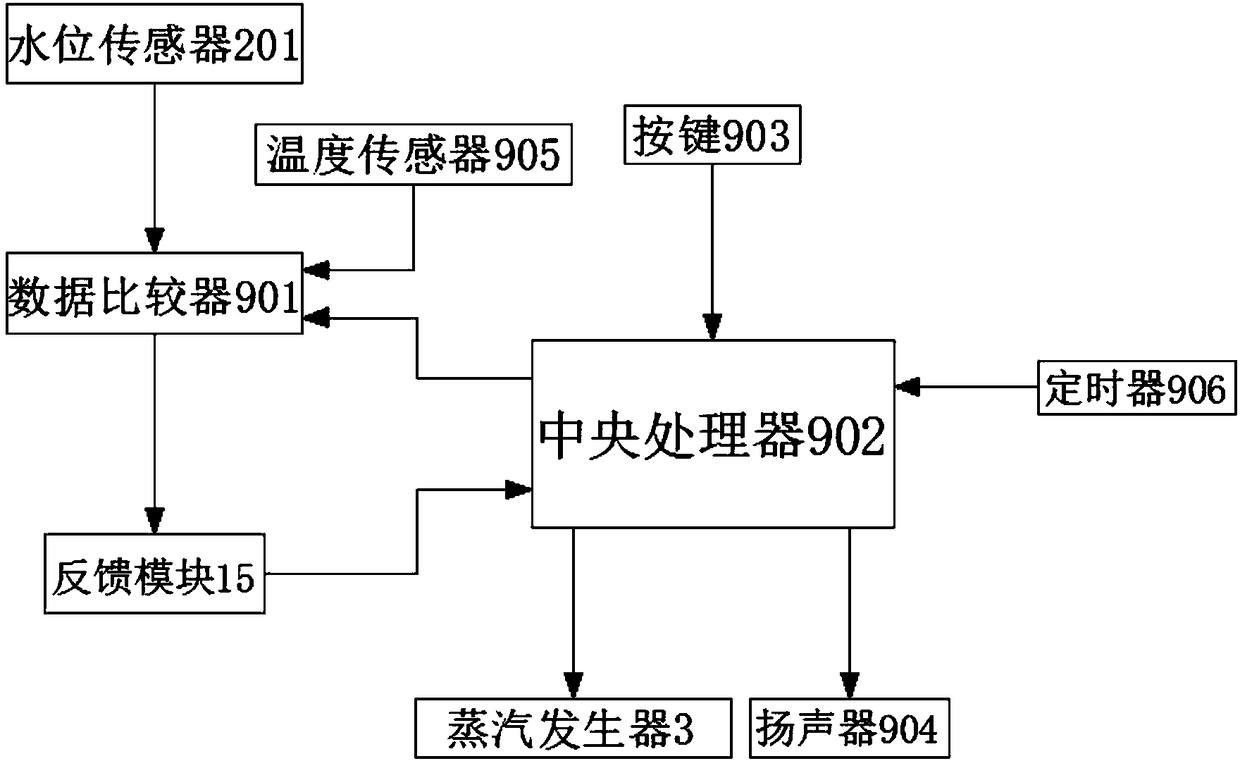

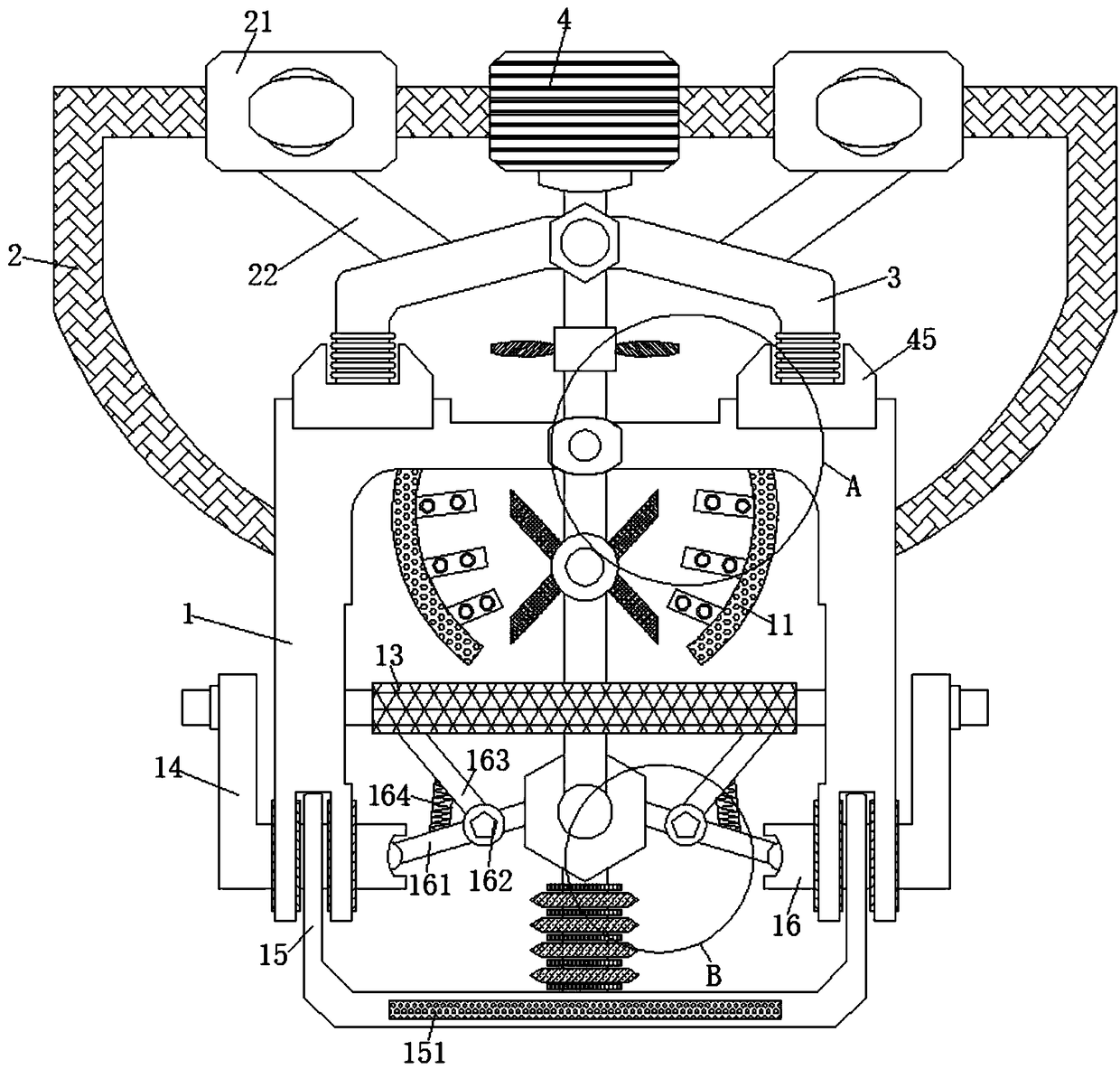

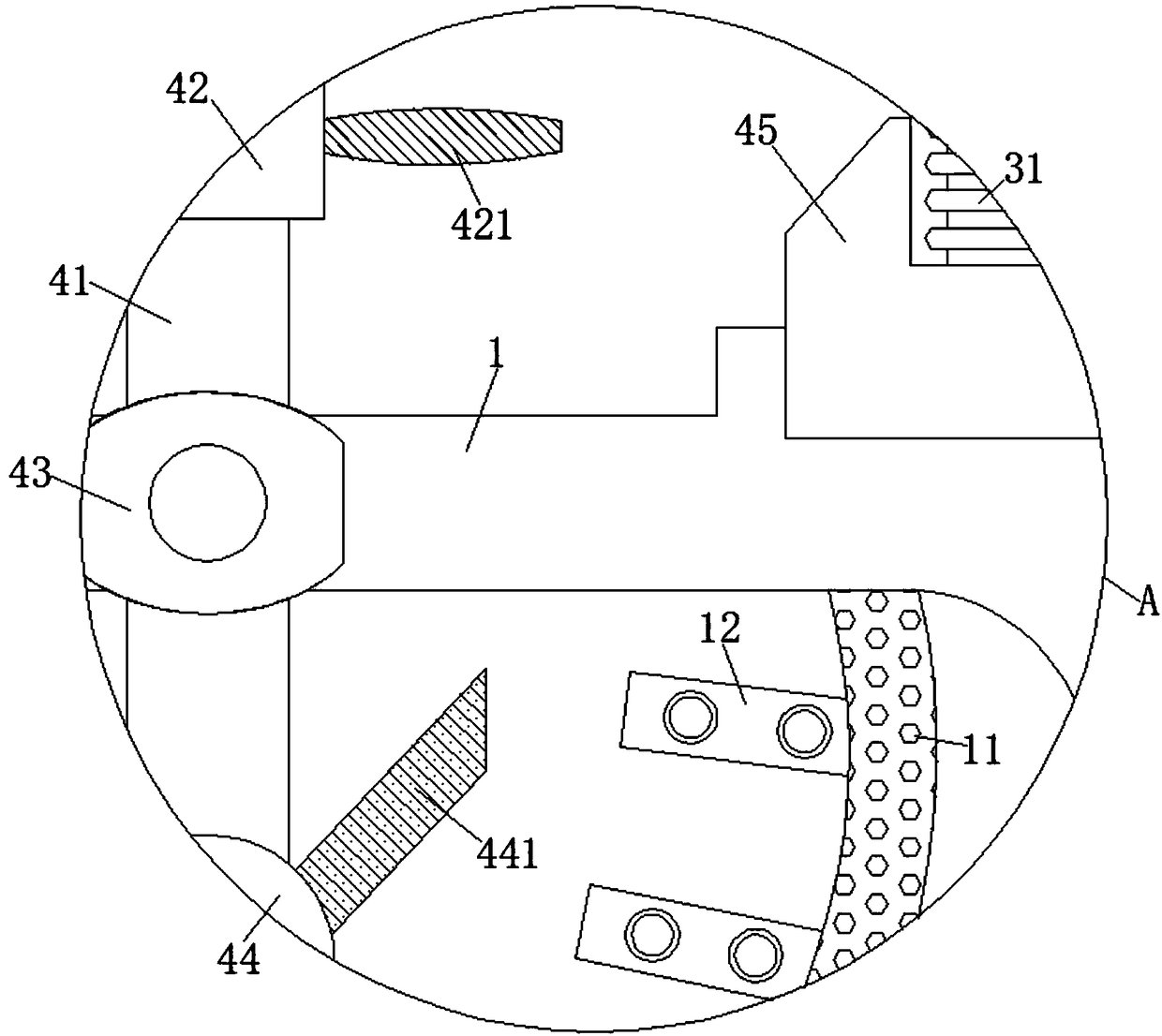

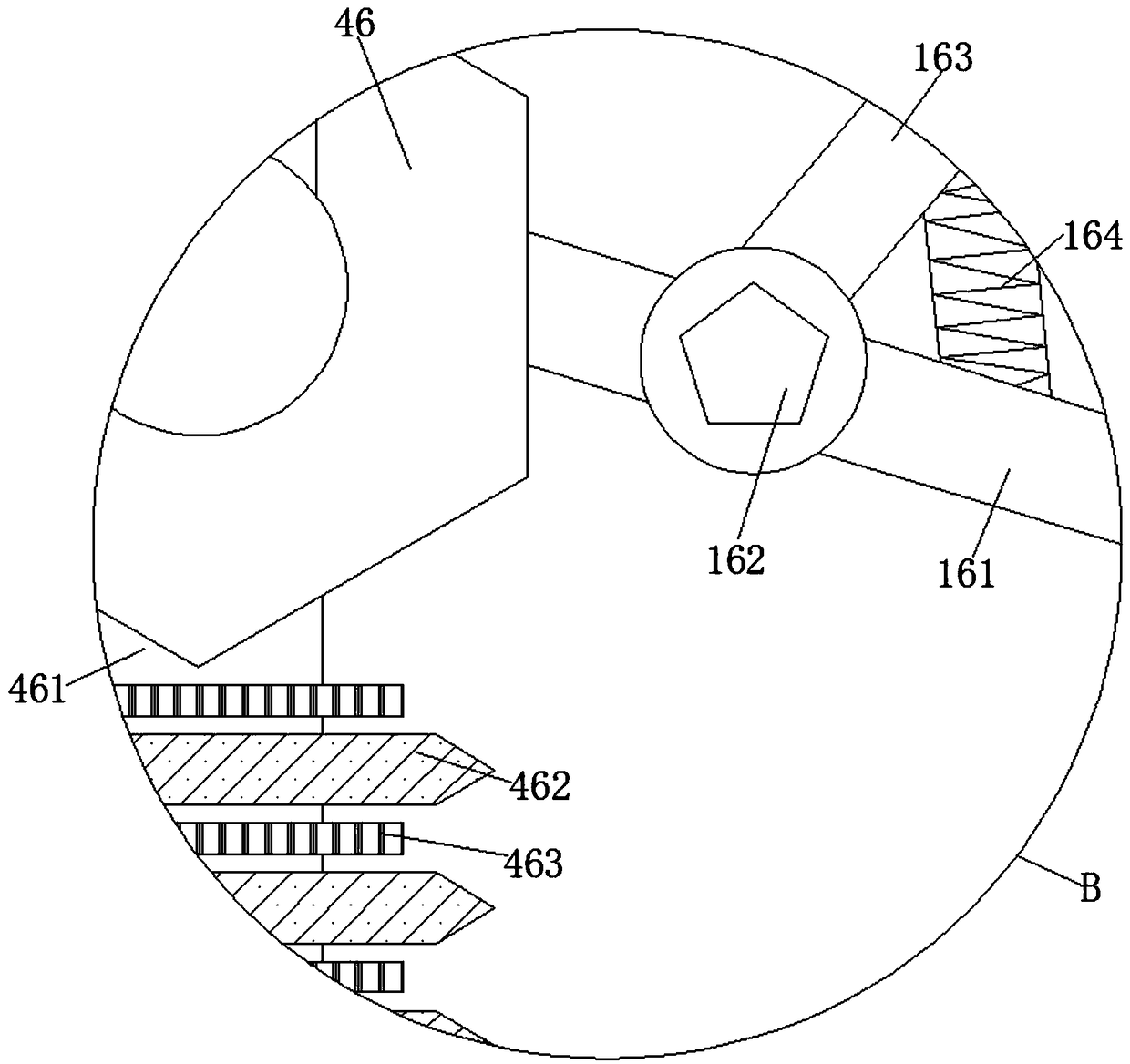

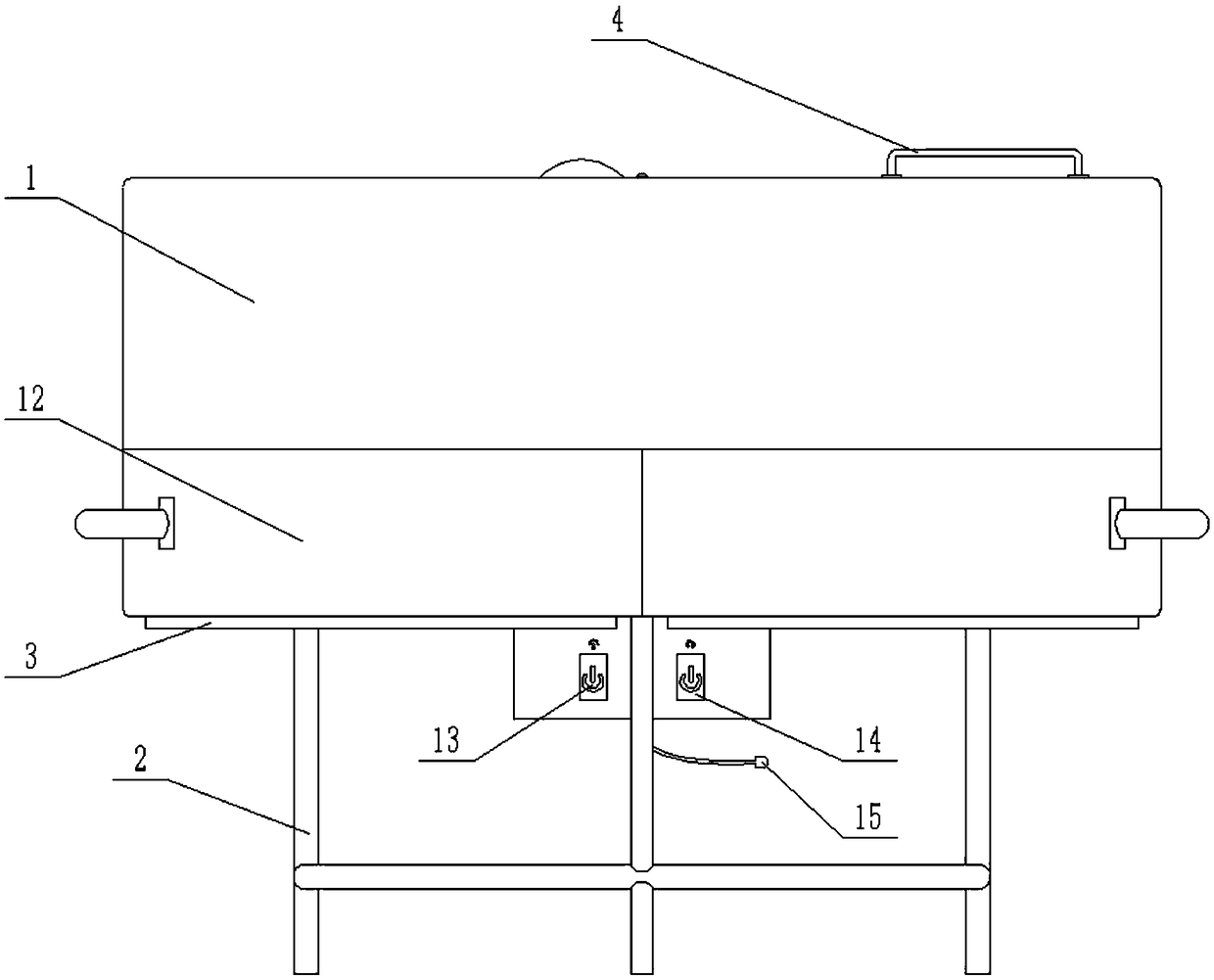

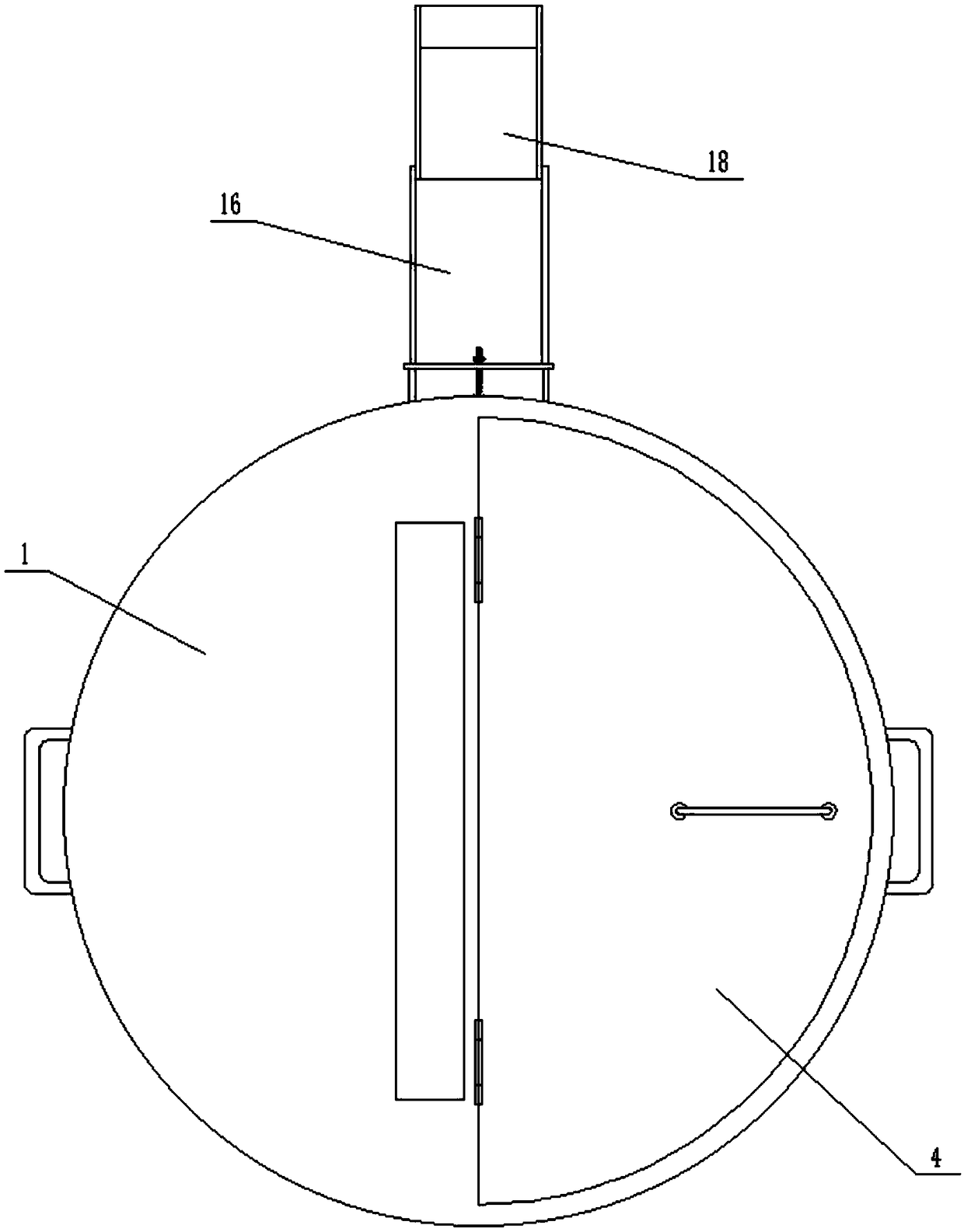

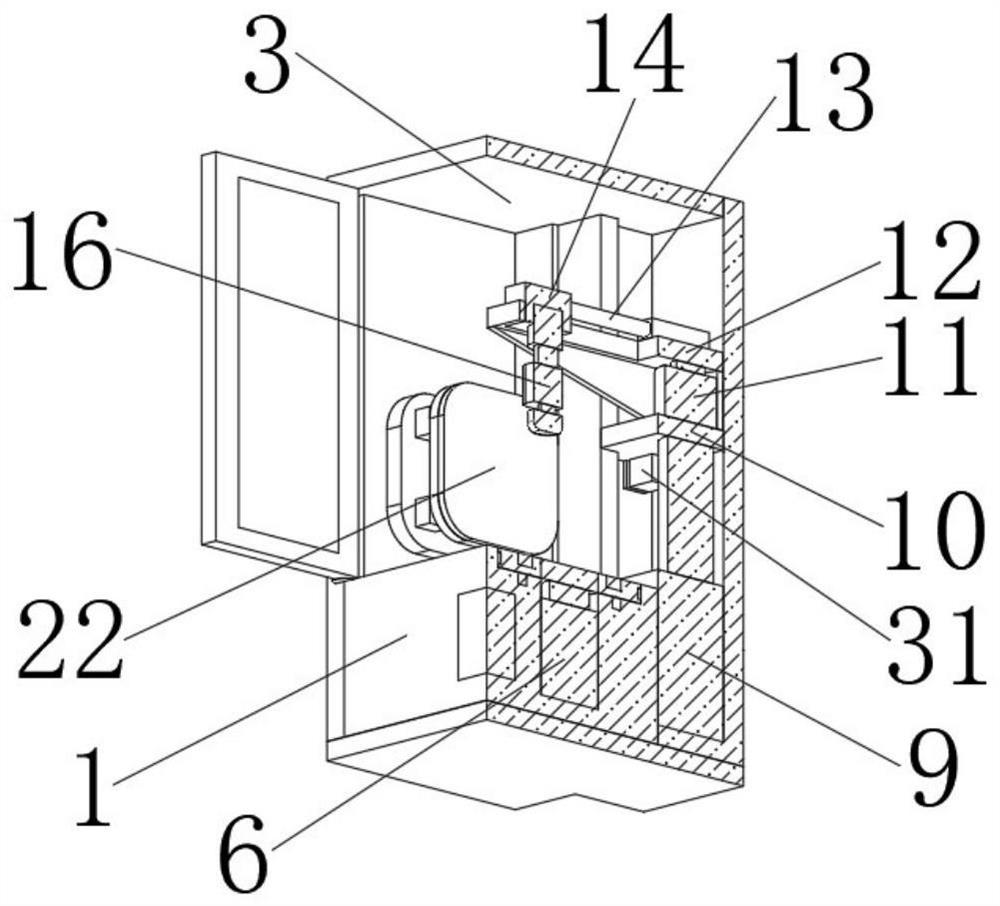

Traditional Chinese medicine moistening machine

PendingCN108553303AFully infiltratedIncrease infiltration ratePharmaceutical product form changeMedicinal herbsEngineering

The invention discloses a traditional Chinese medicine moistening machine, and relates to the technical field of pharmaceutical equipment. The machine comprises a shell, a partition plate is fixedly connected between the top and the bottom of the inner wall of the shell, the top of the inner wall of the shell and one side of the partition plate are provided with steam disks, a cross plate is fixedly connected between one side of the partition plate and one side of the inner wall of the shell, a water tank is fixedly connected on one side of the bottom of the inner wall of the shell and positioned on one side of the partition plate, a water level sensor is fixedly connected at the bottom of one side of the inner wall of the water tank, and a steam generator is fixedly connected at the top of the cross plate. According to the traditional Chinese medicine moistening machine, working of a moving device drives a support frame to bilaterally shake to drive supporting plates storing medicinesto bilaterally move, so that the medicines are mutually staggered, contact areas between the medicines and steam are increased, the lower medicines can sufficiently contact with the steam, the steamsufficiently enters inside of the steam, the medicines is thoroughly moistened, moistening of the medicines is accelerated, and working efficiency is improved.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE +1

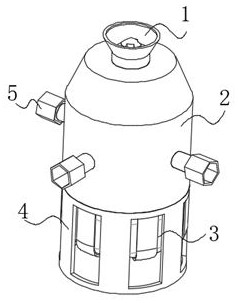

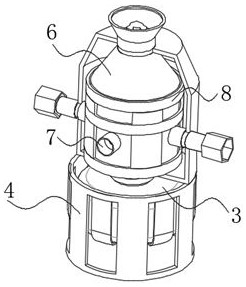

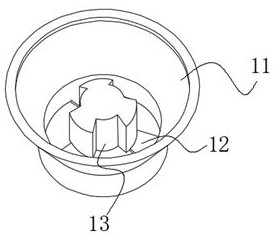

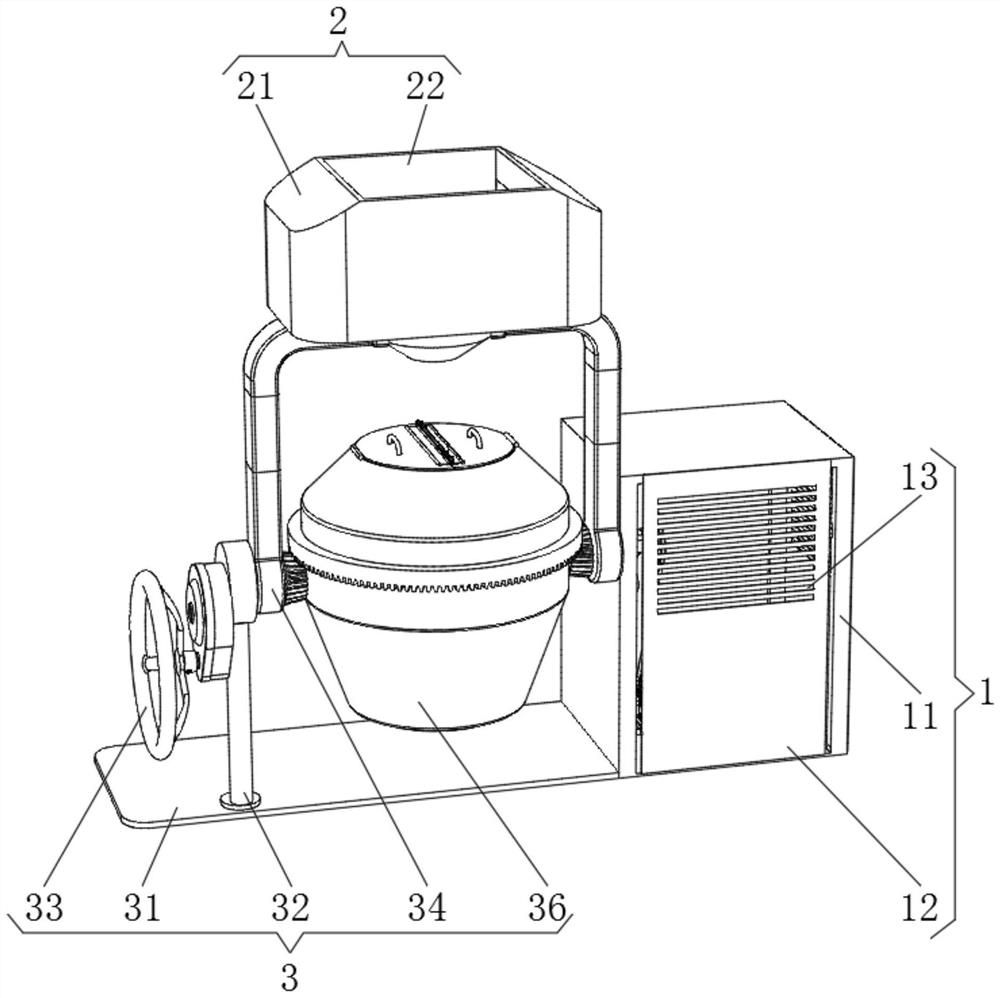

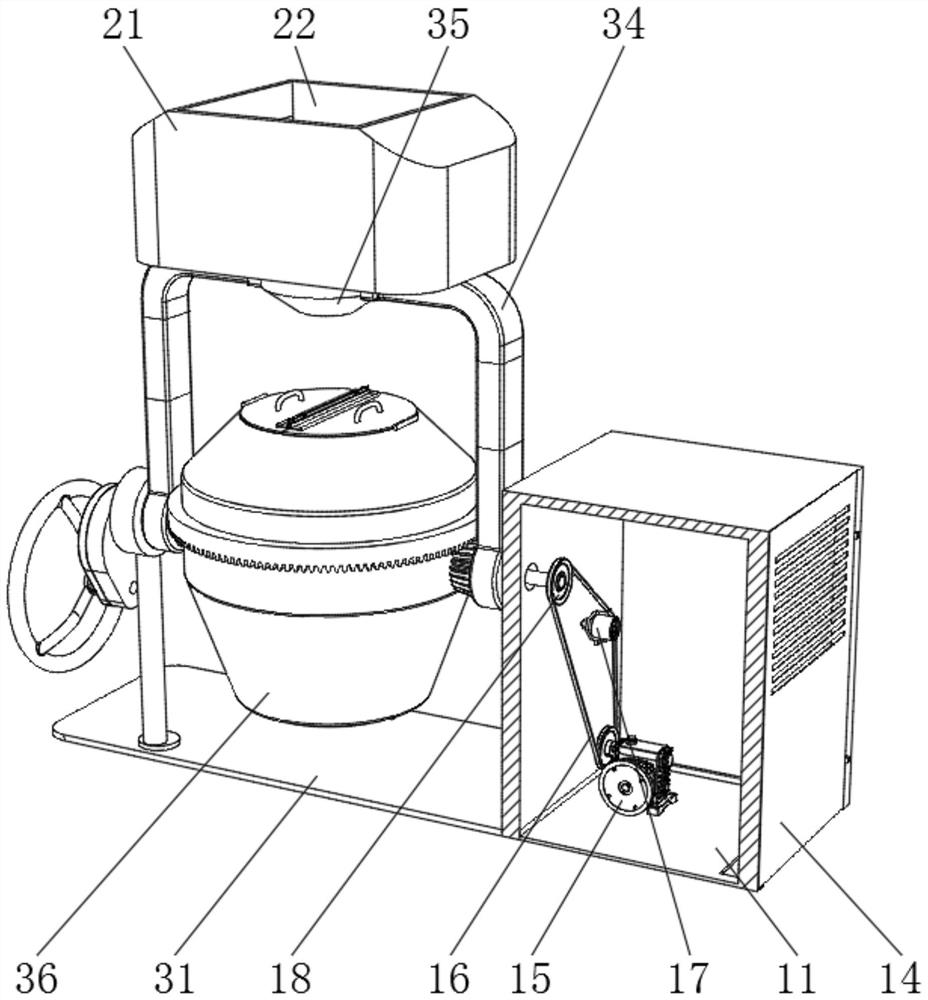

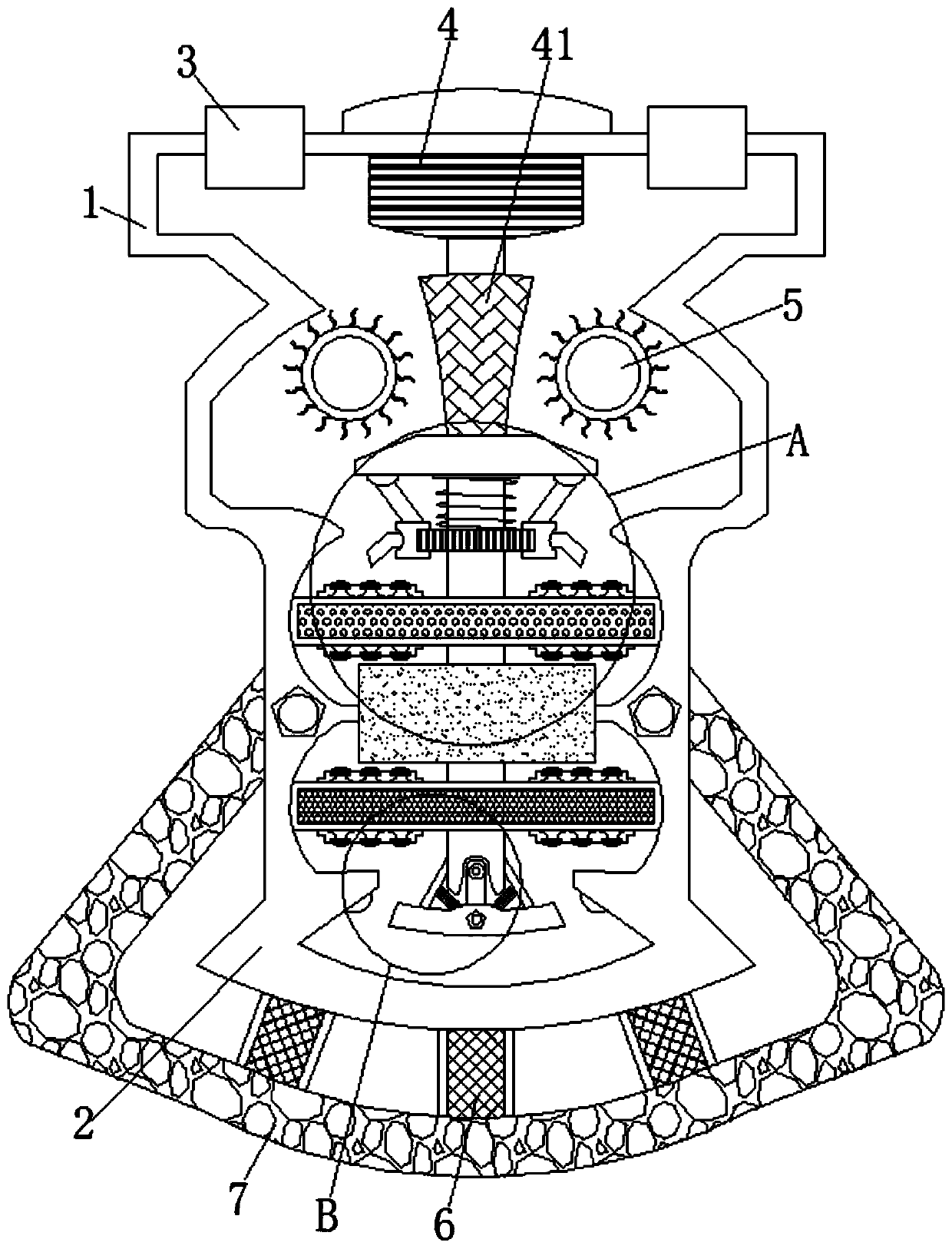

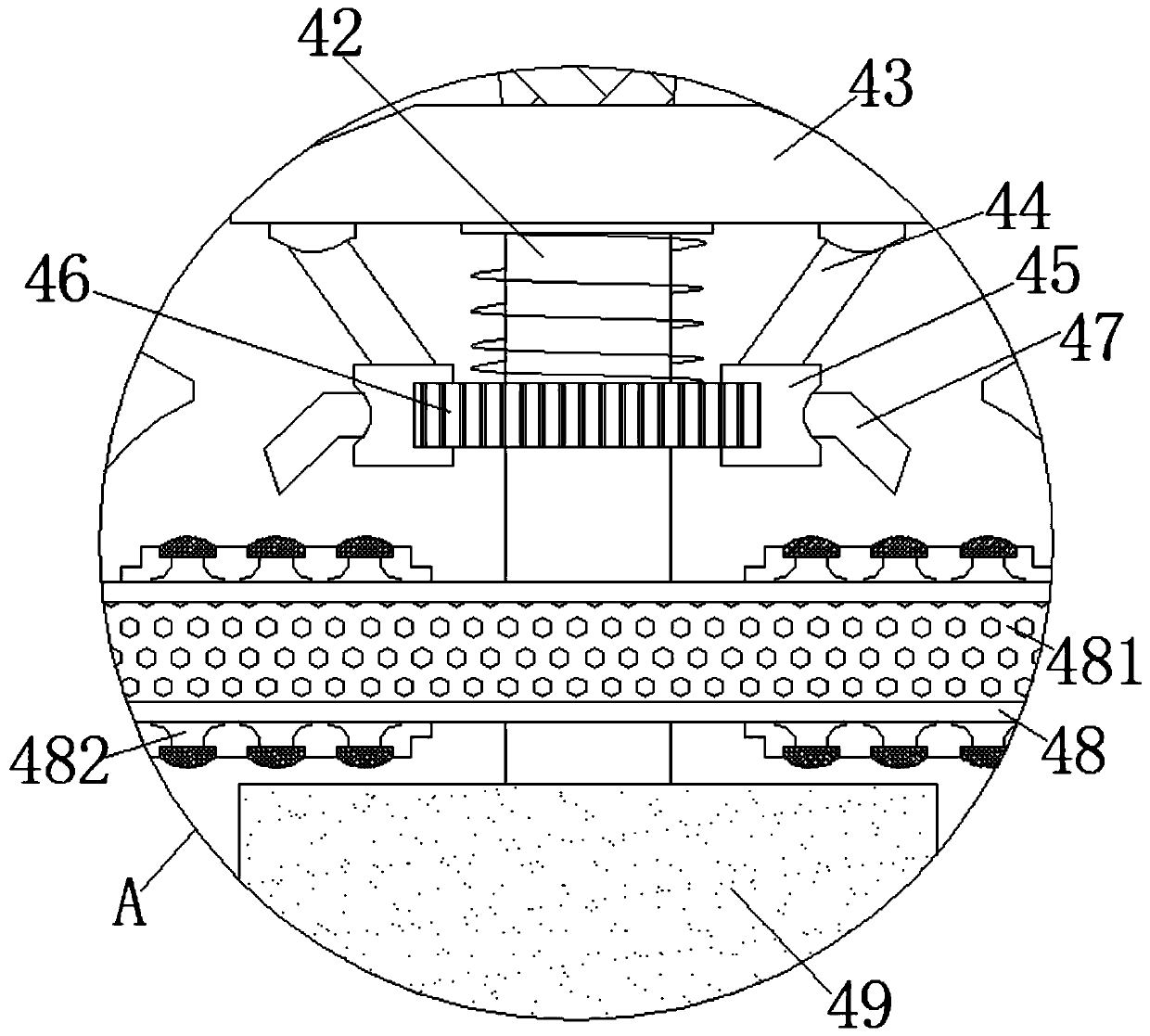

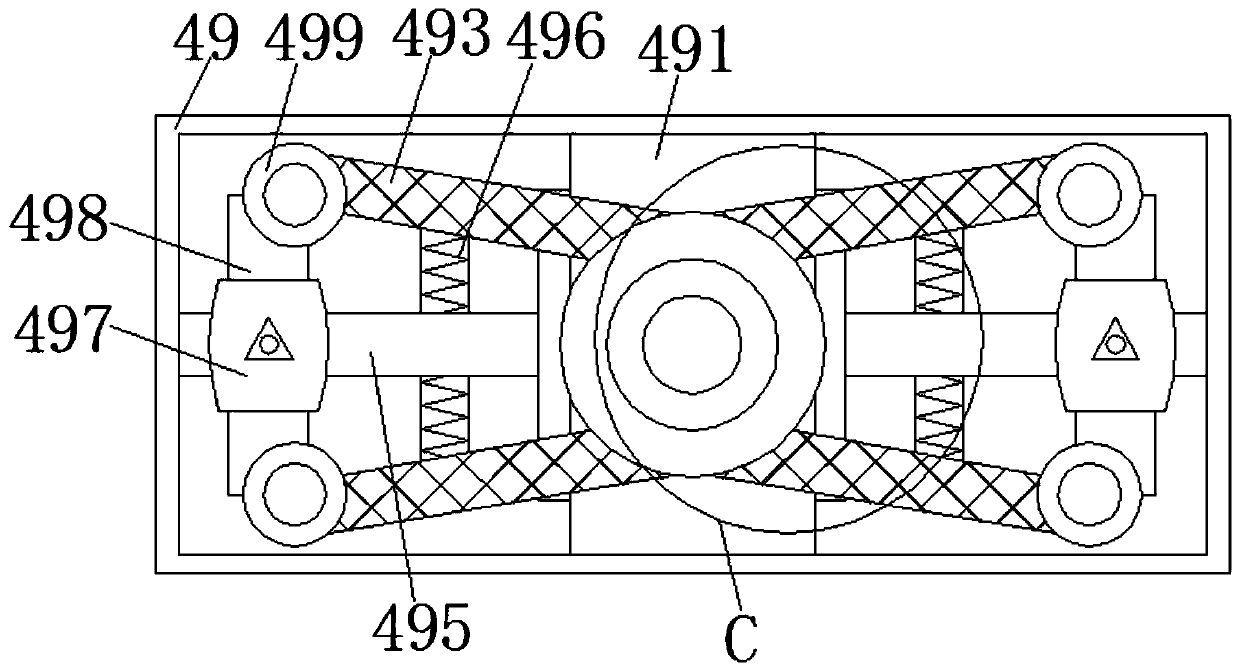

Screening-type micro-processing equipment for peeling of highland barley

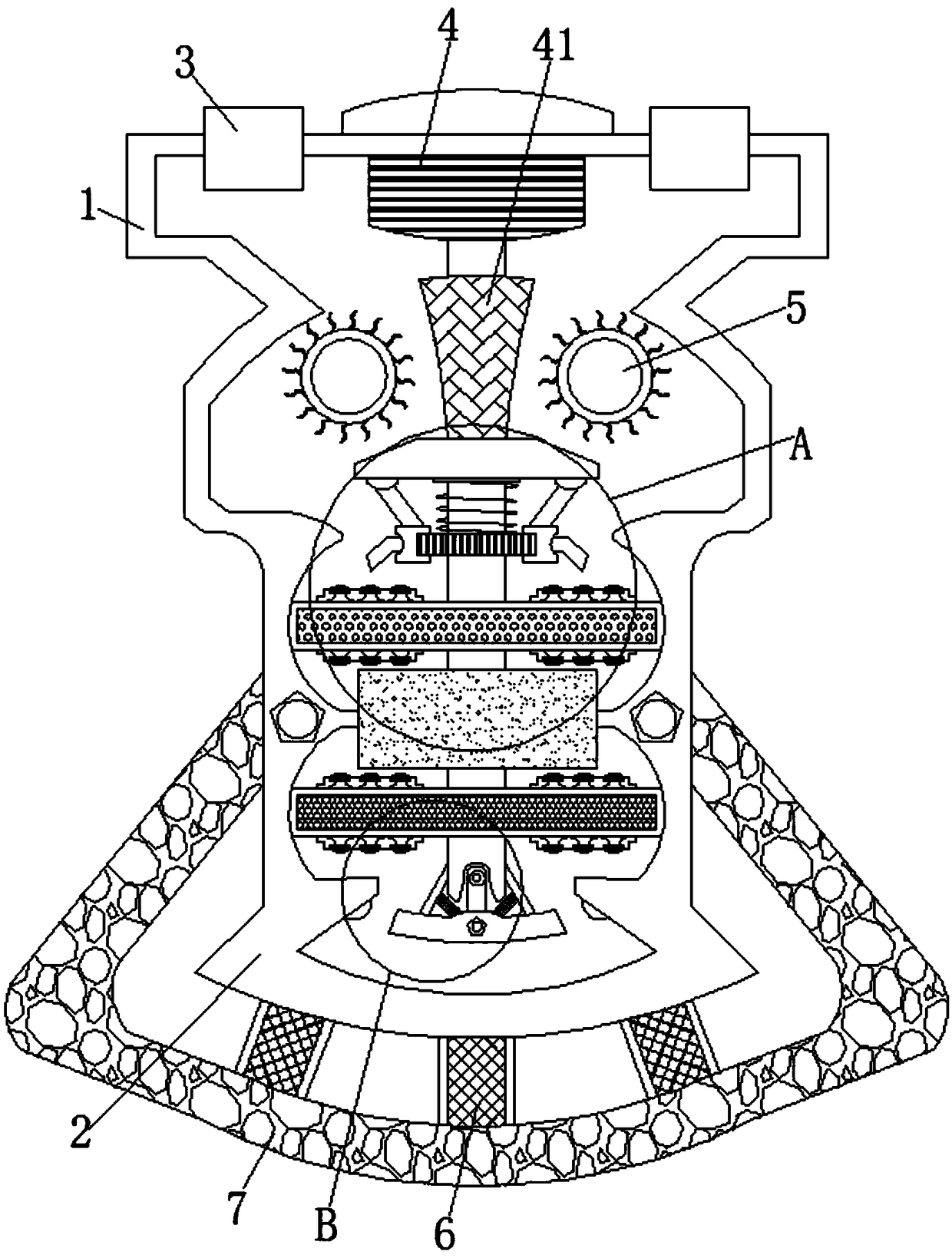

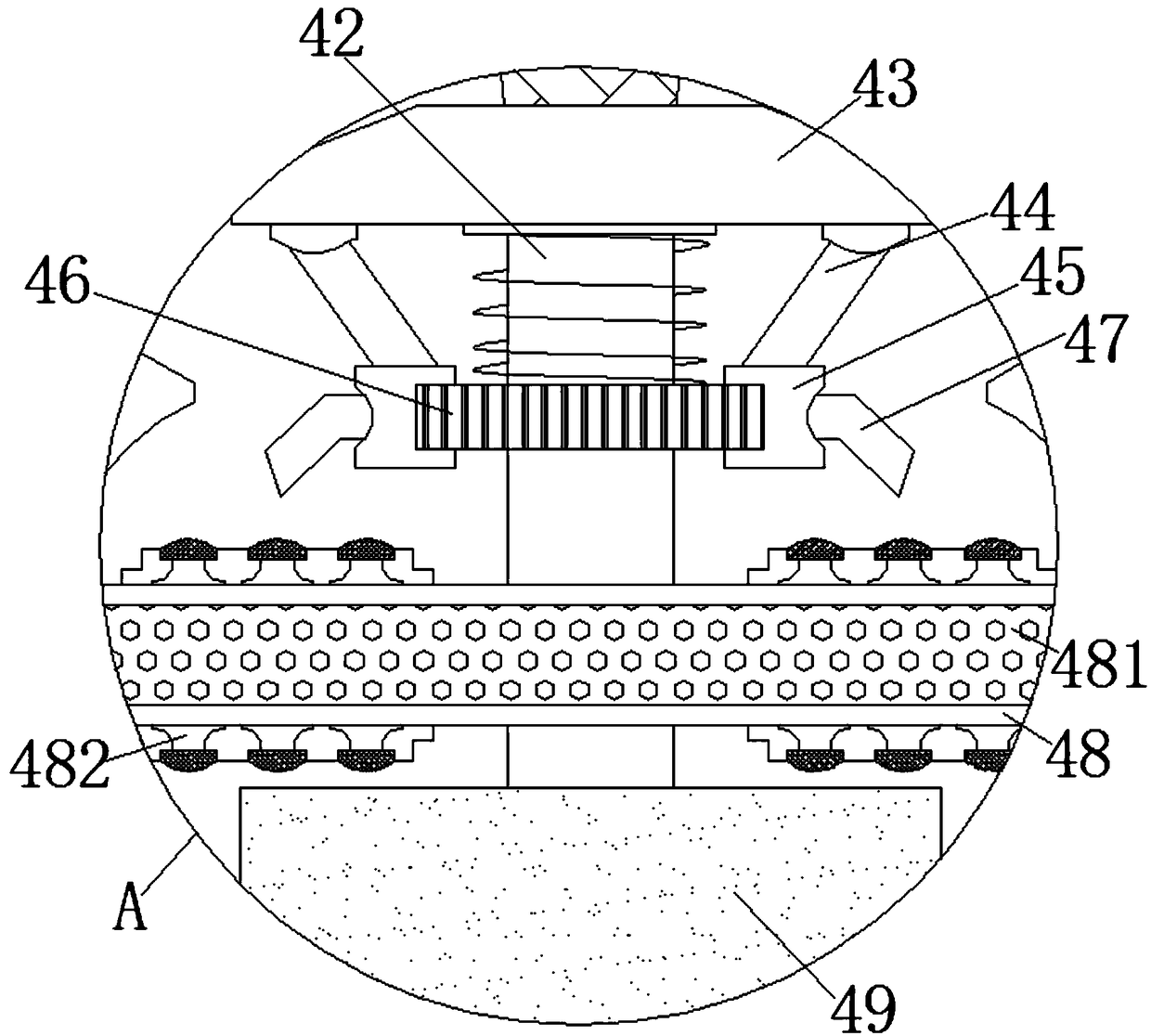

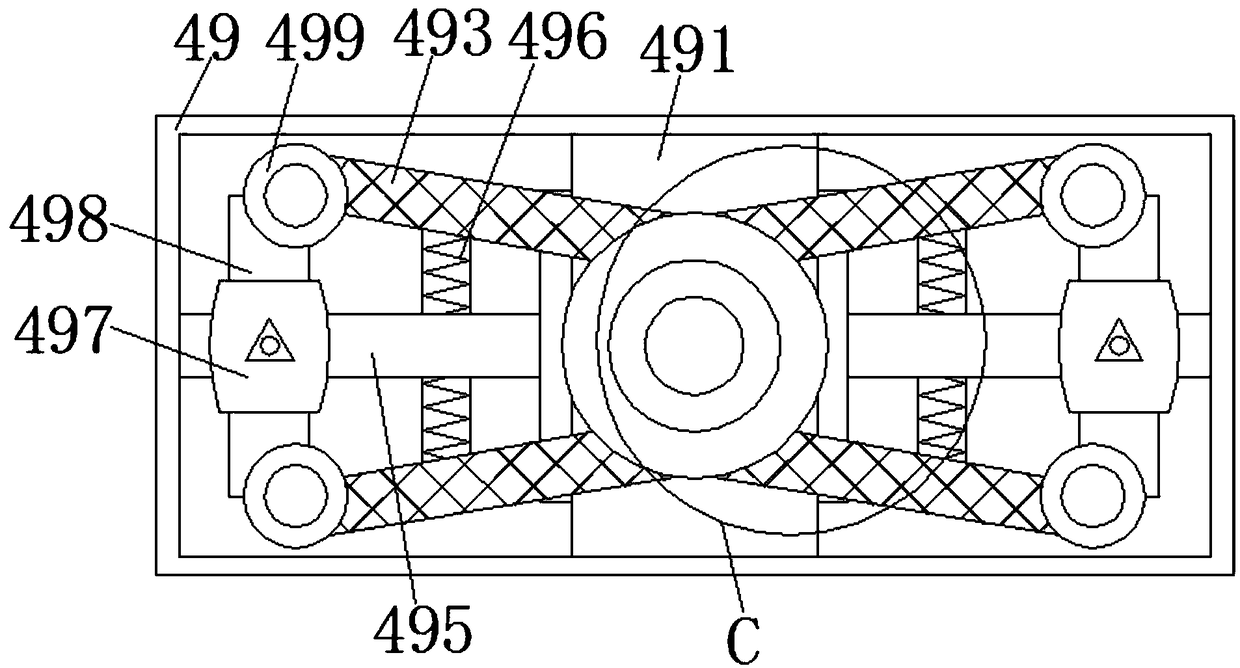

InactiveCN108906168AGood peeling effectReduce the burden onGrain huskingSievingEngineeringCentrifugal force

The invention relates to the technical field of food processing, and discloses screening-type micro-processing equipment for peeling of highland barley. The screening-type micro-processing equipment comprises a peeling processing device, the two sides located at the top of the peeling processing device are welded to the two ends of the bottom of a feeding supporting device respectively, putting openings are clamped in inner cavities in the two sides of the top of the feeding supporting device, putting pipes are welded to the bottoms of the two putting openings, one ends of the bottoms of the two putting pipes are inserted into the two sides of the top of a feeding hopper respectively, the two sides of the bottom of the feeding hopper are welded to the inner sides of two fixing clamping bases, the two fixing clamping bases are welded to the two sides of the top of the peeling processing device respectively, and the two sides of the top of a discharging hopper are inserted into inner cavities of the bottoms of the two sides of the peeling processing device. According to the screening-type micro-processing equipment for peeling of the highland barley, a user puts highland barley required to be peeled into the feeding hopper, highland barley skins can be subjected to hull breaking through a hull breaking device, peeled skins can be effectively reduced through generated centrifugalforce, and fall down along with the highland barley, and the peeling effect on the highland barley is thus improved.

Owner:庞成军

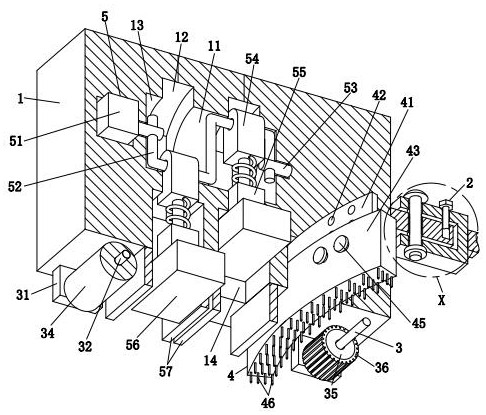

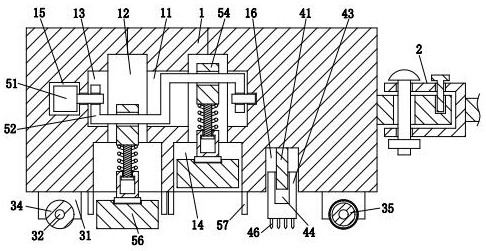

Tin soldering device with pin protection function for electronic part assembling

InactiveCN112317917AControl lengthControl pin clippingWelding/soldering/cutting articlesMetal working apparatusCapacitanceHydraulic cylinder

The invention relates to a tin soldering device with a pin protection function for electronic part assembling. The tin soldering device comprises an equipment shell and a second belt conveyor, whereina first motor is installed at the lower end of the equipment shell, a rotating platform is arranged in the middle of the lower wall of the interior of the equipment shell, a positioning support is fixed to the rotating platform, a pin shearing mechanism and a first belt conveyor are sequentially arranged on the lower wall of the interior of the equipment shell anticlockwise, an electronic part body is placed at the upper end of the equipment shell, a first electric sliding rail is arranged on the rear wall of the equipment shell, and a second multi-section hydraulic cylinder is installed at the lower end of the first electric sliding rail. The tin soldering device with the pin protection function for electronic part assembling has the beneficial effects that pins of capacitors are inserted into pin protection sleeves to be protected, so that the situation of waste caused by the fact that the pins are bent or damaged due to collision and other problems in the conveying process and thecapacitors cannot be used consequently is prevented.

Owner:东莞市帕特慕可科技有限公司

Constant temperature control device and constant temperature control of artificial joint curved surface turbulence polishing equipment

ActiveCN106475915AHigh polishing precisionIncreased turbulent kinetic energy and velocityAbrasive feedersAbrasive blasting machinesParticle flowArtificial joints

The invention discloses a constant temperature control device and a constant temperature control method of artificial joint curved surface turbulence polishing equipment. The constant temperature control device comprises a glass restriction component, an electromagnetic wave heating matrix, a supporting rack and an electromagnetic wave controller; the electromagnetic wave heating matrix is arranged on one side of the glass restriction component, and comprises a plurality of electromagnetic wave heaters; the distribution shape of the electromagnetic wave heaters is the same as the projection shape of a modeling runner on the side surface of an artificial joint; and each electromagnetic wave heater is arranged on the supporting rack, and is over against the modeling runner. The electromagnetic wave heating matrix is placed on the side surface of the glass restriction component, so that turbulence energy and a speed of an abrasive particle flow cutting fluid are increased, linear loss and head loss of an abrasive particle flow in the modeling runner are compensated, then the integral processing effect is improved, the temperature of the abrasive particle flow is kept constant in the integral processing procedure, and the surface processing quality of the artificial joint is more uniform.

Owner:ZHEJIANG UNIV OF TECH

Quality improvement and control method for surface of copper alloy pipe

InactiveCN107116103AQuality improvementAffect the processing effectDrawing diesExtrusion cleaning devicesTherapeutic effectAqueous solution

The invention relates to a quality improvement and control method for the surface of a copper alloy pipe. The production and manufacturing process comprises the following technological steps of (1), soaking through an aqueous solution for degreasing, (2), rinsing through clear water, (3), transferring without dust and bump damage, (4), on-line blowing of compressed air, (5), strong flushing through a lubricant of a drawing mold and (6), water blanking of the drawn pipe. According to the method, multiple control methods are adopted, the quality of the surface of the copper alloy pipe is improved effectively, it is avoided that the machining treatment effect of the surface of the alloy pipe is influenced by impurities, the use is convenient, the number of flaws of the surface of the produced copper alloy pipe is small, the use effect is good, and the service life is long.

Owner:浙江同诚合金铜管有限公司

Edge folding device for right-angled bed sheet

The invention relates to an edge folding device for a right-angled bed sheet. The edge folding device comprises a supporting plate, a first edge folding mechanism, a second edge folding mechanism, a worktable, a rack and a blowing device, wherein the worktable is arranged in the middle of the rack; the first edge folding mechanism and the second edge folding mechanism are both arranged on the rack and respectively positioned outside the two parallel side edges of the worktable; the supporting plate allows cloth to be placed thereon; a plurality of air outlets are formed in at least two parallel side edges of the supporting plate; all the air outlets are communicated with an air inlet through pipelines; the worktable is used for supporting the supporting plate; the blowing device is arranged on the worktable under the supporting plate and comprises a blowing nozzle capable of being matched with the air inlet. The edge folding device lifts up the edge of the cloth through blowing to conduct edge folding, performs secondary edge folding through moving a cloth supporting device and a cloth pressing device, does not need manual operation, and is simple in structure and good in effect.

Owner:WUHAN TEXTILE UNIV

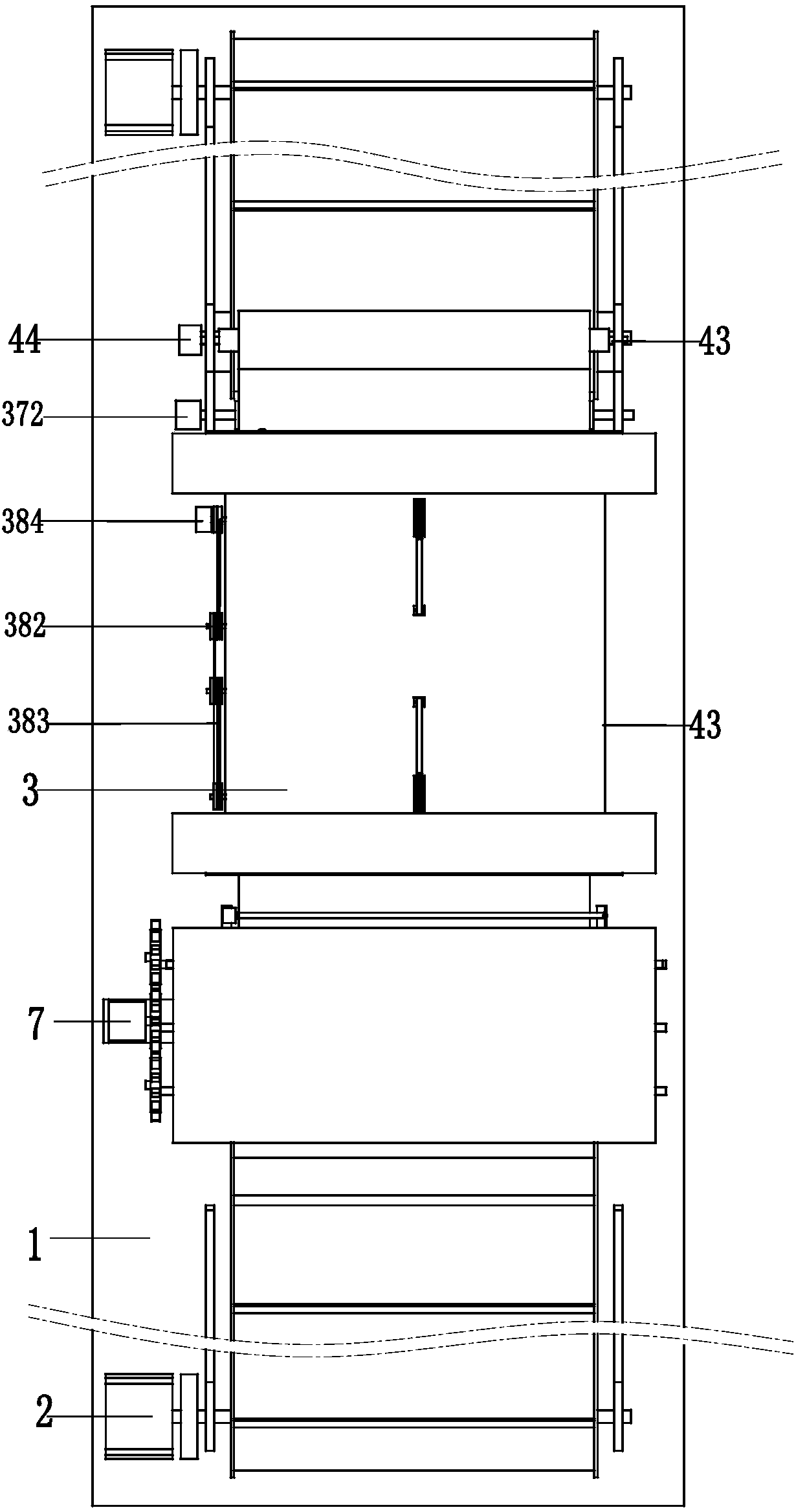

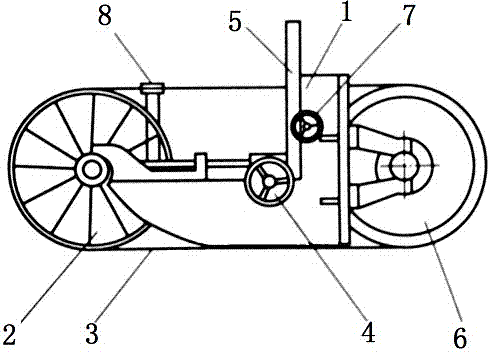

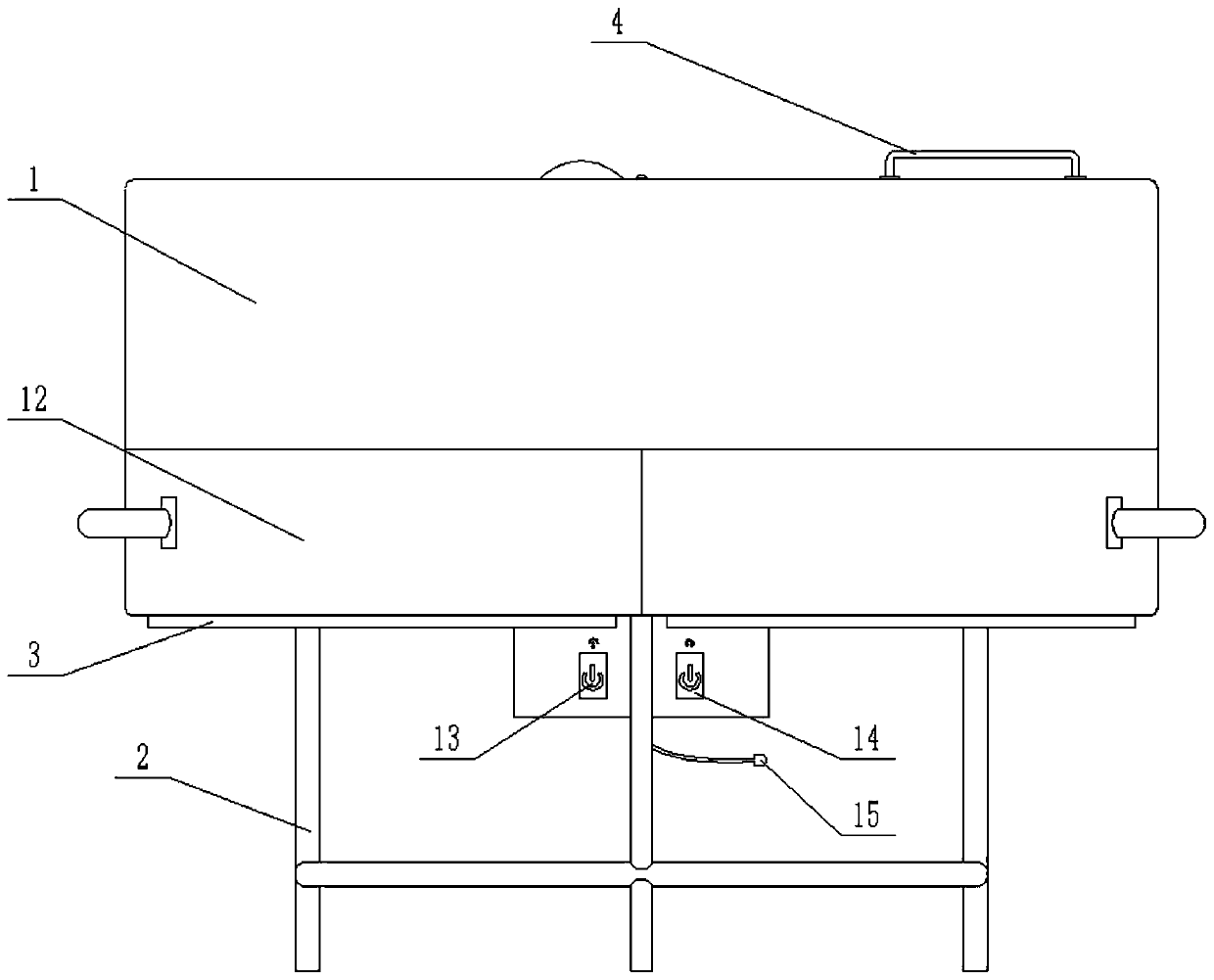

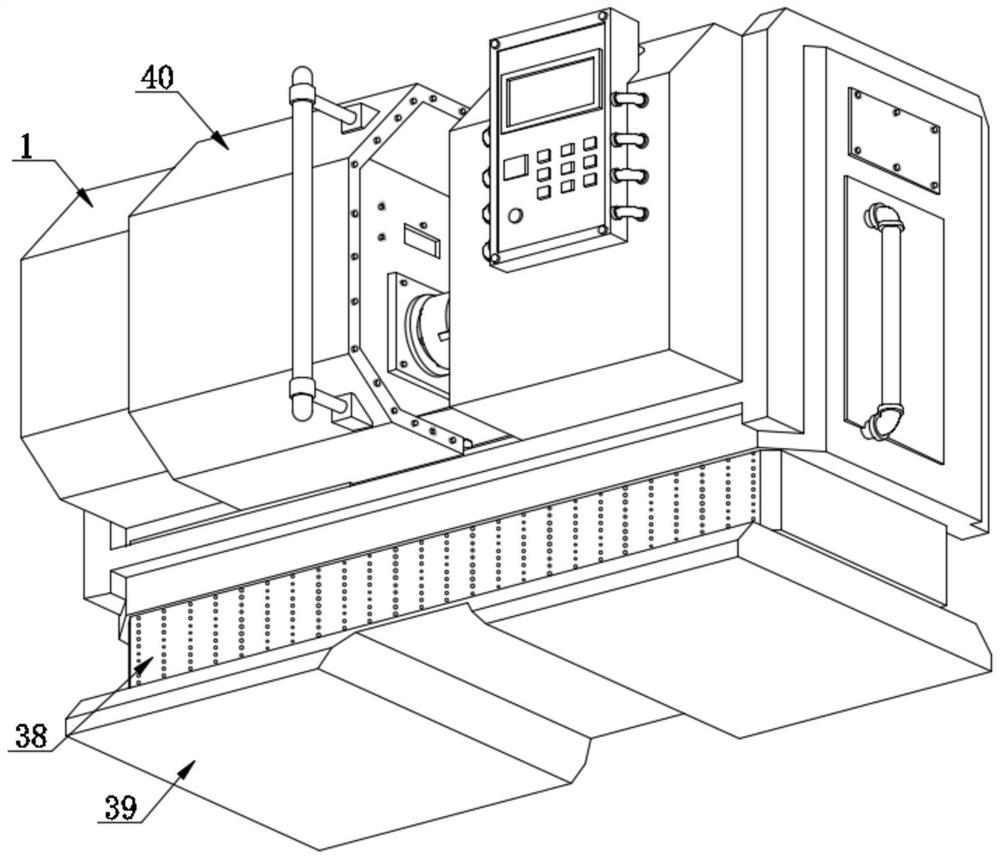

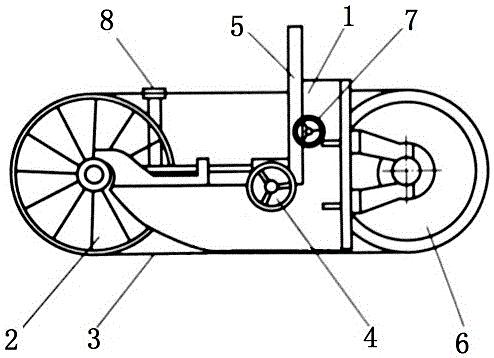

Horizontal finishing batching machine

InactiveCN104495453AAffect the processing effectSolve the problem of line speed change afterFunction indicatorsWebs handlingBatch machineMechanical engineering

The invention discloses a horizontal finishing batching machine which comprises a support. Two rollers are arranged on the support and are connected with each other by a belt in a tensioned manner, and rotary drums are coaxially connected onto the rollers by keys. The horizontal finishing batching machine has the advantages that the rollers which are connected with each other by the belt can drive the rotary drums on the two rollers to rotate, and accordingly cloth can be wound on the rotary drums; a positional relation between the two rollers can be regulated by the aid of a horizontal distance regulating device and a vertical distance regulating device, and can be particularly regulated by a horizontal turning wheel and a vertical turning wheel which rotate, accordingly, a tension state of the cloth can be changed within a certain range, and the problem of influence on follow-up processing due to the fact that existing cloth is in different tension states can be solved.

Owner:桐梓县创兴自动化设备有限公司

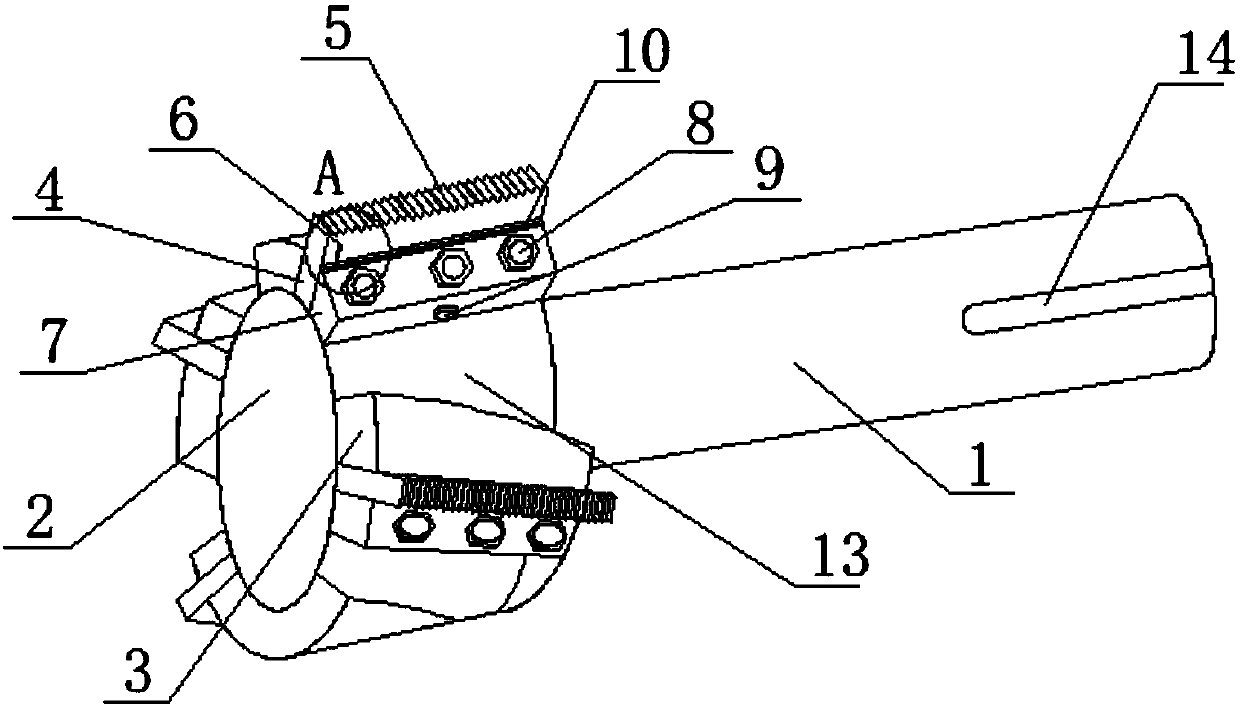

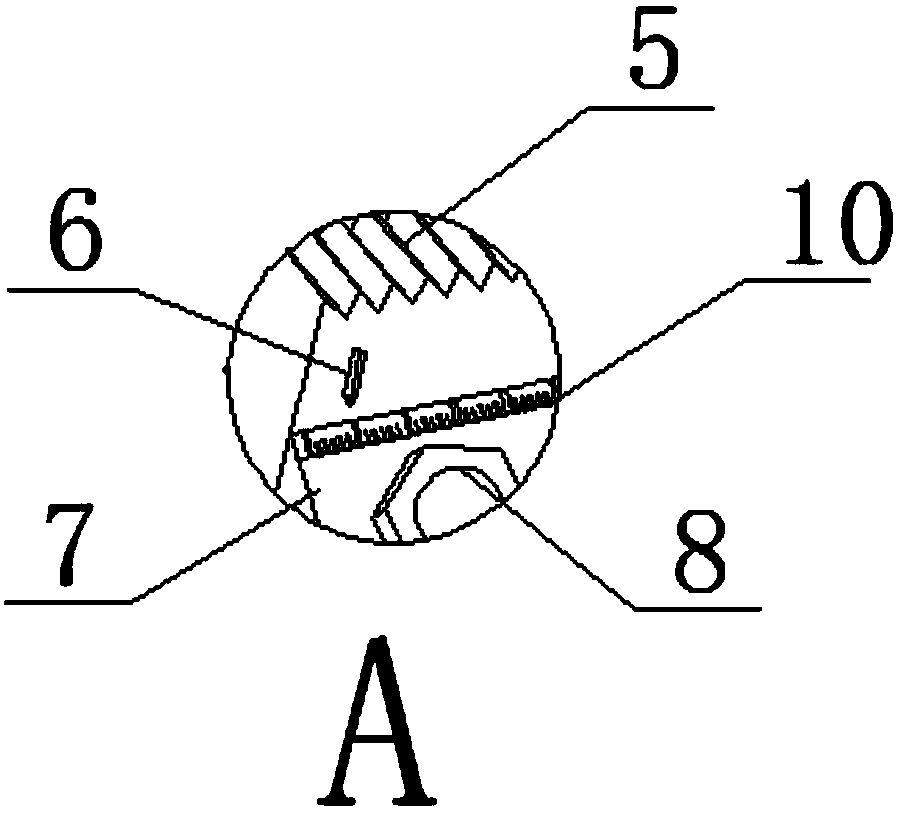

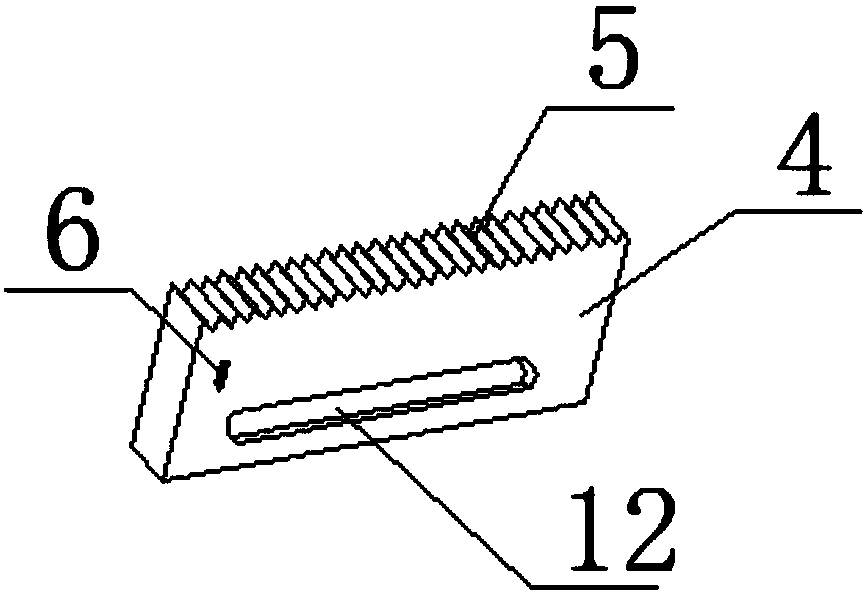

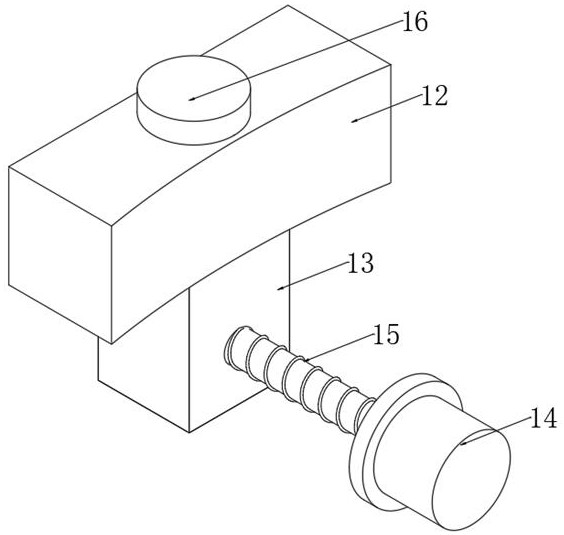

Thread milling cutter structure

InactiveCN107671374APrevent rotationImprove machining accuracyThread cutting toolsMilling cutterMechanical engineering

The invention discloses a thread milling cutter structure, which comprises a main shaft, a rotating body, a block, a cutting and milling plate, a cutting and milling thread, a pointer, a fixed block, a connecting bolt, an adjusting bolt, a scale, a friction block, an adjusting groove, and a material guide groove and snap slots. The main shaft of the present invention is provided with a symmetrical clamping groove, which can be clamped with the installation interface, and the device can effectively prevent the rotation in the horizontal direction during the rotation process. It is fixed with the rotating body through the fixed block, and the milling plate is connected with the rotating body. Different types of cutting plates can be replaced to cut and mill threads of different types and diameters. There is a pointer on the cutting plate corresponding to the scale on the fixed plate. Cooperate to facilitate the adjustment of the position of the cutting board. There is an adjustment groove on the cutting board. The adjusting groove cooperates with the adjusting bolt. After the cutting board is fine-tuned, further fixing is carried out, which effectively improves the fixing strength of the cutting board.

Owner:常州巨丰精密工具制造有限公司

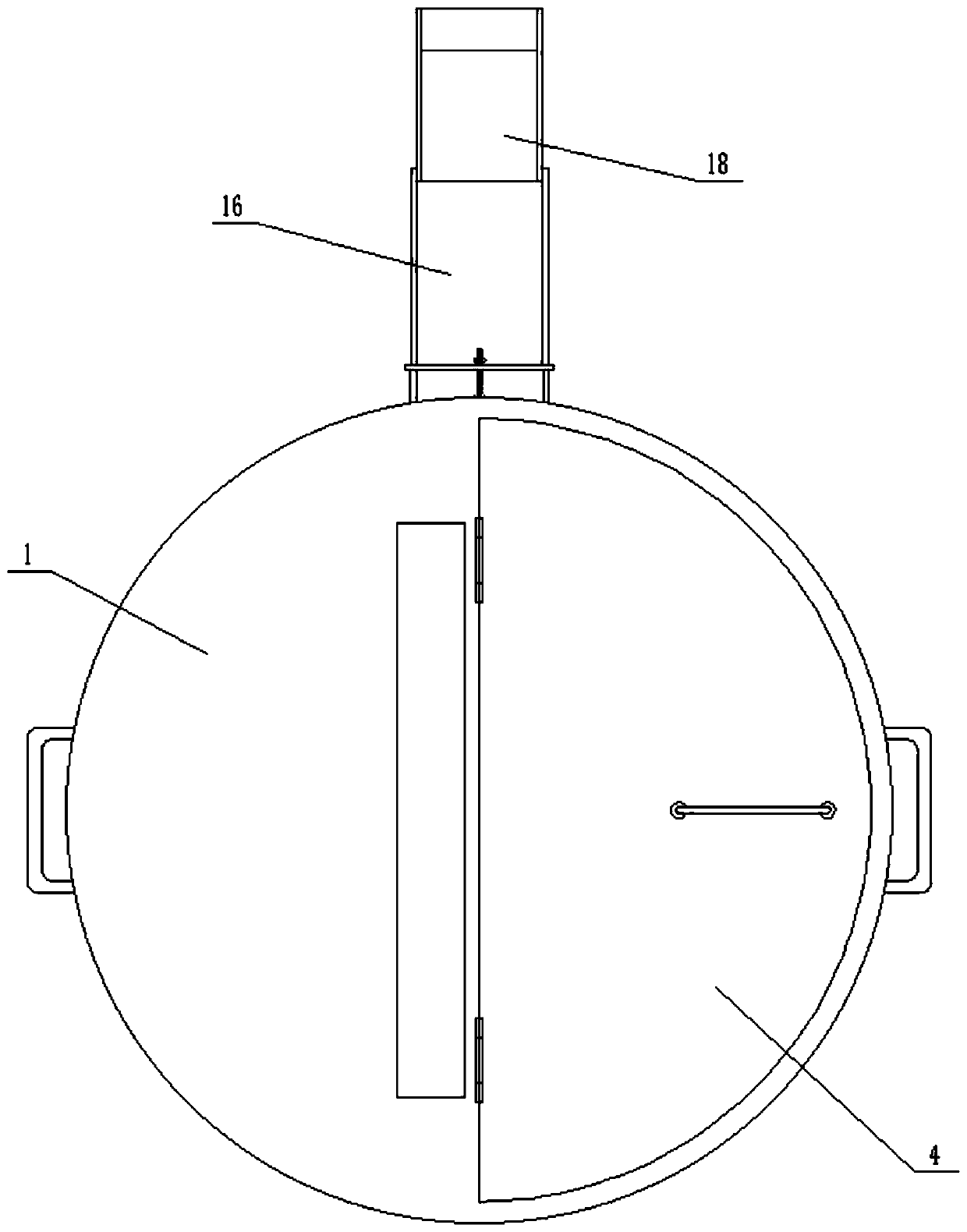

Sorting disc used for processing of fruit and vegetable products

ActiveCN108945996AAffect processing operationsAffect securityLoading/unloadingRotary conveyorsSlagEngineering

The invention provides a sorting disc used for processing of fruit and vegetable products. The sorting disc comprises a second-stage discharging groove and an angle adjusting column. A fruit sorting disc body is of a cylindrical structure, and a sorting cavity is formed in the fruit sorting disc body. A fruit discharging outlet is formed in the rear end of the fruit sorting disc body and communicates with the sorting cavity. A sorting disc supporting frame is mounted on the bottom end surface of the fruit sorting disc body, two supporting plates are mounted on the sorting disc supporting frame, slag storage tanks are arranged on the top end surfaces of the supporting plates correspondingly, sterilization and disinfection operation can be performed on the interior of the device periodicallyand easily, and the situation that bacteria breed in the device and adhere to the outer walls of fruits, and the safety of the fruit products is affected is avoided; and in combination with arrangement of a turnplate and screening holes, the fruits moving in the device can be screened, impurities contained in the fruits are removed, the fruit product quality is improved, and the situation that the impurities contained in the fruits are involved in subsequent fruit processing, and the subsequent fruit processing operation is affected is avoided.

Owner:青岛吉龙农产有限公司

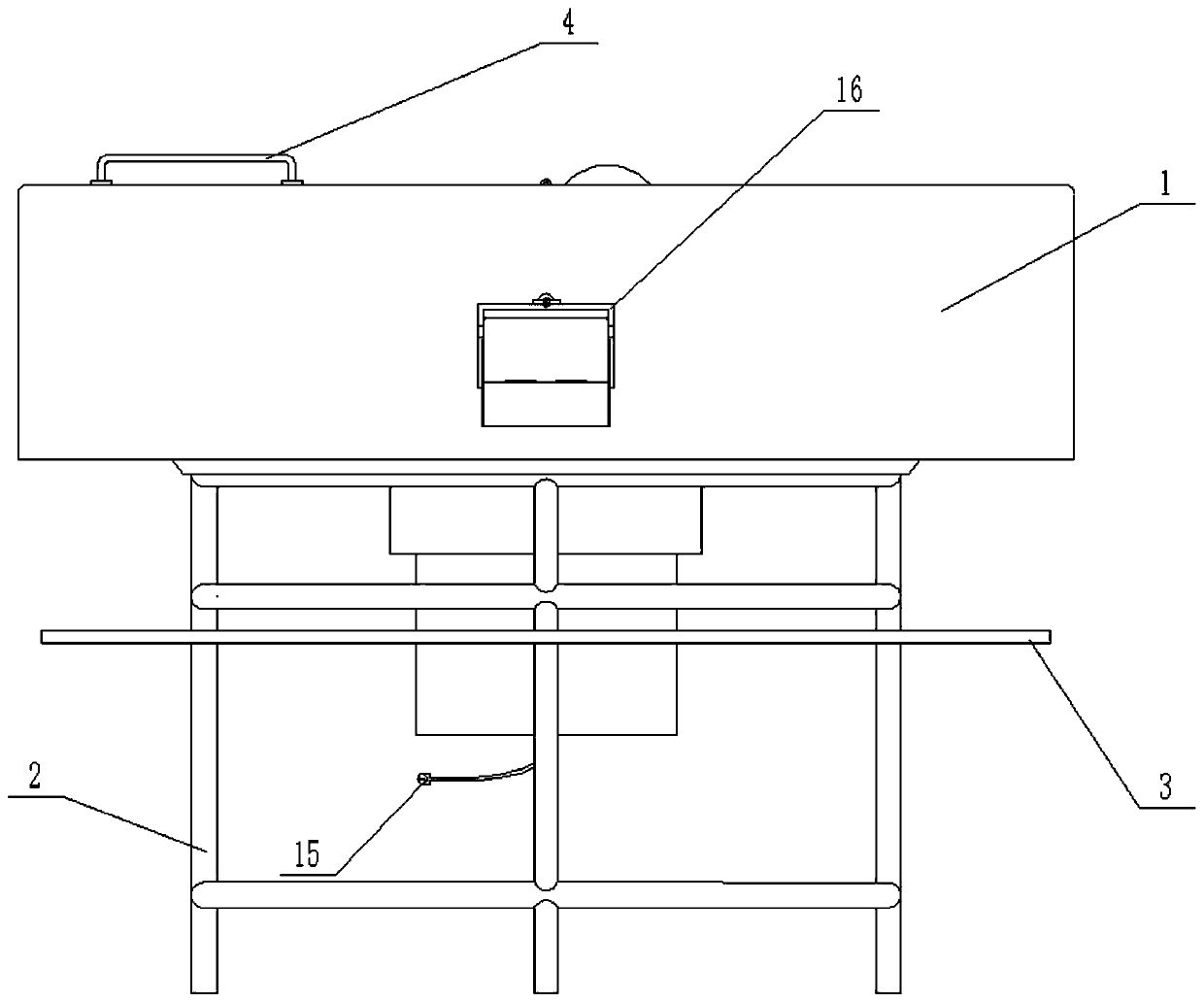

Rapid mask assembling mold and assembling method

PendingCN114734676AFacilitates stamping and forming assembly workMovement is accurateCleaning using gasesPressesHydraulic cylinderManufactured material

The invention discloses a mask rapid assembly die and an assembly method, and relates to the technical field of mask machining, the mask rapid assembly die comprises a concave base, a die cavity is formed in the concave base, a stamping hydraulic cylinder is mounted at the top of the concave base, and an upper die corresponding to the die cavity is connected to the position, located in the concave base, of an output shaft of the stamping hydraulic cylinder; and a material conveying assembly is arranged on the front side of the concave base and comprises a concave table, a conveying belt is installed in the concave table, and two guide rollers are horizontally and rotationally installed at the positions, located on the rear side of the conveying belt, in the concave table. According to the mask rapid assembly mold and the assembly method, when a mask is assembled, under the work of a servo motor, the two limiting blocks can clamp the two sides of a raw material, the conveyed mask raw material can be kept at a designated position to move, the deviation condition is avoided, and the assembly efficiency is improved. Therefore, the mask raw material can be accurately moved to the position of the die cavity.

Owner:仙桃市美凯尔防护用品有限公司

Road construction foundation pavement tamping equipment

ActiveCN113355984AEasy to limitAvoid swingingRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to the technical field of road construction, in particular to road construction foundation pavement tamping equipment which comprises a base frame, a connecting unit, a moving unit, a slicking unit and a knocking unit, the connecting unit is arranged at the right end of the base frame, the moving unit is mounted at the lower end of the base frame, and the slicking unit is mounted on the right side of the lower end of the base frame; a knocking unit is arranged in the base frame; the road construction foundation pavement tamping equipment can solve the following problems: 1, when tamping treatment is carried out on a traditional basic road surface, the traditional basic road surface is firstly slicked by using the existing slicking equipment and then tamped by using the existing tamping equipment, so that unnecessary working procedures are added, and sundries on the road surface need to be picked out by workers, so that the working time is influenced; and 2, after the foundation pavement is slicked, a vibration rammer compactor is generally adopted to perform compaction treatment on the foundation pavement, but the vibration rammer compactor generally performs single-point compaction treatment on the foundation pavement, and a certain vibration time is needed, so that continuous processing cannot be performed, and the processing effect is influenced.

Owner:新沂市盛翔节能保温工程有限公司

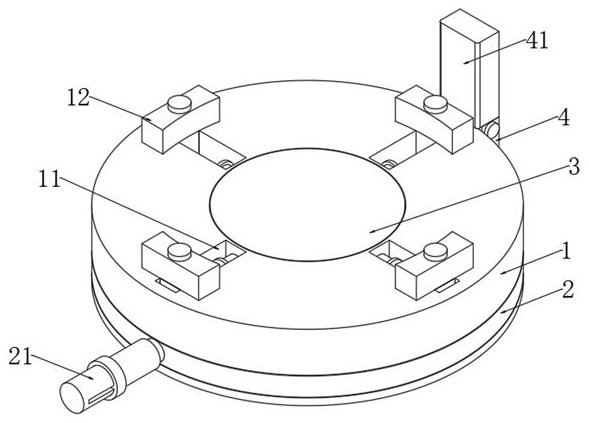

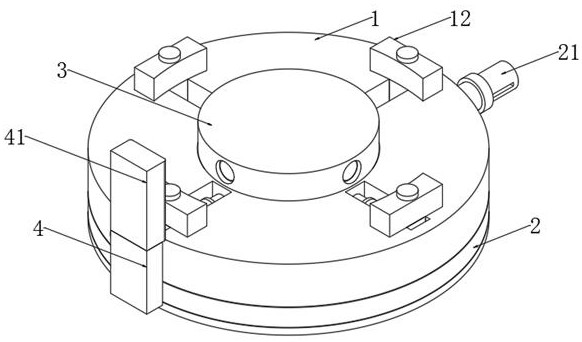

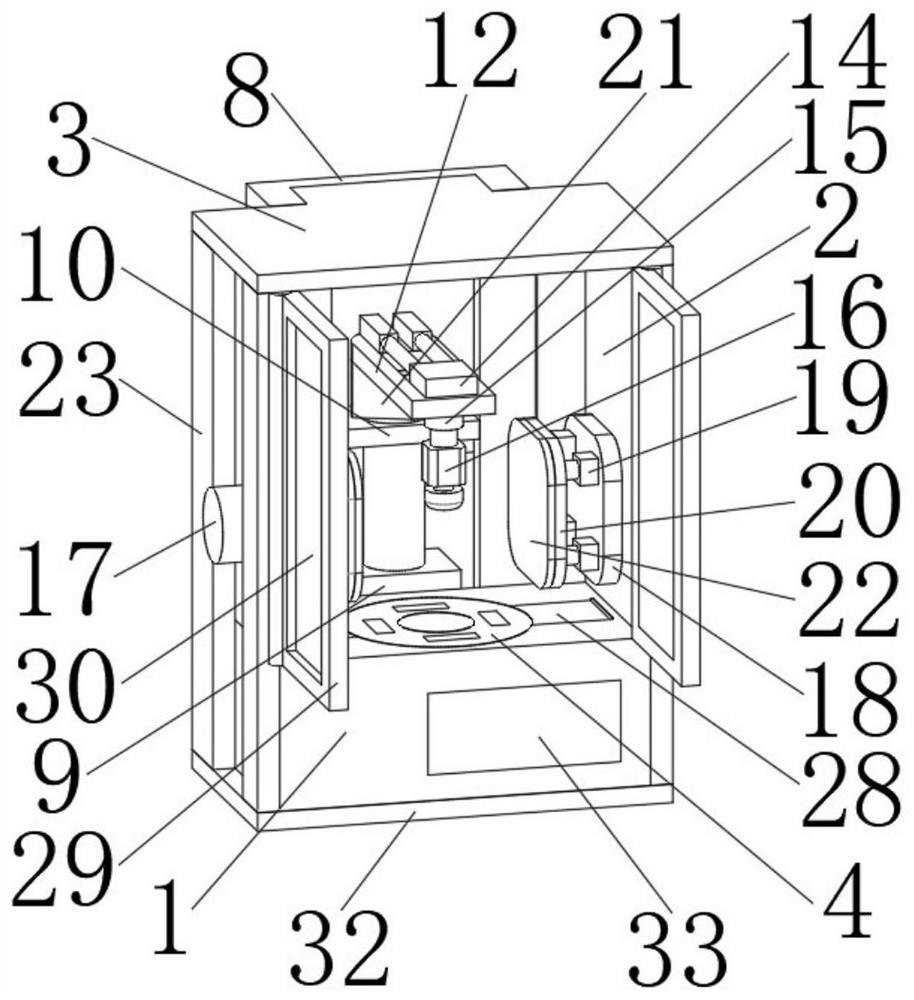

Multifunctional fixing tool for machining

ActiveCN114043399AQuick Visual CheckRealize adsorption collectionWork holdersMagnetic tension forceMachine parts

The invention discloses a multifunctional fixing tool for machining, and particularly relates to the field of machining, the multifunctional fixing tool comprises a base, and the outer surface of the base is sleeved with a mounting ring. By arrangement of the base, clamping plates, rotary knobs and first sliding blocks, the two sides of the clamping plates are designed into curved surfaces and planes correspondingly, adjustment can be conducted according to the shape of a part, and when the machined part is of an annular structure, an air cylinder in the base can be started to drive an inner table to be pushed out of a containing groove and located in the annular part; then a second electromagnet at one end of a push rod is started, the second electromagnet can move towards one side of a first baffle ring through magnetic force, so that the push rod is pushed outwards, an ejector block at the other end of the push rod abuts against the inner wall of the part, the ejector block is made of rubber and can be well attached to the inner wall of the part, internal and external fixation is conducted through an outer side clamping plate, and the fixing effect is greatly improved; and parts of different specifications can be fixed, and the practicability of the fixing tool is greatly improved.

Owner:浙江荣孚工智能科技有限公司

Processing and forming combination device of aluminum foil for condenser.

ActiveCN104550551AImprove cleanlinessReasonable designMetal-working feeding devicesHeat exchange apparatusElectric machinerySlide plate

The invention provides a processing and forming combination device of an aluminum foil for a condenser. The processing and forming combination device comprises a material charging mechanism, a forming device and a material collecting device which are sequentially arranged, wherein the material charging mechanism comprises a material charging frame and a motor, a conveying shaft is fixedly arranged on the material charging frame and is fixedly connected with a motor, the material collecting device comprises an operation platform, a support frame is rotationally and fixedly arranged on the operation platform, a screw rod is arranged at each end of the support frame, a plurality of needle rods are sequentially arranged on a slide plate, a cushion plate penetrates through each needle rod, the two ends of each cushion plate are respectively and fixedly connected with a lifting plate, the two ends of each lifting plate are respectively and glidingly connected with the corresponding screw rod, and a driving motor is fixedly connected with each screw rod. The processing and forming combination device has the beneficial effects that the design is reasonable, the manufacturing is simple, the operation is convenient, the aluminum foils can be continuously and integrally processed and formed, the tidiness of a workshop is guaranteed, the material collecting is convenient, and the processing effect and working efficiency are improved.

Owner:WUHU MEIWEI PACKAGING PROD

Turbulent flow simulation polishing device and method for artificial joint-like surface

ActiveCN106625277BHigh polishing precisionUniform processing qualityAbrasive machine appurtenancesAbrasive blasting machinesElectricityArtificial joints

The invention discloses an artificial joint-like piece curved surface turbulence simulating polishing device and a method thereof. The device comprises a glass constraint component, a profiling electromagnetic wave heater, a temperature detection device, a supporting frame and an electromagnetic wave controller, wherein the glass constraint component is arranged outside an artificial joint-like piece in a sleeving way; the inner surface of the glass constraint component and the curved surface of the artificial joint-like piece form a profiling runner with uniform thickness; the profiling electromagnetic wave heater is arranged on one side of the glass constraint component; the profiling electromagnetic wave heater comprises an outer cover, heating sources, a concave lens and a convex lens; and each heating source of the profiling electromagnetic wave heater is electrically connected with the electromagnetic wave controller and is independently controlled by the electromagnetic wave controller. One heating source is placed on the side surface of the glass constraint component, the turbulence energy and the speed of abrasive flow cutting fluid are increased, and the linear loss and the head loss of the abrasive flow in the profiling runner are compensated, so that the whole processing effect is improved and the surface processing quality of the artificial joint-like piece is more uniform.

Owner:ZHEJIANG UNIV OF TECH

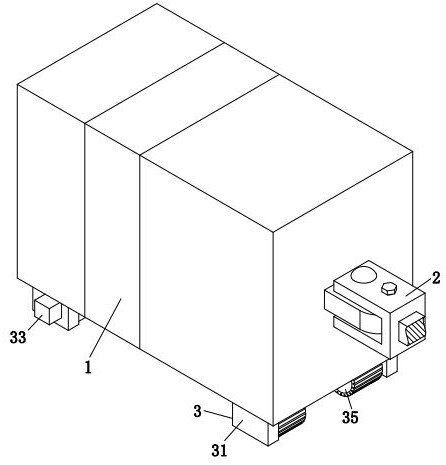

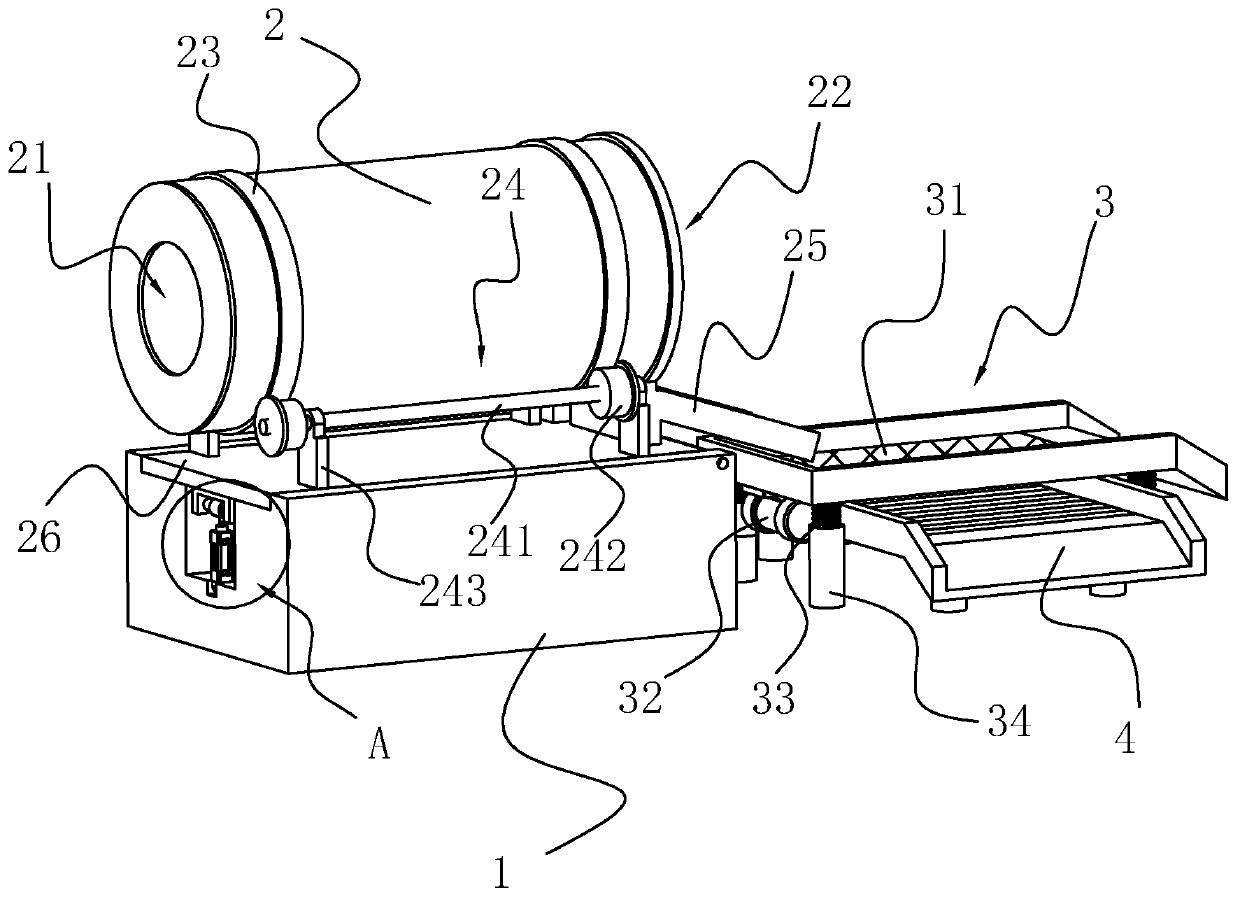

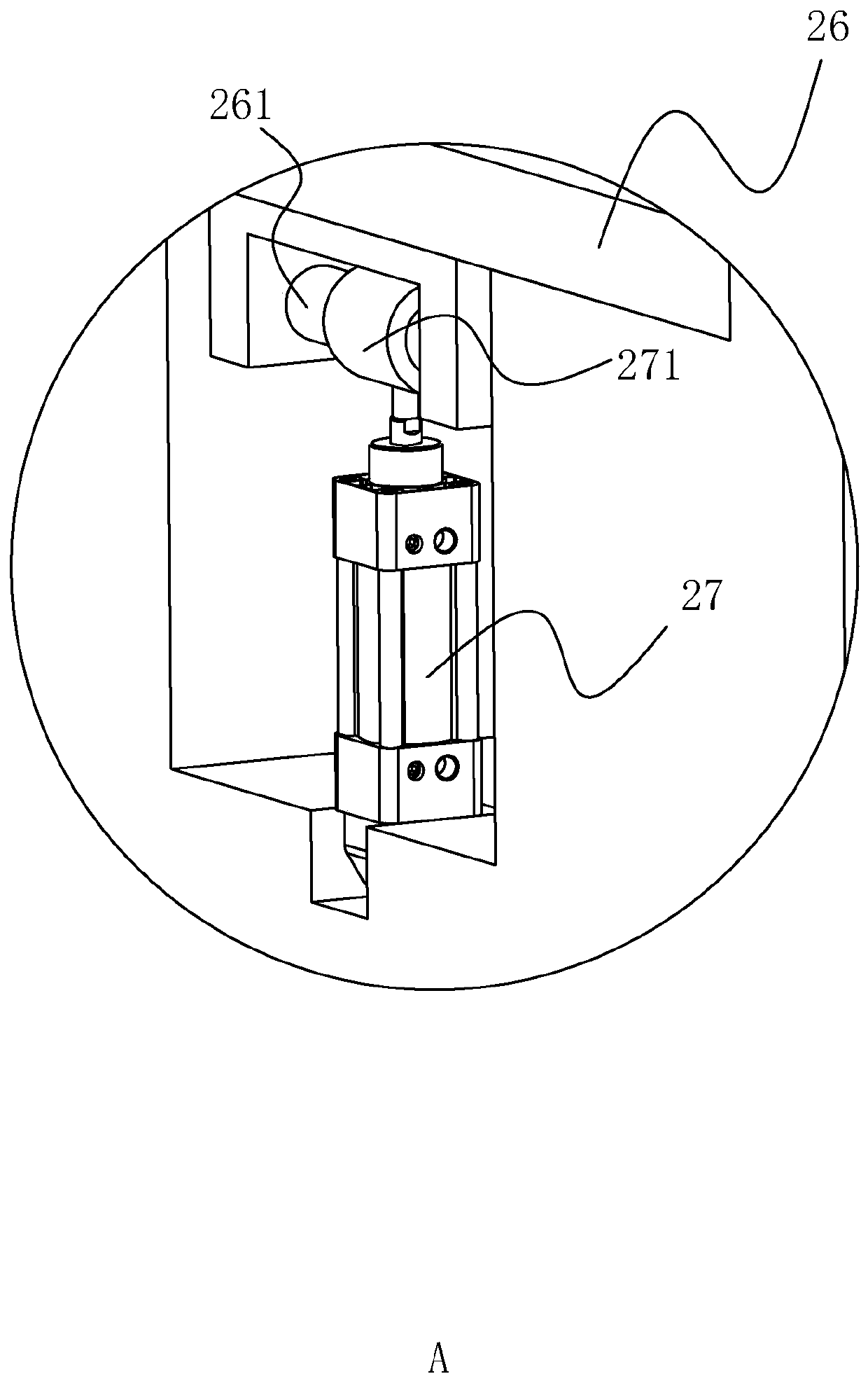

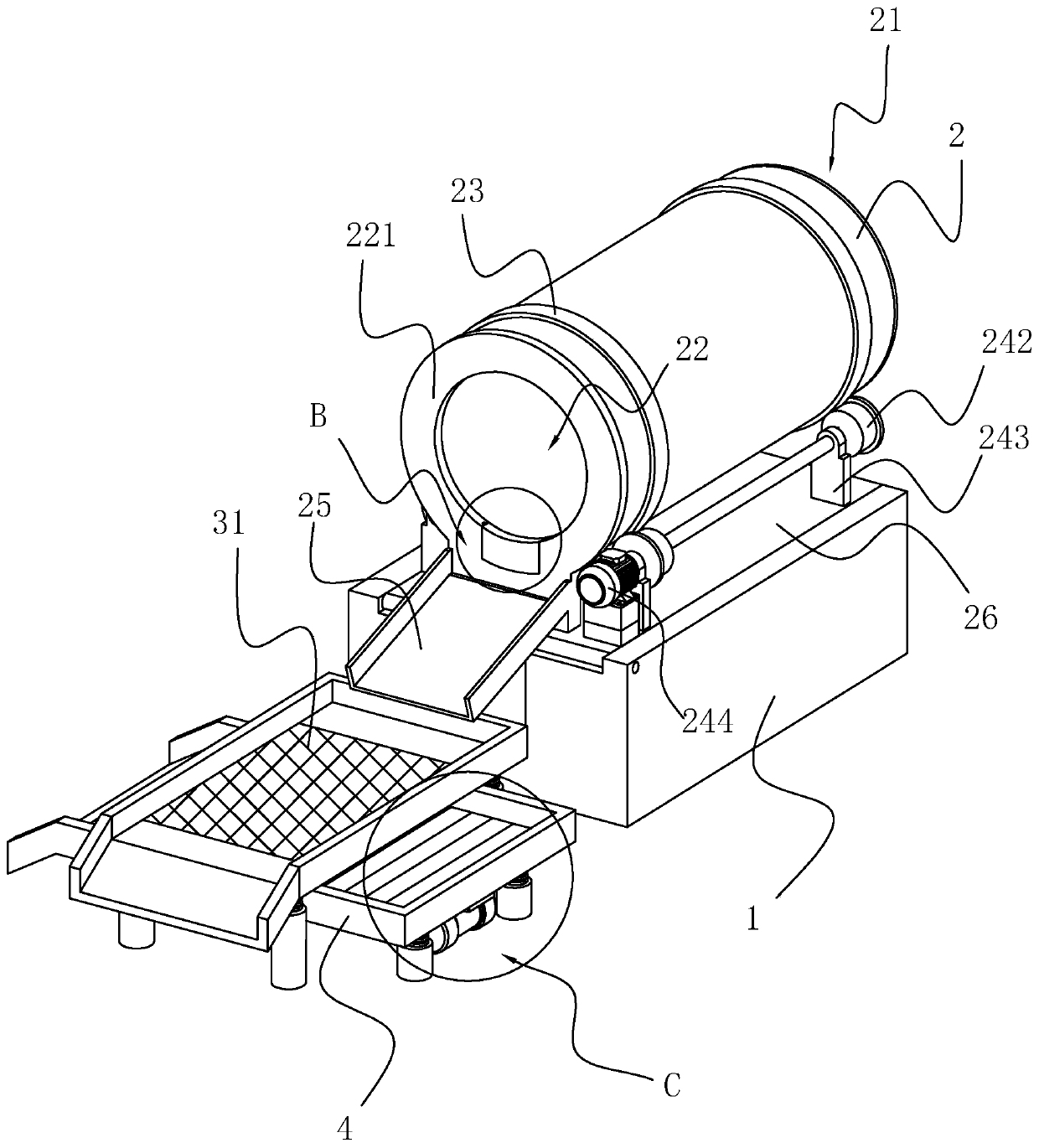

Continuous graphene microwave reduction furnace

ActiveCN113465384AImprove reduction efficiencyAffect the processing effectGrapheneMaintainance of heating chambersEngineeringGraphite

The invention belongs to the field of graphene processing, and particularly relates to a continuous graphene microwave reduction furnace. The continuous graphene microwave reduction furnace comprises a feeding mechanism; and a processing barrel is arranged at the bottom of the feeding mechanism, the bottom of the feeding mechanism is fixedly connected with the top of the processing barrel, air inlet pipelines are evenly arranged on the outer surface of the processing barrel, the outer surface of the processing barrel is fixedly connected with the right ends of the air inlet pipelines, a vacuum pump is arranged at the bottom of the processing barrel, the top of the vacuum pump is movably connected with the bottom of the processing barrel, a support is arranged at the bottom of the vacuum pump, the bottom of the support makes contact with the bottom of the vacuum pump, an inner barrel is arranged in the processing barrel, the inner wall of the processing barrel is movably connected with the bottom of the inner barrel, heating rings are evenly arranged on the outer surface of the inner barrel, the outer surface of the inner barrel makes contact with the inner walls of the heating rings, connecting pipes are symmetrically arranged at the two ends of the heating rings, and the right ends of the heating rings make contact with the left ends of the connecting pipes.

Owner:南通百大石墨设备有限公司

Fish feed processing and treating device capable of reducing nutrition loss through pressure change

The invention relates to the technical field of feed production equipment, and discloses a fish feed processing and treating device capable of reducing nutrition loss through pressure change. The fishfeed processing and treating device comprises a feeding bin and a discharging bin, wherein a driving power supply device is connected to the middle part of the top of an inner cavity of the feeding bin in a penetrating manner; a limiting rotating device is welded to one end of the bottom of an output shaft of the driving power supply device; a driving rod is welded to one end of the bottom of thelimiting rotating device; one end of the bottom of the driving rod is welded to the middle part of the top of a first classifying frame; and the bottom of the first classifying frame is welded to thetop of a lifting and pressing device. The fish feed processing and treating device capable of reducing nutrition loss through pressure change disclosed by the invention, through the lifting and pressing device, lifting and pressing treatment can be performed on products; when fed materials enter an extruding device, according to the quantity of the fed materials, the position can be automaticallyadjusted by an adjusting device, so that each part in the lifting and pressing device is driven to brake, pressure in the extruding device can be increased or reduced, and extrusion processing and treating of a fish feed are convenient.

Owner:唐山大千饲料有限公司

Hammering strengthening machine for workpiece in additive manufacturing process for metal

InactiveCN112620651AEasy to adjustGood fixationAdditive manufacturing apparatusElectric machineryStructural engineering

The invention discloses a hammering strengthening machine for a workpiece in an additive manufacturing process for metal. The hammering strengthening machine for the workpiece in the additive manufacturing process for metal comprises a base, a guide rail and a fourth stepping motor, wherein installation grooves in different shapes are formed in the left end, the right end, the middle part and the right side of the front surface of the base separately, supporting plates with L-shaped structures are installed at the left end and the right end of the upper surface of the base separately, a top plate is fixedly connected to the top ends of the supporting plates, and rotary discs with annular structures are arranged at the upper ends in the installation grooves which are formed in the middle part of the upper surface of the base; grooves are formed in the middle parts of the side ring surfaces of the rotary discs, and a first stepping motor is arranged in the installation groove which is formed in the left side of the upper surface of the base. The position and angle of a hammer head are convenient to adjust, the equipment is high in fixing performance for the workpiece, and meanwhile, the equipment can automatically adjust the position and angle of the workpiece during working, so that the equipment can hammer the corner positions of the workpiece, and the equipment is convenient to use.

Owner:温州兽班机械科技有限公司

Trays for processing fruit and vegetable products

ActiveCN108945996BAffect processing operationsAffect securityLoading/unloadingRotary conveyorsBiotechnologyEngineering

Owner:青岛吉龙农产有限公司

Plate shearing machine beneficial to reduction of blade abrasion

The invention relates to the technical field of forging pressing machinery and discloses a plate shearing machine beneficial to reduction of blade abrasion. The plate shearing machine comprises a base, wherein cushion blocks are fixedly arranged on the two sides of the bottom of the base; a frame is fixedly arranged at the top of the base; a workbench located at the top of the base is fixedly arranged under the frame; a groove is formed on the upper surface of the workbench; a cross bar is fixedly arranged in the groove; a slide block is sleeved on the exterior of the cross bar; slide slots are formed on the two side walls of an inner chamber of the frame; a cylinder is fixedly arranged at the bottom of the frame; a piston rod is fixedly arranged at the bottom of the cylinder. In the plate shearing machine beneficial to the reduction of the blade abrasion, the slide block is arranged and is capable of horizontally moving on the exterior of the cross bar, so that a lower blade can be driven to move back and forth, a clearance between the lower blade and an upper blade can be adjusted, the panels in different thickness and density can be conveniently sheared, the abrasion of the lower blade and the upper blade can be reduced and the service life of the lower blade and the upper blade can be prolonged.

Owner:合肥迅达电器有限公司

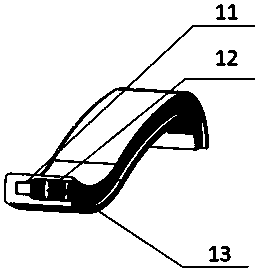

Intelligent processing machine for manufacturing breathing mask

InactiveCN113601785AAchieve continuous injection moldingEasy to removeRespiratory masksMedical devicesEngineeringRespiratory mask

The invention relates to the technical field of breathing masks, in particular to an intelligent processing machine for manufacturing a breathing mask. The intelligent processing machine comprises a base, supporting plates, a conveying unit and a forming unit, the supporting plates are fixedly arranged at the upper end of the base in a front-back symmetry mode, the conveying unit is arranged at the opposite ends of the supporting plates, and the forming unit is installed above the conveying unit. According to the intelligent processing machine, the problems existing during manufacturing and processing of the breathing mask can be solved, a traditional injection machine cannot effectively limit a mold core and a mold cavity, so that the mold core and the mold cavity are easy to shake, and the uniformity of the wall thickness of the breathing mask cannot be ensured; manual trimming treatment is easy to cause defects of the breathing mask due to improper treatment; the mold core can be limited, so that the processing stability is ensured, and the uniformity of the wall thickness of the breathing mask can be ensured; and according to the intelligent processing machine, the breathing mask can be pressed, cut and trimmed, so that the defect of the breathing mask caused by improper manual operation can be prevented.

Owner:莫峻

High-temperature sputtering prevention protection device for numerical control machine tool and use method of high-temperature sputtering prevention protection device

ActiveCN114571280AAccelerate heat dissipationReduce high temperature stateMaintainance and safety accessoriesPhysicsCooling fluid

The invention discloses a high-temperature-sputtering-preventing protection device for a numerical control machine tool and a using method of the high-temperature-sputtering-preventing protection device, and particularly relates to the technical field of numerical control machine tools. The high-temperature-sputtering-preventing protection device comprises a machine tool body, and the right side face of the inner wall of the machine tool body is fixedly connected with the right side face of a positioning frame; the inner wall of the airtight cylinder is fixedly connected with the outer surface of a first sleeve, and a first guide groove is formed in the left side face of the first sleeve. Through the arrangement of the driving device, the centrifugal cylinder, the oil pump, the second sleeve and the spraying cylinder, the protection device can recycle cooling liquid while assisting in rapid heat dissipation of a workpiece during workpiece machining, the situation that the cooling liquid is in a high-temperature state for a long time is reduced, the cooling liquid can be treated in time, and the cooling efficiency is improved. The cooling liquid is prevented from generating pungent smell due to high-temperature volatilization, the environmental protection effect of the protection device is improved, meanwhile, the requirement of the protection device for resources is reduced, and compared with an existing protection device, a large amount of cost is saved.

Owner:QUZHOU UNIV

Micro-expansive concrete processing device

PendingCN114274360ANot allowed to affect the processing effectAffect the processing effectMixing operation control apparatusHollow article cleaningData displayArchitectural engineering

The invention discloses a micro-expansive concrete processing device which comprises a control device, a feeding device and a stirring device, one side of the control device is movably connected with one side of the stirring device, the feeding device comprises a feeding box, a baffle and a weighing plate, and a feeding groove is formed in the top of the feeding box. Concrete and an expanding agent are weighed by arranging the feeding device and the weighing plate, data are displayed on the display screen on the front side, an operator can accurately control the mixing amount of the expanding agent, the situation that the concrete processing effect is affected by the inaccurate mixing amount of the expanding agent is avoided, the control pipe can be controlled through the operation screen, and the working efficiency is improved. The pushing piece pushes the inclined plate back and forth, so that the inclined plate vibrates to shatter concrete on the inner wall, and the concrete falls into the barrel shell, the internal concrete can be cleaned out of the mixing barrel after processing is completed, and the concrete is prevented from being continuously adhered to the inner wall of the inclined plate during processing; the problem that dry concrete adheres to the inner wall of the mixing drum and is difficult to clean is solved.

Owner:怀宁县四通混凝土制品有限公司

Grain sieving device

InactiveCN108262088BMake sure to shell completelyImprove shelling effectGrain huskingGrain polishingDrive shaftInlet valve

Owner:湖北省天门市青龙米业有限公司

Chain production process and pin fillet processing device applied to this process

InactiveCN108161370BImprove processing efficiencyReduce processing costsOther manufacturing equipments/toolsMachining processChain link

Owner:青岛恒鑫传动有限公司

Horizontal Cloth Finishing Machine

InactiveCN104495453BAffect the processing effectSolve the problem of line speed change afterFunction indicatorsWebs handlingWinding machineLeather belt

The invention discloses a horizontal finishing batching machine which comprises a support. Two rollers are arranged on the support and are connected with each other by a belt in a tensioned manner, and rotary drums are coaxially connected onto the rollers by keys. The horizontal finishing batching machine has the advantages that the rollers which are connected with each other by the belt can drive the rotary drums on the two rollers to rotate, and accordingly cloth can be wound on the rotary drums; a positional relation between the two rollers can be regulated by the aid of a horizontal distance regulating device and a vertical distance regulating device, and can be particularly regulated by a horizontal turning wheel and a vertical turning wheel which rotate, accordingly, a tension state of the cloth can be changed within a certain range, and the problem of influence on follow-up processing due to the fact that existing cloth is in different tension states can be solved.

Owner:桐梓县创兴自动化设备有限公司

Isolated-type vacuum non-oxidation tempering device

The invention discloses an isolated-type vacuum non-oxidation tempering device. The isolated-type vacuum non-oxidation tempering device comprises a front vacuum chamber, a heating area and a rear vacuum chamber, wherein the heating area adopts a transverse hollow structure; a self-locking closed heating box body is arranged in the heating area; a front transition section is arranged at the front end of the heating area; the two ends of the front transition section are respectively connected with the front vacuum chamber and the heating area; a rear transition section is arranged at the rear end of the heating area. As the front vacuum chamber and the rear vacuum chamber are respectively arranged on the two sides of the heating area, the interior of the whole tempering device is in a sealed state, oxidation of metal casting surfaces is reduced in the tempering process, and accordingly, the processed metal castings are excellent in mechanical property; as the self-locking closed heating box body is arranged in the heating area, when the metal castings are fed in and out of the self-locking closed heating box body, only one door of the box body can be opened, and accordingly, cross ventilation, which reduces the temperature in the box body and influences the processing effect, in the box body is prevented.

Owner:李华良

A fish feed processing device that reduces nutrient loss by changing pressure

ActiveCN108783544BReduce churnGuarantee processing qualityFodderFeeding-stuffAnimal scienceNutrition

The invention relates to the technical field of feed production equipment, and discloses a fish feed processing and treating device capable of reducing nutrition loss through pressure change. The fishfeed processing and treating device comprises a feeding bin and a discharging bin, wherein a driving power supply device is connected to the middle part of the top of an inner cavity of the feeding bin in a penetrating manner; a limiting rotating device is welded to one end of the bottom of an output shaft of the driving power supply device; a driving rod is welded to one end of the bottom of thelimiting rotating device; one end of the bottom of the driving rod is welded to the middle part of the top of a first classifying frame; and the bottom of the first classifying frame is welded to thetop of a lifting and pressing device. The fish feed processing and treating device capable of reducing nutrition loss through pressure change disclosed by the invention, through the lifting and pressing device, lifting and pressing treatment can be performed on products; when fed materials enter an extruding device, according to the quantity of the fed materials, the position can be automaticallyadjusted by an adjusting device, so that each part in the lifting and pressing device is driven to brake, pressure in the extruding device can be increased or reduced, and extrusion processing and treating of a fish feed are convenient.

Owner:唐山大千饲料有限公司

A temperature -controlled grinding granular flow of arthric joint surface turbulence machining device and method

ActiveCN106363537BHigh polishing precisionHigh viscosityAbrasive machine appurtenancesAbrasive blasting machinesParticle flowTemperature control

The invention discloses a temperature-control abrasive particle flow humanoid artificial joint part curved surface turbulent machining device and method. The temperature-control abrasive particle flow humanoid artificial joint part curved surface turbulent machining device comprises a glass constraint component, an infrared window, a computer, an infrared temperature detector, an electromagnetic wave heating matrix, a stirrer, a gas membrane pump, a supporting frame and an electromagnetic wave controller, wherein a uniform-thickness profile flow channel is formed between the inner surface of the glass constraint component and the curved surface of a humanoid artificial joint part; the inlet of the profile flow channel is connected with the gas membrane pump, the stirrer and the outlet of the profile flow channel sequentially through a pipeline; the profile flow channel is exposed to the infrared temperature detector through the infrared window; and the electromagnetic wave heating matrix is mounted on the other side of the glass constraint component. The temperature-control abrasive particle flow humanoid artificial joint part curved surface turbulent machining device disclosed by the invention has the advantages that through arrangement of the electromagnetic wave heating matrix on one side of the glass constraint component, the turbulent energy and velocity of an abrasive particle flow cutting fluid are increased, so that the entire machining effect can be improved, the temperature of abrasive particle flow during an entire machining process can be kept constant, and the surface machining quality of the humanoid artificial joint part can be more uniform.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com