Water-washing-free chromium-free treatment process before aluminum profile coating

A treatment process and technology of aluminum profiles, applied in the direction of metal material coating process, etc., can solve the problems of waste water discharge, cure the symptoms but not the root cause, and have little consideration for optimization and improvement, so as to achieve zero discharge of waste water, good stability, and reduction of slots. The effect of number requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

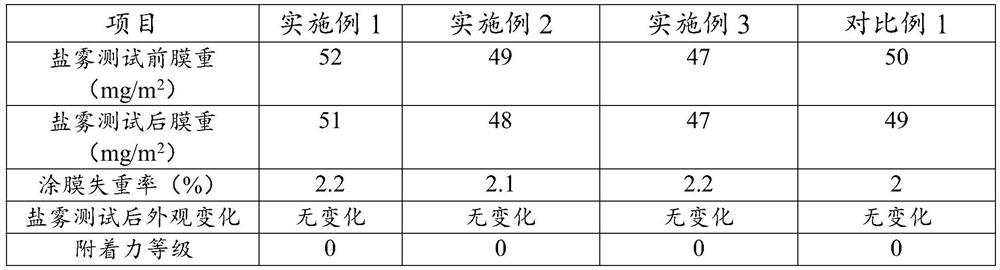

Embodiment 1

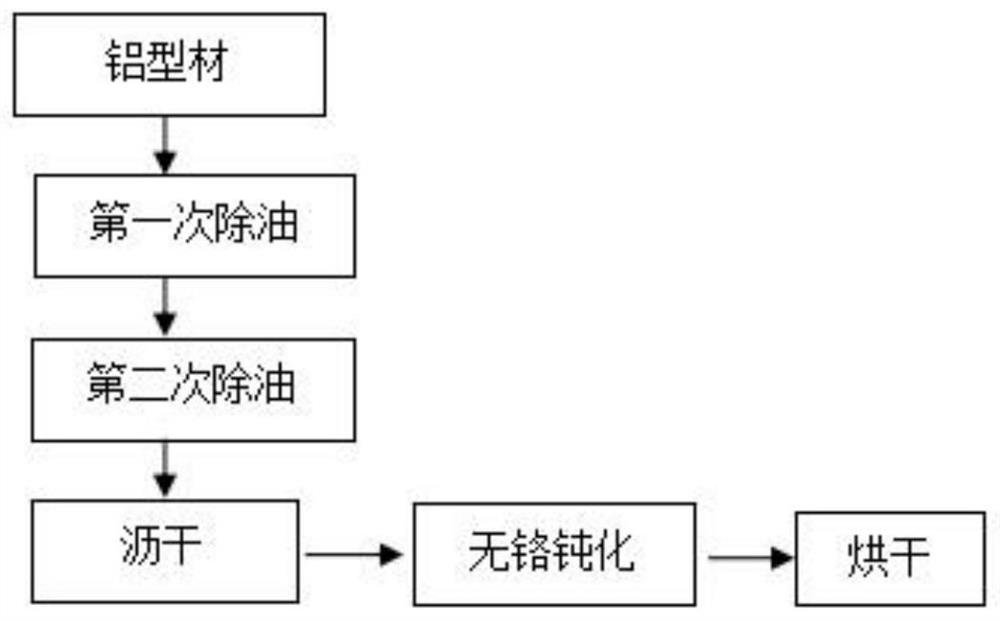

[0029] A chrome-free treatment process for aluminum profiles without washing before painting, such as figure 1 shown, including the following steps:

[0030] Step 1. Adjust the feeding rack and fix the aluminum profile on the feeding rack.

[0031] Step 2: Remove the grease on the surface of the aluminum alloy for the first time, prepare a degreaser, and spray the surface of the aluminum profile with a degreaser prepared by diluting the degreaser; Oils include deionized water 30%, oxalic acid 1%, hydrofluoric acid 1%, hydroxyethylidene diphosphonic acid 1%, benzotriazole 0.1%, block polyether surfactant 0.5%, treatment time 0.5% min, the treatment temperature was 25 °C.

[0032] Step 3: Remove the grease on the surface of the aluminum alloy for the second time, continue to rinse the surface of the aluminum profile with a degreasing treatment solution, the treatment time is 0.5min, and the treatment temperature is 25°C.

[0033] Step 4: Draining, draining is draining in a na...

Embodiment 2

[0037] A chrome-free treatment process for aluminum profiles without washing before painting, comprising the following steps:

[0038] Step 1. Adjust the feeding rack and fix the aluminum profile on the feeding rack.

[0039] Step 2: Remove the grease on the surface of the aluminum alloy for the first time, prepare a degreaser, and spray the surface of the aluminum profile with a degreaser prepared by diluting the degreaser; Oils include 55% deionized water, 10% oxalic acid, 10% hydrofluoric acid, 5% hydroxyethylidene diphosphonic acid, 5% benzotriazole, 5% block polyether surfactant, and the treatment time is 5min , the processing temperature is 25 ℃.

[0040] Step 3: Remove the grease on the surface of the aluminum alloy for the second time, and continue to rinse the surface of the aluminum profile with a degreasing treatment solution for a treatment time of 5 minutes and a treatment temperature of 25°C.

[0041] Step 4: Draining, draining is draining in a natural state, a...

Embodiment 3

[0045] A chrome-free treatment process for aluminum profiles without washing before painting, comprising the following steps:

[0046] Step 1. Adjust the feeding frame and fix the aluminum profile on the feeding frame.

[0047] Step 2: Remove the grease on the surface of the aluminum alloy for the first time, prepare a degreaser, and spray the surface of the aluminum profile with a degreaser prepared by diluting the degreaser; Oils include 80% deionized water, 20% oxalic acid, 20% hydrofluoric acid, 10% hydroxyethylidene diphosphonic acid, 10% benzotriazole, 10% block polyether surfactant, and the treatment time is 10min , the processing temperature is 25 ℃.

[0048] Step 3: Remove the grease on the surface of the aluminum alloy for the second time, continue to rinse the surface of the aluminum profile with a degreasing treatment solution, the treatment time is 10min, and the treatment temperature is 25°C.

[0049] Step 4: Draining, draining is draining in a natural state, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com