Log centering device with good centering effect for log processing

A centering device and log technology, applied in wood processing equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as loosening of screw joints, waste of resources, and low utilization rate of logs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

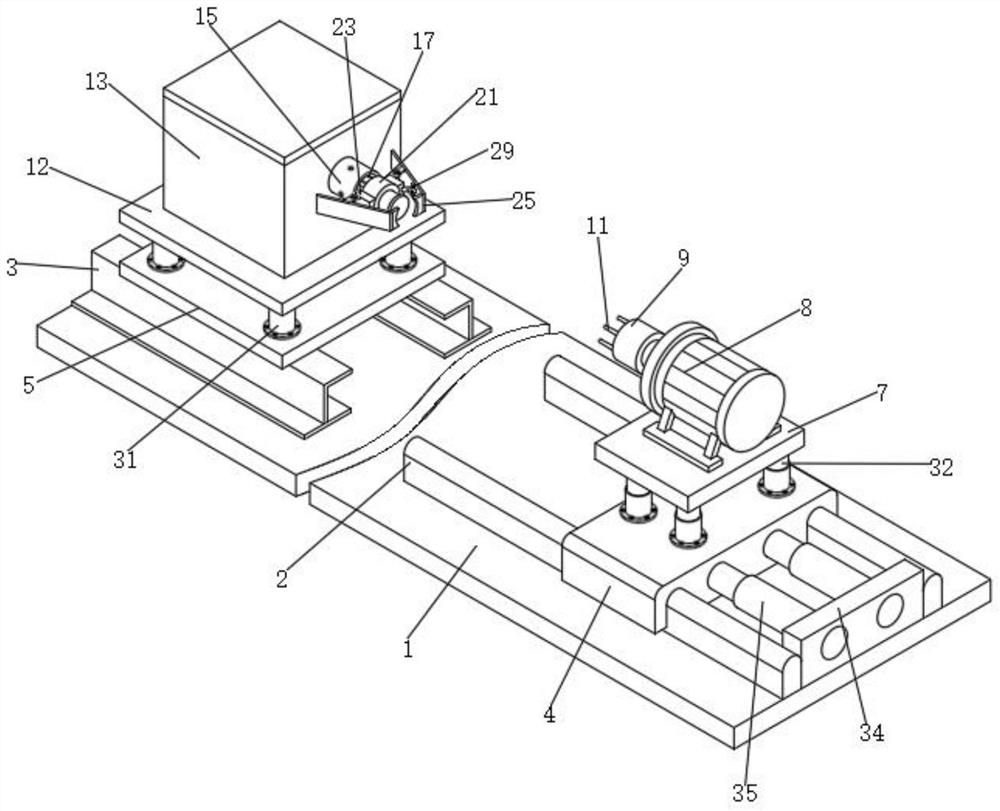

[0040] Such as figure 1 and Figure 8 As shown, a log centering device with good centering effect for log processing includes a base plate 1, a sliding rod 2 and a folding part 3. Two sets of sliding rods 2 arranged in front and behind are installed on the top of the base plate 1, and the top of the base plate 1 is installed There is a folding part 3, and the folding part 3 is located on one side of the slide bar 2;

[0041] Specifically, the bottom plate 1 is used for the sliding bar 2 and the folding part 3 in the combined device, so that the components installed on the top of the sliding bar 2 and the components installed on the top of the folding part 3 can be on the same group of plates, and then form a whole , in order to center the log, the top of the slide bar 2 is arc-shaped, which can reduce the time when the slide plate 4 moves toward or away from the folded part 3 on the outer surface of the slide bar 2 under the push or pull of an external force The received fri...

Embodiment 2

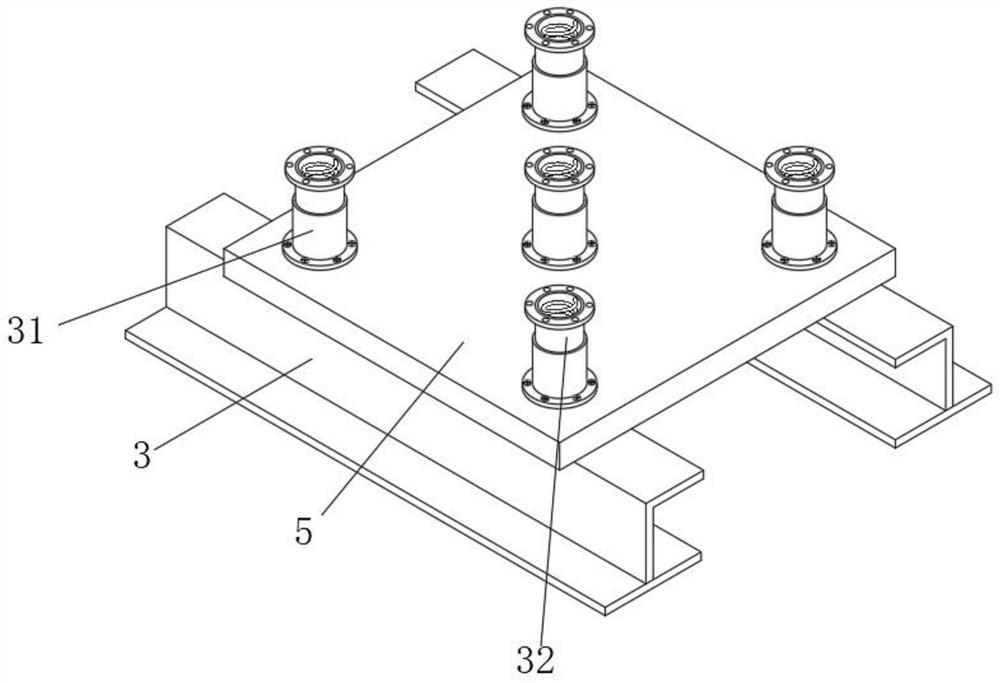

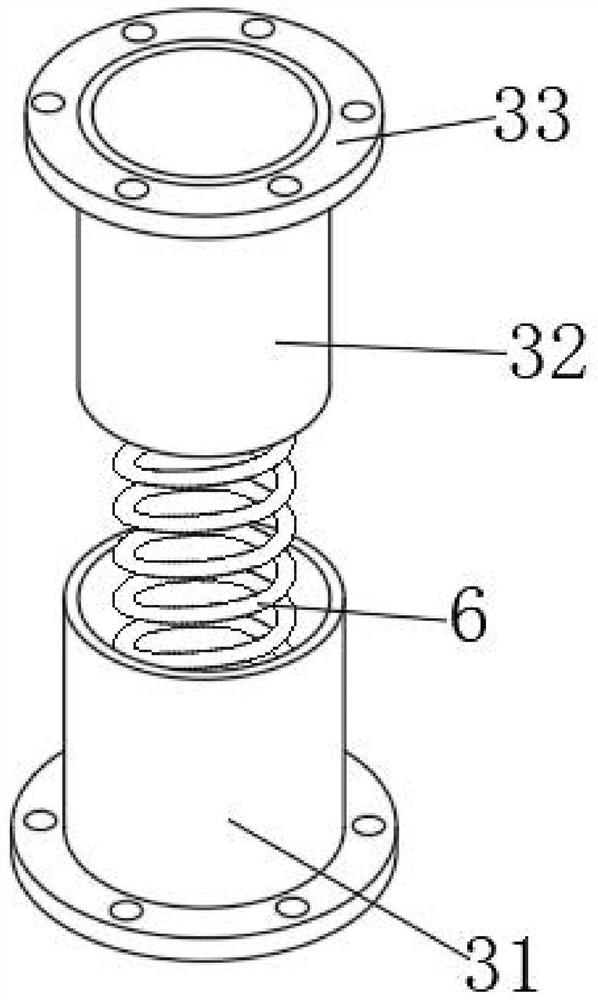

[0047] Such as Figure 5 , Figure 6 and Figure 7 As shown, the tops of the other five groups of telescopic springs 6 are provided with connecting plates 12, and the connecting plates 12 are located above the fixed plate 5, the top of the connecting plates 12 is equipped with a protective frame 13, and the bottom wall of the protective frame 13 is equipped with a rotating motor 14 , the output end of the rotating motor 14 is equipped with a rotating shaft, one end of the rotating shaft is equipped with a connecting cylinder 15, and one end of the connecting cylinder 15 extends out of the inside of the protective frame 13, and the inside of the connecting cylinder 15 is evenly equipped with six groups of fittings arranged in a ring. Block 16, the outer surface of the connecting cylinder 15 is provided with three sets of through grooves.

[0048] The inner wall of the connecting cylinder 15 is equipped with engaging columns 17, and the outer surface of the engaging columns 17...

Embodiment 3

[0053] Such as Figure 4 As shown, the front and back of the cylinder 21 are equipped with connecting blocks 23, and the outer walls of the two groups of connecting blocks 23 away from the cylinder 21 are equipped with two groups of flat plates arranged up and down, wherein the tops of the two groups of flat plates and the tops of the other two groups of flat plates Bottoms are equipped with movable plates 24, wherein splints 25 are installed on the backs of two groups of movable plates 24 arranged up and down and on the fronts of other two groups of movable plates 24 arranged up and down, and movable bars 26 are installed on the tops of two groups of movable plates 24 , and the bottoms of the two groups of movable rods 26 respectively pass through the insides of the other two groups of movable plates 24 , and the outer surfaces of the movable rods 26 are surrounded by spring groups 27 .

[0054]Two groups of splints 25 are equipped with a movable shaft 28 on one side of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com