Patents

Literature

42results about How to "Will not affect the processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

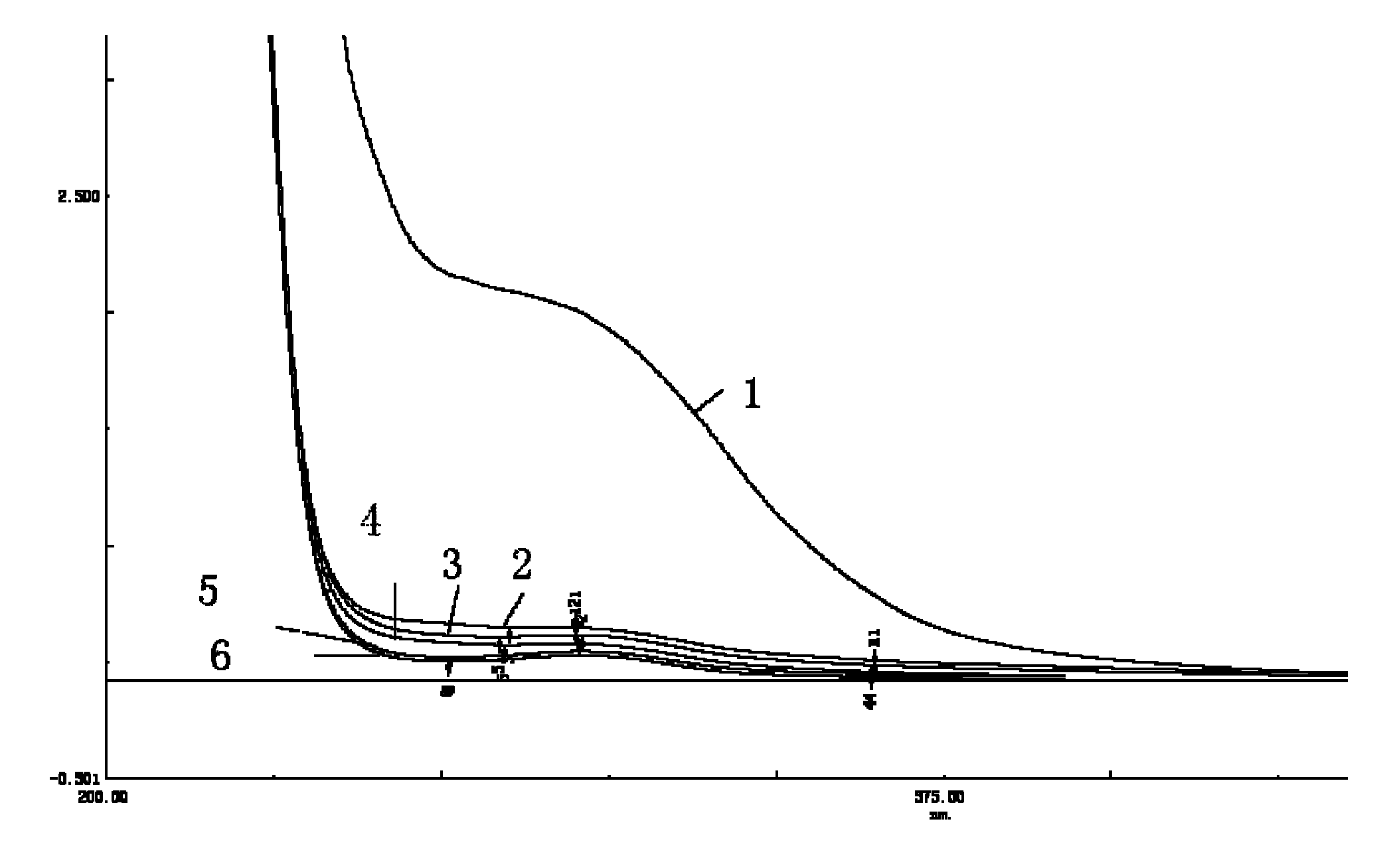

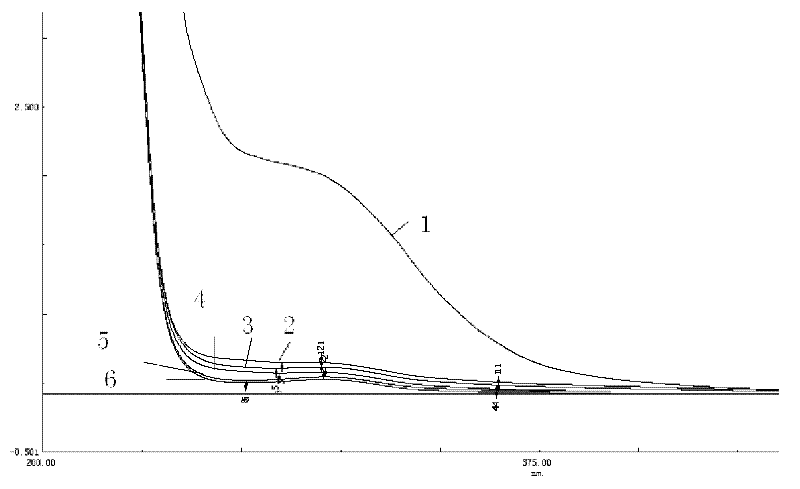

Underwater image enhancement method based on dark channel prior algorithm and white balance

InactiveCN105761227ARemove blur effectImprove clarityImage enhancementImage analysisTransmittancePhases of clinical research

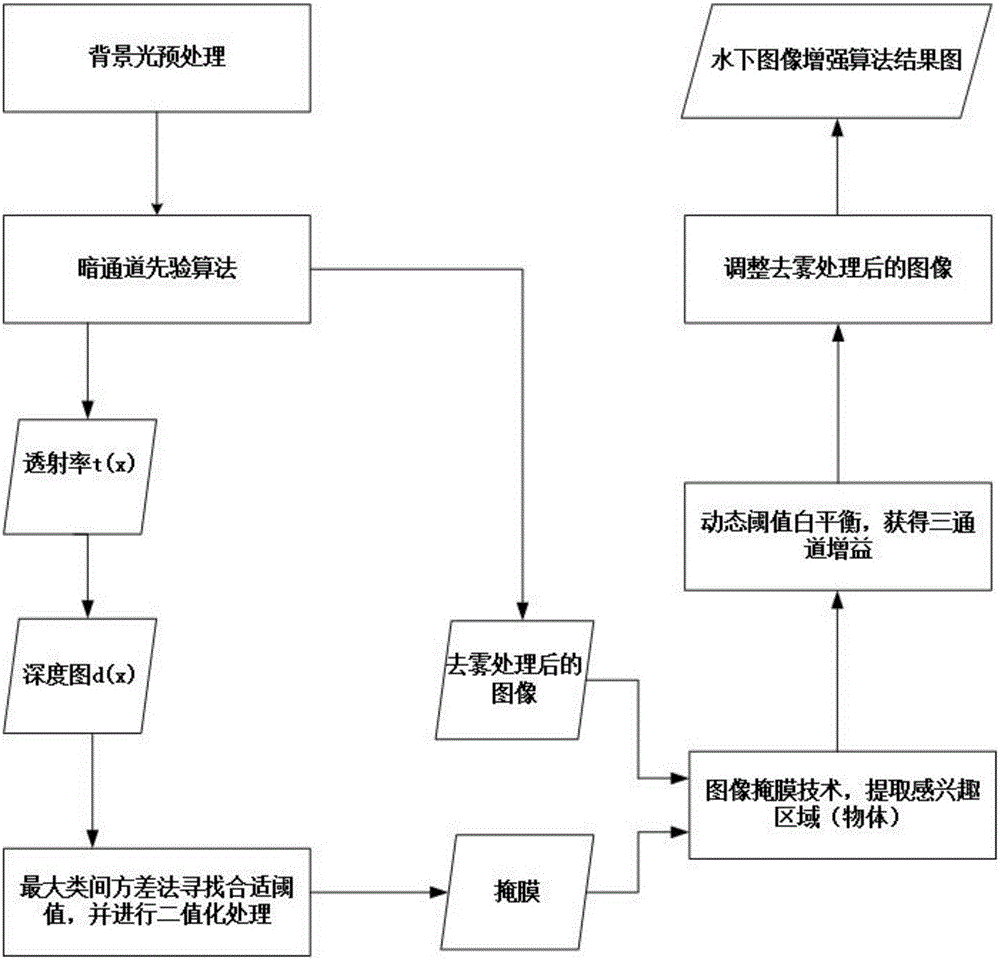

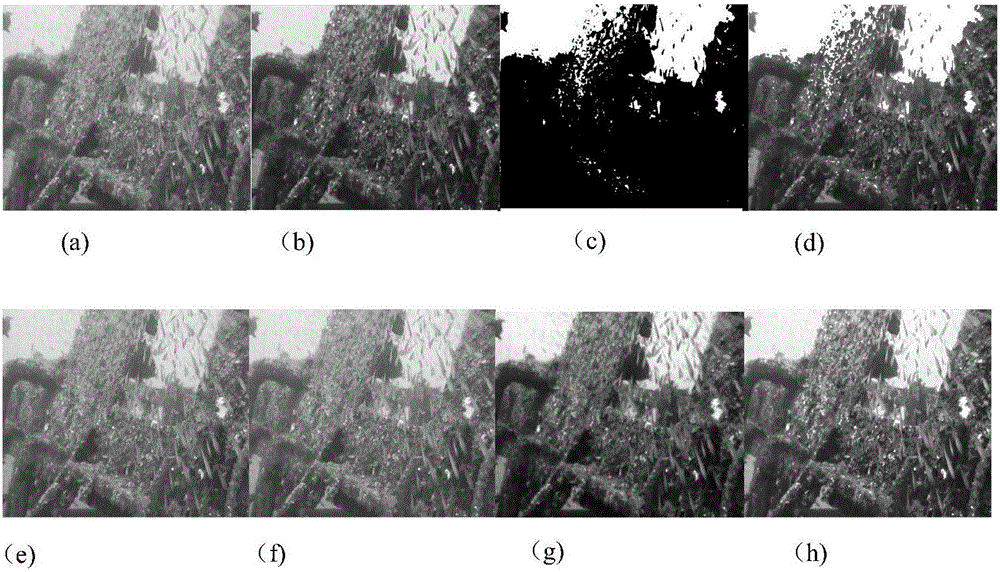

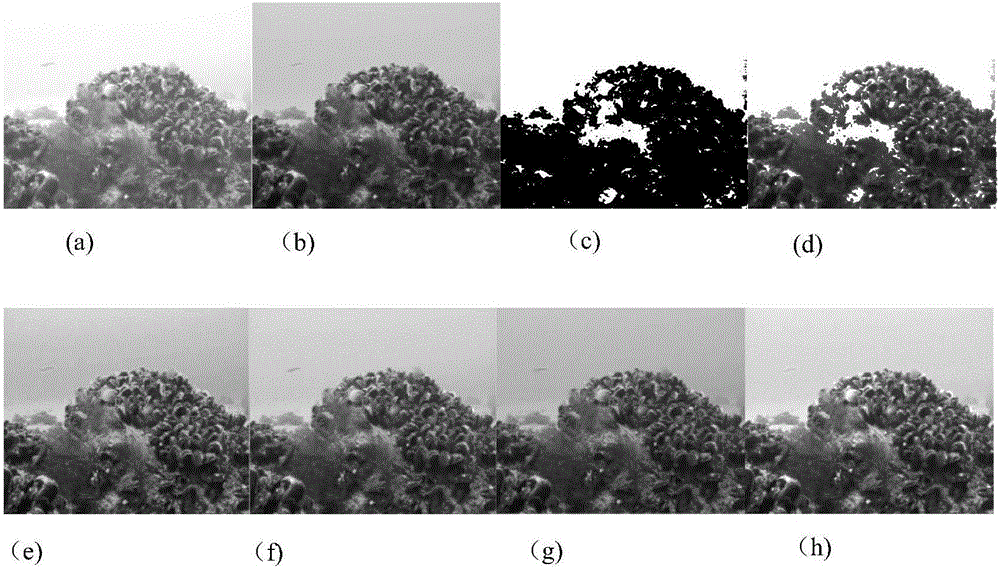

The invention relates to an underwater image enhancement method based on dark channel prior algorithm and white balance. The method achieves better image enhancement through the modification of background light, improves the image definition and contrast, and achieves the purpose of image optimization. The employed technical scheme is that the method comprises the following steps: A, background light processing step; B, dark channel prior step: 1, obtaining a fined transmissivity t(x) after image cut and a defogged image through employing the dark channel prior algorithm; 2, exporting a depth map d(x) through the transmissivity t(x); 3, obtaining a needed mask; 4, extracting an AOI (area of interest); C, white balance step. The method is mainly used in an occasion of underwater image enhancement.

Owner:TIANJIN UNIV

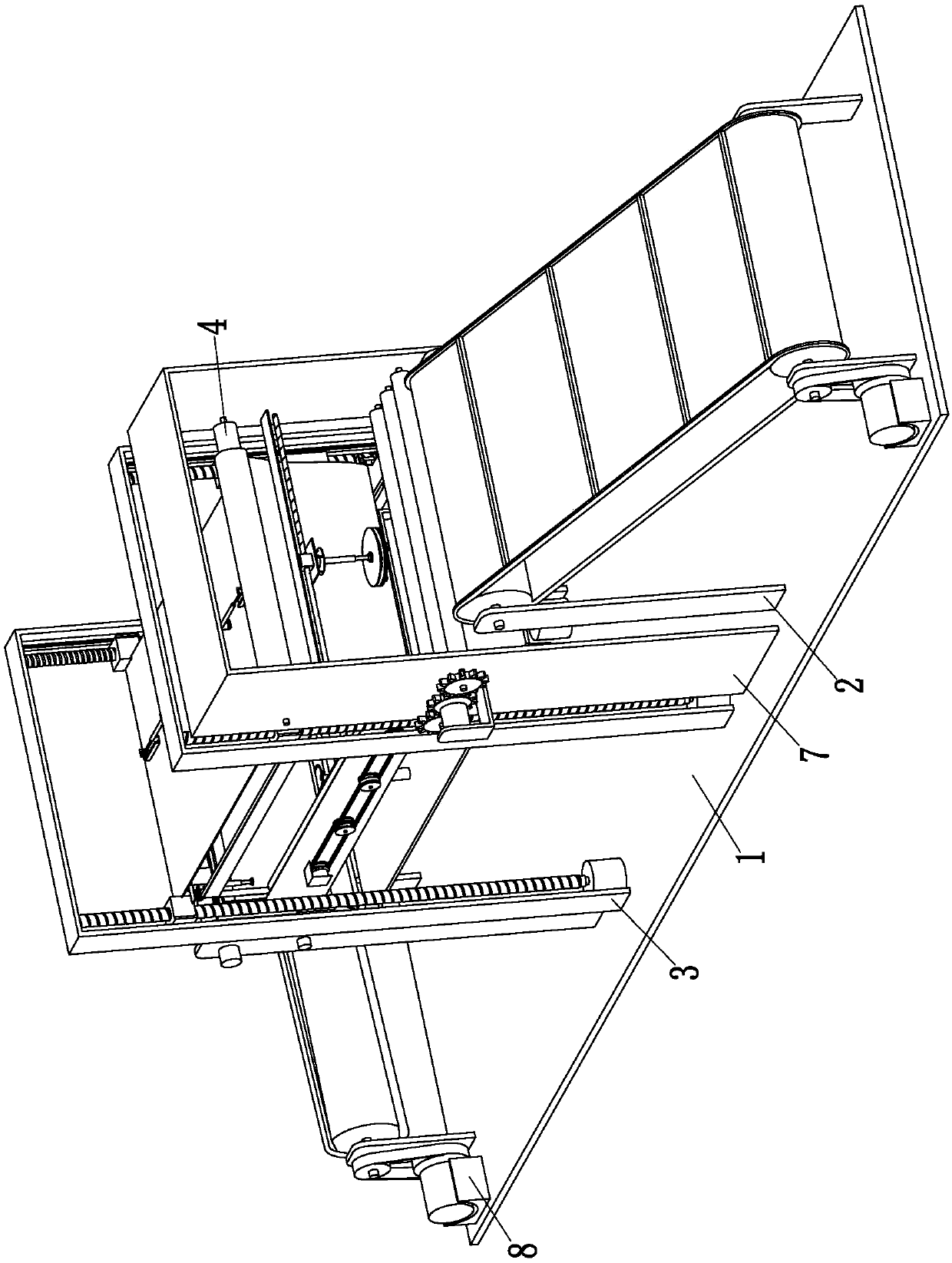

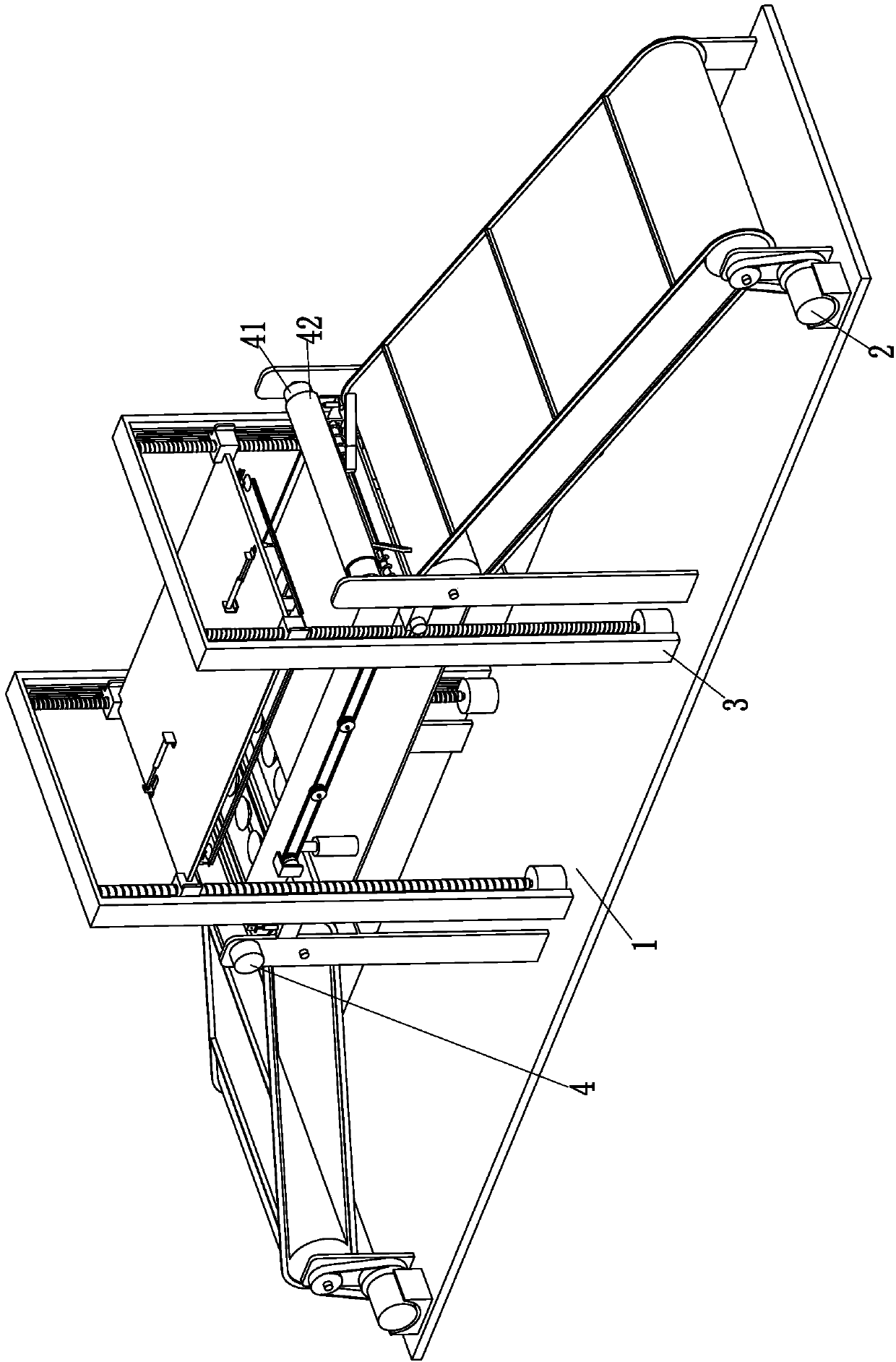

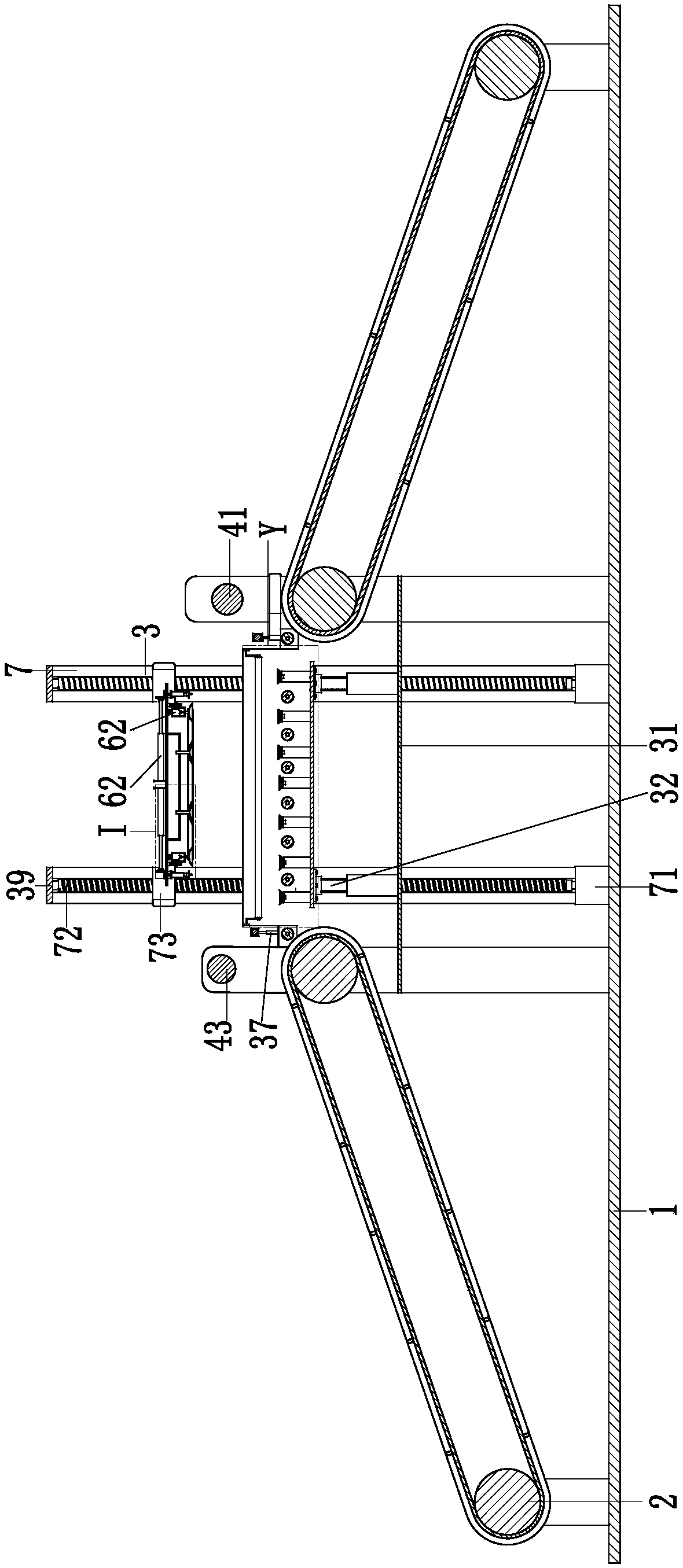

Automatic laminating apparatus special for color steel corrugated sheets of portable houses

ActiveCN107696662ARealize the function of automatic laminationInconsistent processing directionLaminationLamination apparatusEngineeringUltimate tensile strength

The invention relates to an automatic laminating apparatus special for color steel corrugated sheets of portable houses, comprising a bottom plate. A first conveyer, an adjusting device, a conveying laminating device and a second conveyer are arranged on the bottom plate sequentially from front to rear; a winding device is mounted between the adjusting device and the second conveyer; automatic laminating process of color steel corrugated sheets is achieved through the cooperation of the first conveyer, the adjusting device, the winding device, the conveying laminating device, a conveying rolling device and the second conveyer. By using the automatic laminating apparatus, the problems are solved: for instance, processing directions used in the existing laminating process of color steel corrugated sheets are non-uniform; the surface of the color steel corrugated sheets is uneven; since rolling dies in the existing laminating equipment to roll between film and color steel corrugated sheets are simple, manually changing and adjusting concave-convex depth of color steel corrugated sheets is required, and high labor intensity and low working efficiency are caused. The automatic laminating apparatus can provide automatic laminating for color steel corrugated sheets of portable houses.

Owner:重庆远海建筑装配技术开发有限公司

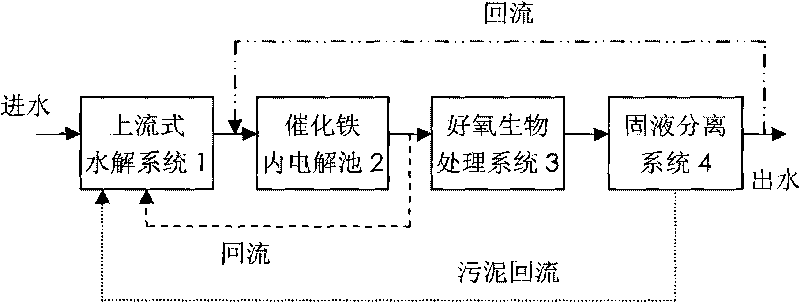

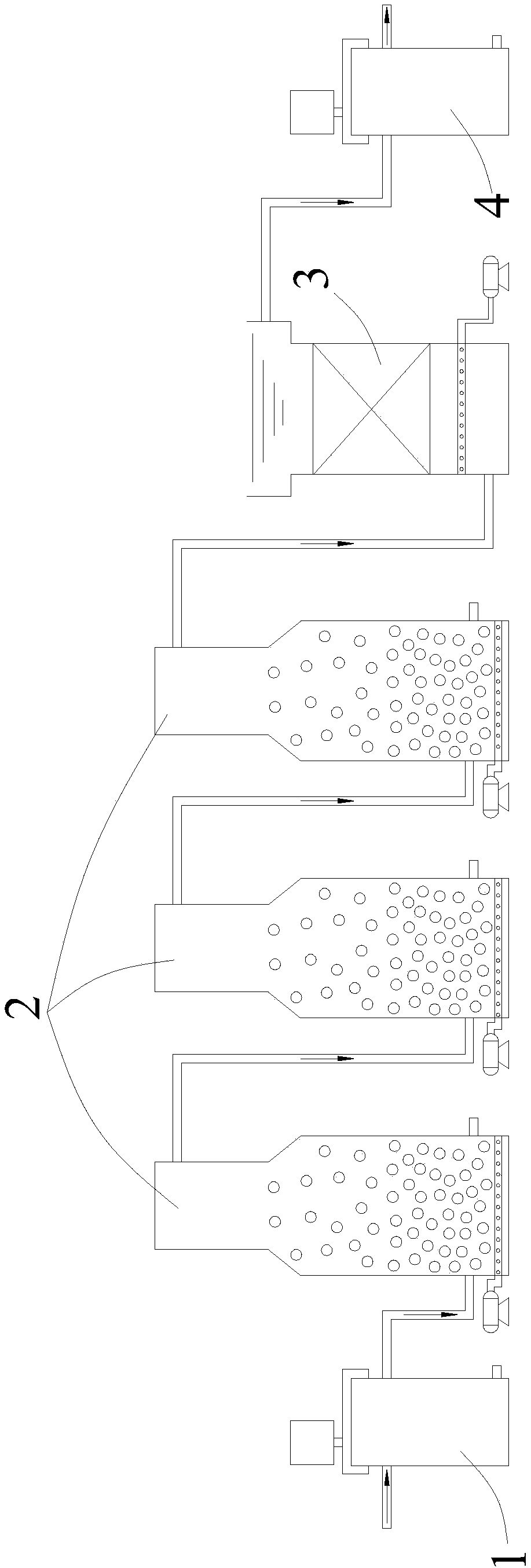

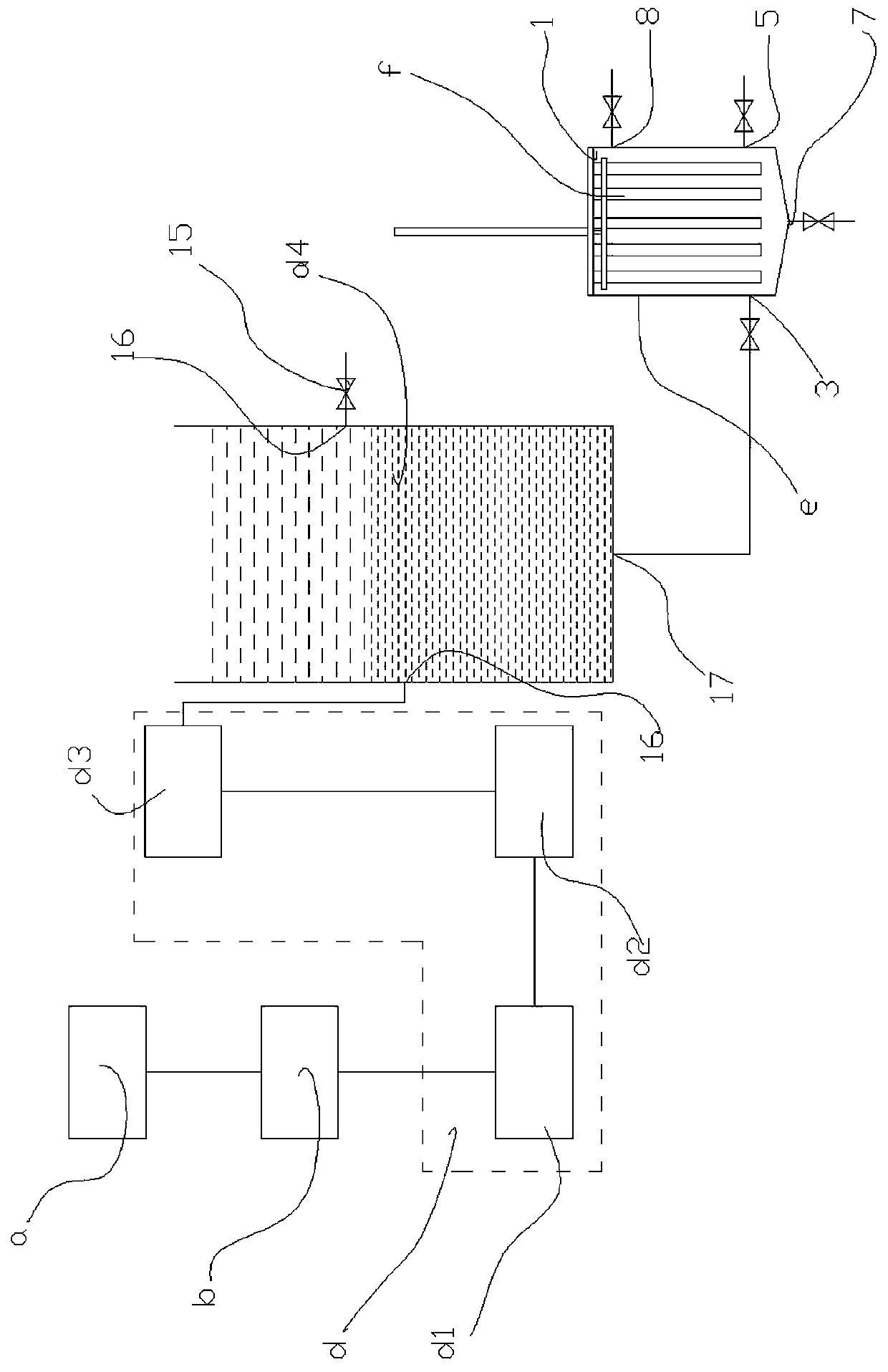

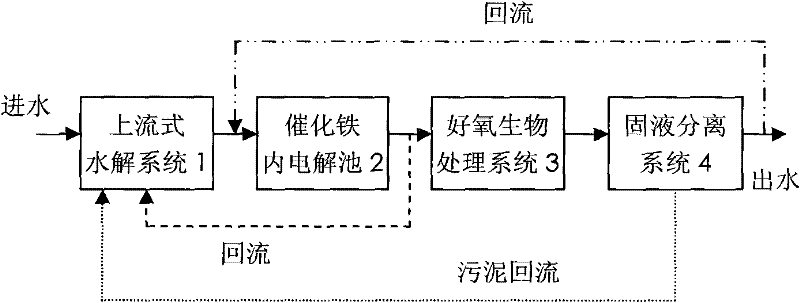

Method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water

InactiveCN101693581AGuaranteed reaction efficiencyEfficient removalWater/sewage treatmentMultistage water/sewage treatmentWater qualityTherapeutic effect

The invention pertains to the technical field of treatment of waste water, and particularly relates to a method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water, which comprises the following steps: waste water after primary treatment directly enters an up flow type hydrolysis system 1 and stays for 4.0-10.0 hours; the effluent enters an electrolytic cell in the catalytic iron; the mass ratio of iron scraps and copper scraps in the electrolytic cell of the catalytic iron is 1:1 to 20:1, the bulk specific weight thereof is 0.1 to 0.3, the contact time thereof in a filling area is 0.5 to 2.0 hours, and the reflux ratio of the effluent refluxing to the up flow type hydrolysis system is 20 to 100 percent; the effluent enters an aerobic biological treatment system and stays for 6.0 to 12.0 hours; then the effluent enters a solid-liquid separation system with a reflux ratio of sludge being 10 to 50 percent; and the effluent of the solid-liquid separation system refluxes to the electrolytic cell of the catalytic iron with the reflux ratio being 20 to 200 percent. Under the premise of fully playing the function of different treatment units and maintaining the treatment effect and respective advantages, the treatment method of waste water realizes the coupling synergetic action of the three units, strengthens the impact of the system to water quality and water quantity load, reduces a plurality of steps of pretreatment, effectively improves the removal rate of ammonia nitrogen, and can be flexibly adjusted.

Owner:TONGJI UNIV +1

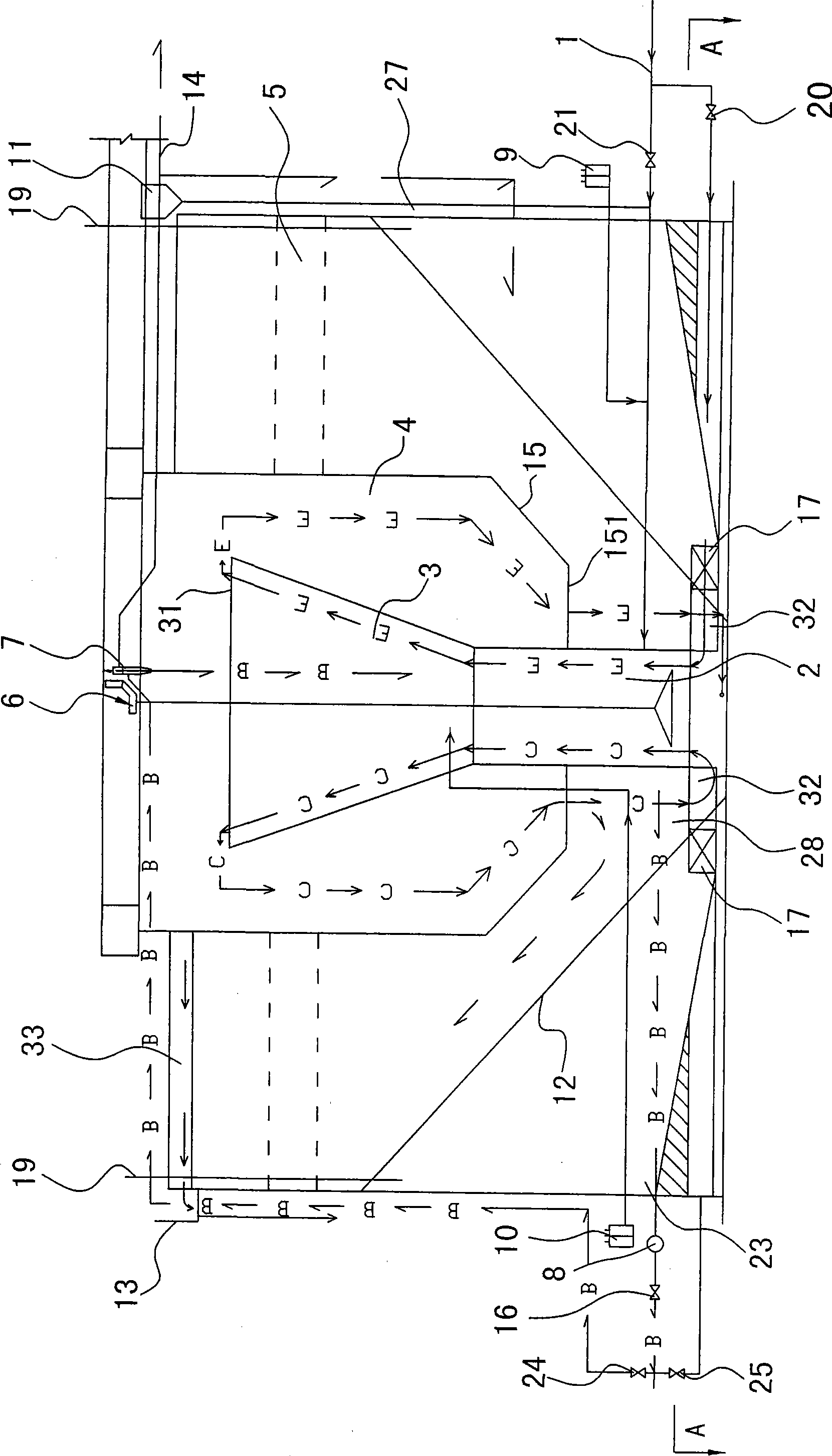

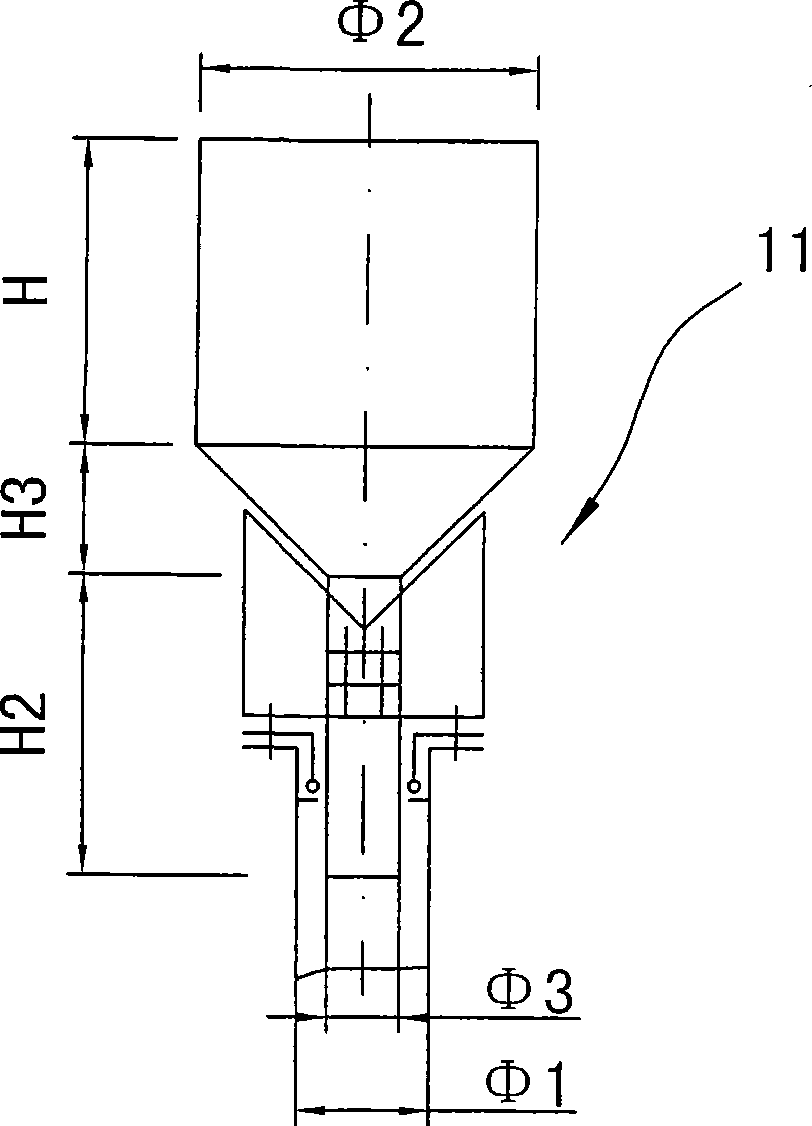

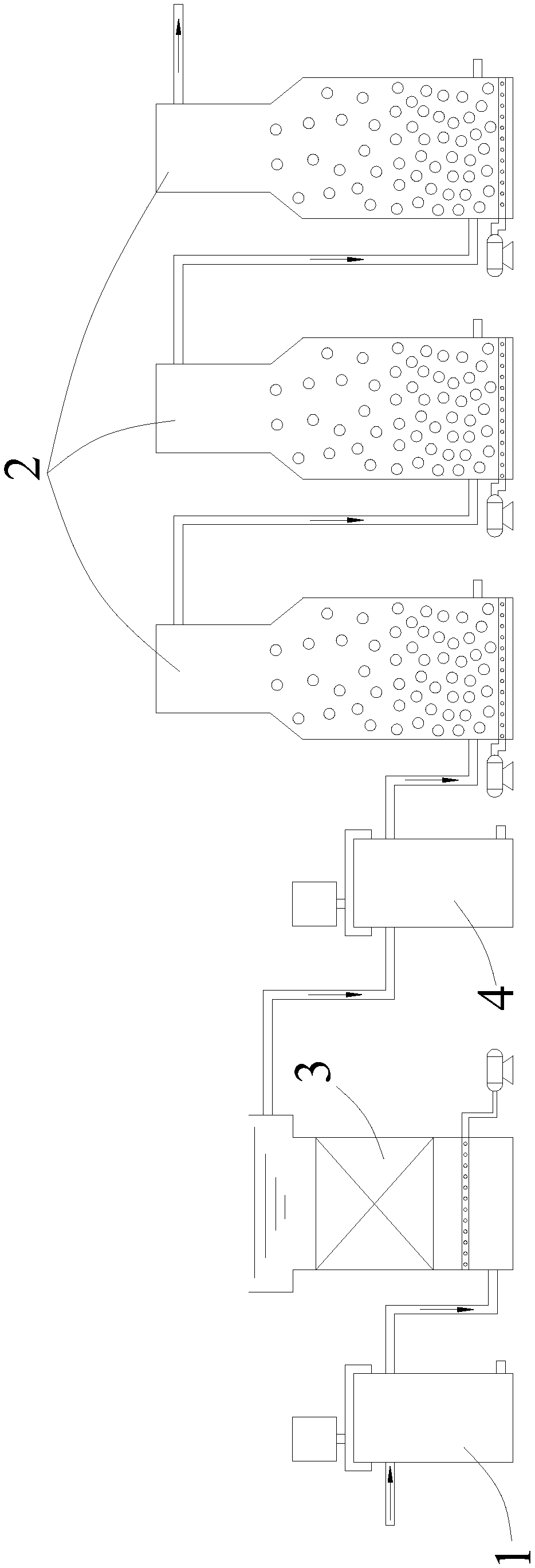

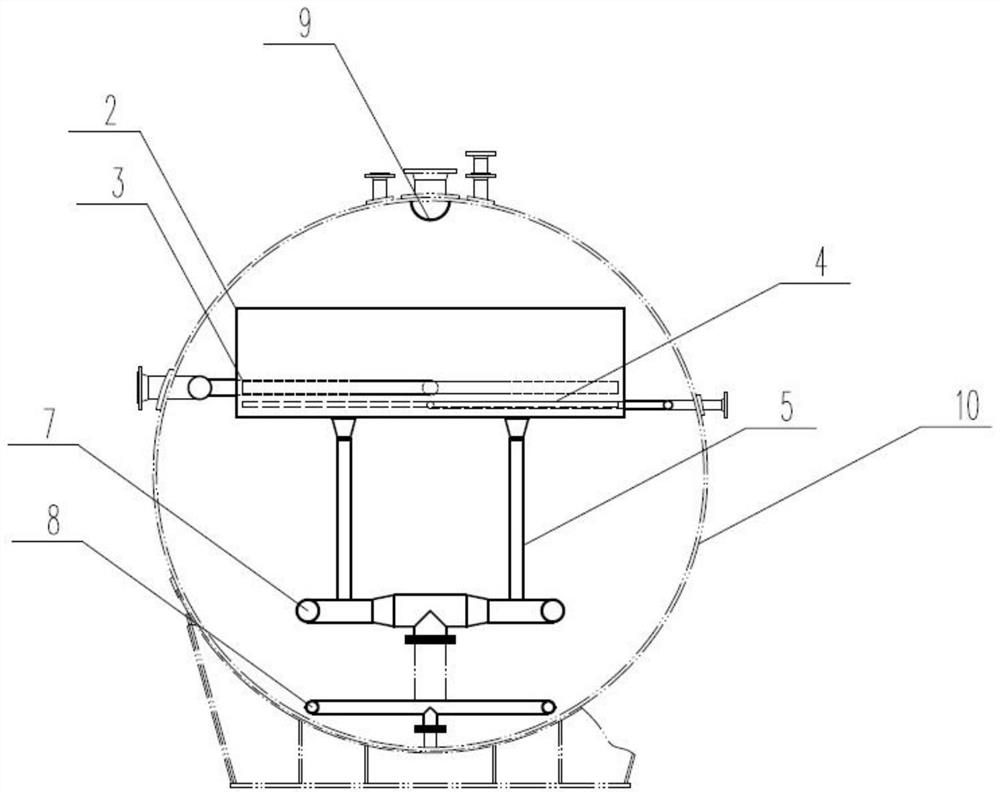

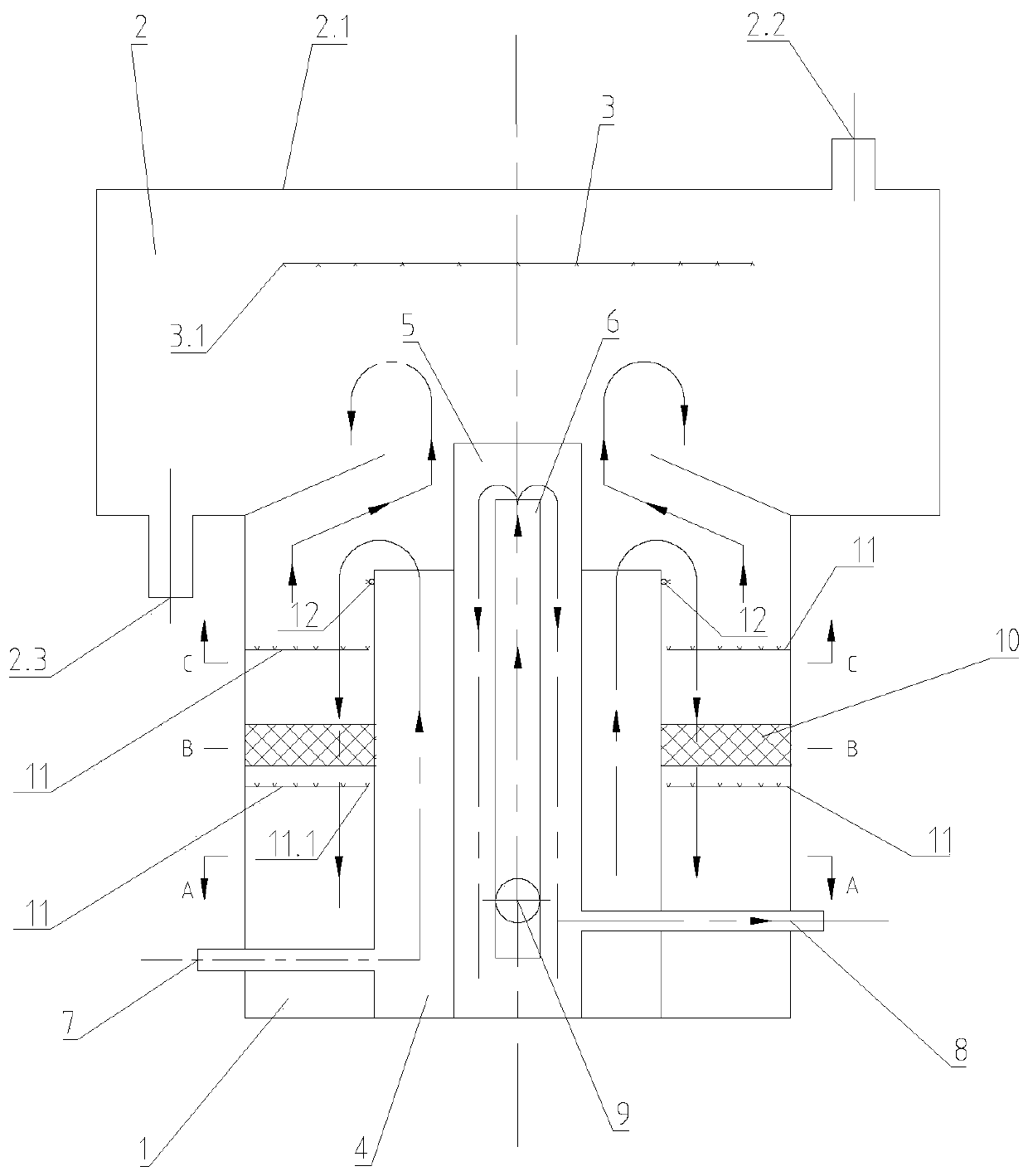

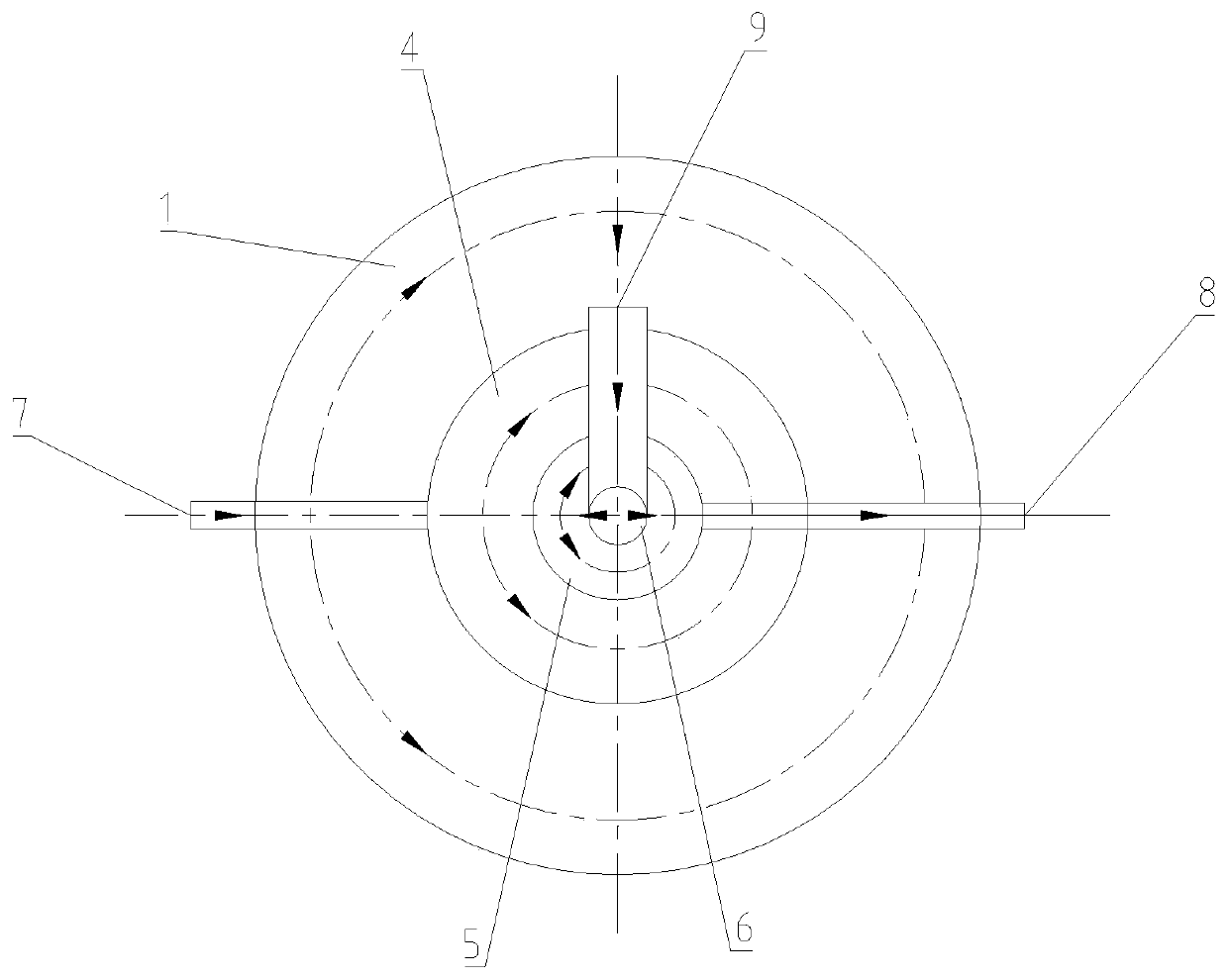

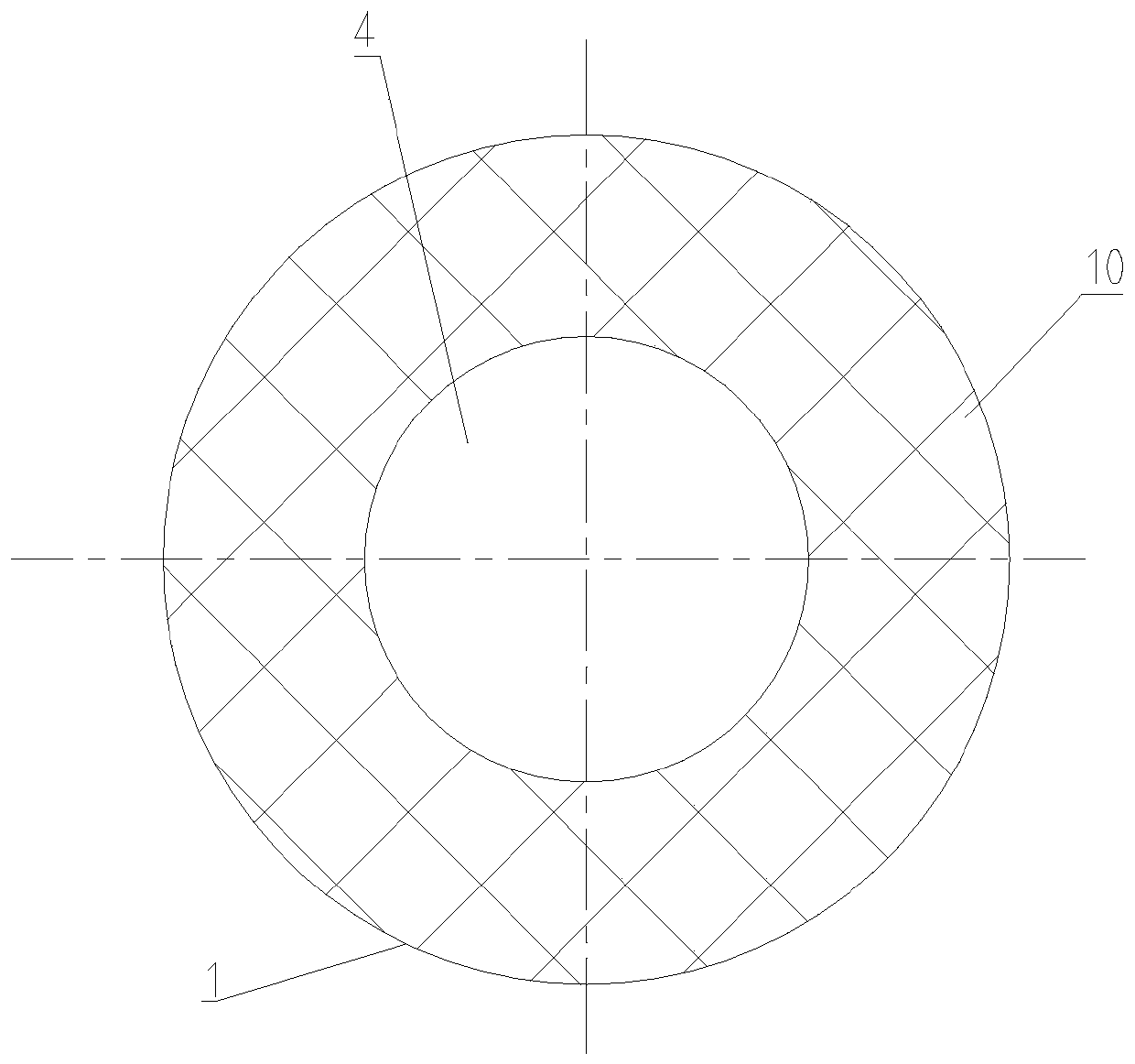

Core-three-circulation combined water treatment process

ActiveCN101508512ACompact structureSave resourcesMultistage water/sewage treatmentSustainable biological treatmentRefluxActivated sludge

The invention relates to a core-added three-cycle combined water treatment method. The method consists of four parts in a water treatment structure, namely a mixing flocculation area, an activated sludge chamber, a taper sludge concentration area and a clarification and separation area. The mixing flocculation area is provided with a water inlet pipe, a water inlet control valve and a nozzle, a first-level flocculation chamber, a second-level flocculation chamber and a reverse skirt plate. A mixing chamber is provided with a speed regulation stirring device; the water inlet pipe is connected with a mixing headwater control device and a coagulant preparation and addition system; the first level flocculation chamber is connected with a flocculant preparation and addition system; a pressure cyclone separator is arranged on the upper part; a sand pump water inlet pipe is connected with the taper sludge concentration area; and the outputted water is connected with the pressure cyclone separator. The activated sludge chamber comprises a vertical pond wall, a built-in underwater stirring machine, an outputted water control valve and a sludge reflux control valve. The taper sludge concentration area is positioned at the center of the activated sludge chamber; and a taper pond wall and a water outlet pipe connected with the outputted water control valve of the activated sludge chamber are arranged between the taper sludge concentration area and the activated sludge chamber. The clarification and separation area comprises a clarification and separation area, a water collecting system and a water outlet trough.

Owner:俞敏厚

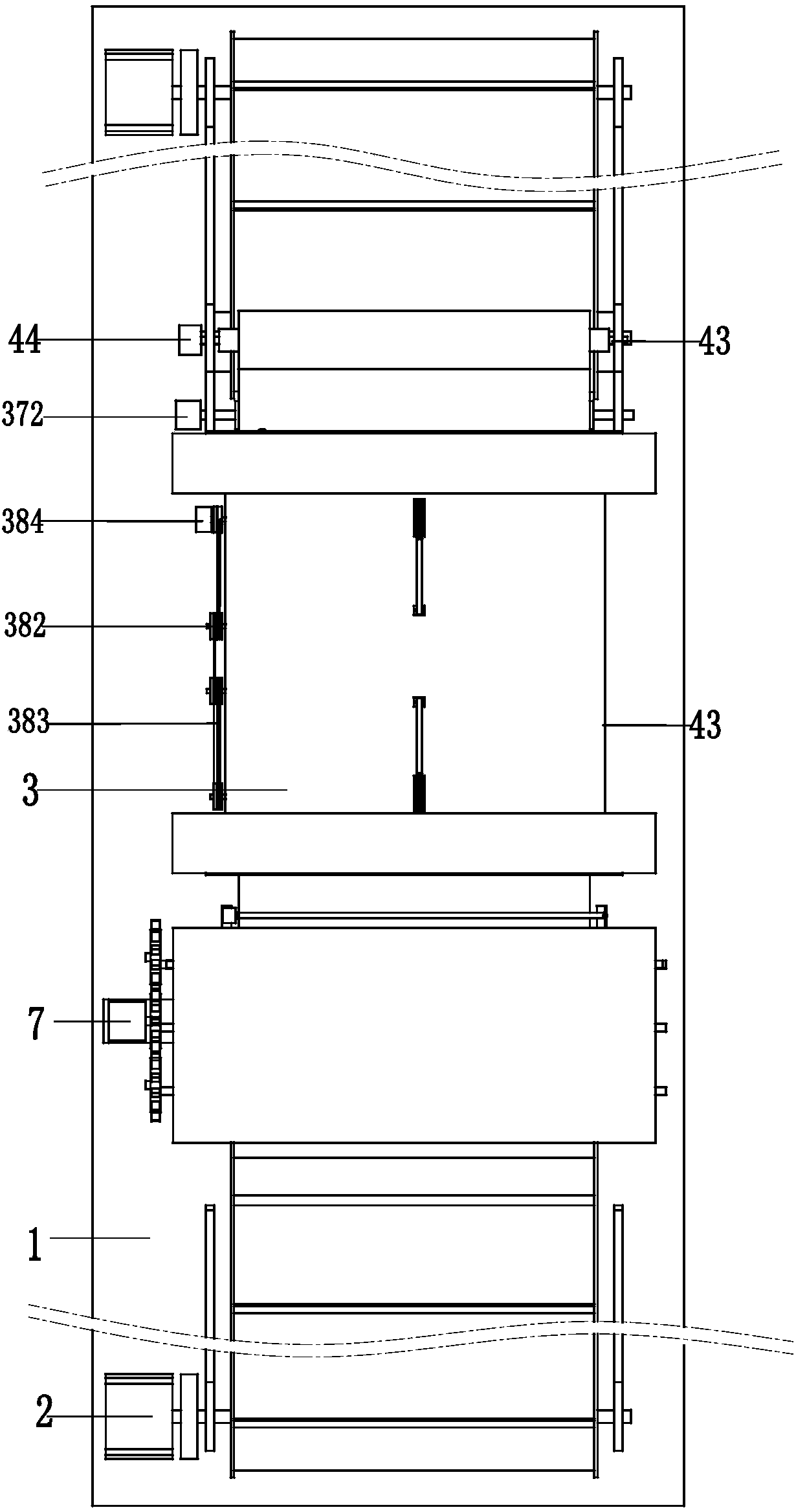

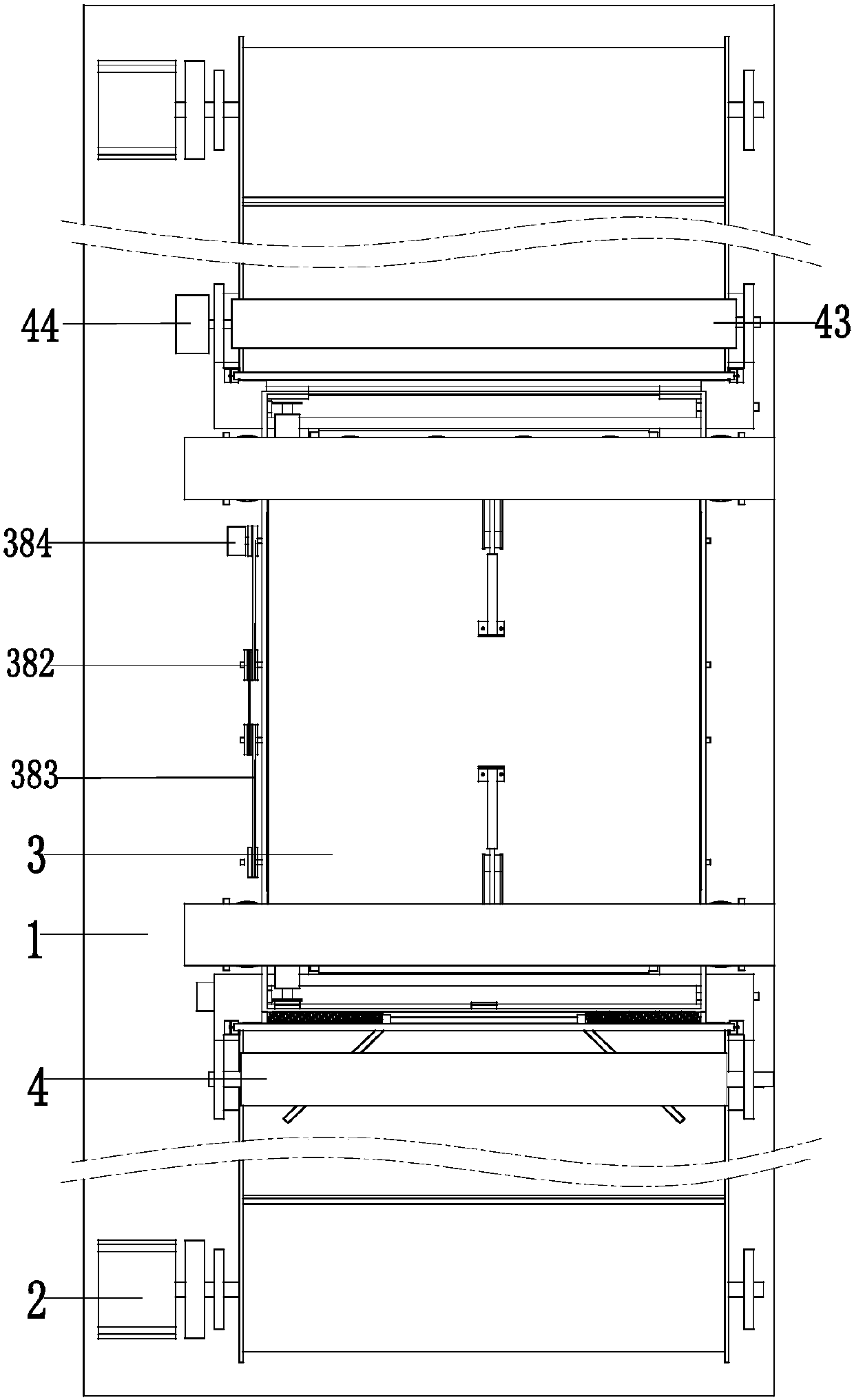

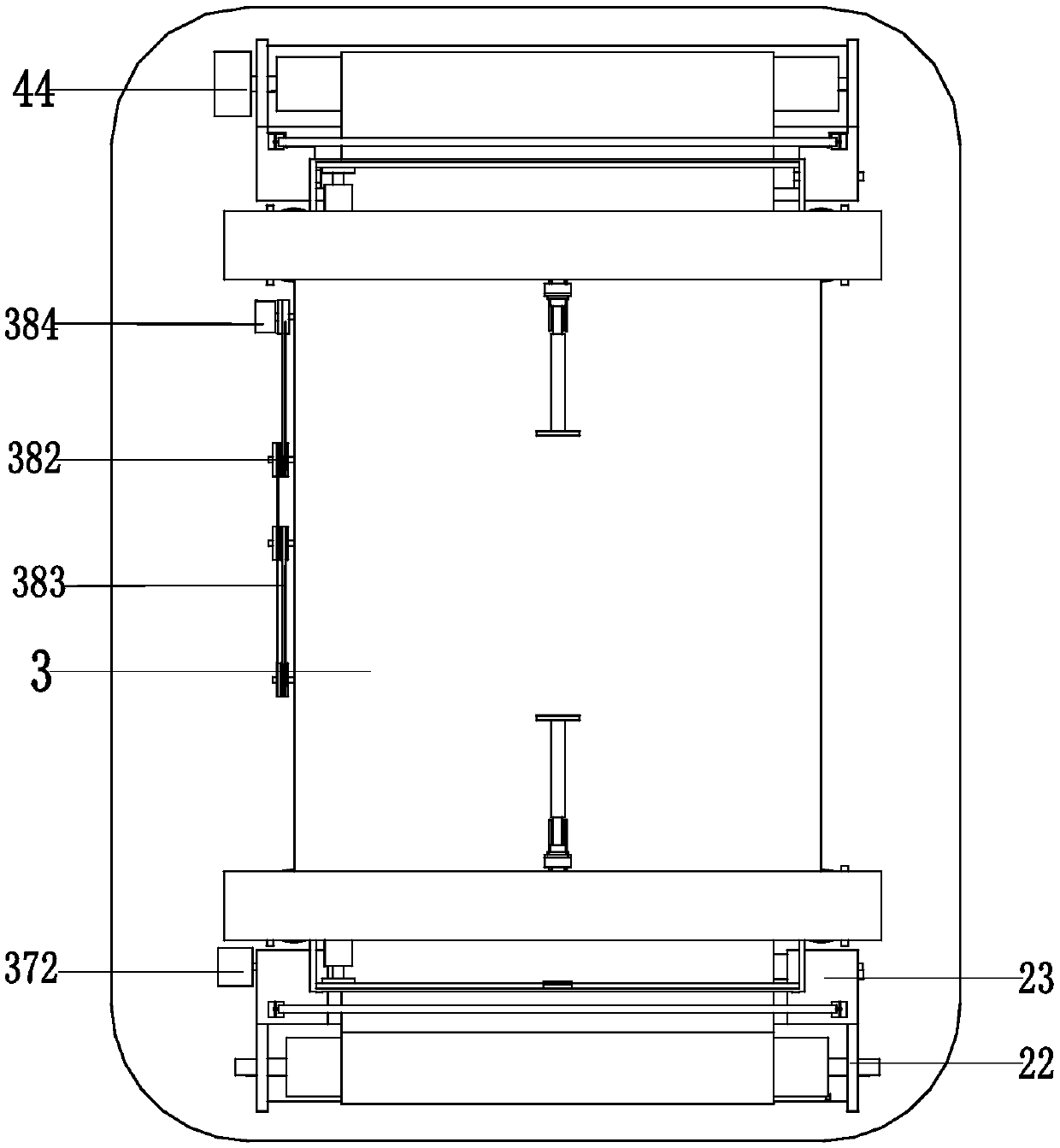

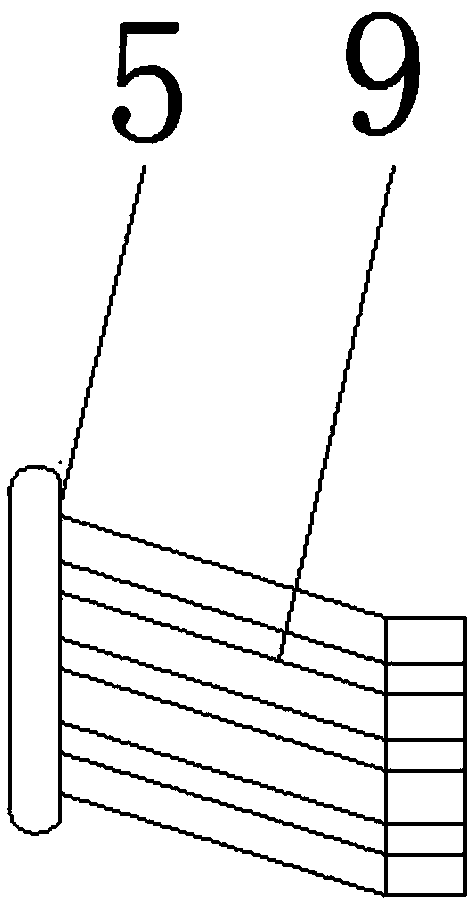

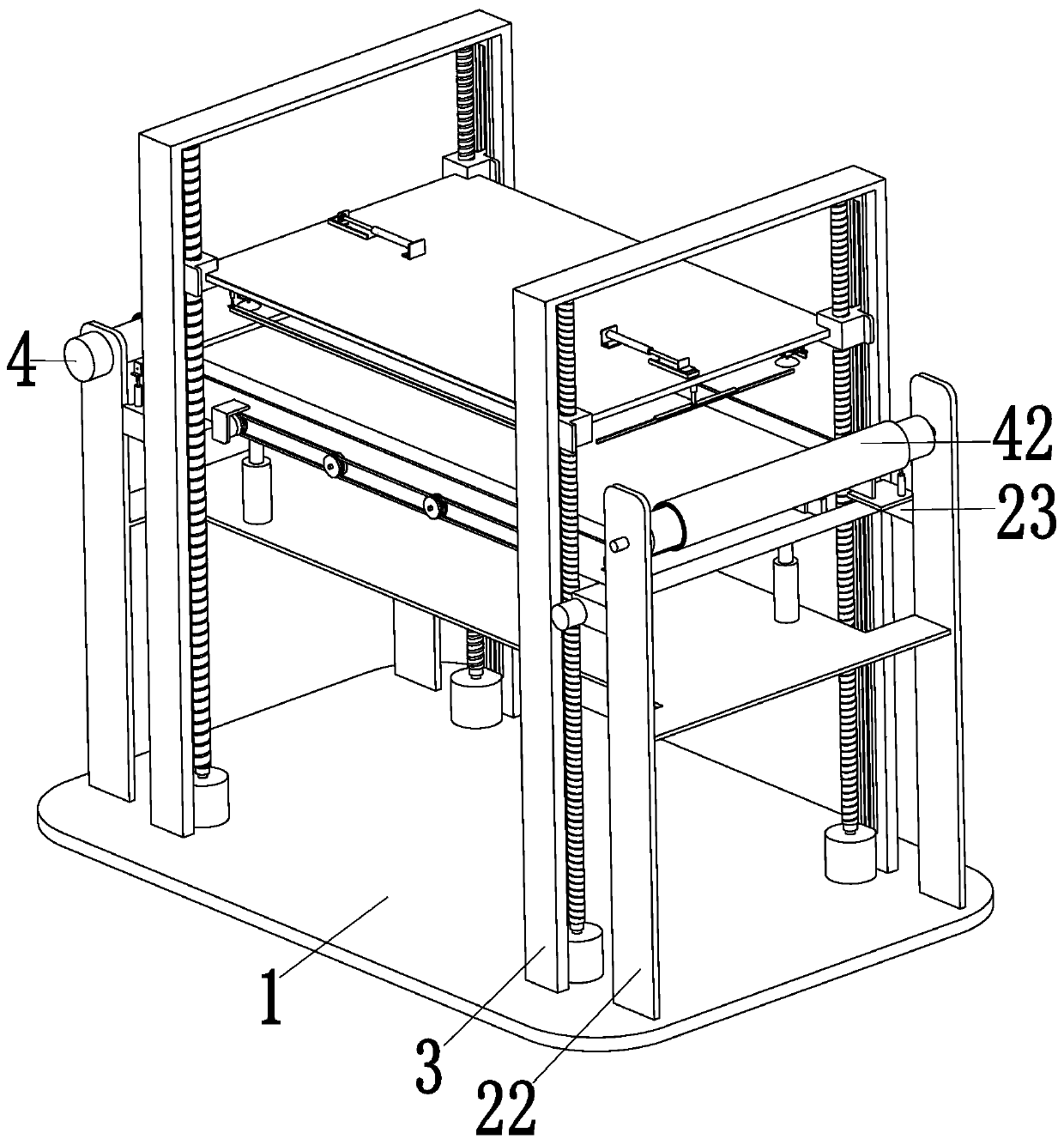

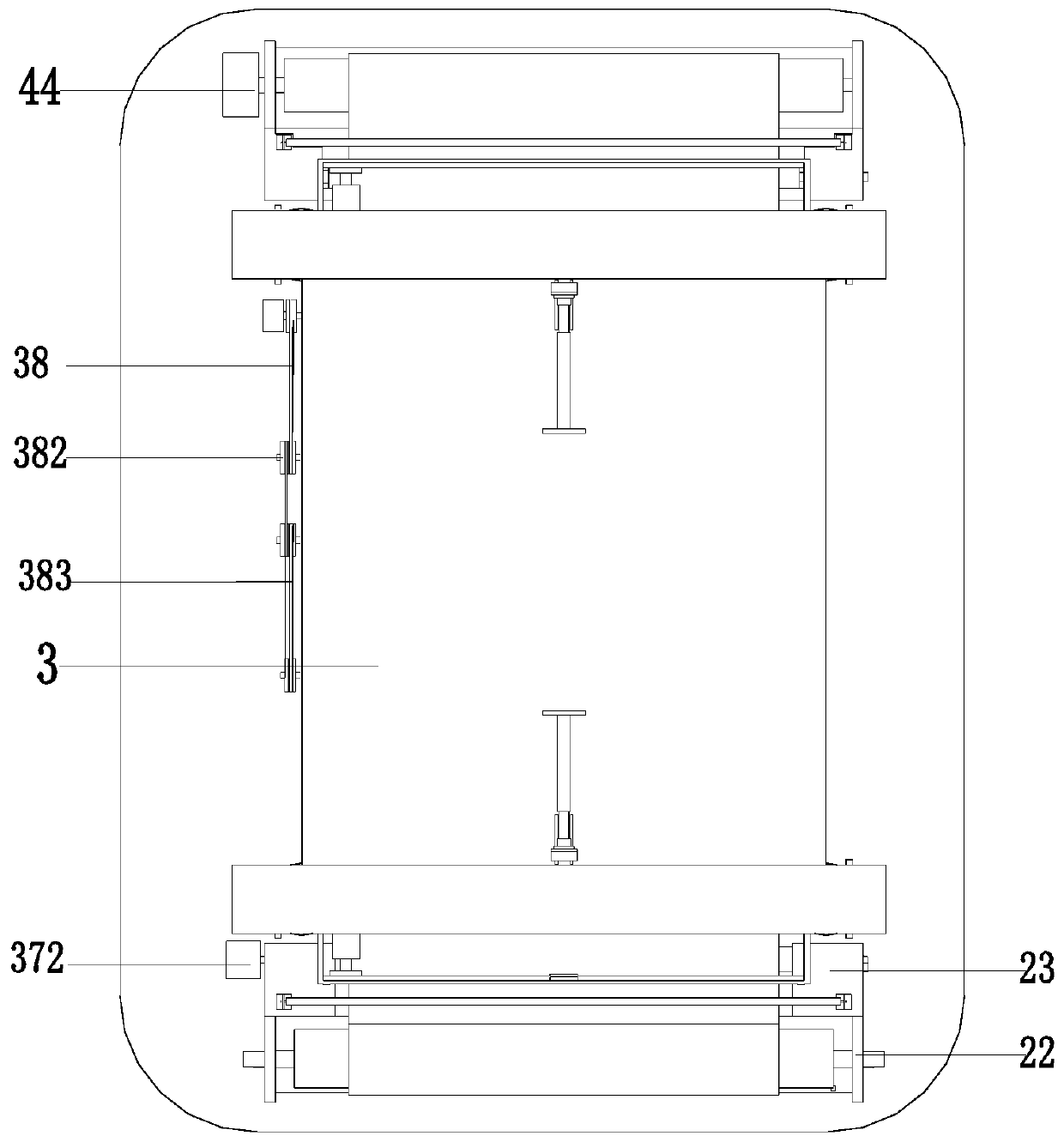

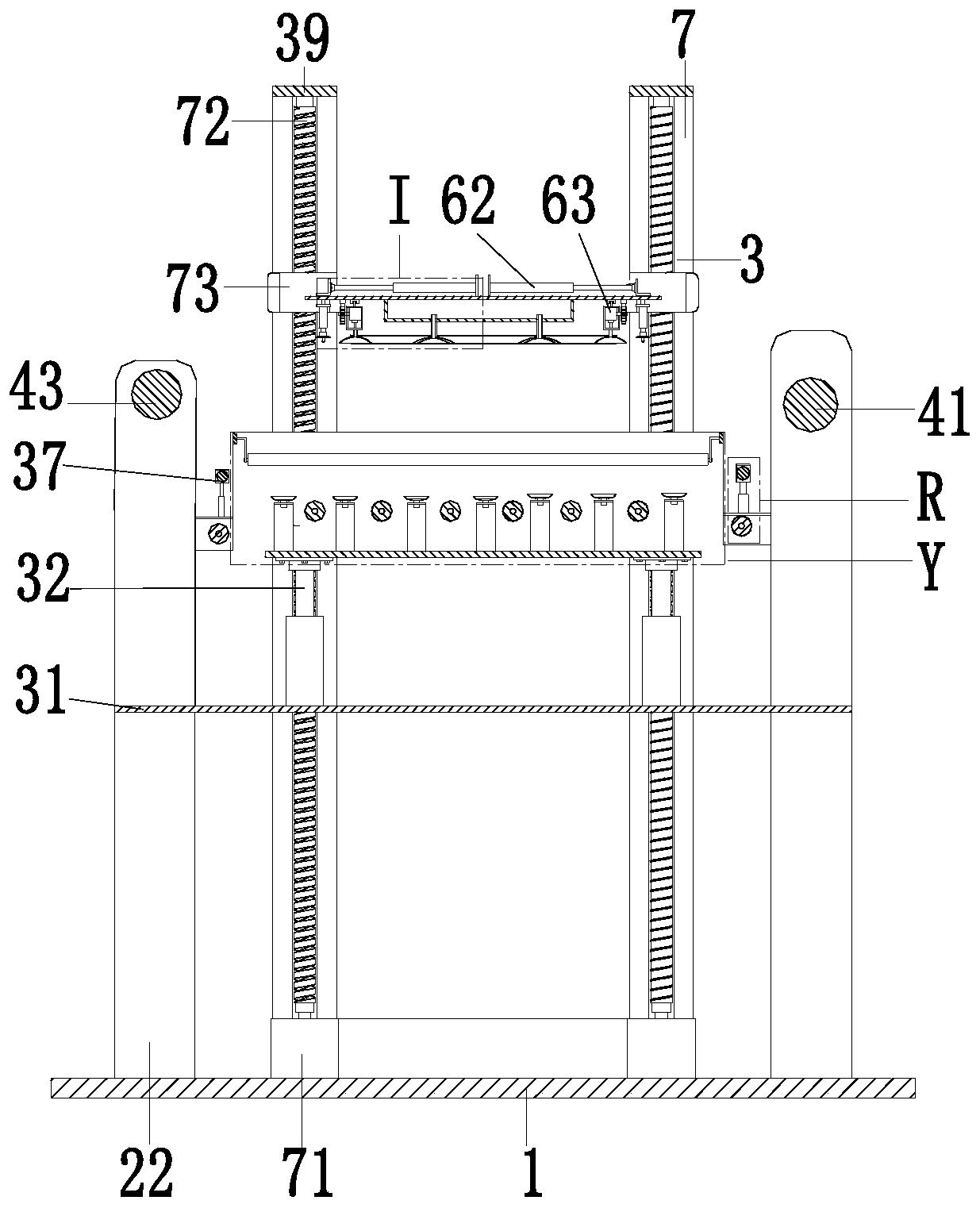

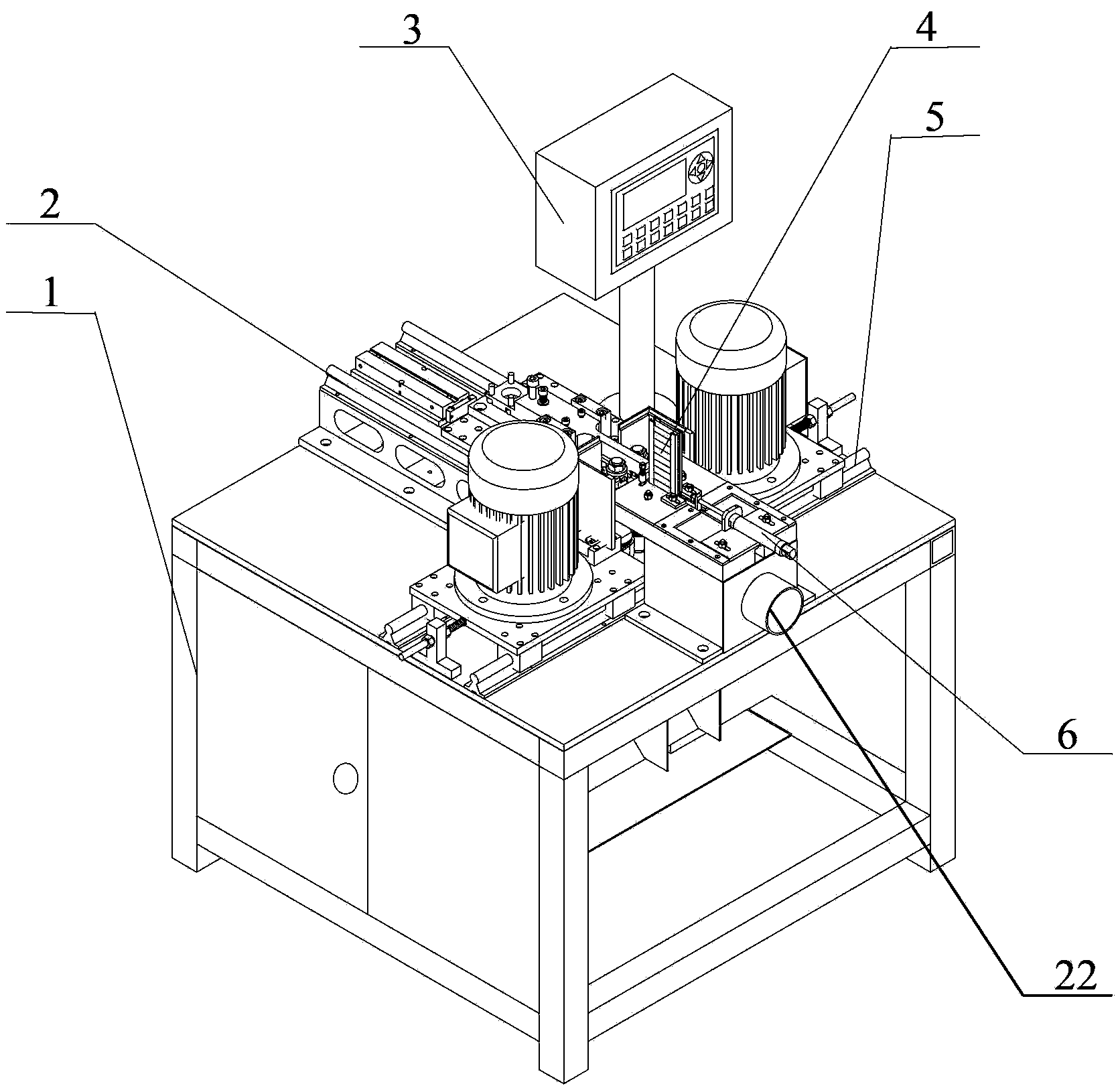

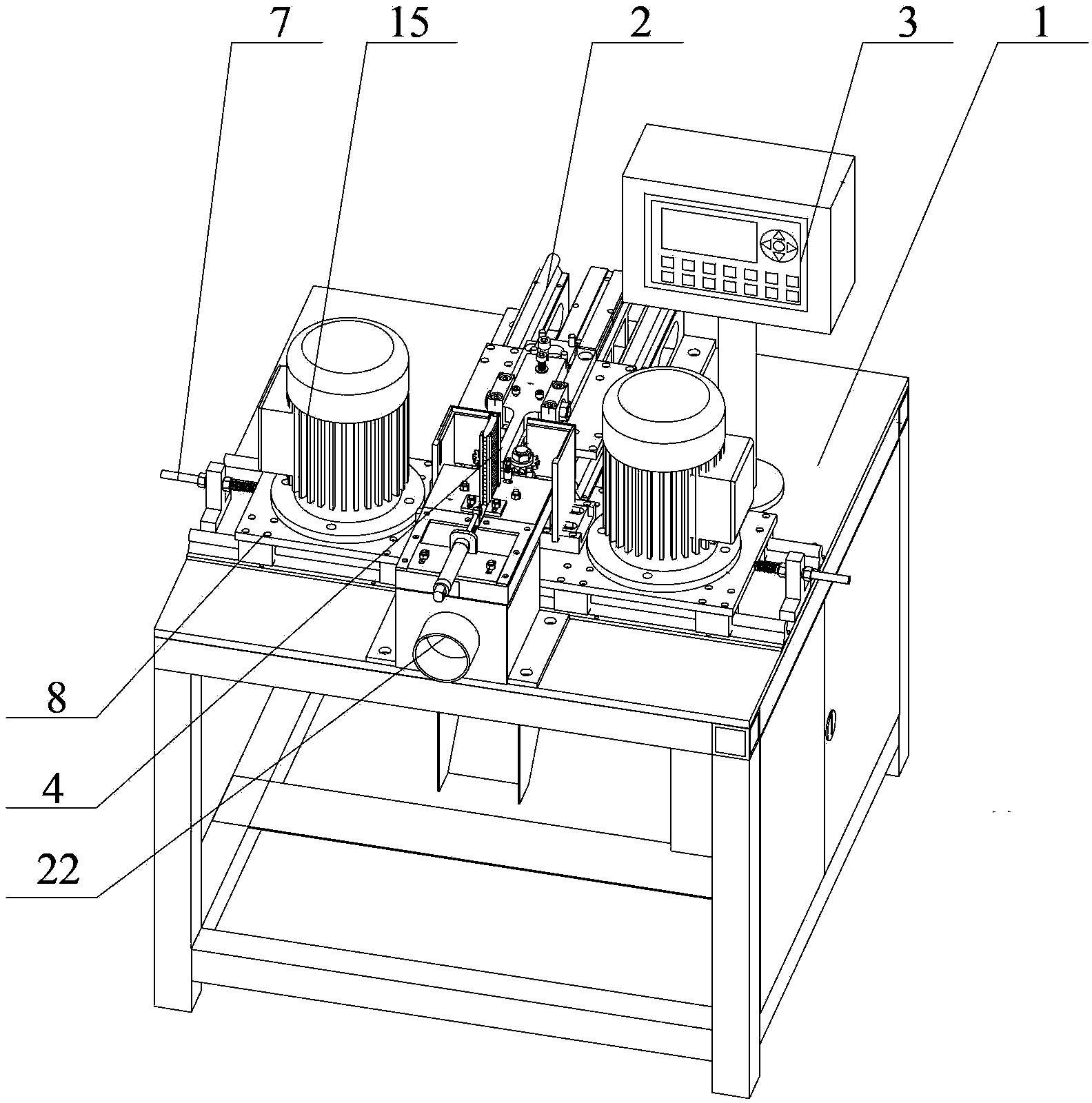

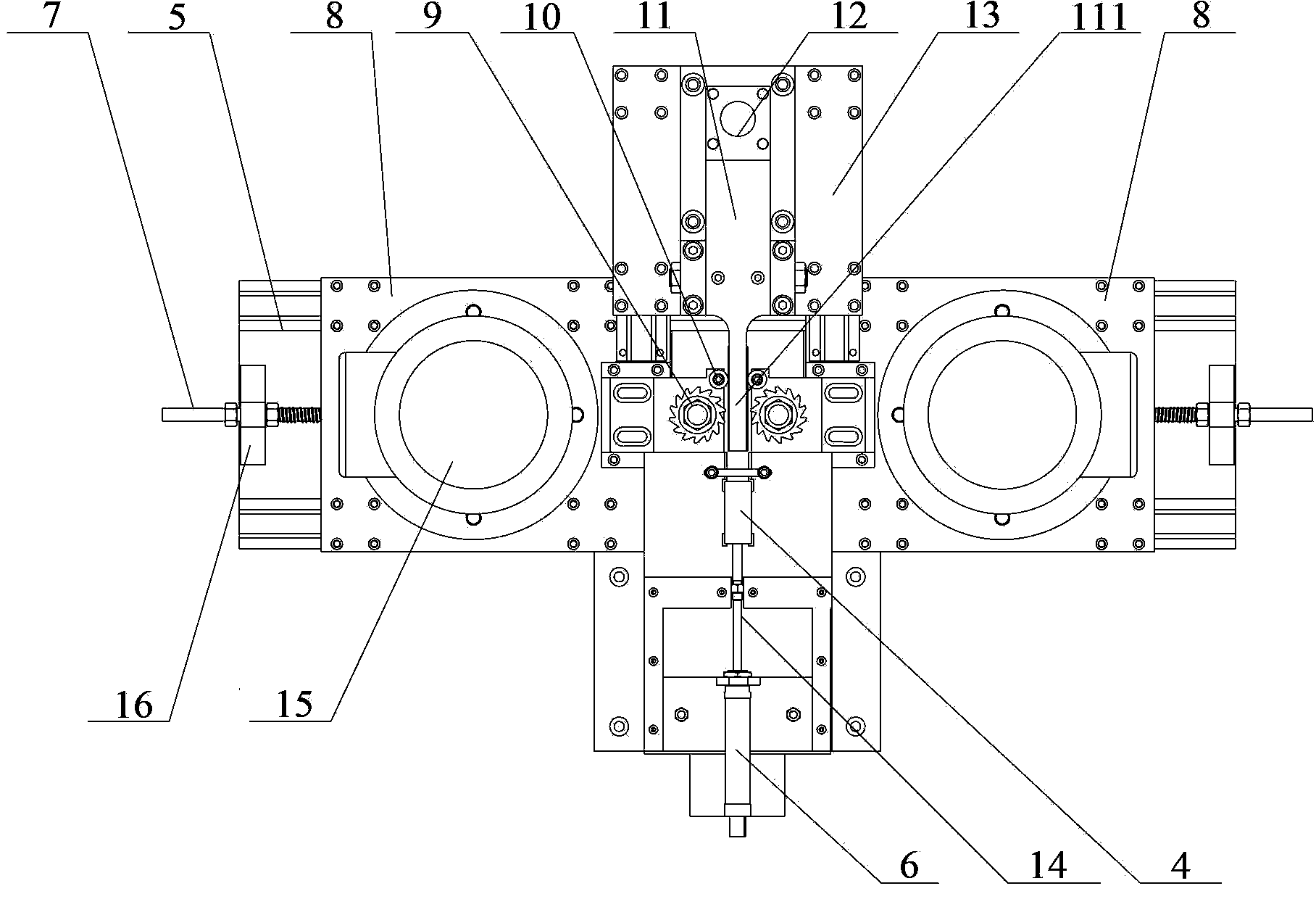

Automatic laminating processing equipment of container house flat color steel plate

ActiveCN107757045AHigh precisionImprove stabilityLamination ancillary operationsLaminationSteel platesEngineering

The invention relates to automatic laminating processing equipment of a container house flat color steel plate. The automatic laminating processing equipment of the container house flat color steel plate comprises a bottom plate; two conveying devices are symmetrically arranged on the bottom plate; a winding device is arranged between the two conveying devices; a conveying and laminating device isarranged between the two conveying devices; and the two conveying devices, the winding device and the conveying and laminating device are cooperatively used to finish the automatic laminating processof the color steel plate. The automatic laminating processing equipment of the container house flat color steel plate can solve the problems that the existing flat color steel plate laminating equipment cannot laminate the upper end and the lower end of the flat color steel plate in the laminating process of the existing flat color steel plate, the flat color steel plate is liable to move under the action of an external force in laminating processing process of the existing laminating processing equipment by the flat color steel plate laminating equipment, the flat color steel plates with different sizes need to be adjusted manually during laminating processing, the precision degree is slow, the labor intensity is large, the time consumption is high, the stability is low, the working efficiency is low and the like, and can realize the function of automatically laminating the container house flat color steel plate.

Owner:新沂市新南环保产业技术研究院有限公司

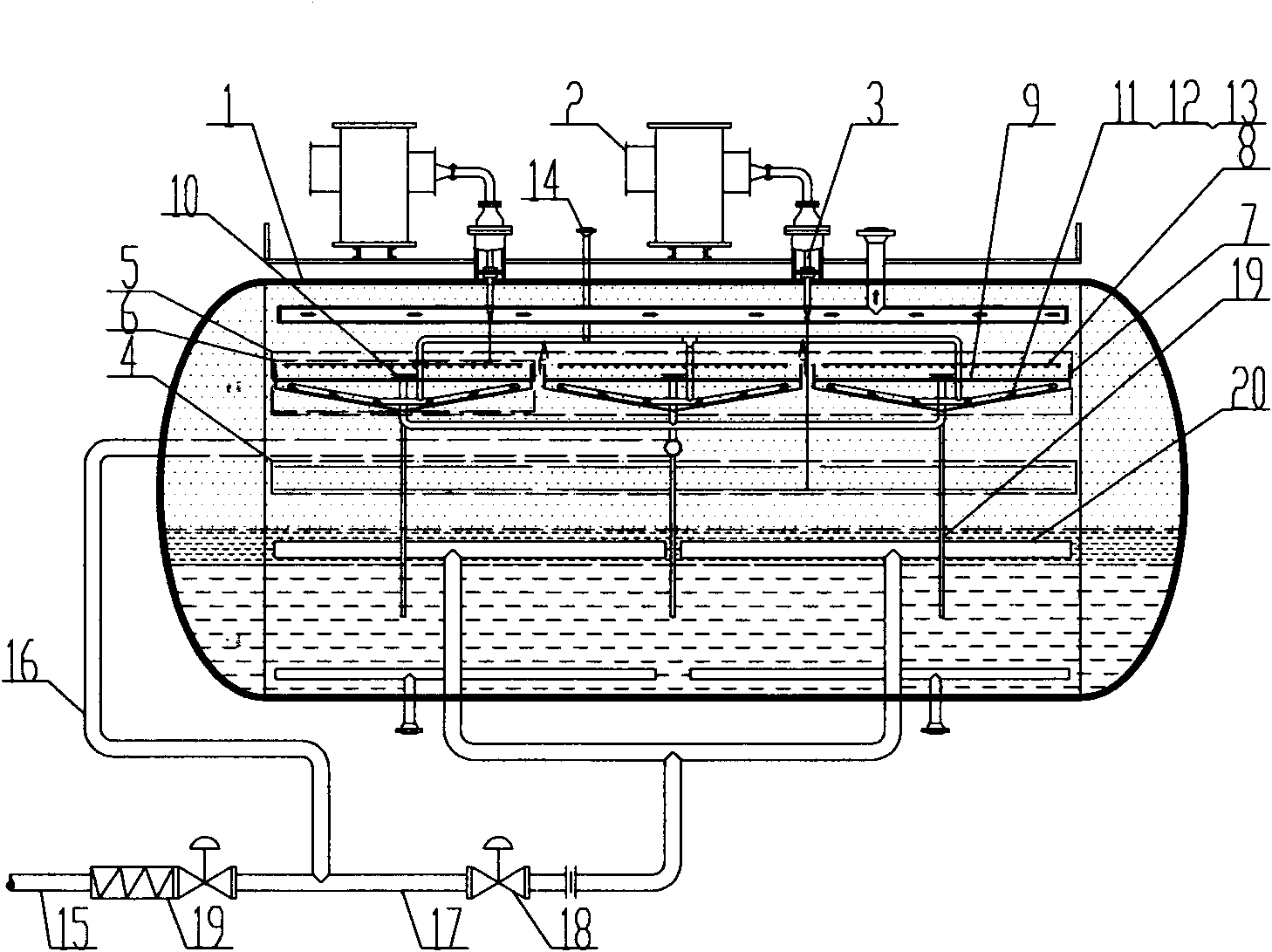

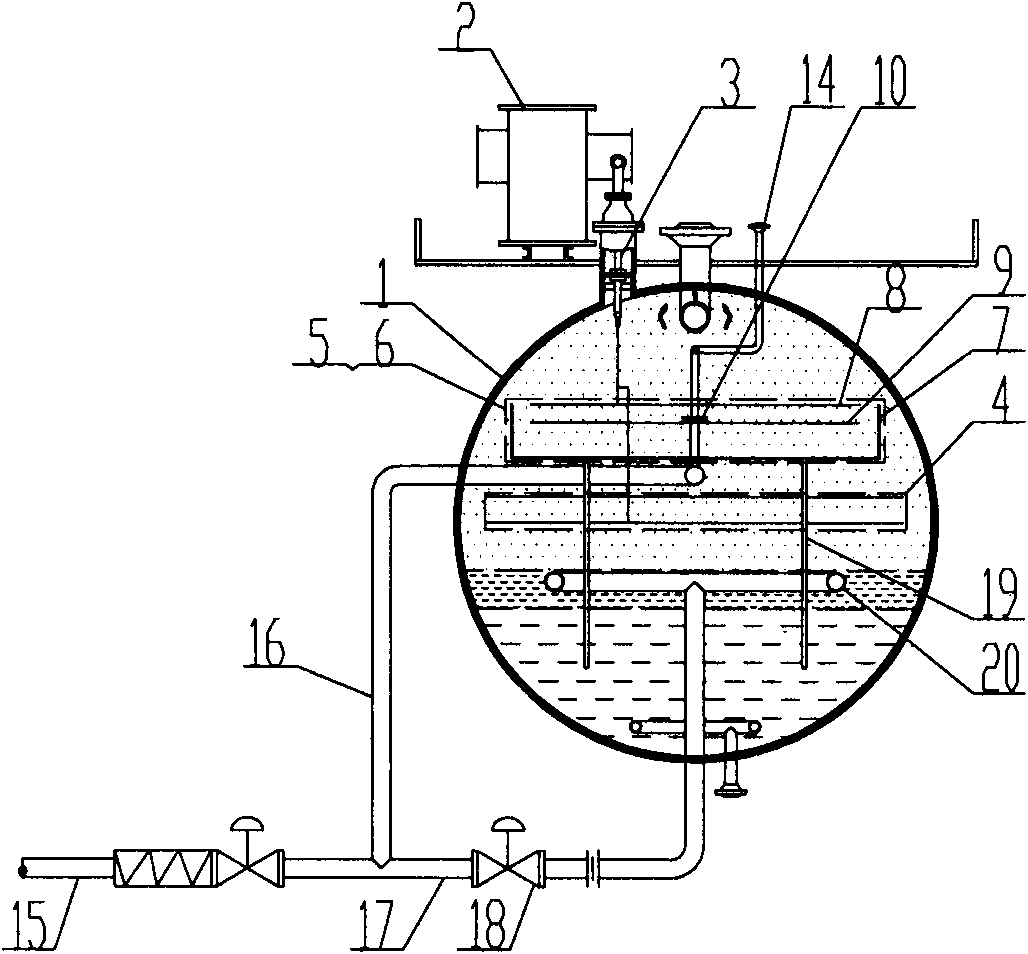

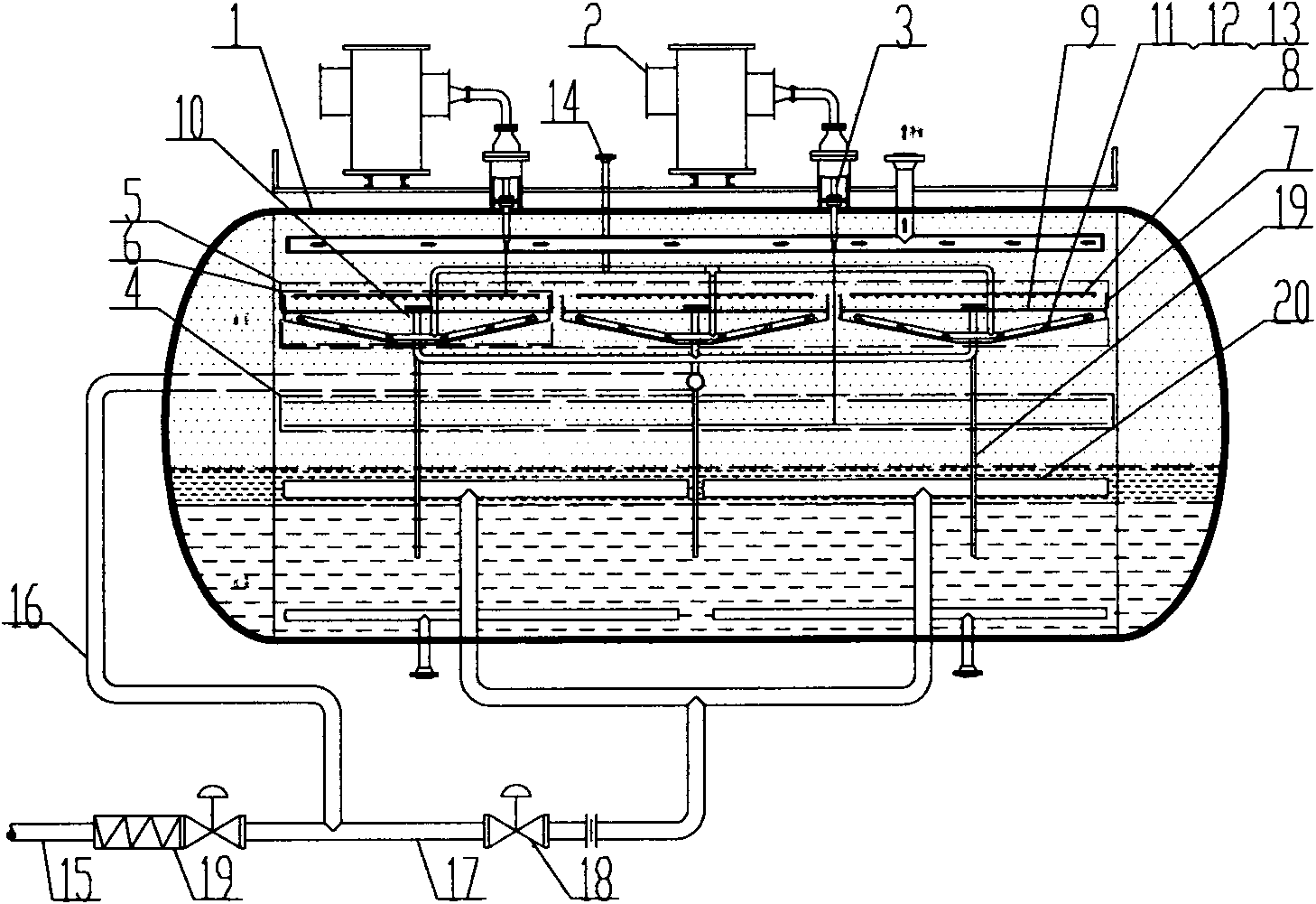

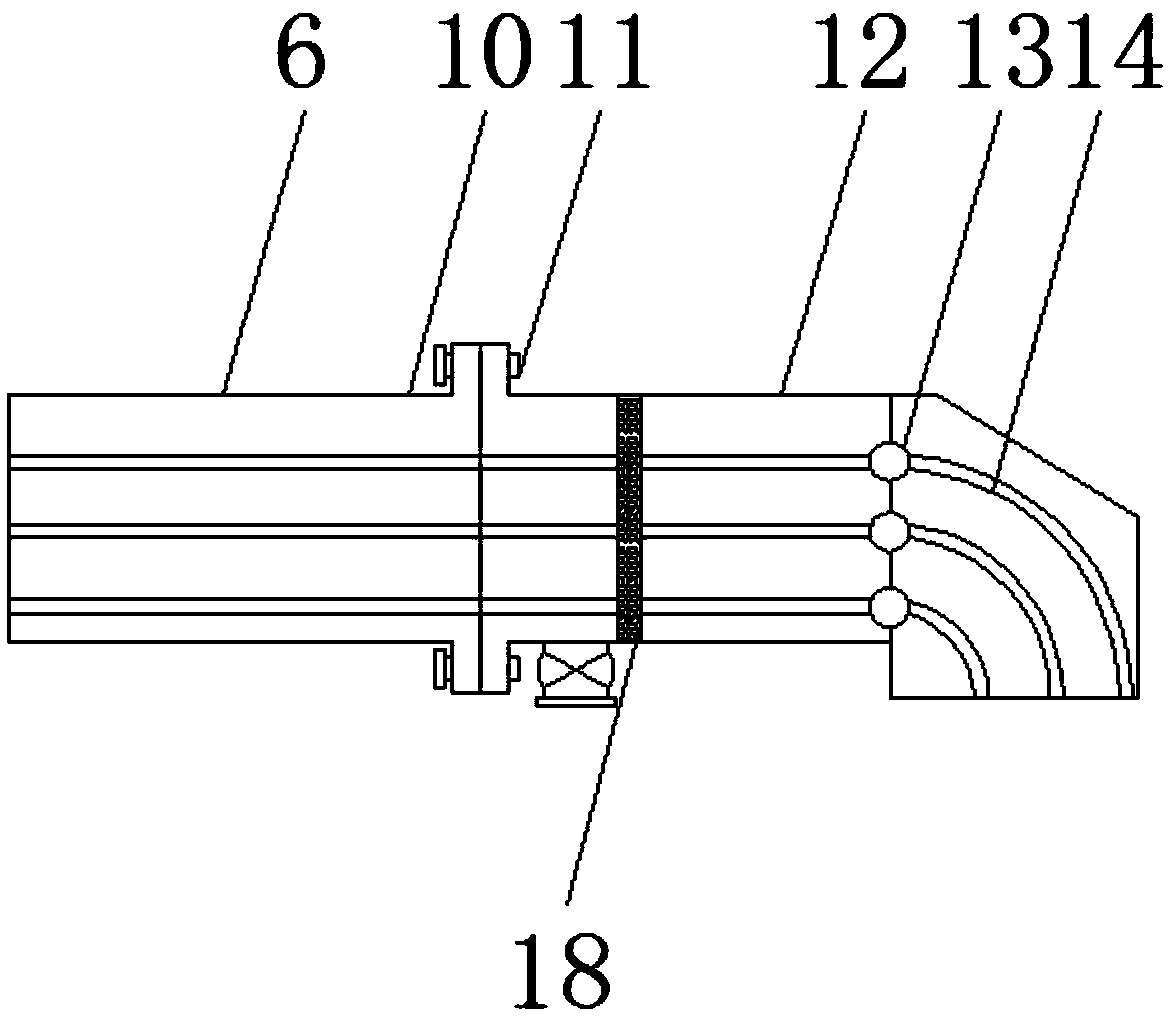

Updated heavy oil desalting and dewatering device

ActiveCN102373076AReasonable configurationEfficient condensationDewatering/demulsification with electric/magnetic meansTransformerHeavy crude oil

The invention discloses an updated heavy oil desalting and dewatering device. The device is composed of an electrical desalting tank, a transformer and a high-voltage electronic joint device, an oil inlet main pipe, oil inlet branched pipes and flow regulating valves, wherein an upper electric field in the electrical desalting tank consists of at least one electric field unit and adopts the multiple electric field distribution technology of single power supply, each electric field unit consists of a drip tray, a live electrode, a grounding electrode, an oil inlet nozzle, a backwashing device and a down pipe; and a fast dewatering and draining device consists of a V-shaped drip tray, a backwashing device and a down pipe, a backwashing nozzle and the bottom surface of the drip tray forms an inclination, the top of the down pipe is connected with the bottom of the drip tray, and the other end is inserted in the water layer of the electrical desalting tank. The field intensity of the upper electric field of the device is optimized, fast dewatering and draining can be ensured, the desalting efficiency is increased; and the updated heavy oil desalting and dewatering device is suitable for the deep desalting and dewatering treatment of crude oil, particularly heavy crude oil, fuel oil and other heavy oil products.

Owner:EAST CHINA UNIV OF SCI & TECH +1

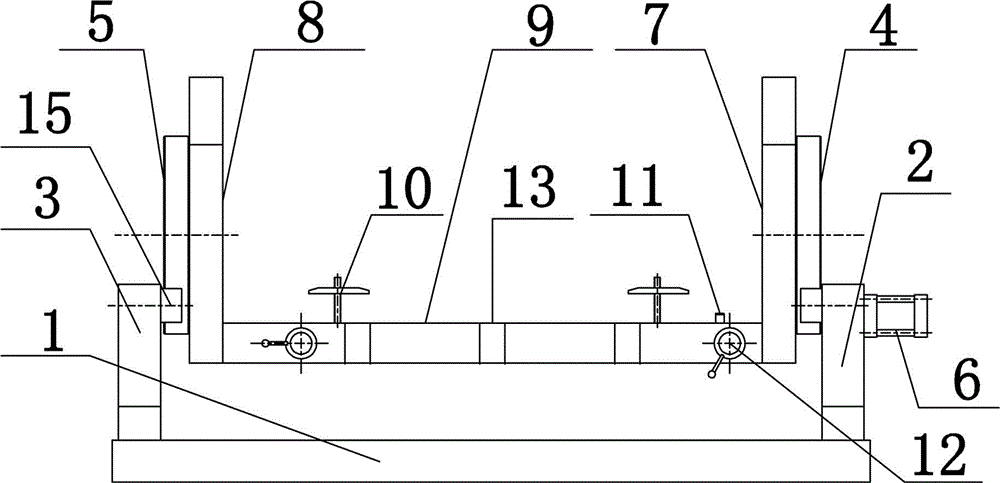

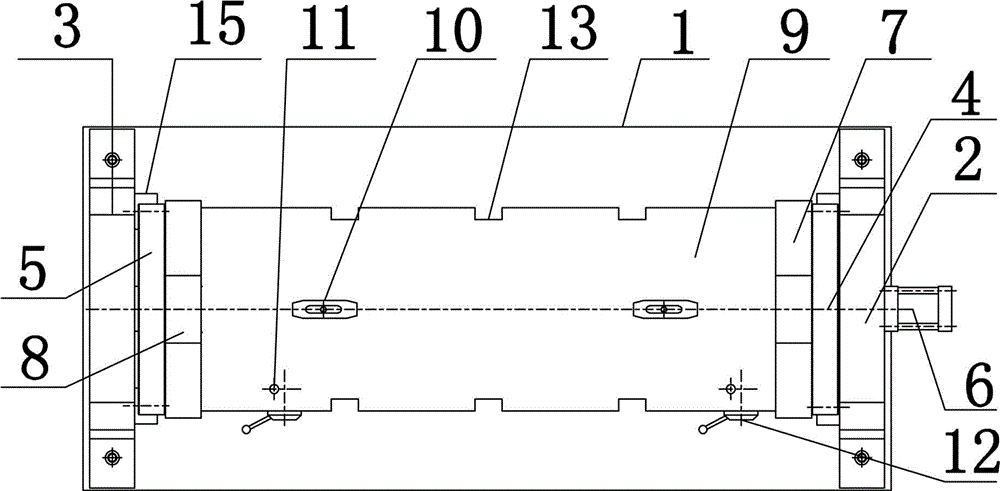

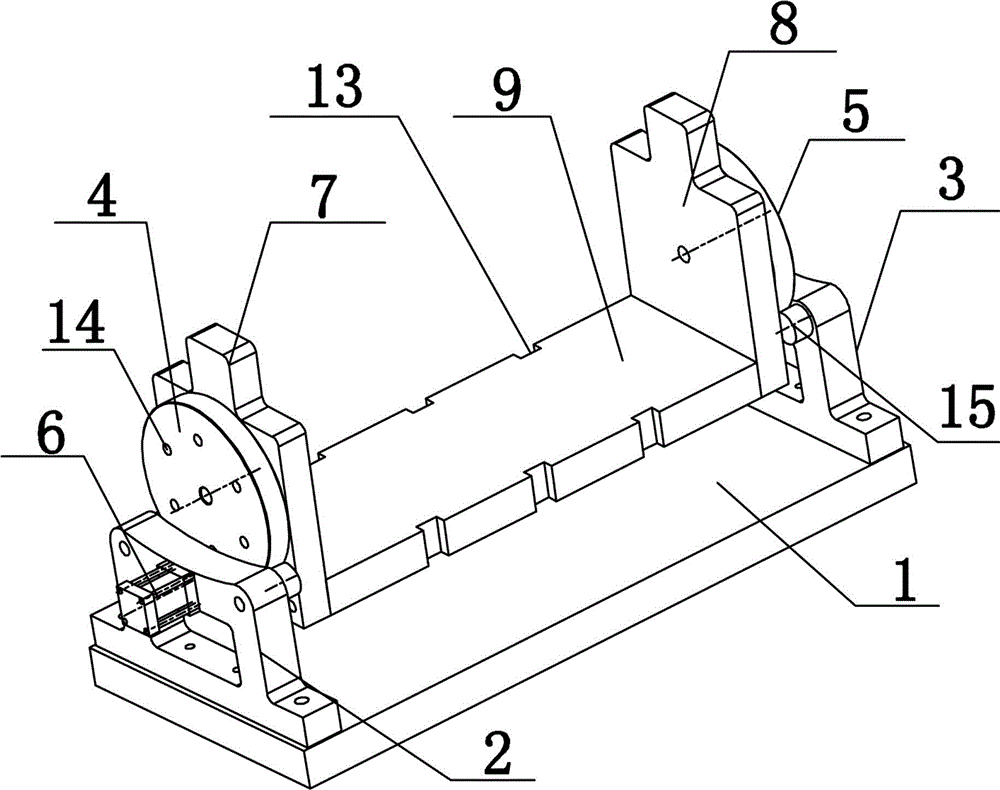

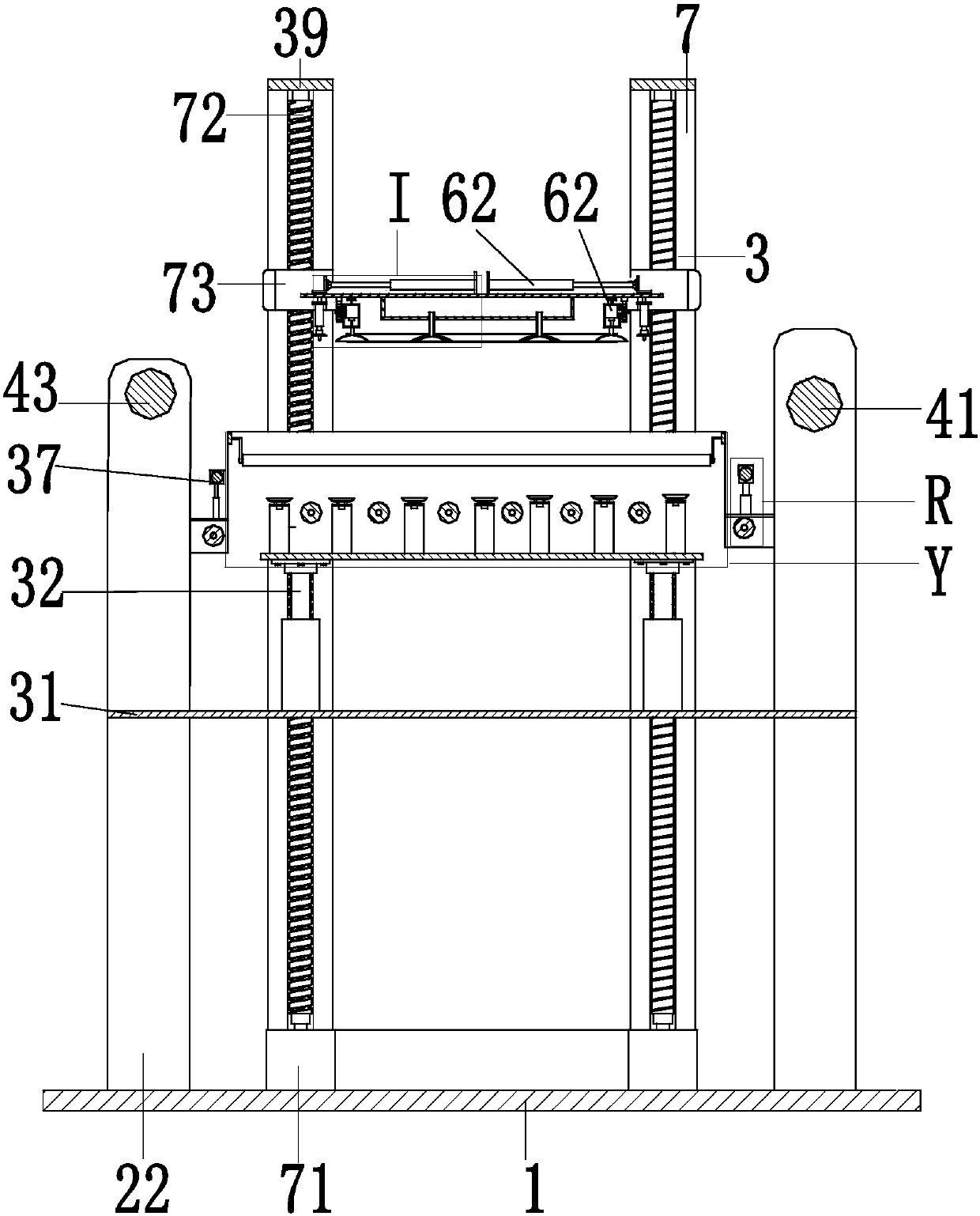

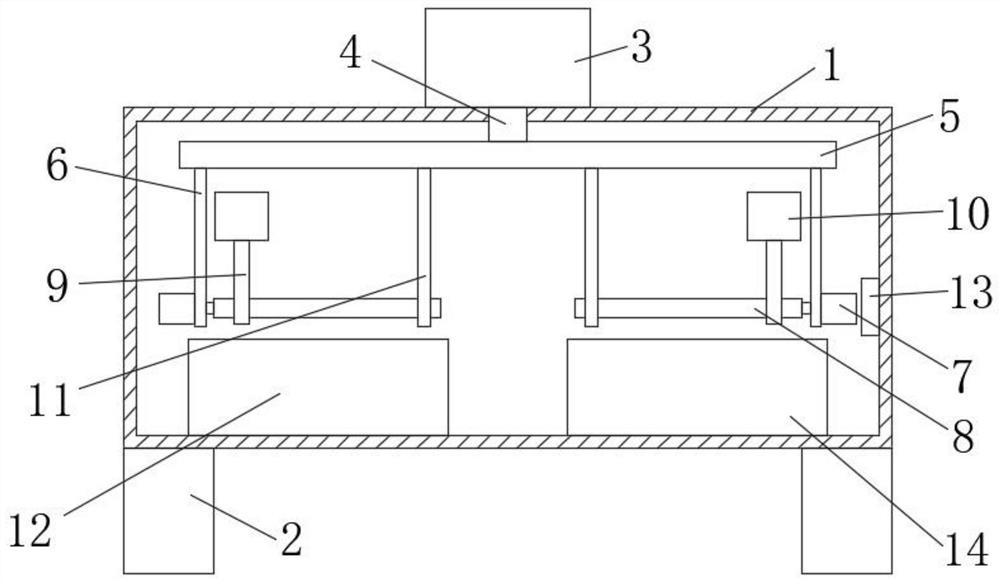

Six-face machining tool and six-face machining method of diesel engine body

ActiveCN105127787ASimple processReduce forceWork clamping meansPositioning apparatusRotary stageMachining process

The invention relates to a six-face machining tool and six-face machining method of a diesel engine body. The six-face machining tool comprises a base, the two ends of the base are provided with a front end disc support and a rear end disc support respectively, and the front end disc support and the rear end disc support are connected with a front end rotating disc and a rear end rotating disc respectively; a rotating table is arranged between the front end rotating disc and the rear end rotating disc, and multiple positioning mechanisms are arranged on the rotating table; the outer side of the front end disc support or the outer side of the rear end disc support is provided with an air pump, a positioning pin is arranged in the air pump, and the air pump is arranged to be matched with the front end rotating disc or the rear end rotating disc. According to the six-face machining tool and six-face machining method of the diesel engine body, working procedures of the machining process of the diesel engine body are simplified, the labor energy consumed on moving or rotating the engine body is greatly reduced, an operator can concentrate on machining operation of the engine body itself, and due to the fact that turning of an engine body workpiece is mechanically controlled, the machining accuracy of the engine body is improved; the accuracy of all faces is more stable, the yield is high, the machining cost is low, the machining efficiency is high, and the labor cost is low.

Owner:浙江东新动力有限公司

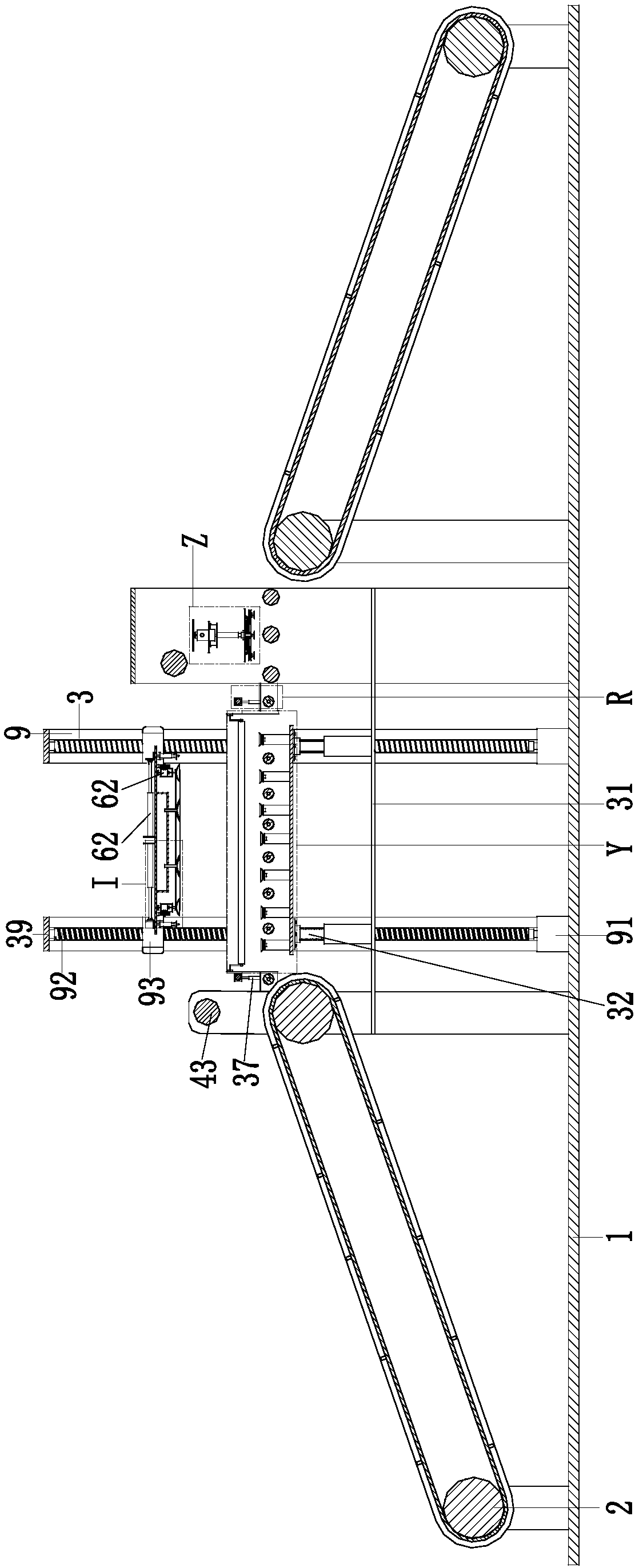

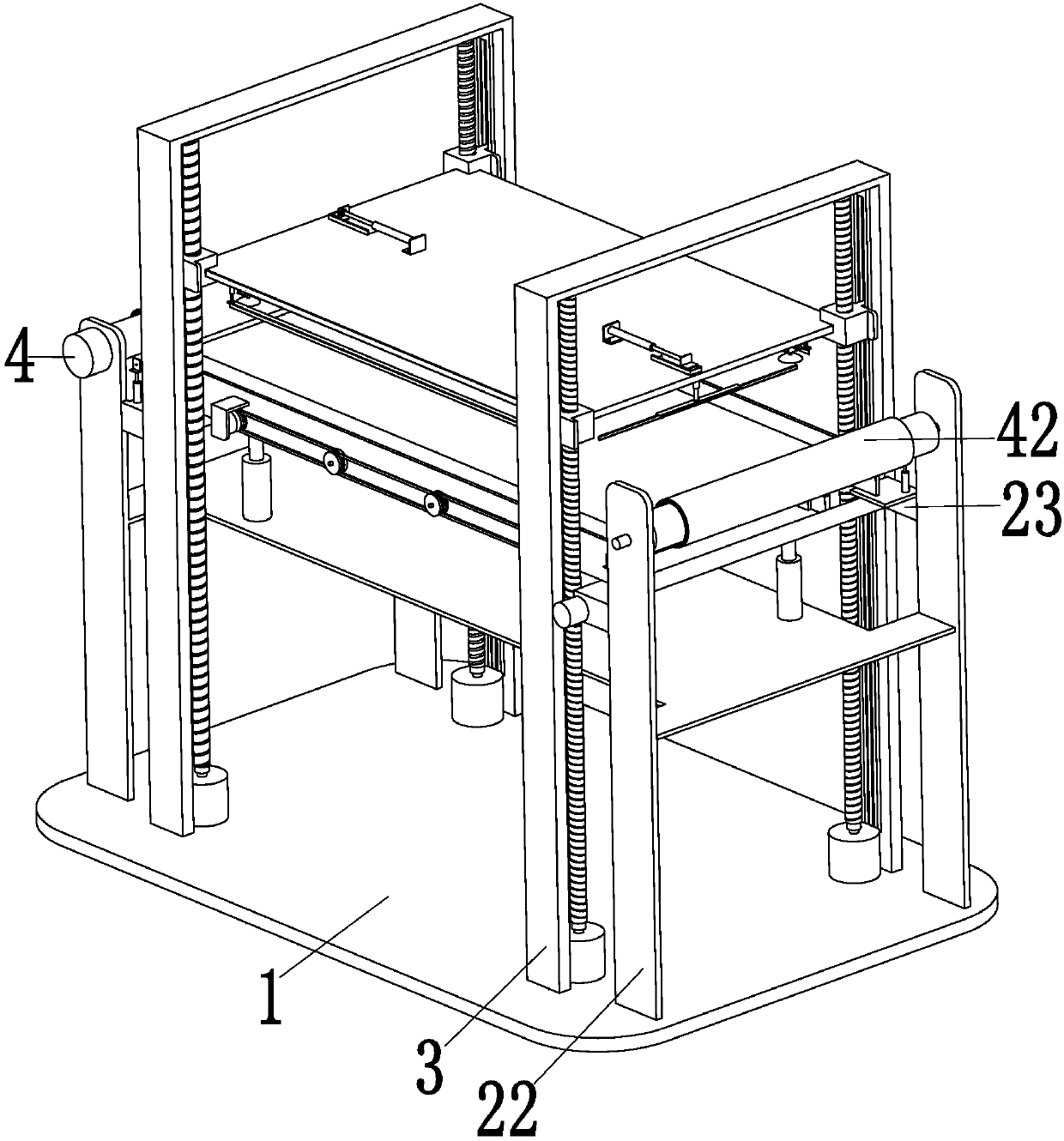

High-efficiency automatic coating device for flat color steel plate

ActiveCN107776948AReduce labor intensityNo manual operationPackagingEngineeringUltimate tensile strength

The invention relates to a high-efficiency automatic coating device for a flat color steel plate. The high-efficiency automatic coating device comprises a bottom plate, wherein two pairs of baffles IIare symmetrically mounted on the front and rear sides of the bottom plate, winding devices are arranged between upper sides of the two pairs of baffles II, a coating conveying device is mounted at the lower ends of the two pairs of baffles II, and an automatic coating process of the flat color steel plate is finished under matched use of the winding devices and the coating conveying device. The high-efficiency automatic coating device can solve the problems that the upper and lower ends of the flat color steel plate cannot be coated by the existing flat color steel plate coating equipment, the flat color steel plate is easy to move under the action of external force in the flat color steel plate coating process by the existing coating equipment, manual adjustment is needed when flat colorsteel plates in different sizes are coated, the precision is low, the labor intensity is high, long time is consumed, the stability and the working efficiency are low and the like in the coating process of the existing flat color steel plate, and high-efficiency automatic coating of the flat color steel plate can be realized.

Owner:唐山海德林纳新型建材有限公司

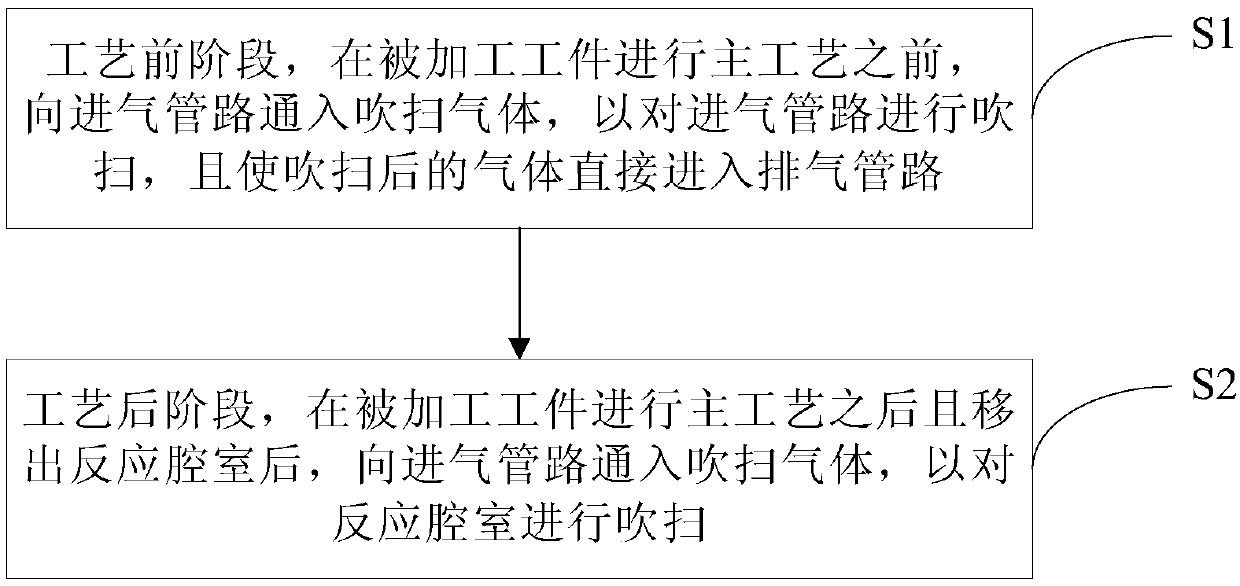

Process gas purging method

ActiveCN110943003AReduce process gasesReduce particle countFinal product manufactureSemiconductor/solid-state device manufacturingThermodynamicsProcess engineering

The invention provides a process gas purging method which comprises the following steps: in a pre-process stage, namely introducing purging gas into a gas inlet pipeline to purge the gas inlet pipeline before a processed workpiece is subjected to a main process, and enabling the purged gas to directly enter an exhaust pipeline; and in the post-process stage, after the processed workpiece is subjected to the main process and is moved out of a reaction chamber, introducing blowing gas into a gas inlet pipeline so as to blow the gas inlet pipeline and a reaction chamber. According to the processgas purging method provided by the invention, residual process gas in the gas inlet pipeline and the reaction chamber can be reduced, so that the number of particles on the processed workpiece afterthe processing process is reduced, and the standard of granularity control is met.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Coal chemical wastewater pretreatment method and pretreatment system

PendingCN108383299AReduce pollutionImprove flocculation and sedimentation abilityMultistage water/sewage treatmentNature of treatment waterChemistryCoal chemical industry

The invention discloses a coal chemical wastewater pretreatment method. The method includes flocculent settling treatment, hydrogen peroxide catalytic oxidation treatment and internal electrolysis treatment, and effluent quality reaches that COD is smaller than or equal to 500mg / L, ammonia nitrogen content is smaller than or equal to 200mg / L, and suspended matter content is smaller than or equal to 70mg / L after treatment. After treatment according to the pretreatment method, wastewater available for biochemical treatment is obtained and can be directly discharged or recycled after biochemicaltreatment. A treatment system is stable in operation, and biochemical degradability of coal chemical wastewater is effectively achieved. The coal chemical wastewater pretreatment method and the pretreatment system have positive popularization significance and remarkable application value.

Owner:HEBEI CHAOLYU ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

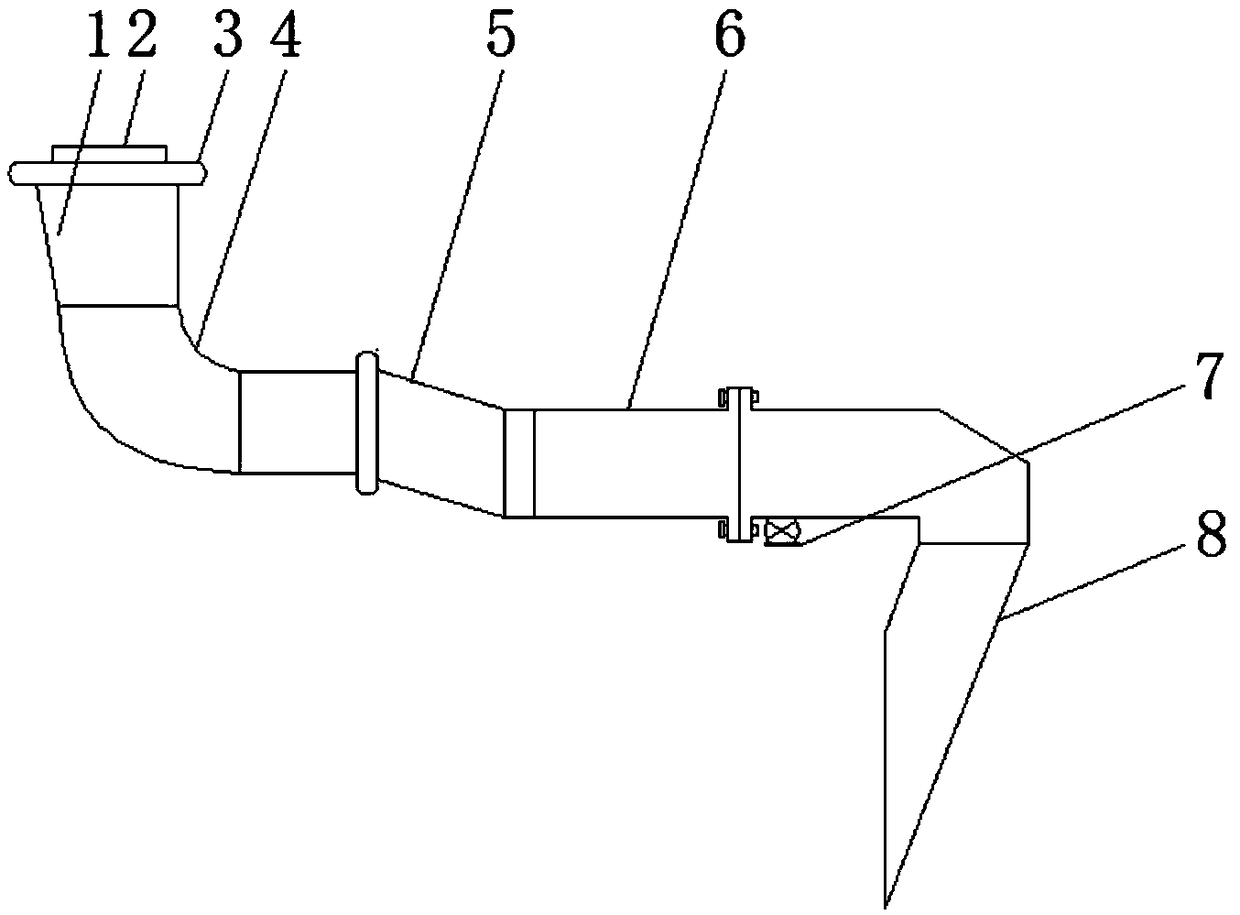

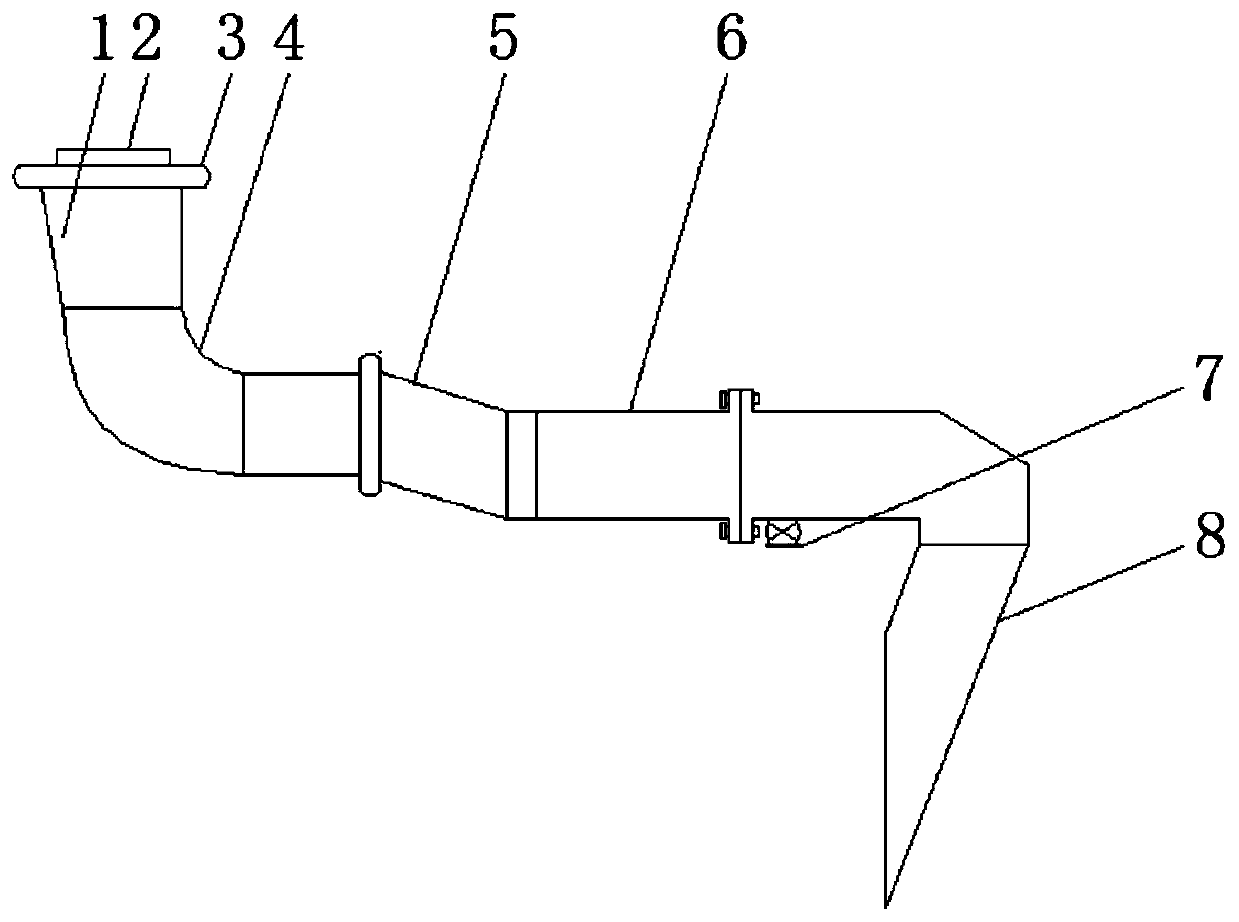

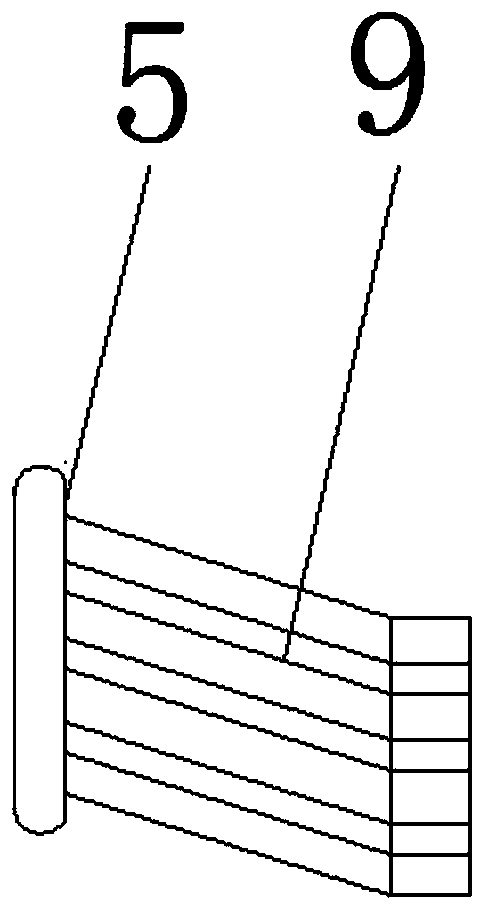

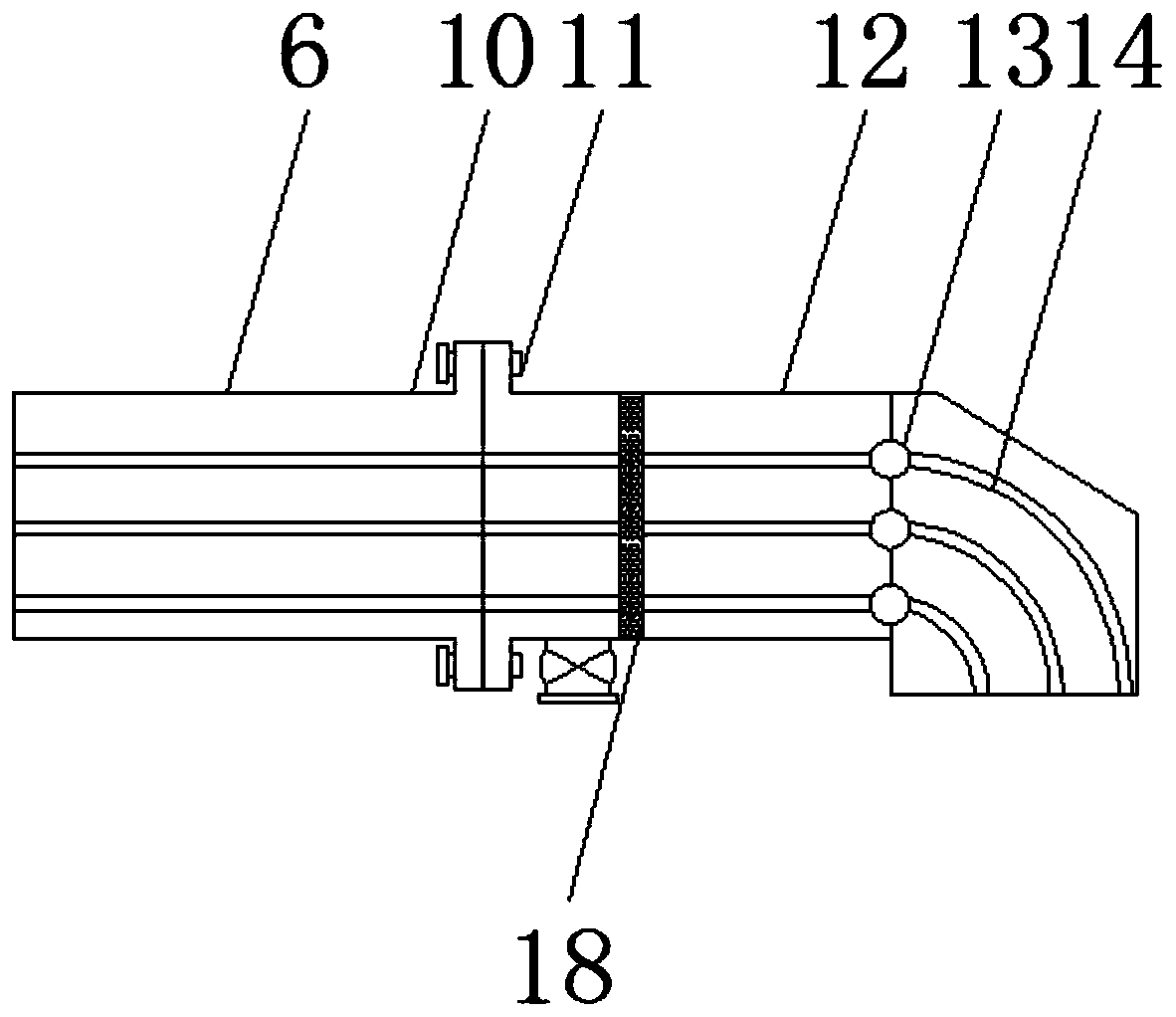

Denitration smoke flue guide plate for thermal power plant

The invention discloses a denitration smoke flue guide plate for a thermal power plant. The denitration smoke flue guide plate for the thermal power plant comprises a smoke inlet pipe, a smoke straight-through pipe and a guide plate body a. A connecting opening is formed in the top circumferential end surface of the smoke inlet pipe through a leakproof rubber sleeve. An arc-shaped smoke conveyingpipe is installed at the bottom of the smoke inlet pipe. An inclined pipe is installed on the right side of the arc-shaped smoke conveying pipe through a connecting rubber sleeve. The smoke straight-through pipe is installed at one end of the inclined pipe, and a smoke conveying opening is formed in the bottom of the smoke straight-through pipe. The guide plate body a is installed in a groove formed in the inclined pipe, the smoke straight-through pipe is composed of a combined pipe a and a combined pipe b, the guide plate body a penetrates through the inclined pipe and the smoke straight-through pipe and is provided with the guide plate body b through a connecting arc-shaped opening, and storage square grooves are formed in the guide plate body a. According to the denitration smoke flue guide plate for the thermal power plant, the smoke is effectively and evenly distributed in the smoke conveying process, so that the burden of a denitration system of a unit and the environmental protection risk are greatly reduced.

Owner:DATANG HUAIBEI POWER PLANT

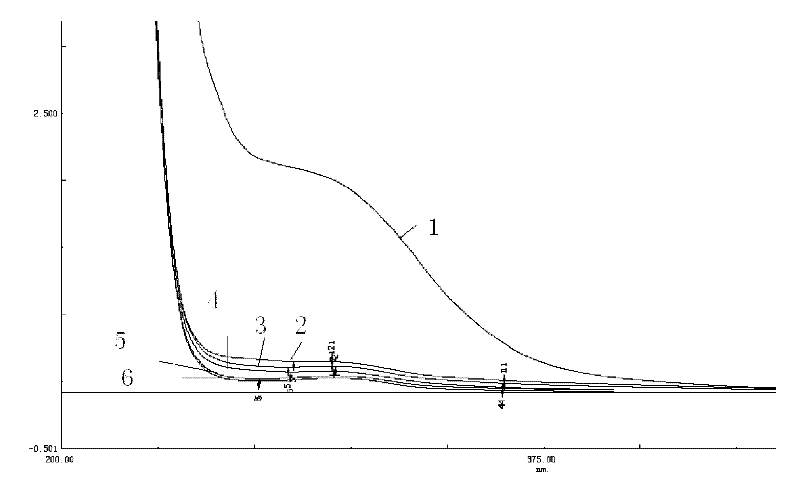

Method for optimizing long-term operating performance of VOC gas biological filtration device by utilizing ozone

ActiveCN101966421ARegulation of proliferation rateActivity is not affectedDispersed particle separationAir quality improvementBio filtrationFiltration

The invention belongs to the technical field of environmental treatment, and in particular relates to a method for optimizing the long-term operating performance of a volatile organic compound (VOC) gas biological filtration device by utilizing ozone. In the method, after the biological filtration device is started and operated stably, ozone gas is introduced into VOC gas to be treated to form a mixed gas to enter the biological filtration device, wherein the concentration of the VOC gas in the mixed gas is 500 to 2,000mg / m<3> and the concentration of the ozone gas is 40 to 400 mg / m<3>. The method can effectively control the biomass in the biological filtration device and simultaneously does not affect the VOC removal activity of microorganisms, so that a packing layer is not easy to clog, pressure reduction is maintained stably and a VOC removal effect is not reduced in a long-term operating process of the biological filtration device.

Owner:紫荆汇智环境科技(北京)有限公司

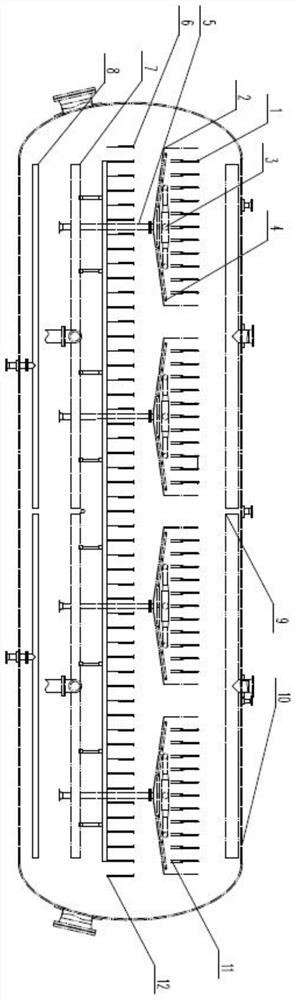

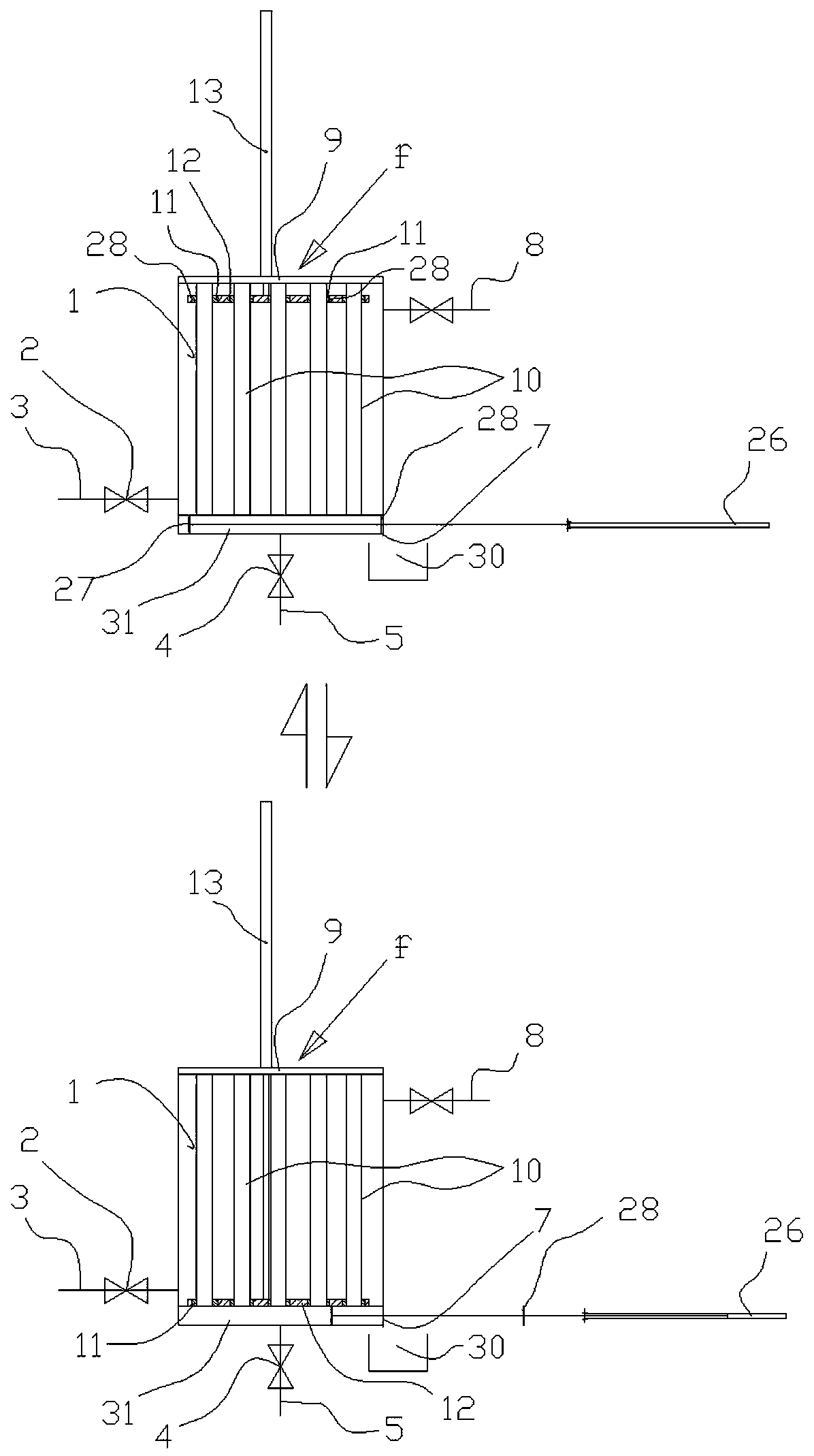

Multi-electric-field electric desalting and dewatering system and equipment adopting vertical polar plates

PendingCN114317028ASlow ascentLess investmentDewatering/demulsification with electric/magnetic meansRefining by electric/magnetic meansMechanical engineeringBackwashing

The invention discloses a multi-electric-field electro-desalting and dewatering system and equipment adopting vertical polar plates, and belongs to the field of crude oil electro-desalting and dewatering, the multi-electric-field electro-desalting and dewatering equipment adopting the vertical polar plates comprises an electro-desalting and dewatering tank, the electro-desalting and dewatering tank is internally provided with an upper electric field unit and a lower electric field unit, the electric field unit is mounted in the electric desalting and dewatering tank through the mounting accessory, the upper electric field unit comprises a semi-closed water disc, a downpipe, an upper vertical polar plate, an upper oil inlet distributor and an upper backwashing device, and the lower electric field unit comprises a lower vertical polar plate, a lower oil inlet distributor and a lower backwashing device; an oil outlet collecting pipe is further arranged in the electric desalting and dewatering tank; according to the invention, the size of the electro-desalting and dewatering tank can be reduced, and the occupied area and investment can be reduced in a large-scale electro-desalting and dewatering system under the conditions of certain treatment capacity and oil product property.

Owner:JIANGSU GOLDEN GATE ENERGY & EQUIP CO LTD +1

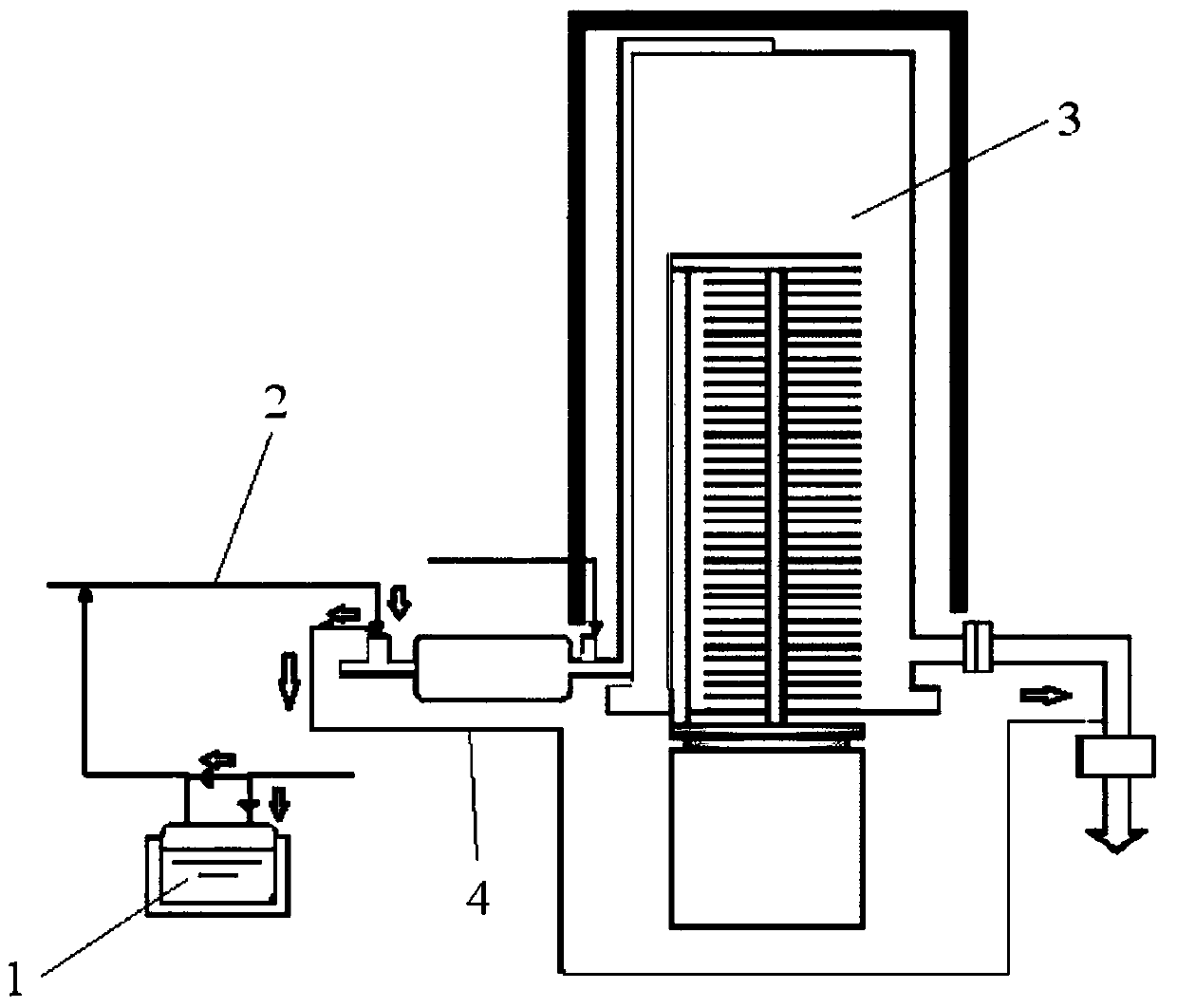

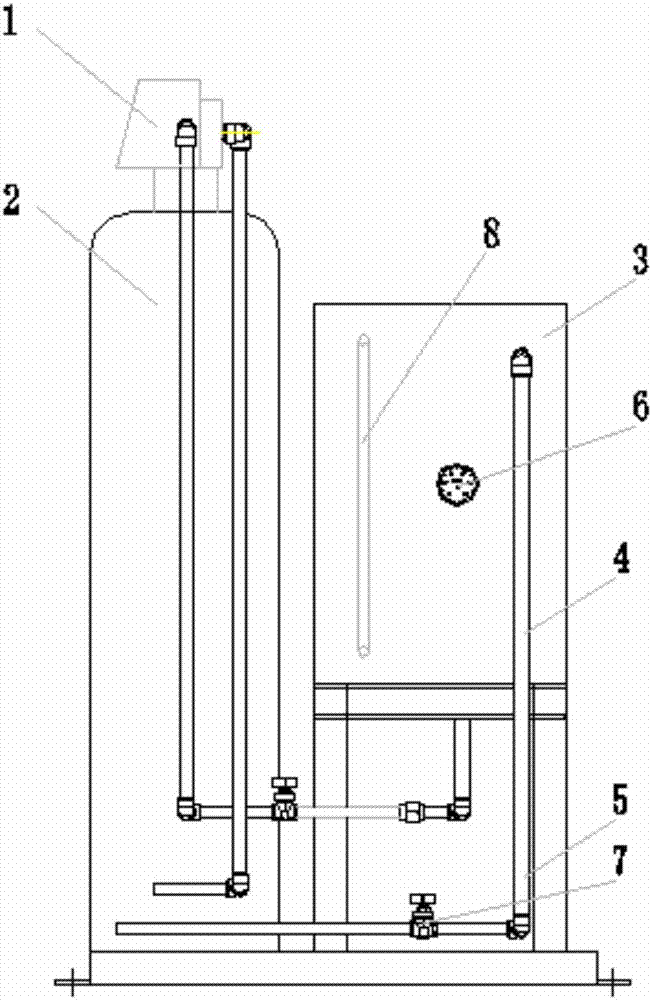

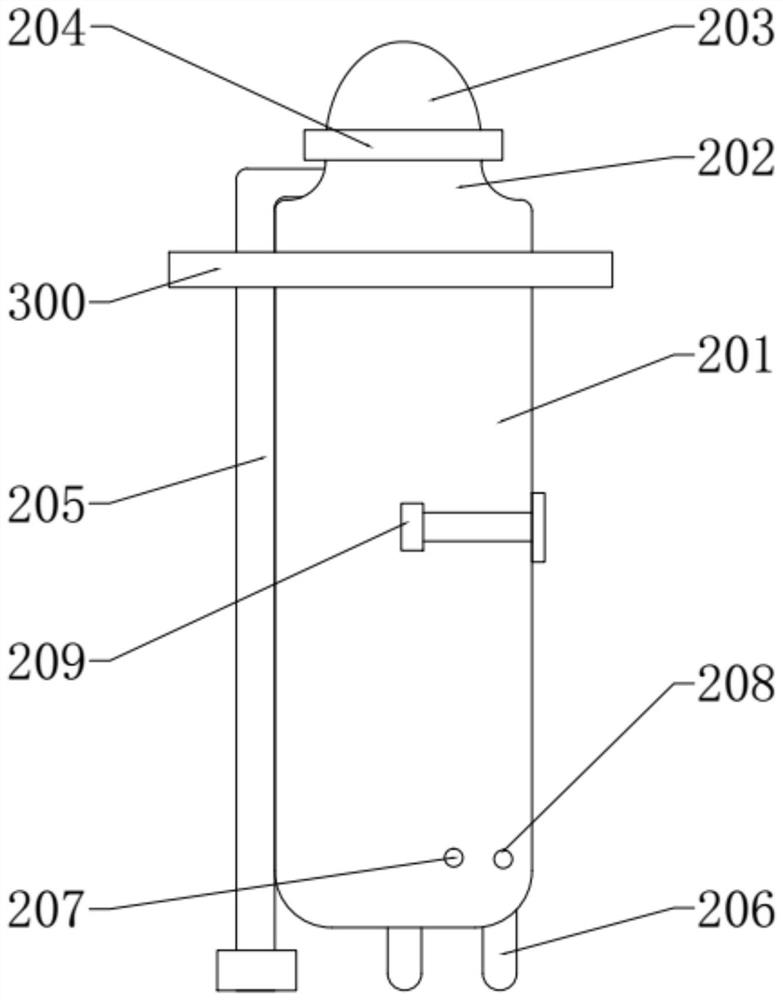

Water softening device with high temperature condensation water cooling recovery function

PendingCN106907700AAchieve recyclingWill not affect the processing effectFeed water supplyScale removal and water softeningSoft waterElectric control

The invention discloses a water softening device with a high temperature condensation water cooling recovery function. The device comprises a water treatment machine head, a water treatment, a mixing water box, a tap water inlet pipe, a high temperature condensation water inlet pipe, a thermometer, a high temperature magnetic valve, a liquid level meter and a water feeding pump set. According to the water softening device with the high temperature condensation water cooling recovery function, recycle and utilization of the high temperature condensation water are achieved through the mixing cooling of the tap water and the condensation water; water inflowing of an inlet of the condensation water is controlled by an electric control box through the water box temperature, the temperature of the water box is ensured to below 40 DEG C, and the using effect of the water treatment is not affected; the water feeding of the mixing water box is softened by the water treatment device, the content of Ca 2 +, Mg 2+ plasma of the high temperature condensation water is reduced, the incrustation of a pipeline and the reduced service life of the stream generator are solved through the device applies to a stream generator; and the discharge load of the high temperature condensation water is reduced through the water softening device with the high temperature condensation water cooling recovery function, and the utilization rate of the system water feeding is improved.

Owner:ZHEJIANG SHANGNENG BOILER

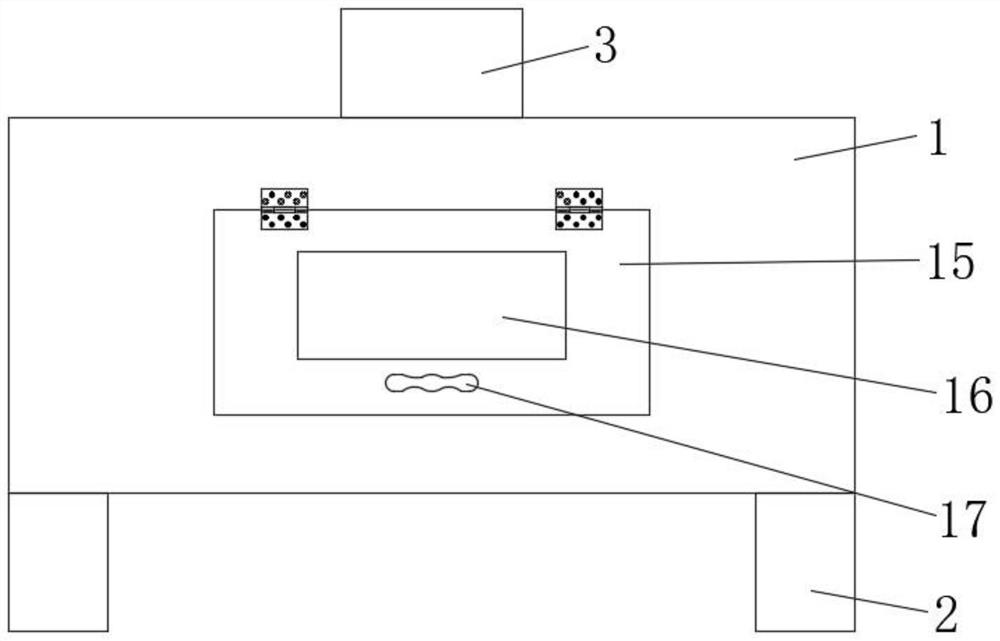

Hydrolysis descaling processing device for hair product production

InactiveCN112064247AWill not affect the processing effectEasy to cleanBiochemical fibre treatmentTextile treatment machine arrangementsMechanical engineeringRectangular array

The invention provides a hydrolysis descaling processing device for hair product production, and relates to the technical field of hair product production. The hydrolysis descaling processing device for the hair product production comprises a processing box, fixed bases, a movable door, an observation window and a handle. The multiple fixed bases are distributed at the bottom of the processing boxin a rectangular array mode, the movable door is rotationally connected to the front wall of the processing box through hinges, the observation window is formed in the outer surface of the movable door, the handle is fixed to the outer surface of the movable door, and a driving motor is fixedly connected to the center position of the top of the processing box. A hair product is fixed by a fixingdevice, the fixing device can be driven by a servo motor to be immersed into a descaling box, protease MP processing liquid in the descaling box can descale the hair product conveniently, a first threaded rod can drive the fixing device to rotate, so that the fixing device stirs the protease MP processing liquid, and therefore, the protease MP processing liquid cannot be precipitated to influencethe processing effect.

Owner:安徽亿海工艺品有限公司

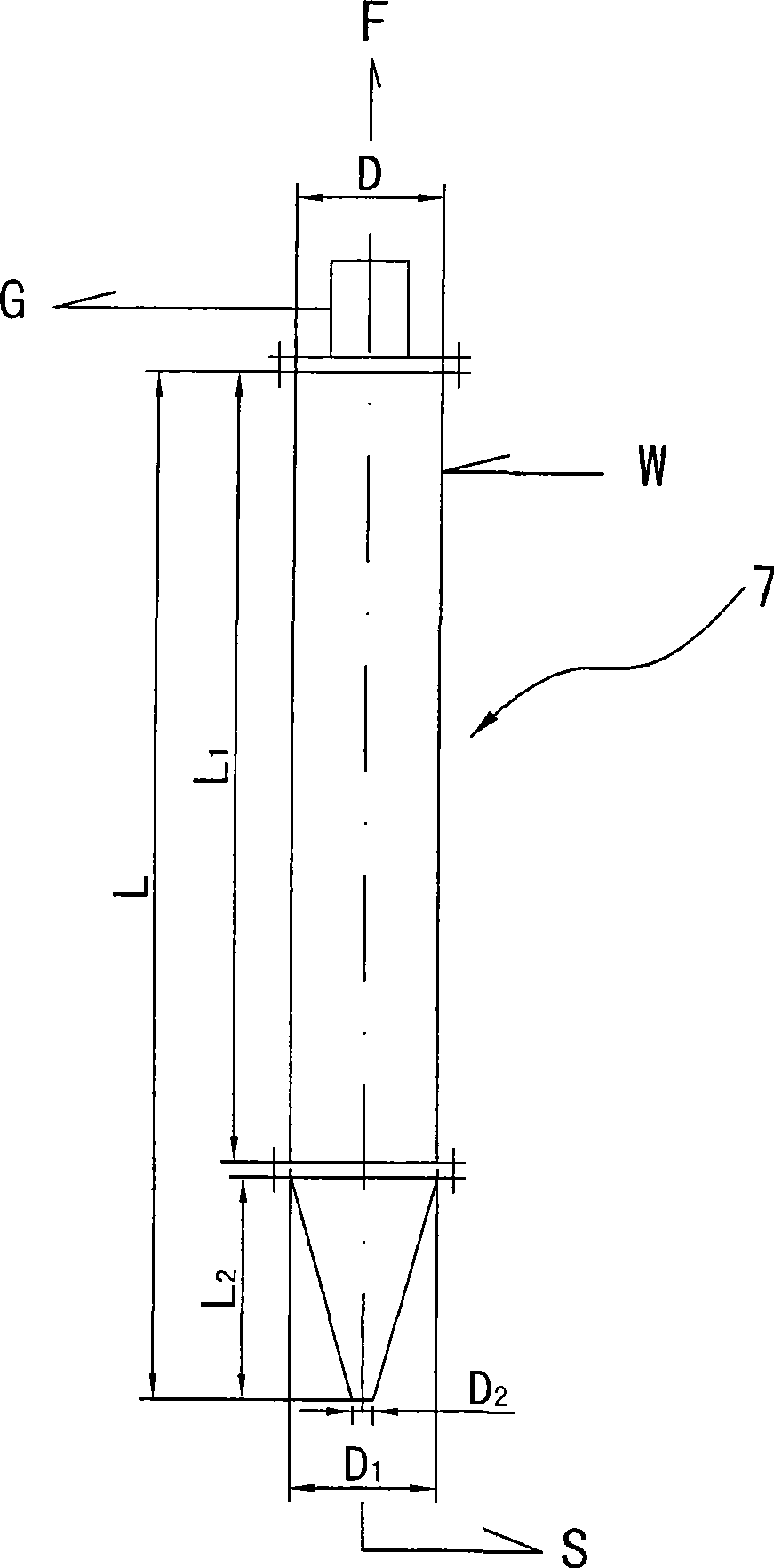

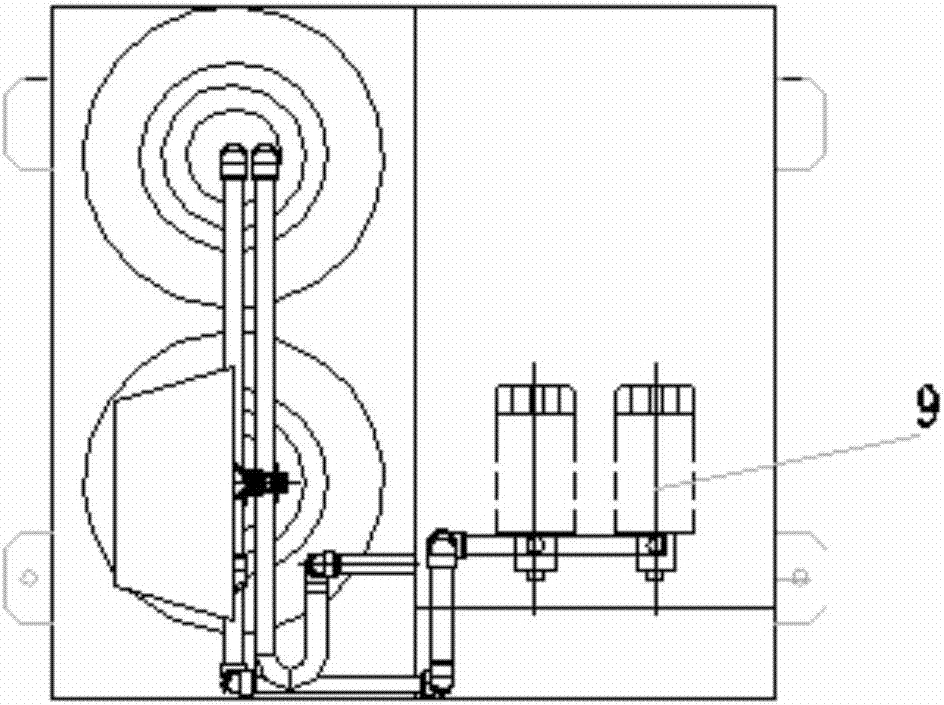

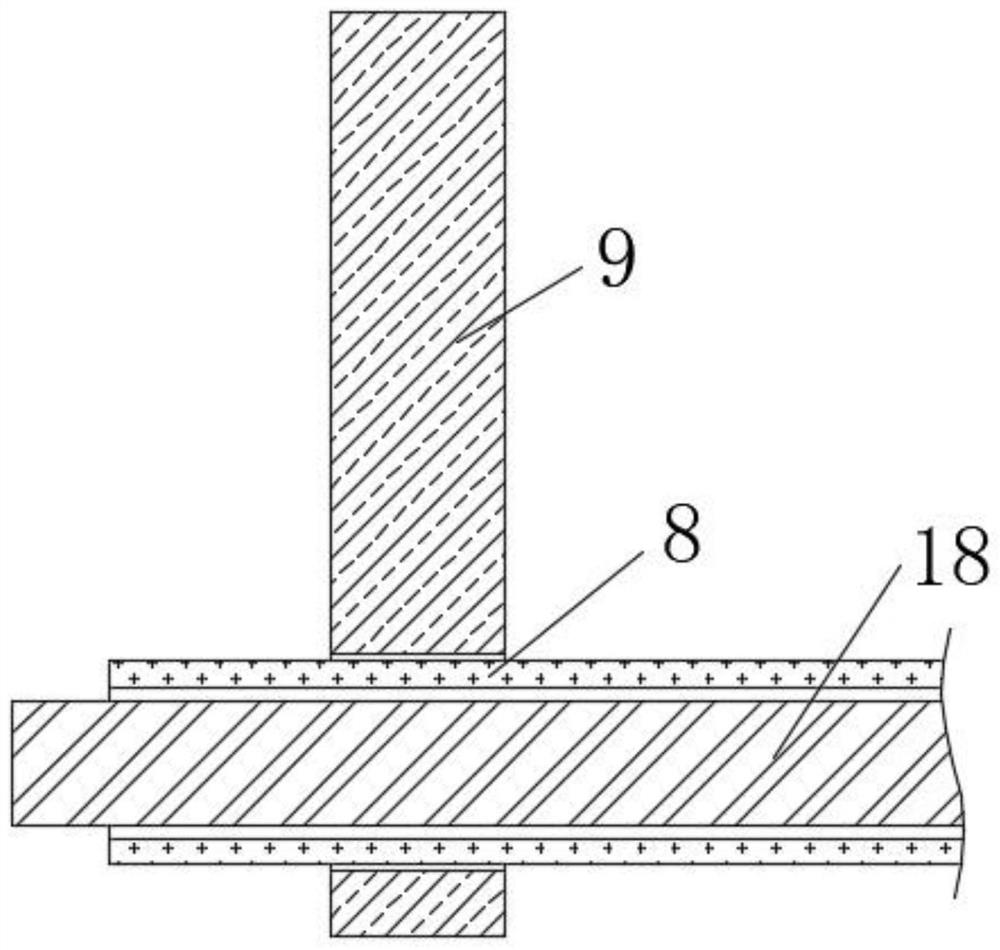

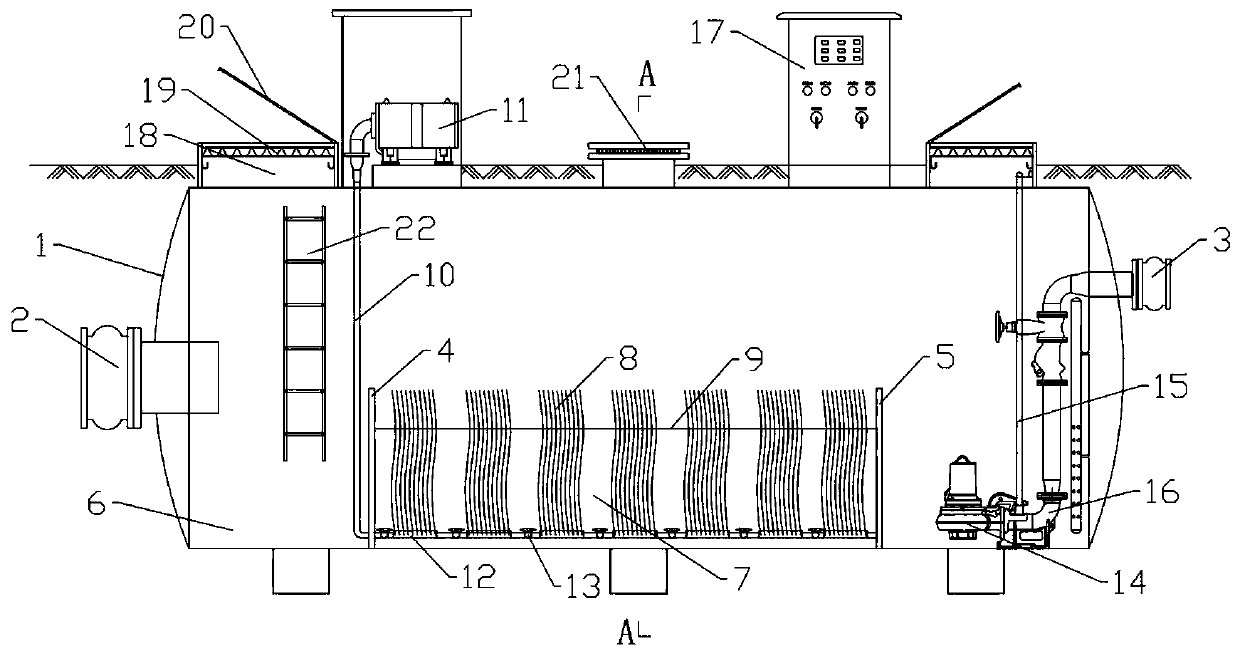

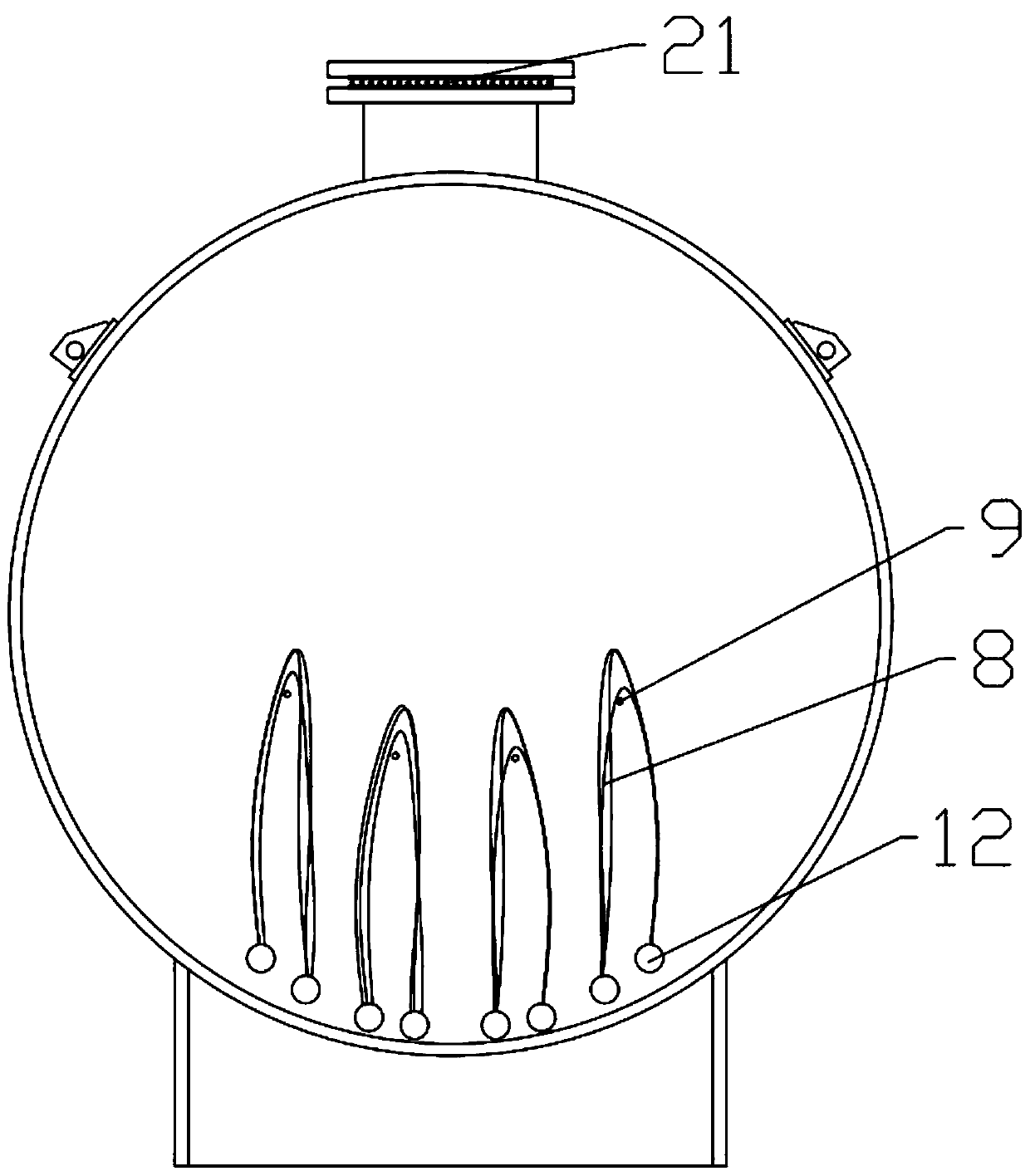

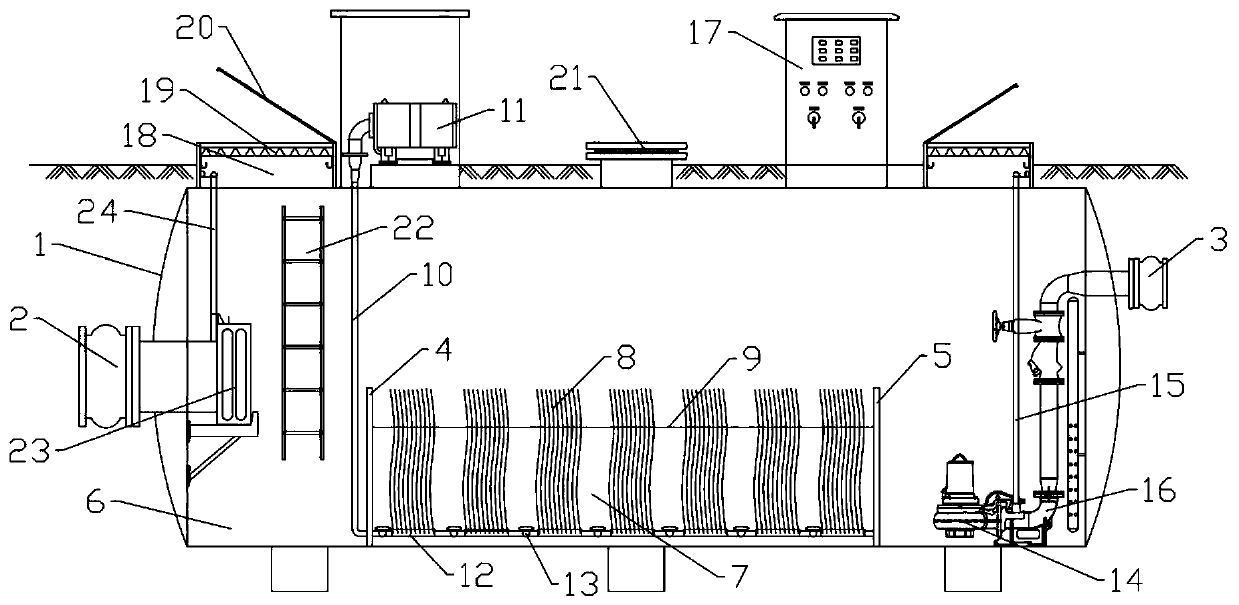

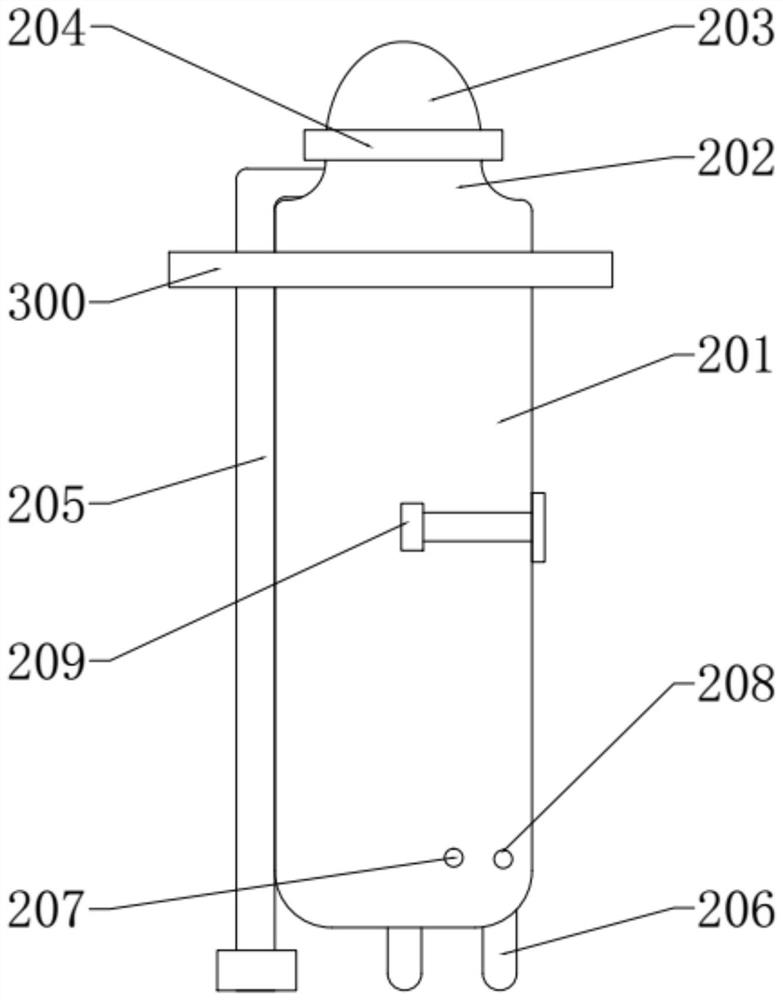

Prefabricated pumping station used for sewage pretreatment

PendingCN110156266AEfficient purification treatmentReduce pollutant contentFatty/oily/floating substances removal devicesSewerage structuresPrecipitationSewage sludge treatment

The invention discloses a prefabricated pumping station used for sewage pretreatment, and belongs to the field of sewage treatment. The prefabricated pumping station comprises a pumping station main body; the pumping station main body is provided with a water inlet and a water outlet; the water outlet is communicated with an immersible pump; a first separating plate and a second separating plate are arranged in the pumping station main body; a precipitation zone is formed between the first separating plate and the water inlet; a film processing zone is formed between the second separating plate and the first separating plate; the immersible pump is arranged between the second separating plate and the water outlet; a membrane assembly used for purifying sewage is arranged in the film processing zone. A plurality of groups of bio-membrane are arranged in the film processing zone, and an aeration pipe communicated with a blower is arranged below the bio-membrane, so that the aeration pipeand the bio-membrane are used for high efficiency purifying of sewage in the film processing zone, the content of pollutants in sewage discharged through the water outlet is reduced greatly, and sewage processing station processing burden is reduced.

Owner:SHANGHAI SANXING WATER SUPPLY & DRAINAGE DEVICECO

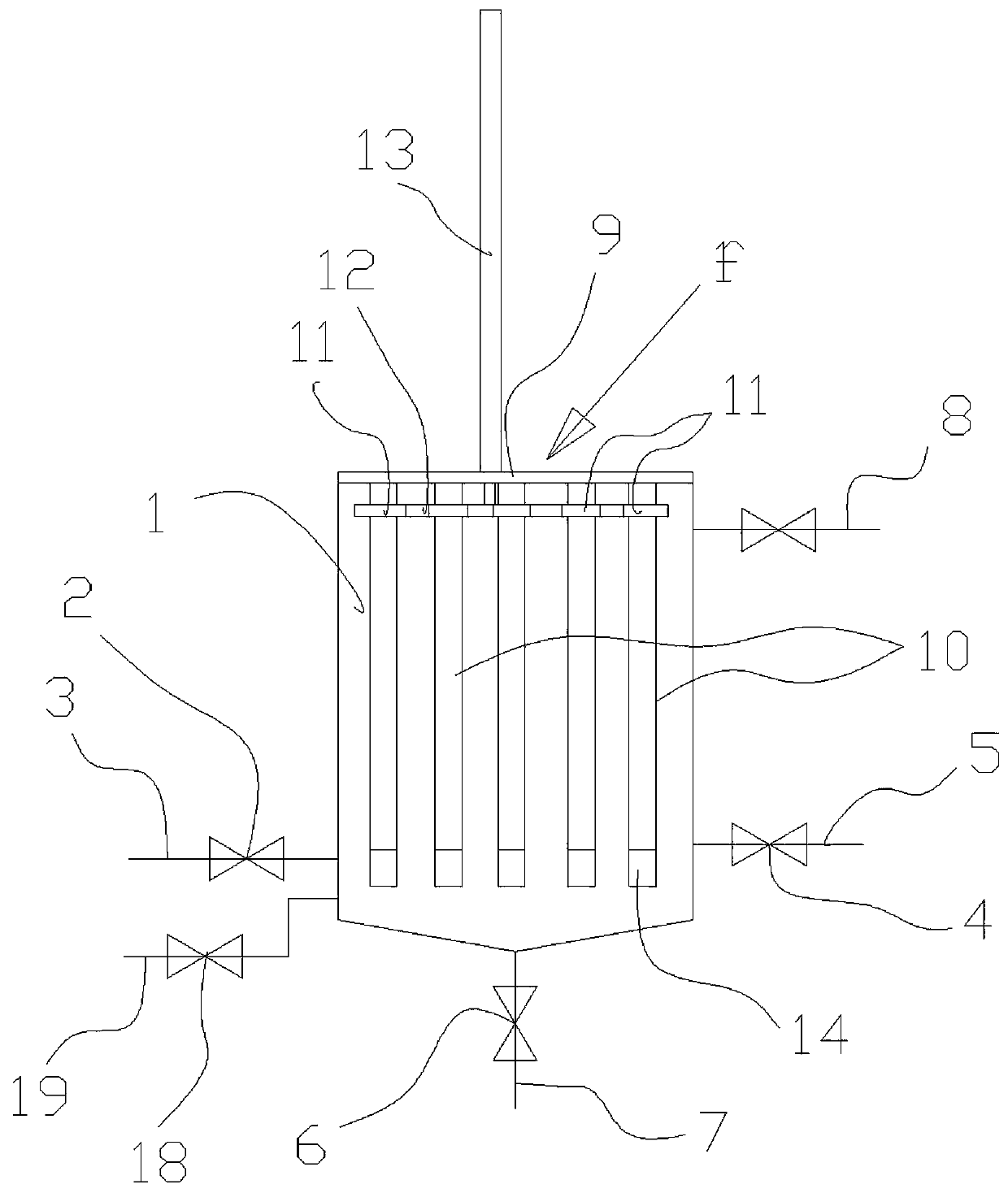

Kitchen wastewater treatment method and device

PendingCN109095700AEasy to handleReduce processingFatty/oily/floating substances removal devicesTreatment involving filtrationMagnetic tension forceWastewater

The invention provides a kitchen wastewater treatment method and device. The device is characterized by comprising a filtering part, an oil-water separation part, a flocculant, coagulant aid and magnetic seed mixing-in part and a ferromagnetic substance separation part, wherein the ferromagnetic substance separation part comprises a container, a permanent magnet treatment mechanism, a water inletprovided with a first valve, a drain port provided with a second valve, a blowdown port provided with a third valve as well as a discharge port; the permanent magnet treatment mechanism comprises a plurality of permanent magnet bars, an annular scraper and a power mechanism, and the lower ends of the permanent magnet bars are connected with non-magnet-conductive bars. Compared with the prior art,the kitchen wastewater treatment device has the advantages that device size is small, ferromagnetic substance removal effect can be improved by fully using the sinking characteristic of ferromagneticsubstances, and the route for absorbing the ferromagnetic substances by magnetic force can be increased.

Owner:佛山市己阿已磁电设备有限公司

A high-efficiency automatic coating device for flat color steel plates

The invention relates to a high-efficiency automatic coating device for a flat color steel plate. The high-efficiency automatic coating device comprises a bottom plate, wherein two pairs of baffles IIare symmetrically mounted on the front and rear sides of the bottom plate, winding devices are arranged between upper sides of the two pairs of baffles II, a coating conveying device is mounted at the lower ends of the two pairs of baffles II, and an automatic coating process of the flat color steel plate is finished under matched use of the winding devices and the coating conveying device. The high-efficiency automatic coating device can solve the problems that the upper and lower ends of the flat color steel plate cannot be coated by the existing flat color steel plate coating equipment, the flat color steel plate is easy to move under the action of external force in the flat color steel plate coating process by the existing coating equipment, manual adjustment is needed when flat colorsteel plates in different sizes are coated, the precision is low, the labor intensity is high, long time is consumed, the stability and the working efficiency are low and the like in the coating process of the existing flat color steel plate, and high-efficiency automatic coating of the flat color steel plate can be realized.

Owner:唐山海德林纳新型建材有限公司

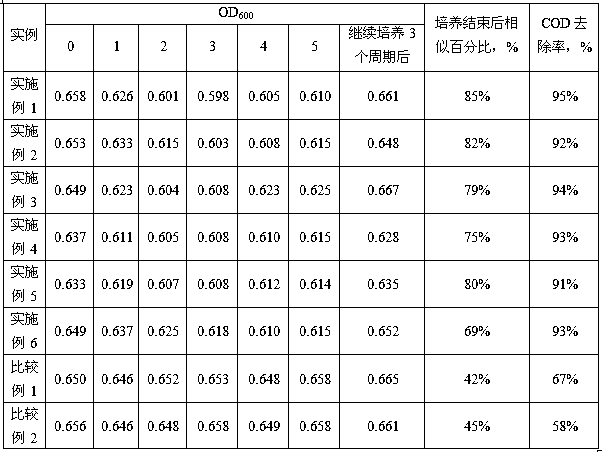

A kind of open culture method and application of Pseudomonas stutzeri fstb-5

ActiveCN106635856BEasy to handleWill not affect the processing effectBacteriaMicroorganism based processesNalidixic acidTherapeutic effect

Owner:CHINA PETROLEUM & CHEM CORP +1

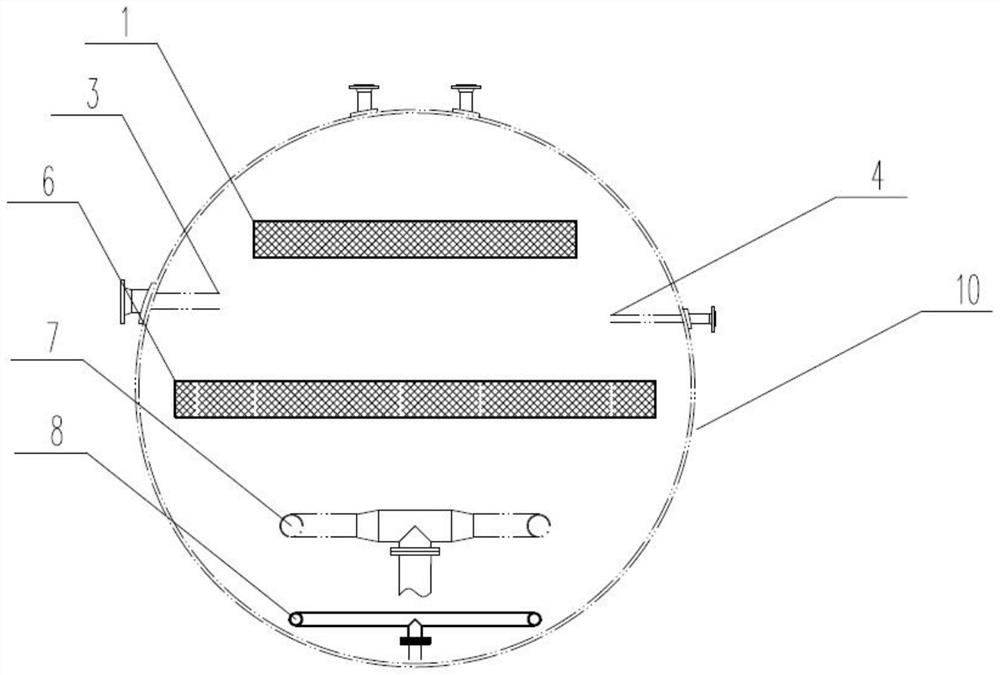

A device for preventing scum crusting in anaerobic reactor

ActiveCN112777737BEasy to handleGuaranteed uptimeSpecific water treatment objectivesBiological treatment apparatusProcess engineeringEnvironmental engineering

Owner:HUAZHONG UNIV OF SCI & TECH

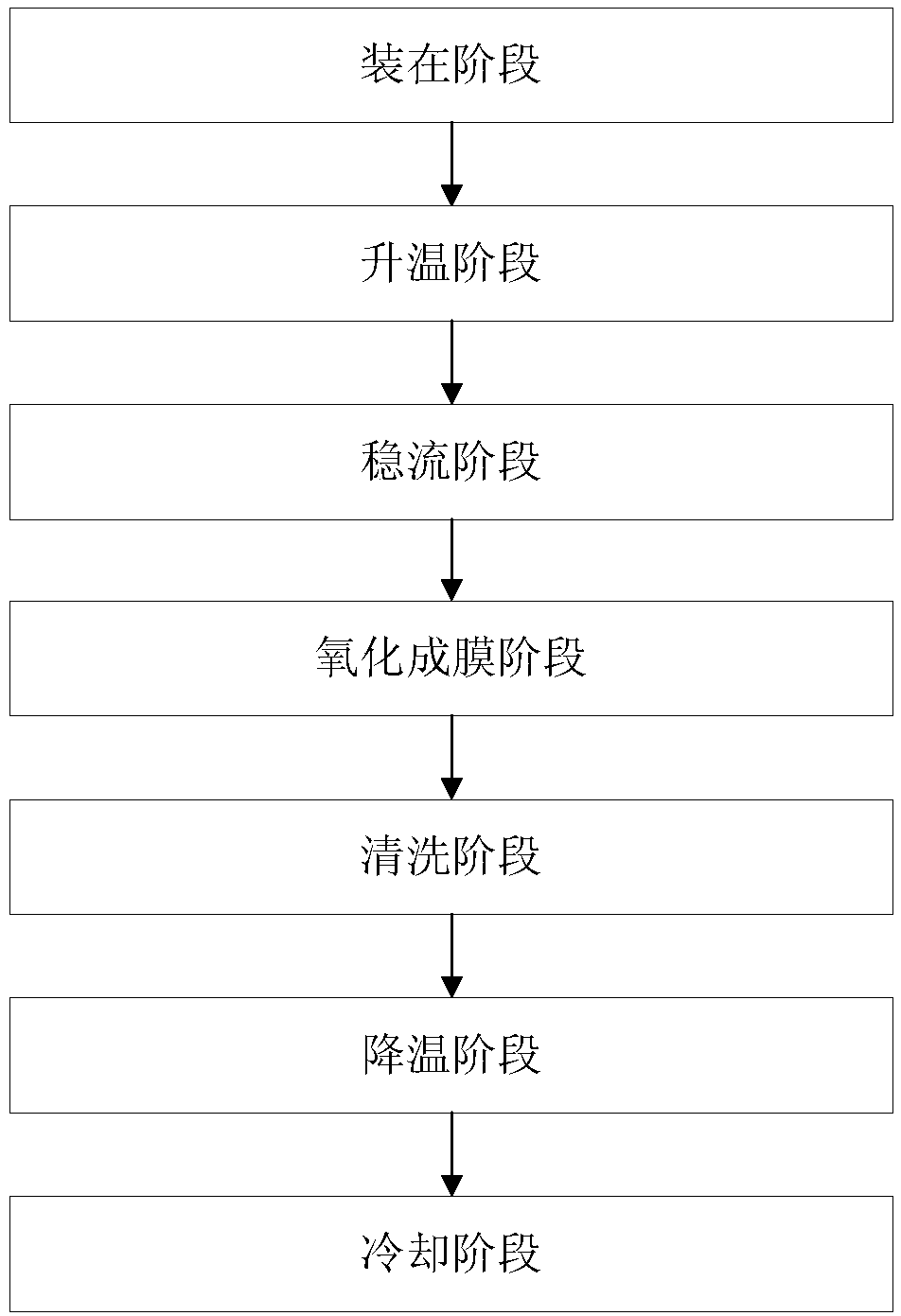

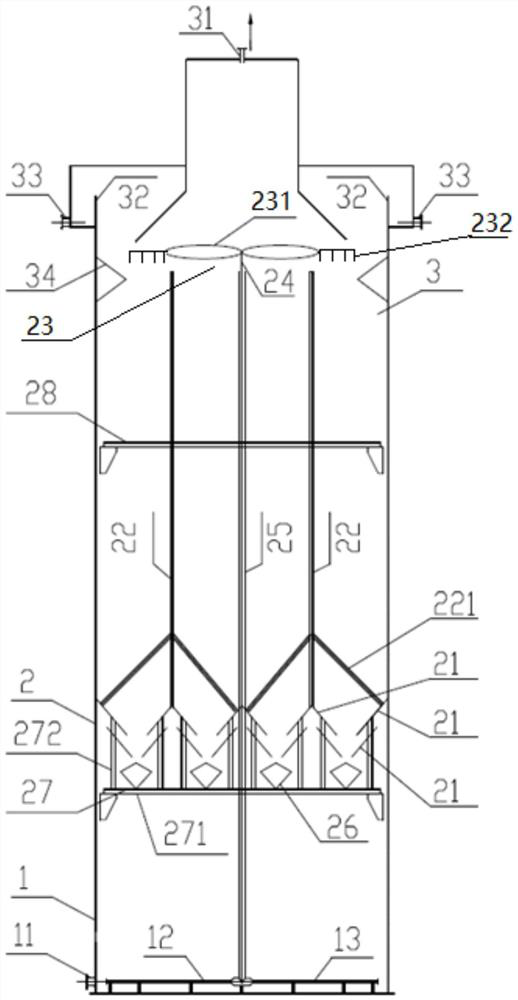

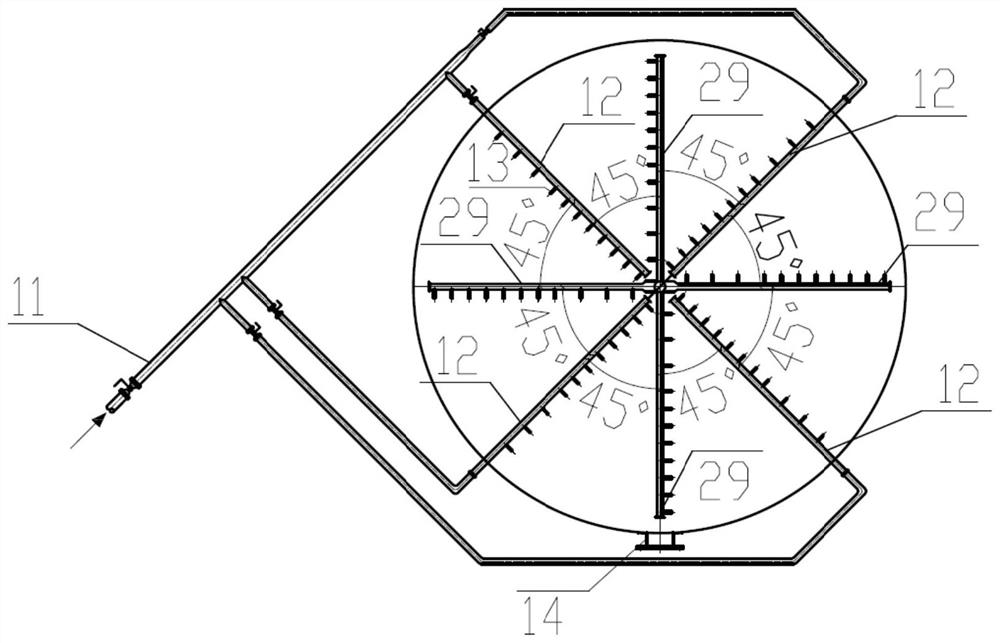

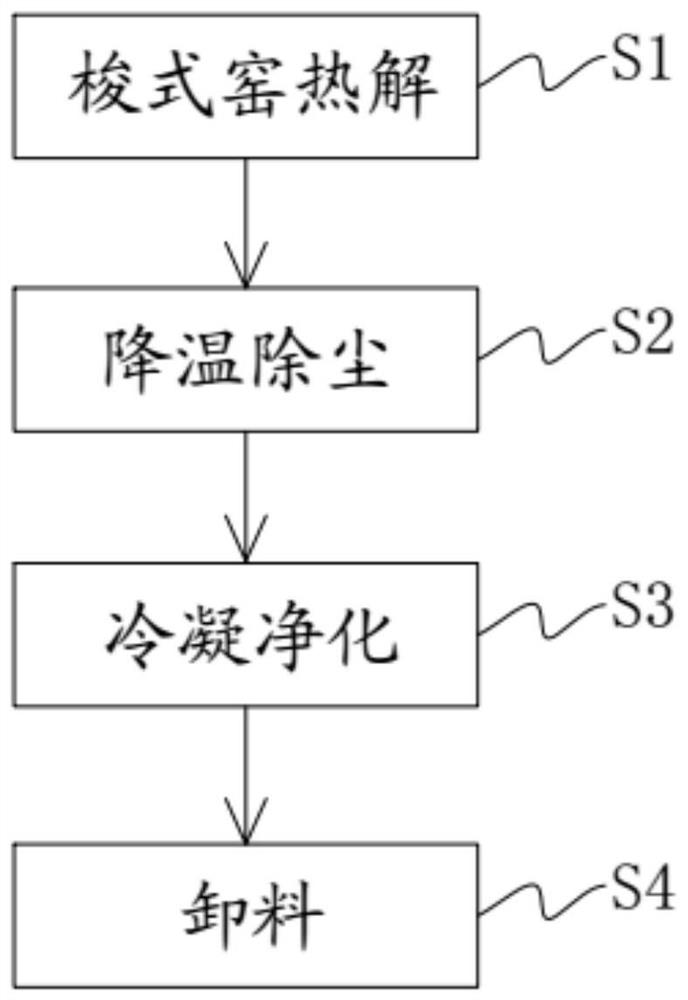

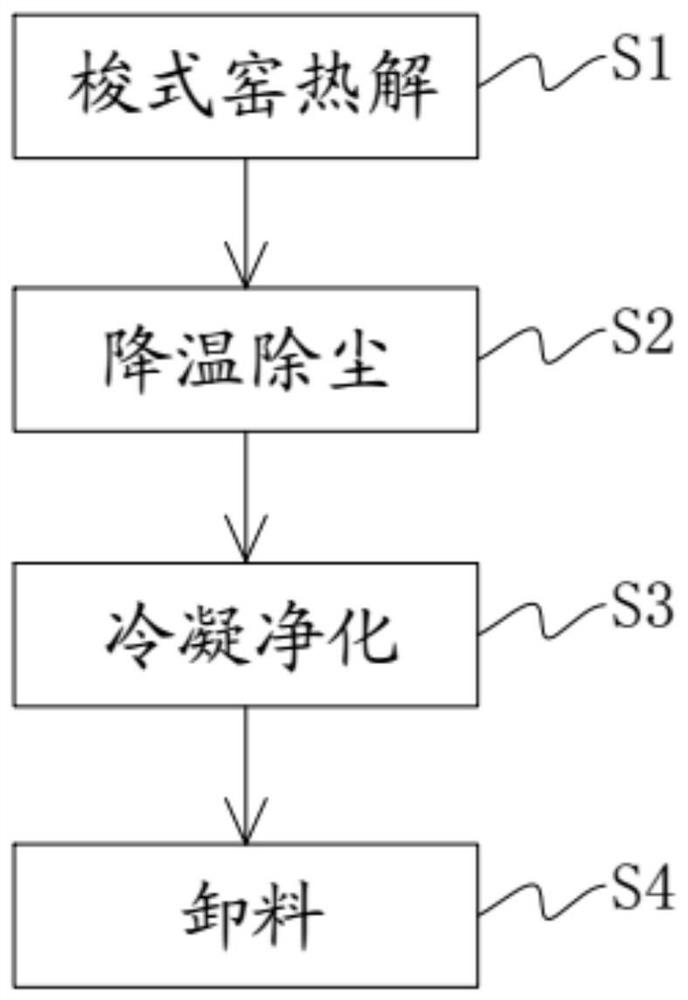

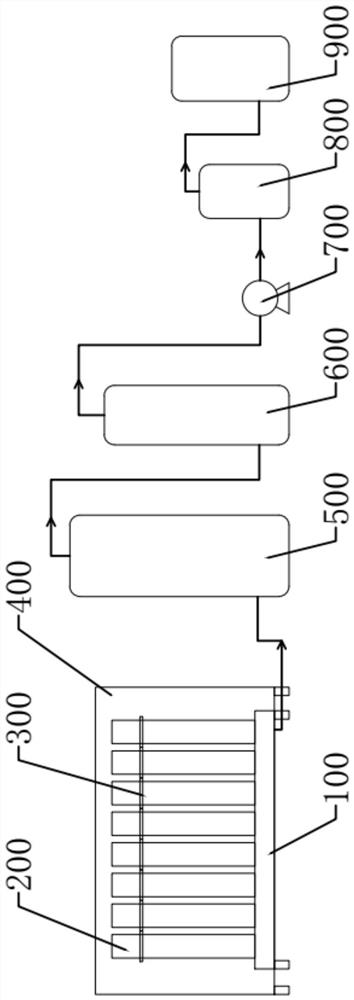

Treatment method for industrial organic solid waste

ActiveCN111774402AShorten heating timePrevent leakageSolid waste disposalMultiple-effect/fractional condensationDust controlEngineering

The invention discloses a treatment method for an industrial organic solid waste. The treatment method comprises the following steps of: S1. shuttle kiln pyrolysis: putting the solid waste into a miniature pyrolysis tank, heating the solid waste by a shuttle kiln, and directly volatilizing an organic matter in the solid waste or volatilizing the organic matter through high temperature cracking; S2, cooling and dust removal: accessing pyrolysis gas into a cooling and dust removal system, and recovering base oil in the pyrolysis gas; S3, condensation and purification: inputting the pyrolysis gasafter cooling and dust removal into an condensation purification system, recovering liquid and gaseous organic matters in the pyrolysis gas gradually; and S4, unloading: after the pyrolysis is completed, removing the organic matters out of a kiln car, unloading the miniature pyrolysis tank whose internal solid waste has been pyrolyzed, installing the miniature pyrolysis tank with the solid wasteto be pyrolyzed in the next batch, and carrying out the next batch of pyrolysis. According to the invention, the pyrolysis of the solid waste containing organic pollutants is not limited to rotary kiln pyrolysis any longer, dynamic sealing is avoided, a high-temperature oil and gas cavity is minimized, and accidents during a treatment process are avoided.

Owner:天津市丽碧朗环保科技有限公司

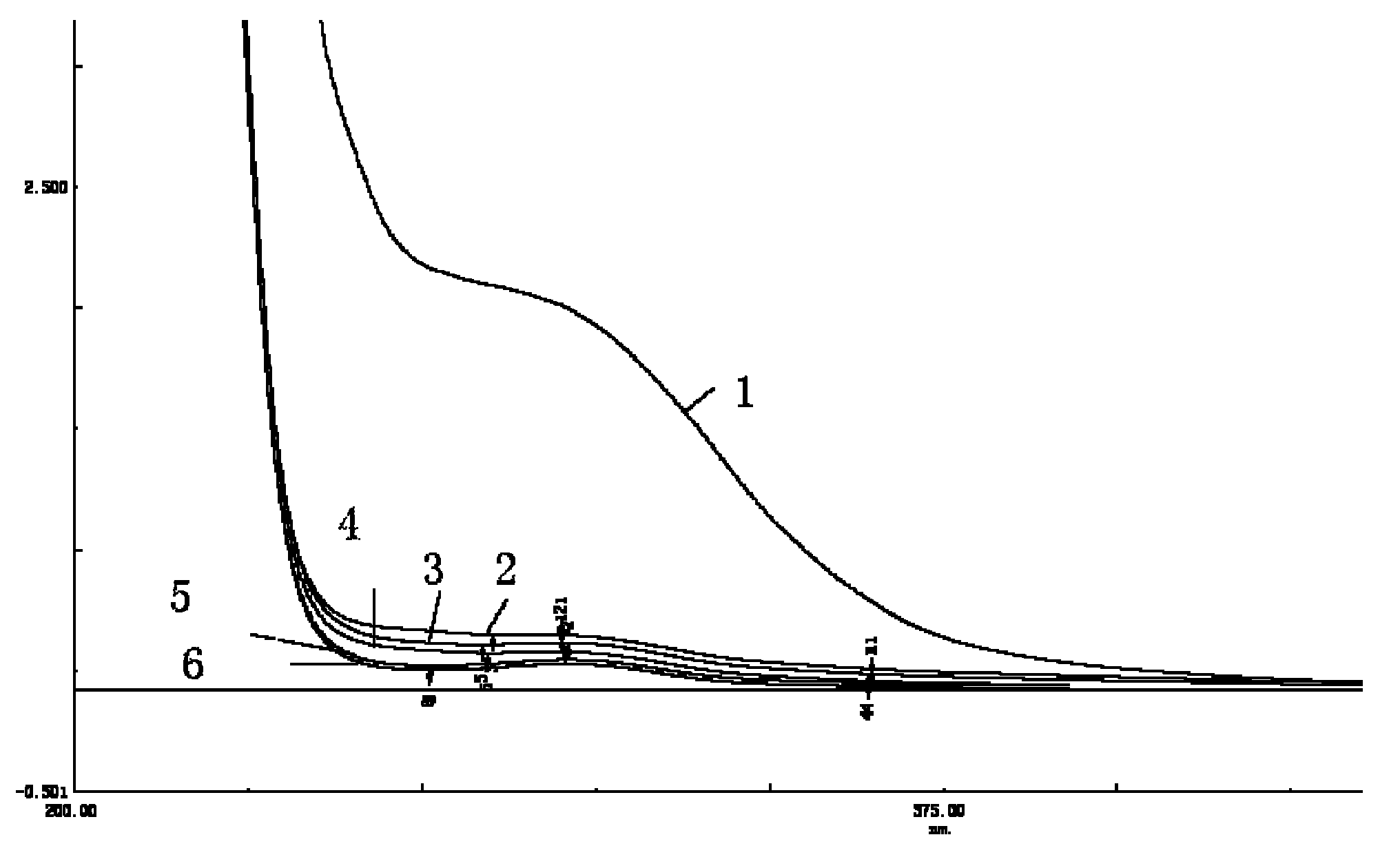

Biochemical exterior drainage decoloring agent and preparation method thereof

InactiveCN101891273ATrue density reductionImprove adsorption capacityWaste water treatment from metallurgical processWater/sewage treatment by sorptionResource utilizationRoom temperature

The invention discloses a biochemical exterior drainage decoloring agent, solving the problems of expensive price, low decolorizing efficiency, easy generation of secondary pollution and complex production and operation process of the existing decoloring agent. The decoloring agent of the invention is prepared by the method comprising the following steps: putting 200 parts of semi-coke particles by weight and 1-3 parts of catalyst by weight into a closed reactor, wherein the catalyst is an alkali carbonate catalyst; raising the temperature of the closed reactor to 700-1100 DEG C, and then introducing CO2 gas into the closed reactor to carry out an activating reaction on raw materials in the presence of the catalyst to generate a semi-coke modifier; and cooling down to room temperature after gas introduction, and taking out the activation reactant semi-coke modifier, i.e. the decoloring agent. The decoloring agent of the invention has simple process, low cost of the raw materials, low production cost, good decoloring effect, no secondary pollution on the environment and extremely high resource utilization rate.

Owner:武钢集团有限公司

Biochemical exterior drainage decoloring agent and preparation method thereof

InactiveCN101891273BTrue density reductionImprove adsorption capacityWaste water treatment from metallurgical processWater/sewage treatment by sorptionResource utilizationRoom temperature

Owner:武钢集团有限公司

Flotation cabinet device with multi-stage flow guide and overflow structural form

ActiveCN111498936AAvoid consumptionAffect runnabilityAuxillariesSpecific water treatment objectivesStraight tubeFixed bed

The invention relates to a flotation cabinet device with a multi-stage flow guide and overflow structure form. The flotation cabinet device comprises a flotation cabinet body and a solid matter collecting chamber, wherein the top of the flotation cabinet body is conical and is provided with an opening; an opening is formed in the bottom of the solid matter collecting chamber; the conical top of the flotation cabinet body is positioned in the inner cavity of the solid matter collecting chamber; a flushing water pipe is arranged in the solid matter collecting chamber; a first-stage flow guide groove, a second-stage flow guide groove and a third-stage flow guide groove are sleeved in the flotation cabinet body stage by stage and are coaxially arranged with the flotation cabinet body; the topof a primary diversion trench is open and is positioned below the lower edge of the conical top of the flotation cabinet body; a domestic sewage inlet pipe is communicated with the first-stage flow guide groove, a clear water outlet pipe is communicated with the second-stage flow guide groove, the two ends of the supernatant inlet pipe are connected with the flotation cabinet body and the third-stage flow guide groove respectively, and a fixed bed reactor, a radial compressed air straight pipe and an annular compressed air pipe are further arranged in the flotation cabinet body. The device iscompact in arrangement, convenient to use, reliable in operation, high in treatment capacity and low in energy consumption.

Owner:WUHAN SECOND SHIP DESIGN & RES INST

A kind of industrial organic solid waste processing method

ActiveCN111774402BWill not affect the processing effectShorten heating timeSolid waste disposalMultiple-effect/fractional condensationDust controlProcess engineering

Owner:天津市丽碧朗环保科技有限公司

Method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water

InactiveCN101693581BGuaranteed reaction efficiencyEfficient removalWater/sewage treatmentMultistage water/sewage treatmentMass ratioWater quality

The invention pertains to the technical field of treatment of waste water, and particularly relates to a method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water, which comprises the following steps: waste water after primary treatment directly enters an up flow type hydrolysis system 1 and stays for 4.0-10.0 hours; the effluent enters an electrolytic cell in the catalytic iron; the mass ratio of iron scraps and copper scraps in the electrolytic cell of the catalytic iron is 1:1 to 20:1, the bulk specific weight thereof is 0.1 to 0.3, the contact time thereof in a filling area is 0.5 to 2.0 hours, and the reflux ratio of the effluent refluxing to the up flow type hydrolysis system is 20 to 100 percent; the effluent enters an aerobic biological treatment system and stays for 6.0 to 12.0 hours; then the effluent enters a solid-liquid separation system with a reflux ratio of sludge being 10 to 50 percent; and the effluent of the solid-liquid separation system refluxes to the electrolytic cell of the catalytic iron with the reflux ratio being 20 to 200 percent. Under the premise of fully playing the function of different treatment units and maintaining the treatment effect and respective advantages, the treatment method of waste water realizes the coupling synergetic action of the three units, strengthens the impact of the system to water quality and water quantity load, reduces a plurality of steps of pretreatment, effectively improves the removal rate of ammonia nitrogen, and can be flexibly adjusted.

Owner:TONGJI UNIV +1

Wood chip form-milling equipment

ActiveCN102756400BTo achieve the purpose of milling and formingWill not affect the processing effectProfiling/shaping machinesMilling cutterEngineering

The invention discloses wood chip form-milling equipment, which comprises a workbench, a longitudinal guiding device, a transverse guiding device, two first sliding tables and a second sliding table, wherein the longitudinal guiding device and the transverse guiding device are arranged on the workbench; the first sliding tables can move on the transverse guiding device, and are distributed on the two sides of the longitudinal guiding device; a milling component is arranged on each of the two first sliding tables, and comprises a main shaft, a milling cutter arranged on the main shaft, a driving device for driving the main shaft to rotate, and a locking device capable of positioning the sliding table; the second sliding table can move on the longitudinal guiding device; and a fixture capable of conveying a wood chip to be machined to a part between the two milling cutters is arranged on the second sliding table, and is used for clamping the upper and lower end faces of the wood chip to be machined. By the structural design of the equipment, the problem that the wood chip easily moves to directions away from the milling cutters in the form-milling machining process of the wood chip to cause influence on the machining quality and low working efficiency can be effectively solved.

Owner:重庆谭木匠工艺品有限公司

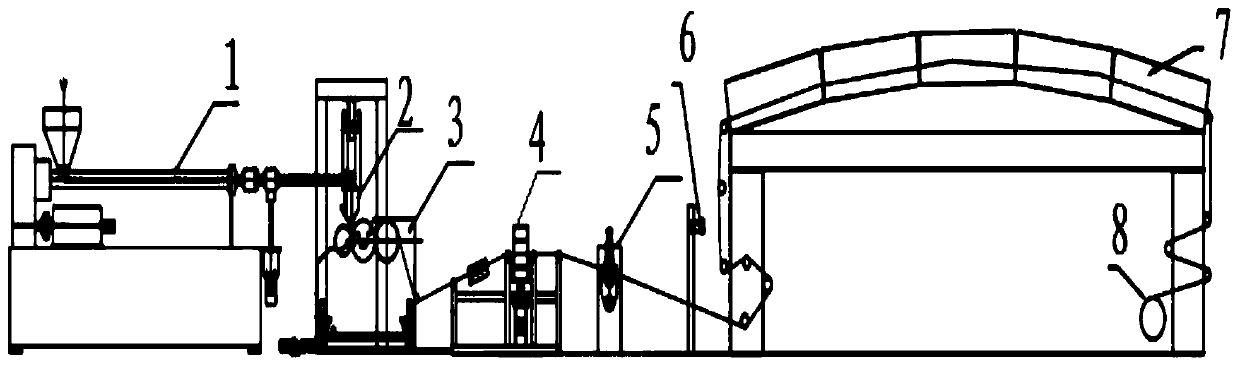

Device for diaphragm online spraying and using method thereof

The invention discloses a device for diaphragm online spraying and a using method thereof. The device comprises a plastic extruder, a die head, a three-roller machine, a thickness gauge, a pulling unit, a spraying unit, a drying tunnel and a winder which are sequentially arranged; the plastic extruder provides a plastic material for the die head; three-roller machine is fixedly arranged under thedie head; the three-roller machine is used for extruding an extruded material of the die head into a diaphragm; the thickness gauge is used for measuring the thickness of the diaphragm; the pulling unit is used for pulling the diaphragm to the spraying unit; the drying tunnel is used for allowing the sprayed diaphragm to pass through; and the winder is used for winding the dried diaphragm. The device has the characteristics that a diaphragm forming unit, the spraying unit and a drying unit are combined into an integrated structure, the production efficiency of the diaphragm is improved, and the manufacturing cost of the diaphragm is reduced.

Owner:GUANGDONG WANSHIJIE PLASTIC TECH

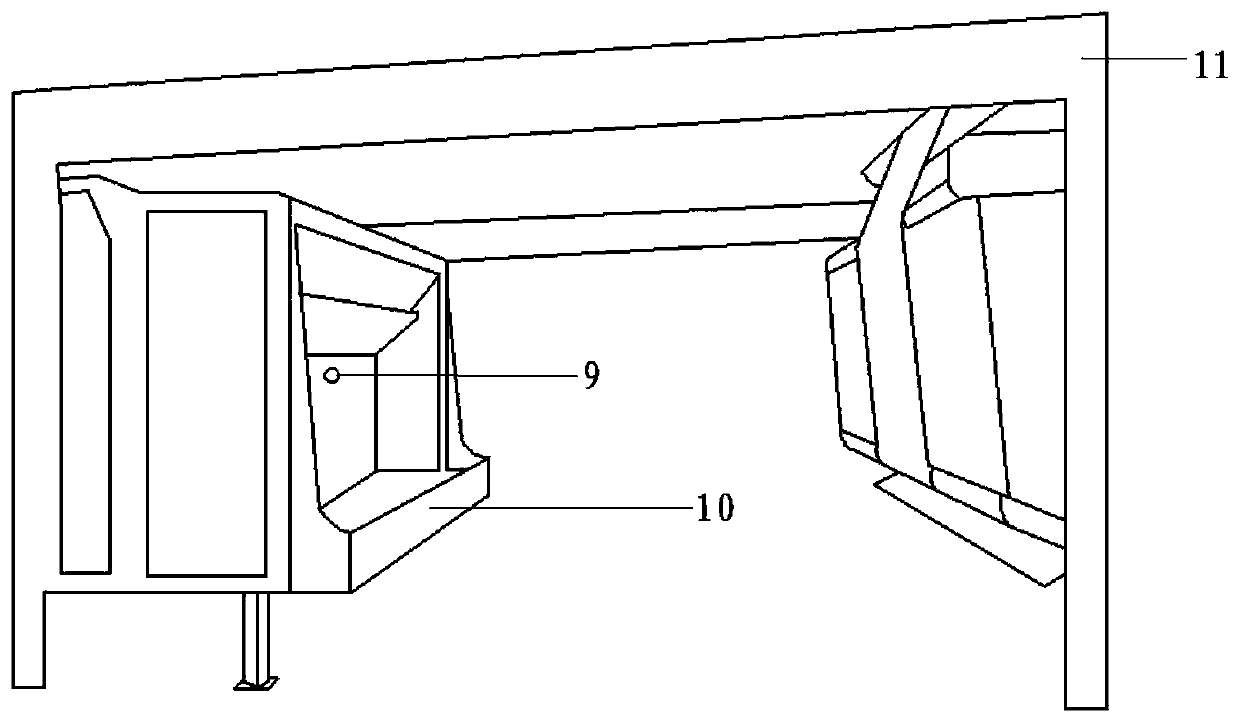

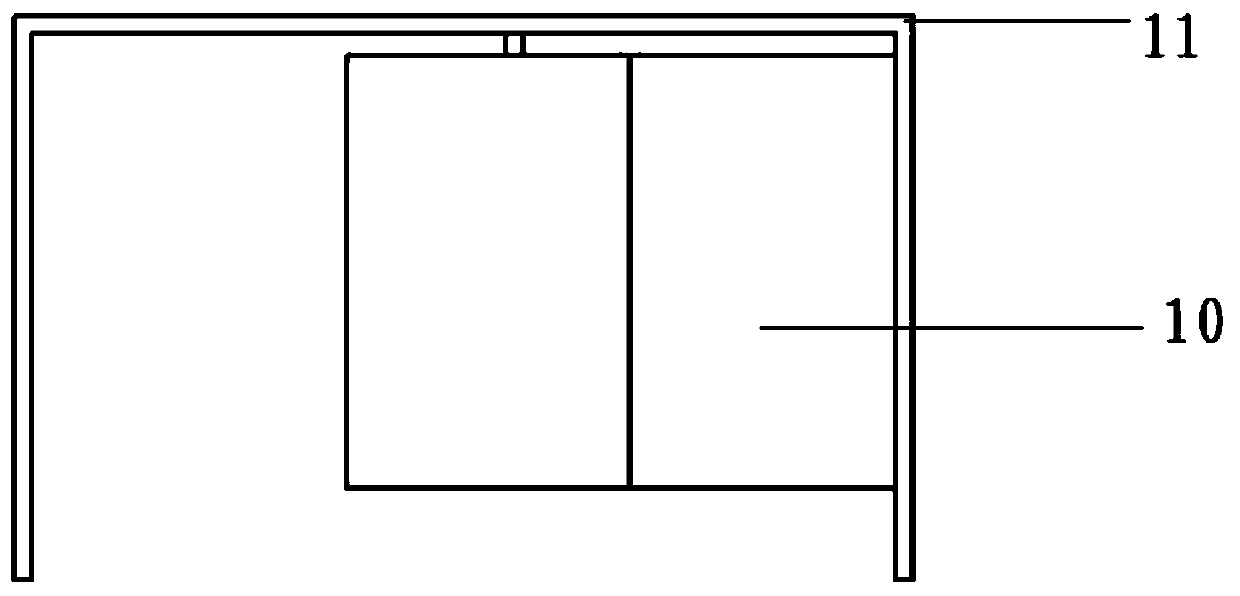

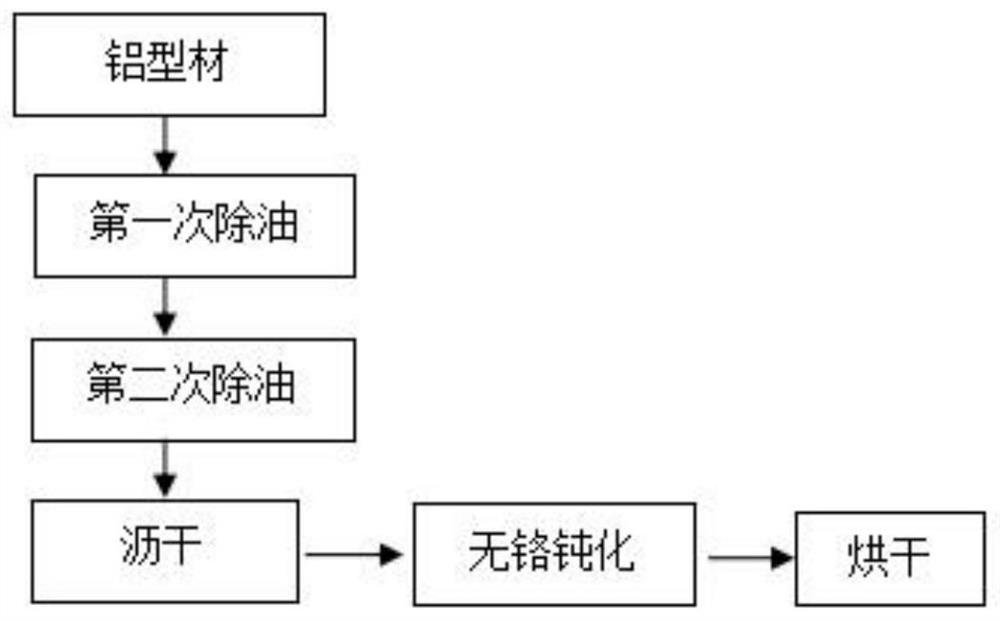

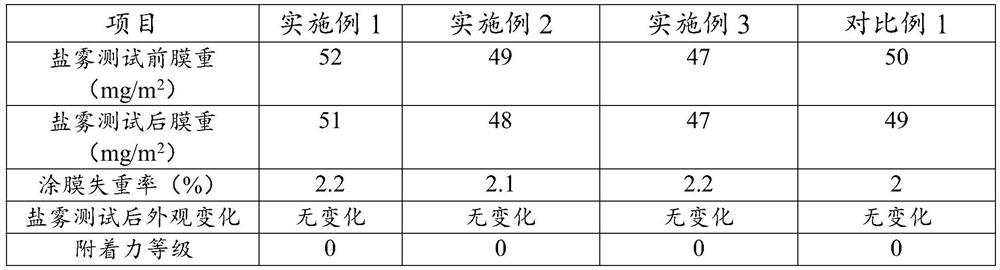

Water-washing-free chromium-free treatment process before aluminum profile coating

ActiveCN114855153AWill not affect the processing effectImprove corrosion resistanceMetallic material coating processesOrganic acidActive agent

The invention discloses a washing-free chromate-free treatment process before aluminum profile coating, and belongs to the technical field of metal surface treatment.The washing-free chromate-free treatment process comprises the procedures of first-time oil removal, second-time oil removal, draining, chromate-free passivation, drying and the like, and an oil removal agent comprises, by weight, 30%-80% of deionized water, 1%-20% of organic acid, 1%-20% of fluoride and 1%-10% of a complexing agent; the chromium-free passivator comprises the following components in percentage by weight: 30%-90% of deionized water, 1%-20% of organic acid, 1%-20% of zircon salt main agent, 1%-10% of fluoride, 1%-10% of complexing agent and 1%-10% of cross-linking agent; the degreasing agent and the chromate-free passivation agent are efficient, environmentally friendly, simple in treatment process, good in stability and capable of well meeting relevant coating performance requirements of the aluminum profile, a washing procedure is omitted in the whole coating pretreatment process, the requirement for the number of grooves in a pretreatment line body is greatly reduced, zero discharge of waste water is achieved, and good economical efficiency is achieved.

Owner:安徽光铧帝业化学有限公司

A thermal power plant denitrification flue deflector

The invention discloses a denitration smoke flue guide plate for a thermal power plant. The denitration smoke flue guide plate for the thermal power plant comprises a smoke inlet pipe, a smoke straight-through pipe and a guide plate body a. A connecting opening is formed in the top circumferential end surface of the smoke inlet pipe through a leakproof rubber sleeve. An arc-shaped smoke conveyingpipe is installed at the bottom of the smoke inlet pipe. An inclined pipe is installed on the right side of the arc-shaped smoke conveying pipe through a connecting rubber sleeve. The smoke straight-through pipe is installed at one end of the inclined pipe, and a smoke conveying opening is formed in the bottom of the smoke straight-through pipe. The guide plate body a is installed in a groove formed in the inclined pipe, the smoke straight-through pipe is composed of a combined pipe a and a combined pipe b, the guide plate body a penetrates through the inclined pipe and the smoke straight-through pipe and is provided with the guide plate body b through a connecting arc-shaped opening, and storage square grooves are formed in the guide plate body a. According to the denitration smoke flue guide plate for the thermal power plant, the smoke is effectively and evenly distributed in the smoke conveying process, so that the burden of a denitration system of a unit and the environmental protection risk are greatly reduced.

Owner:DATANG HUAIBEI POWER PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com