Water-cooled air tight box combination sealing device for blast furnace iron making distributor

A combination of sealing and blast furnace ironmaking technology, which is applied in the direction of cooling device, bell and funnel arrangement, etc., can solve the problems that the sealing effect cannot be achieved, the installation method and installation space of the trunnion sleeve seal are limited, and the design of the transmission device is inconvenient, etc. , to achieve the effect of convenient design and operation, good sealing effect and convenient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

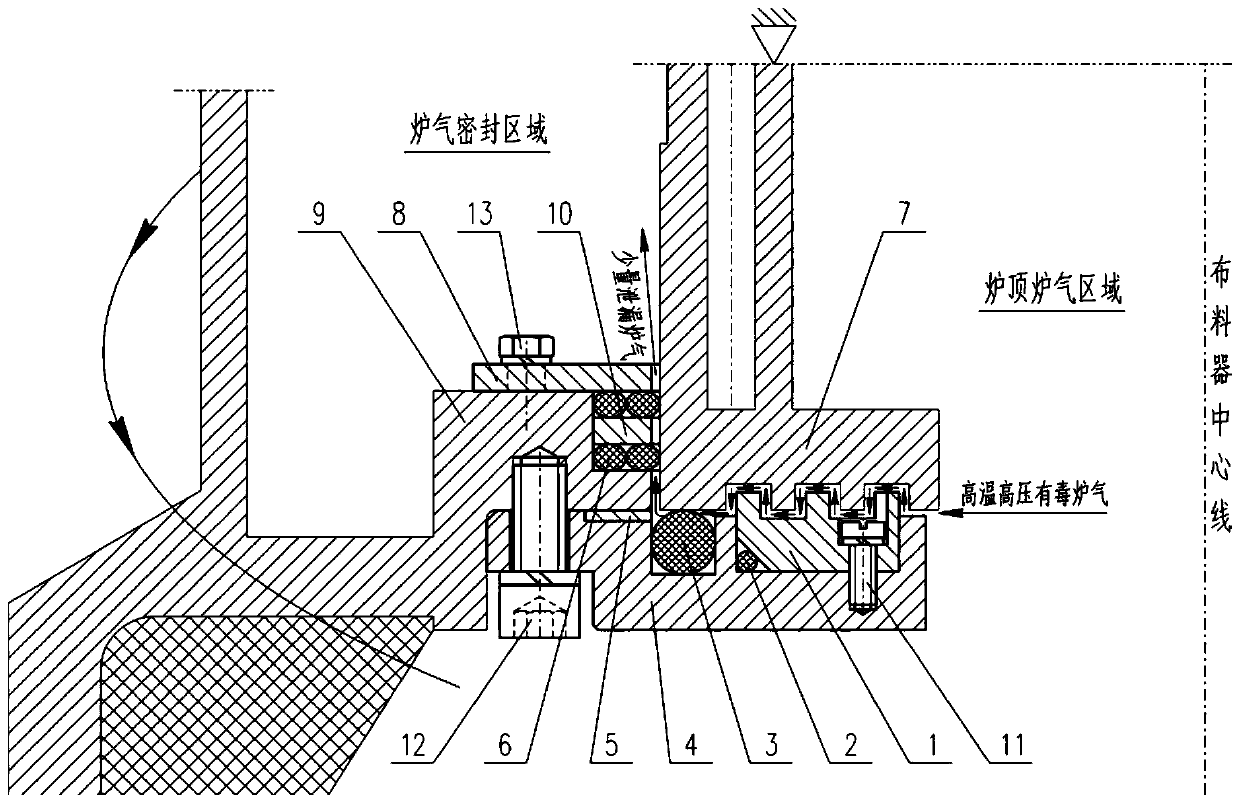

[0009] The invention includes: sealing ring 1, flexible graphite packing 1 2, flexible graphite packing 2 3, stuffing box 4, metal-coated gasket 5, flexible graphite packing 3 6, central throat 7, three-split pressure plate 8. Trunnion rotary sleeve 9, three-point washer 10, bolt one 11, bolt two 12 and bolt three 13.

[0010] The blast furnace gas with high temperature, high pressure and high dust content is sealed in three stages. In the first stage of sealing, the sealing ring 1 and the lower end of the central throat 7 form a labyrinth seal, which is used as the front seal of the dynamic seal behind. There is a gap between the labyrinth seals. Clearance, no solid contact, no lubrication, and thermal expansion is allowed, suitable for high temperature, high pressure, high speed occasions. After the toxic furnace gas with high temperature, high pressure and high dust content passes through the labyrinth, due to the "labyrinth effect", the temperature, pressure, leakage rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com