Corner assembly with built-in blind window

A corner assembly and corner piece technology, applied in the field of shutters, can solve the problems of increasing the installation difficulty of the lifting guide wheel and the turning wheel, affecting the assembly efficiency of the corner piece, etc., and achieves the effect of reducing the installation difficulty, prolonging the service life and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will be described in detail in the form of the embodiment, but the description of the embodiment is not a limitation to the solution of the present invention, and any equivalent transformation made according to the concept of the present invention is only in form and not in substance. The scope of the technical solution of the invention.

[0017] In the following descriptions, all the directional or azimuthal concepts related to up, down, left, right, front and back, etc. are based on the positions shown in the drawings, so they cannot be understood as the meaning of the present invention. Special restrictions on technical solutions.

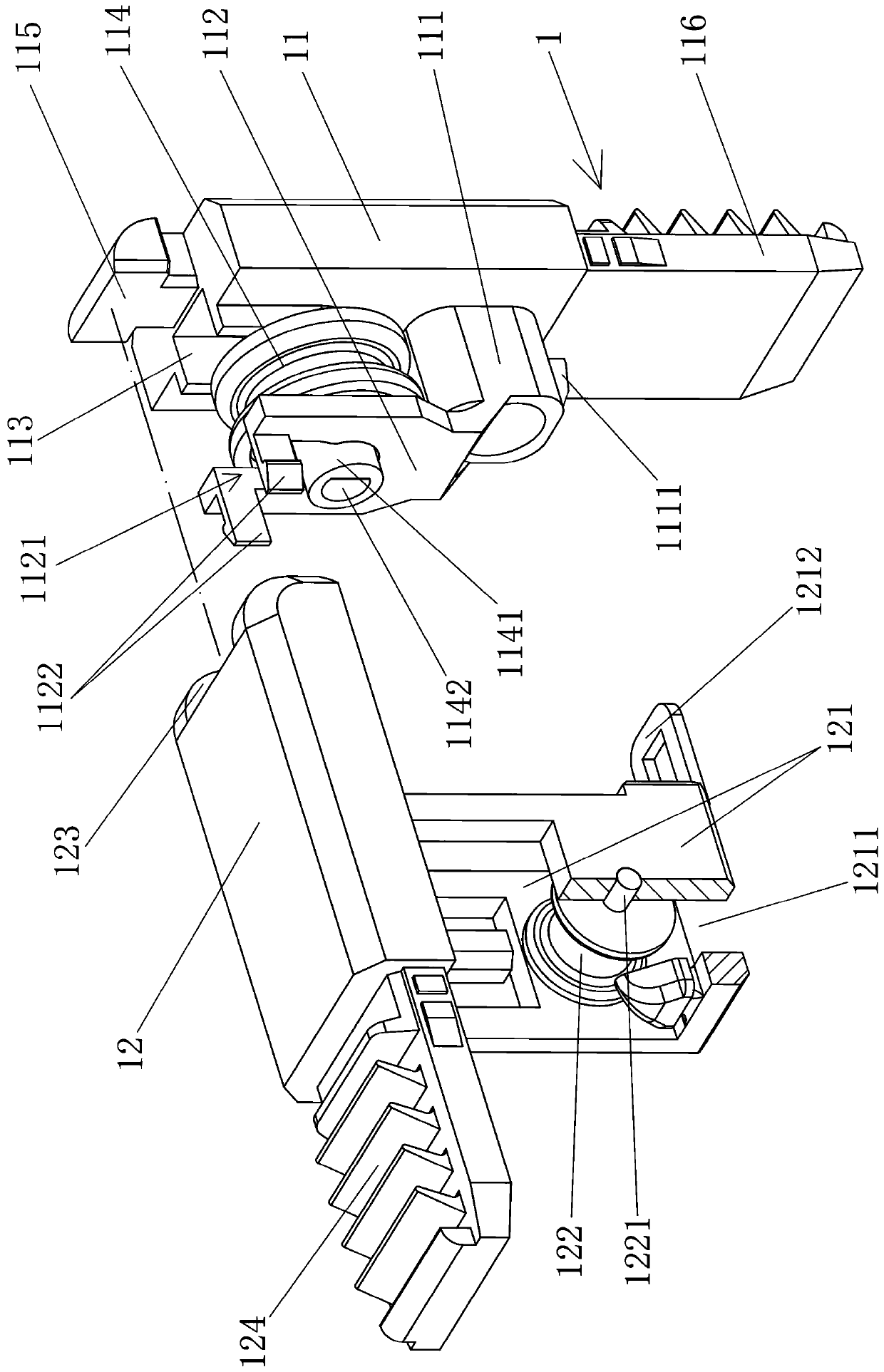

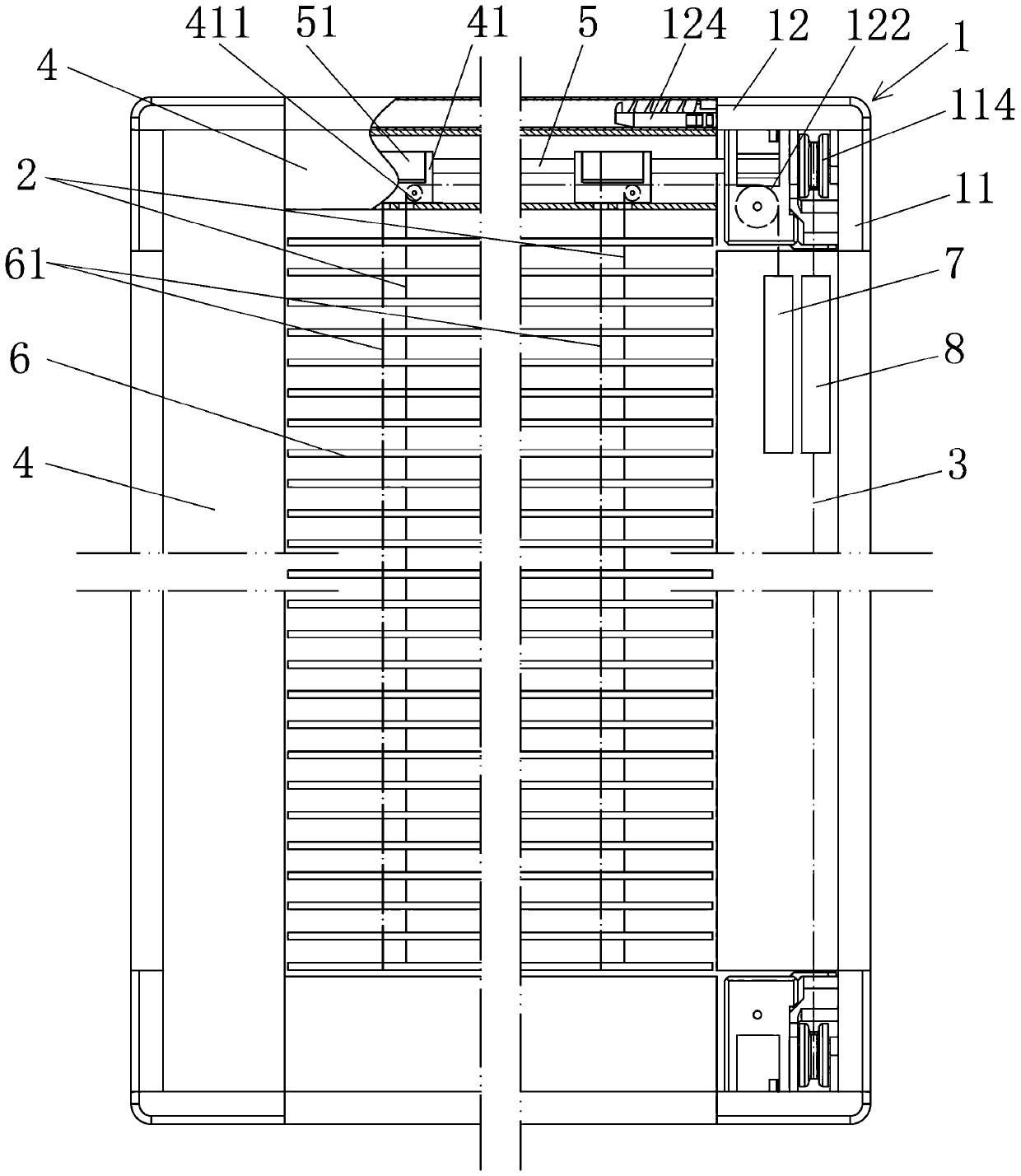

[0018] see figure 1 and combine figure 2 , the present invention relates to a corner assembly with built-in shutters, which includes a corner assembly body 1, the aforementioned corner assembly body 1 includes a first corner piece 11 and a second corner piece 12, the aforementioned second corner piece 12 and the aforement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com