Prefabricated pumping station used for sewage pretreatment

A sewage pretreatment and pumping station technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of long treatment time, concentration, and increased treatment pressure of sewage treatment stations, etc. Achieve the effect of reducing pollutant content, reducing treatment burden, and efficient purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

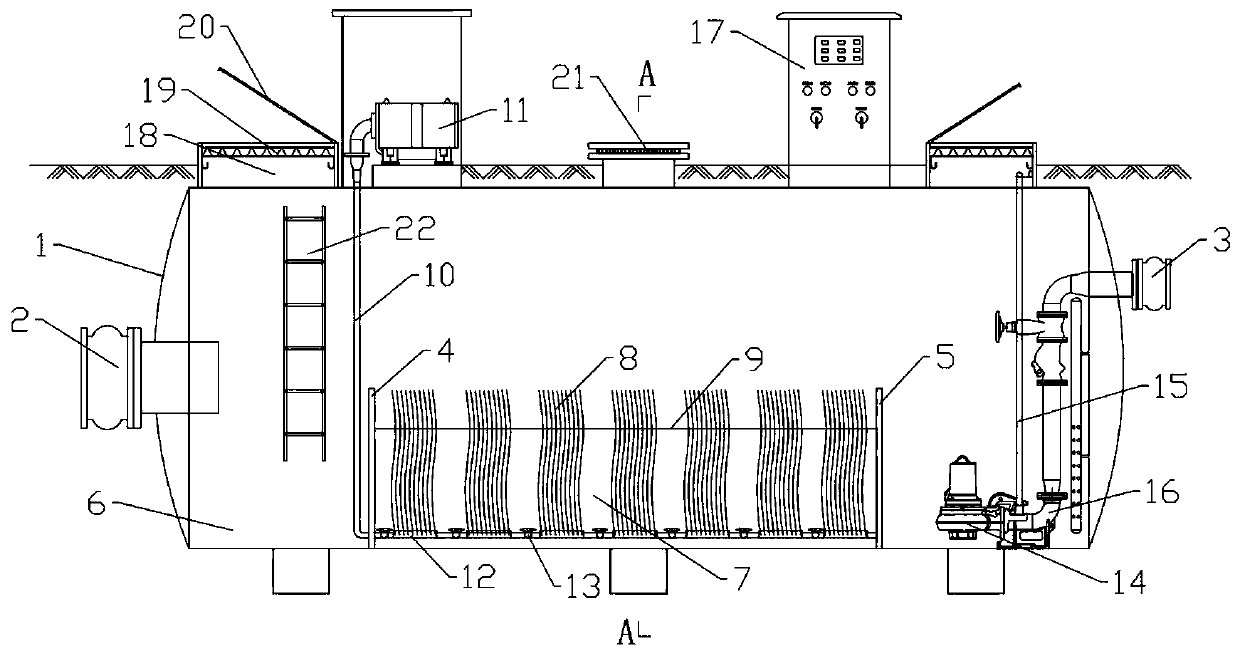

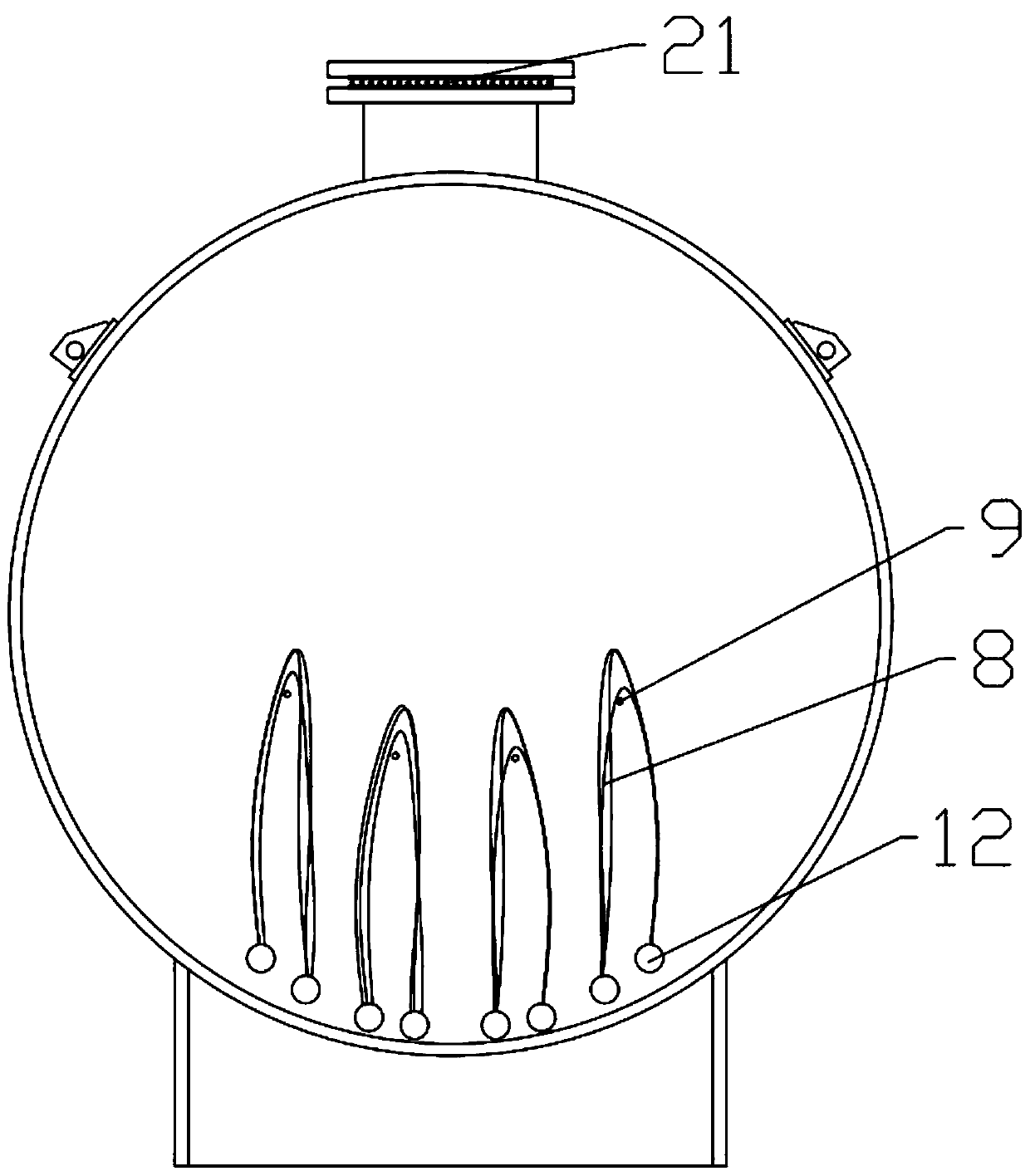

[0023] Refer to attached Figure 1-2 , this embodiment provides a prefabricated pumping station capable of sewage pretreatment, including a pumping station main body 1 and a control cabinet 17, the two ends of the pumping station main body 1 are respectively provided with a water inlet 2 and a water outlet 3, and The top of the main body 1 of the pumping station is provided with a set of sight mirrors 21 and two sets of safety entrances 18. The setting of the sight mirrors 21 is convenient for observing the working state inside the main body of the pumping station 1. A safety grid 19 is detachably installed in the safety entrance 18. A ladder 22 can be provided below the safety entrance 18, and a manhole cover 20 is hinged above the safety grid 19. Through two groups of safety entrances 18, the inside of the pump station main body 1 can be entered, so as to facilitate maintenance of the equipment in the pump station main body 1.

[0024] In addition, the water outlet 3 communi...

Embodiment 2

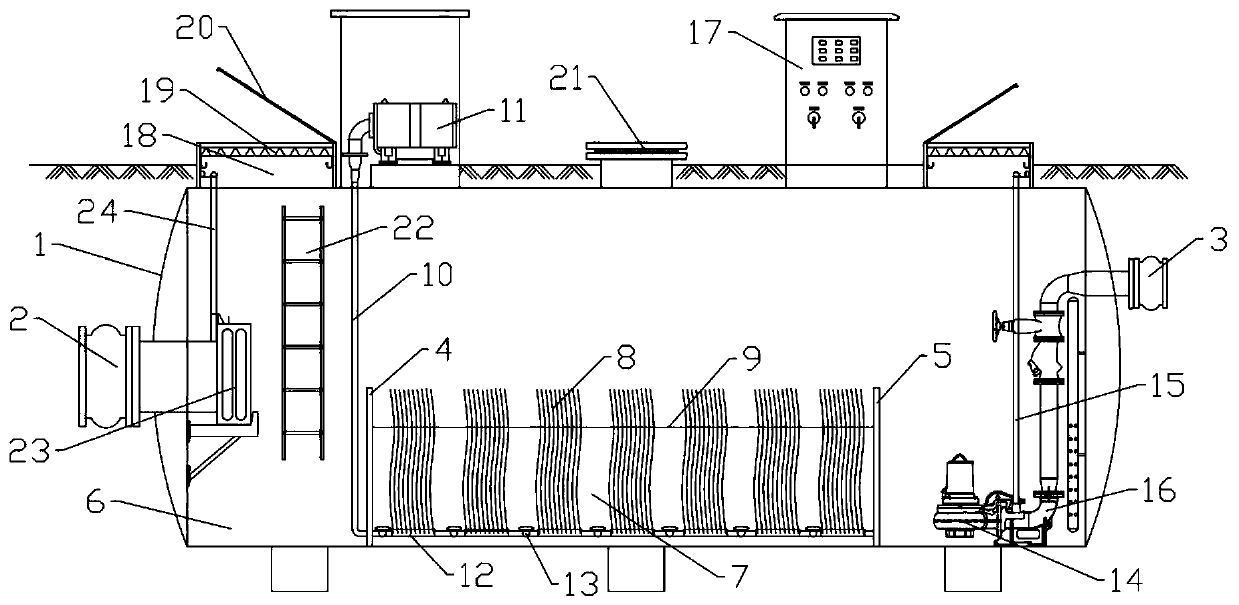

[0030] Refer to attached image 3In order to prevent large-volume pollutants such as suspended solids from entering the membrane treatment area 7, this embodiment is improved on the basis of embodiment 1. Specifically, the sedimentation area 6 is provided with a barrier for intercepting dirt The dirt assembly, the water inlet 2 communicates with the sedimentation area 6 through the dirt block assembly. Wherein, the trash blocking assembly includes a basket grille 23 and a second guide rail 24, the basket grille 23 is slidably matched with the second guide rail 24, and the second guide rail 24 is installed above the water inlet 2 to facilitate Lift the basket grill 23 out for cleaning or maintenance. Through the setting of the basket grid 23, the suspended solids and large particle pollutants in the sewage can be intercepted to prevent large volume pollutants such as suspended solids from entering the membrane treatment area 7, thereby avoiding the adsorption of suspended soli...

Embodiment 1-2

[0031] In combination with Embodiment 1-2, the prefabricated pump station provided by the embodiment of the present invention, when in use, the sewage first flows in from the water inlet 2, and enters the sedimentation area 6 through the basket grid 23; then, the sewage continues to enter, When the water level in the sedimentation zone 6 was higher than the first dividing plate 4, the sewage could enter the membrane treatment zone 7; The sewage is purified; then, when the water level in the membrane treatment area 7 is higher than the second partition 5, the purified sewage can overflow from the second partition 5, and pass through the submersible pump 14 from the water outlet 3 discharge.

[0032] In summary, in the embodiment of the present invention, by setting the first partition 4 and the second partition 5 in the pump station main body 1, the precipitation zone 6 and the membrane treatment zone 7 can be formed in the pump station main body 1; in addition, the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com