Adaptive Multi-plate Sequencing High Torque Friction Clutch

A friction clutch and high torque technology, applied in the direction of friction clutches, clutches, mechanically driven clutches, etc., can solve problems such as poor wear resistance, short service life, and friction plates that cannot withstand high torque, etc., to prolong service life and improve Abrasion resistance and the effect of shortening the response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

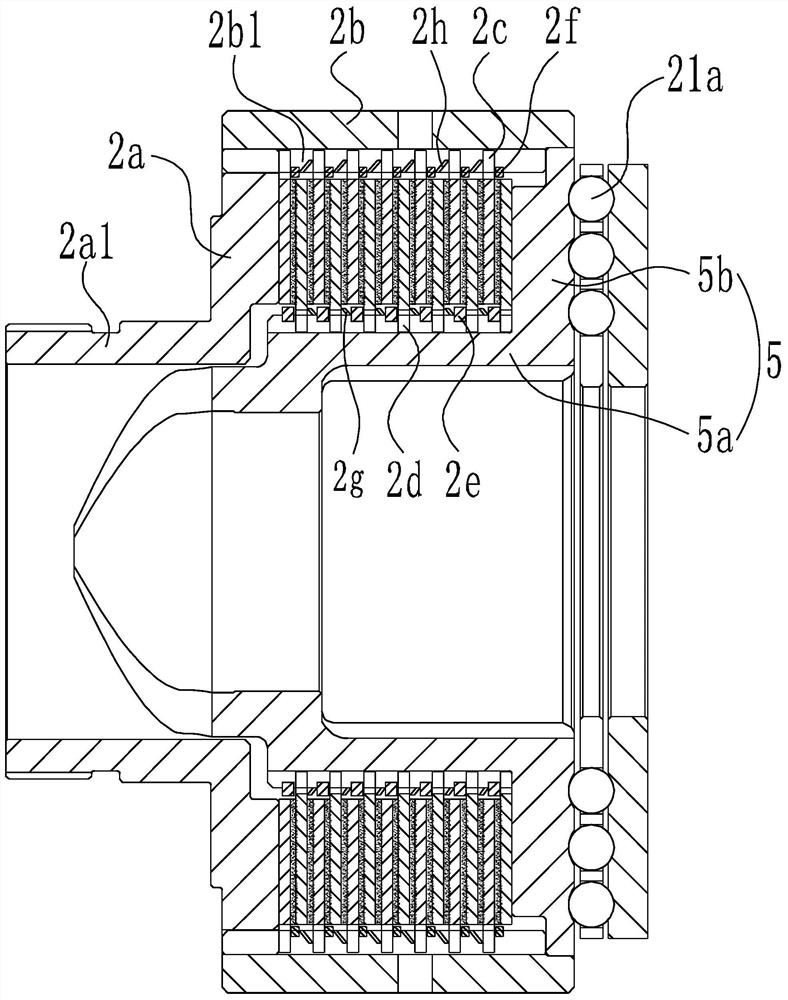

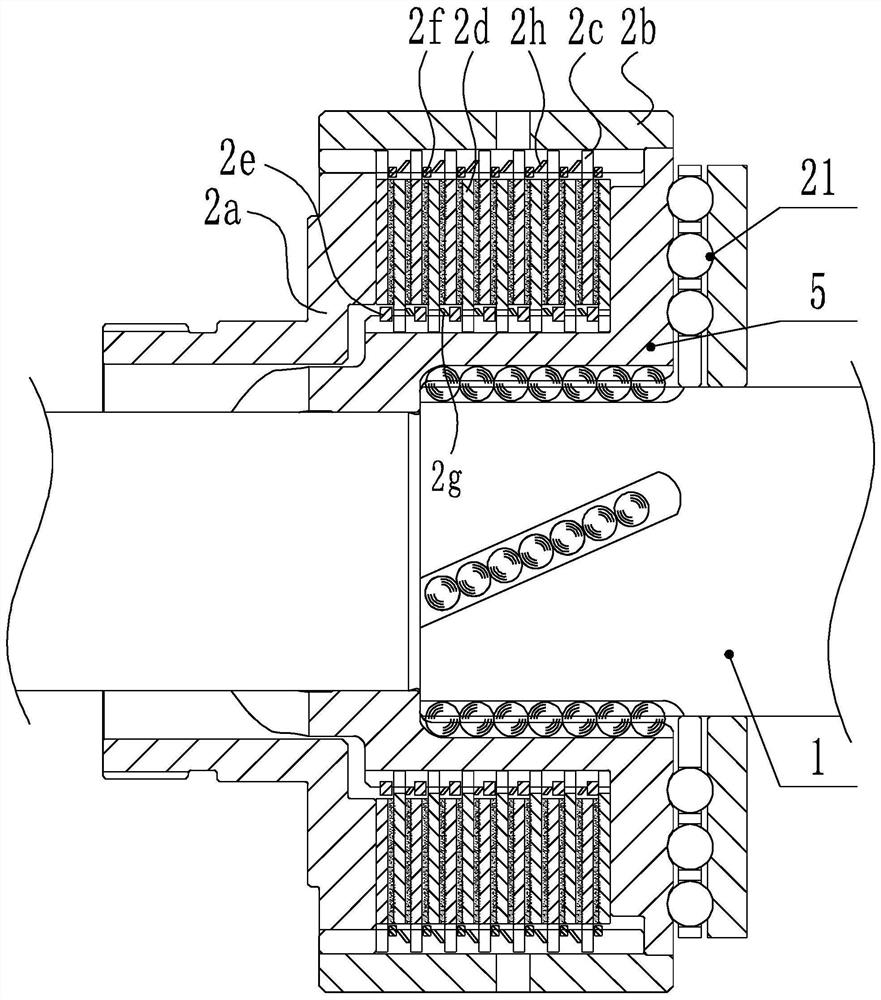

[0051] See Figure 8 , the output spiral raceway cylinder 5a is sleeved on the main shaft 1, and forms a helical transmission pair with the main shaft 1, so that the output helical raceway cylinder 5a can slide axially along the main shaft 1, specifically, the helical transmission pair It includes an inner spiral raceway 5a3 distributed on the inner wall of the output spiral raceway barrel 5a along the circumferential direction and an outer spiral raceway 1a distributed on the outer wall of the main shaft 1 along the circumferential direction, and each outer spiral raceway 1a is embedded with A plurality of outwardly protruding balls 27, each ball 27 can roll in the corresponding inner helical raceway 5a3 and outer helical raceway 1a respectively. When the output spiral raceway cylinder 5a rotates relative to the main shaft 1, it can move axially relative to the main shaft 1, so as to compress or release each outer friction plate 2c and inner friction plate 2d, and switch betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com