Flotation cabinet device with multi-stage flow guide and overflow structural form

A structure and cabinet technology, applied in the field of flotation cabinet devices, can solve the problems of heavy equipment weight, eutrophication pollution of water bodies, long cleaning time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and examples, but these examples should not be construed as limiting the present invention.

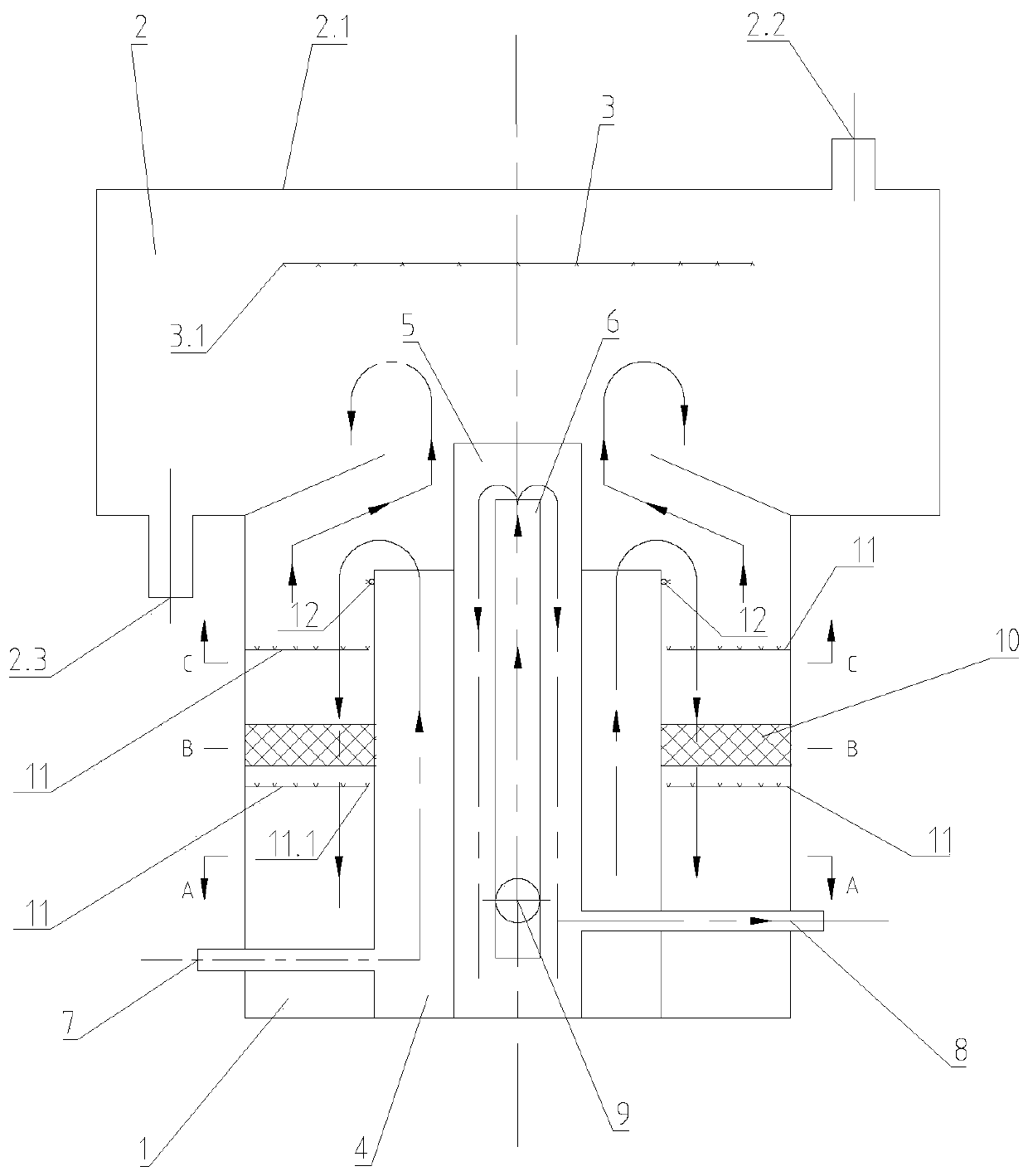

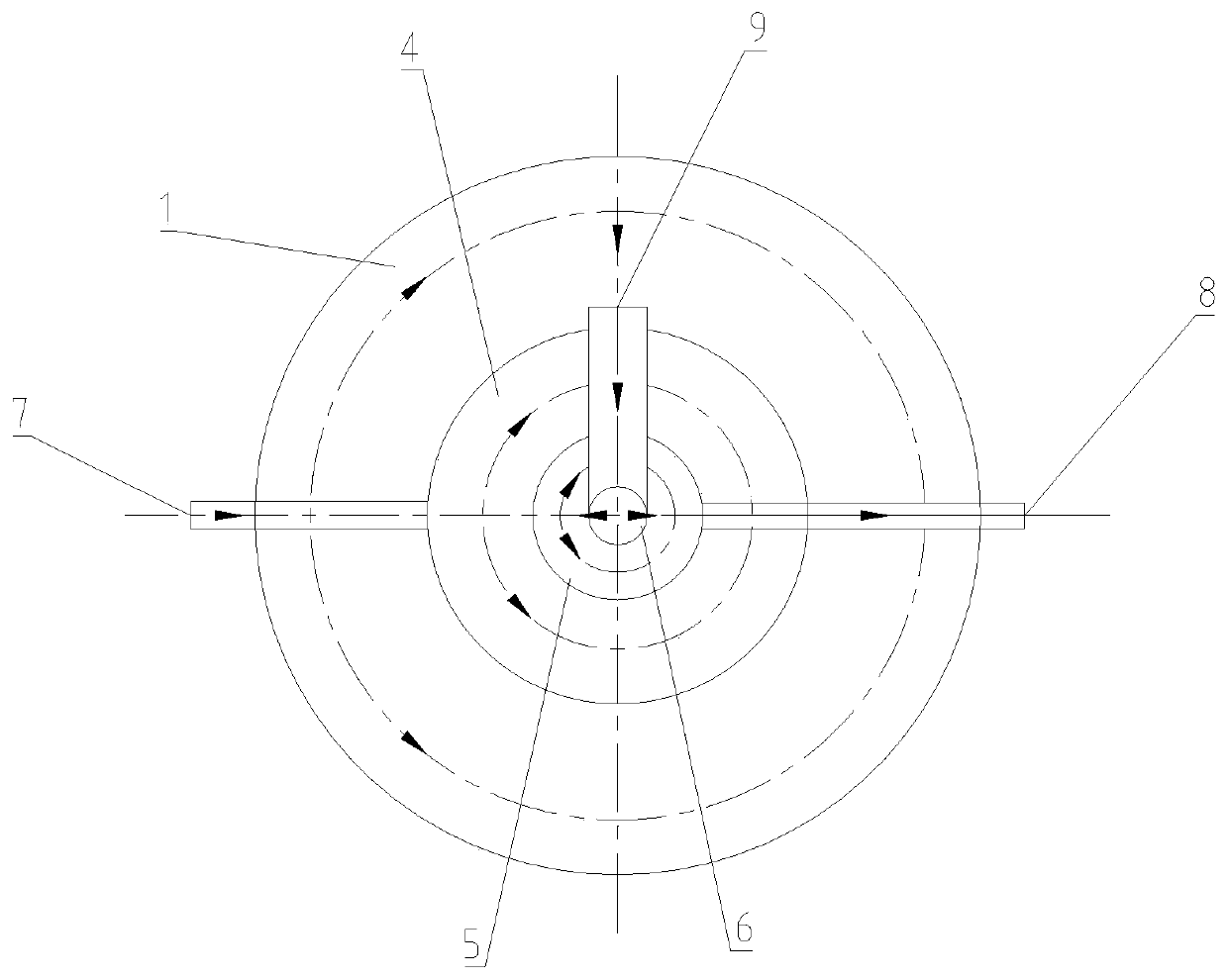

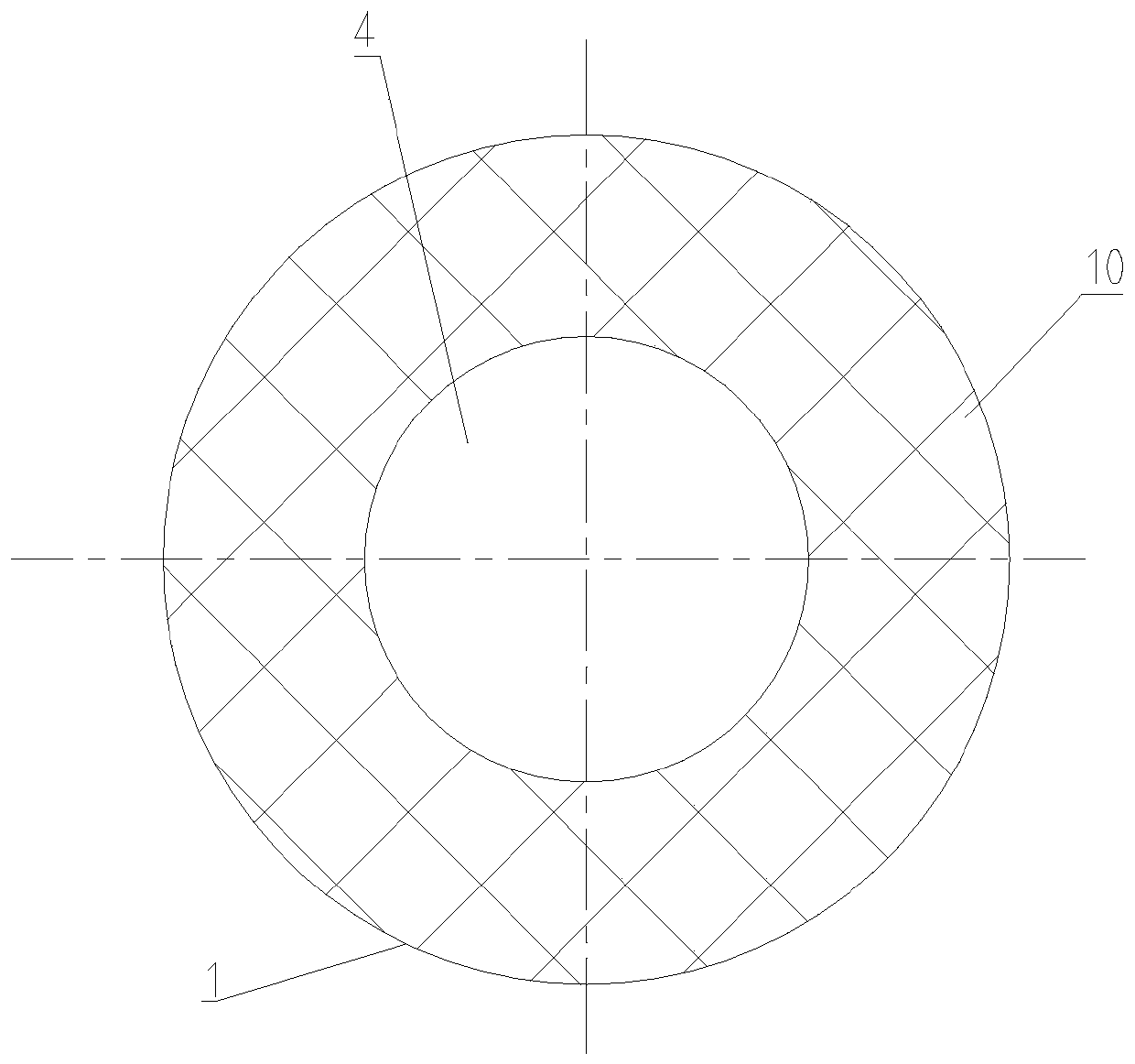

[0027] A flotation cabinet device with multi-stage diversion and overflow structure as shown in the figure includes a flotation cabinet 1 and a solid matter collection chamber 2, the flotation cabinet 1 is a circular container, and the flotation cabinet The top of 1 is conical and has an opening in the central part. The solid matter collection chamber 2 is a circular container with an opening at the bottom. The solid matter collection chamber 2 is coaxially connected with the flotation cabinet 1 and makes the The conical top is located in the inner cavity of the solid matter collection chamber 2. The solid matter collection chamber 2 includes a cover 2.1, an air vent 2.2 and a solid matter discharge port 2.3. The upper part of the solid matter collection chamber 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com