Updated heavy oil desalting and dewatering device

A dehydration equipment, heavy oil technology, applied in the direction of electricity/magnetic dehydration/demulsification, etc., can solve problems such as failure to meet requirements, inability to transmit electricity for desalination, and failure to fundamentally solve the problem of direct desalination of heavy oil, and achieve applicability Wide, stable quality and stable field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

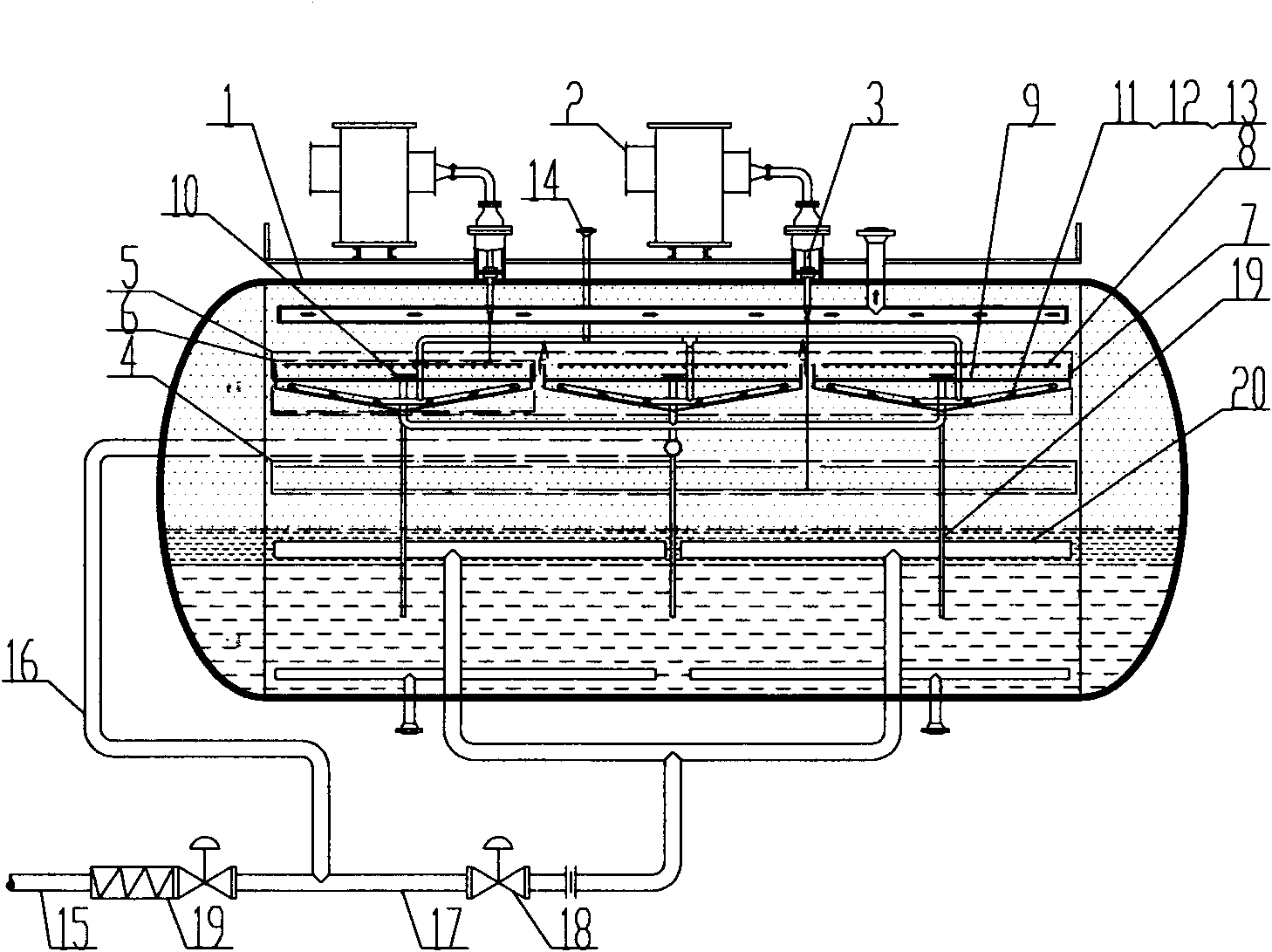

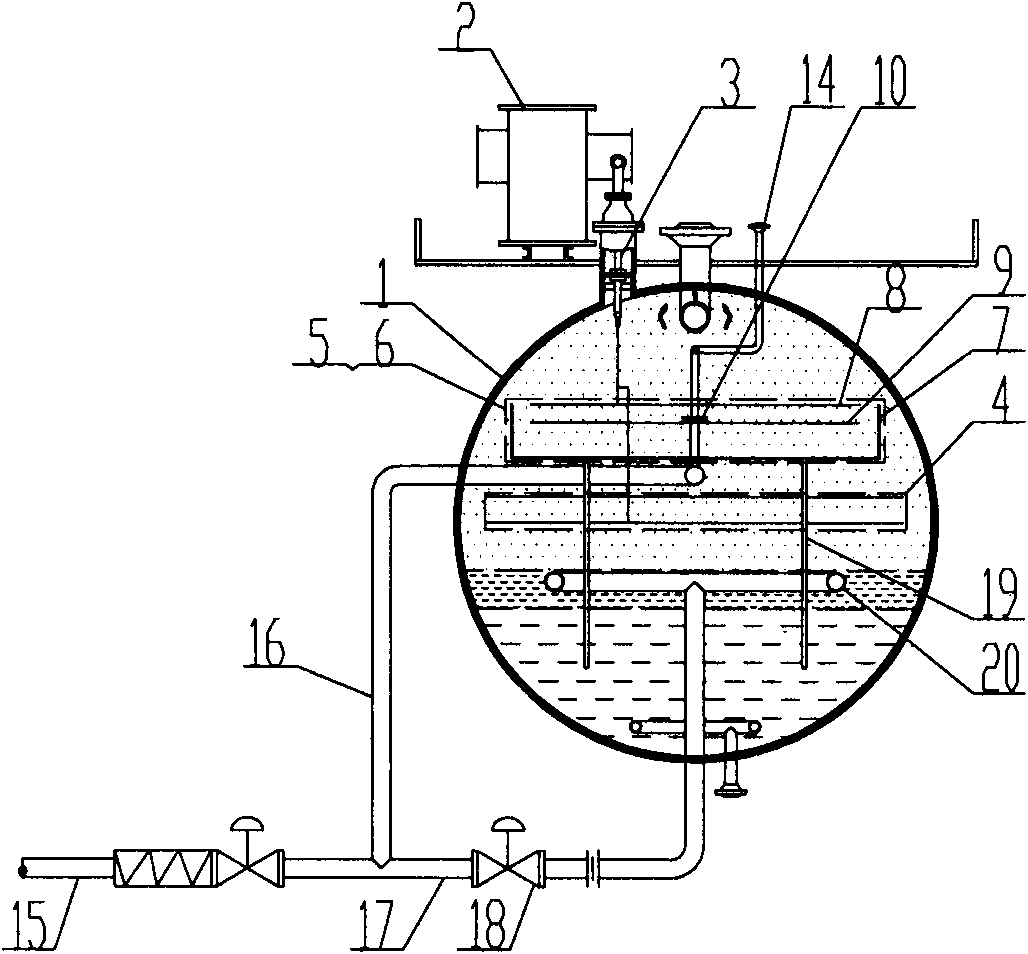

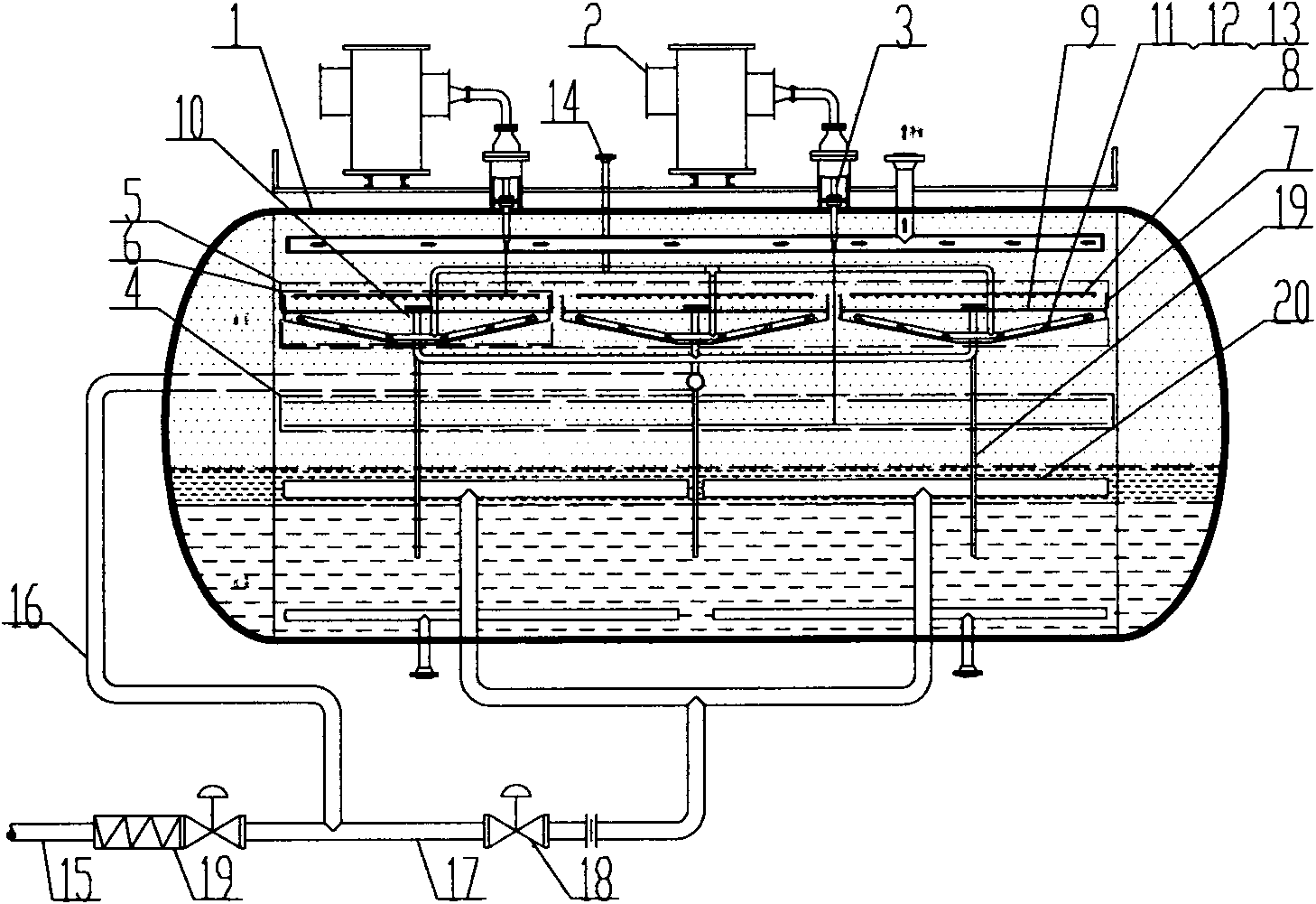

[0025] in the attached Figure 1-a , 1-b , with Figure 2-a , 2-b , with Figure 3-a , 3-b In , for the convenience of observation, the electric desalination tank 1 is drawn as transparent.

[0026] refer to Figure 1-a , Figure 1-b , and refer to Figure 4-a , 4-b, the desalination and dehydration equipment includes an electric desalination tank 1, an electric desalination transformer 2 installed above the electric desalination tank 1, a high-voltage electricity introduction device 3, an oil inlet main pipe 15, oil inlet branch pipes 16 and 17, and a flow regulating valve 18 . Inside the electric desalination tank 1, a lower electric field 4 is installed. The lower electric field 4 is a combined horizontal electrode (see attached Figure 1-a , 1-b ), can also be a combined vertical electrode (see attached Figure 3-a , 3-b ). In the electric desalination tank 1 , an upper electric field 5 is installed above the lower electric field 4 . The upper electric field 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com