Stacking collecting equipment of resistance melting heat preservation furnace

A collection equipment and holding furnace technology, applied in the field of stacked collection equipment, can solve problems such as affecting the stability of transportation and placement, the overall deviation of parts, and left and right shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

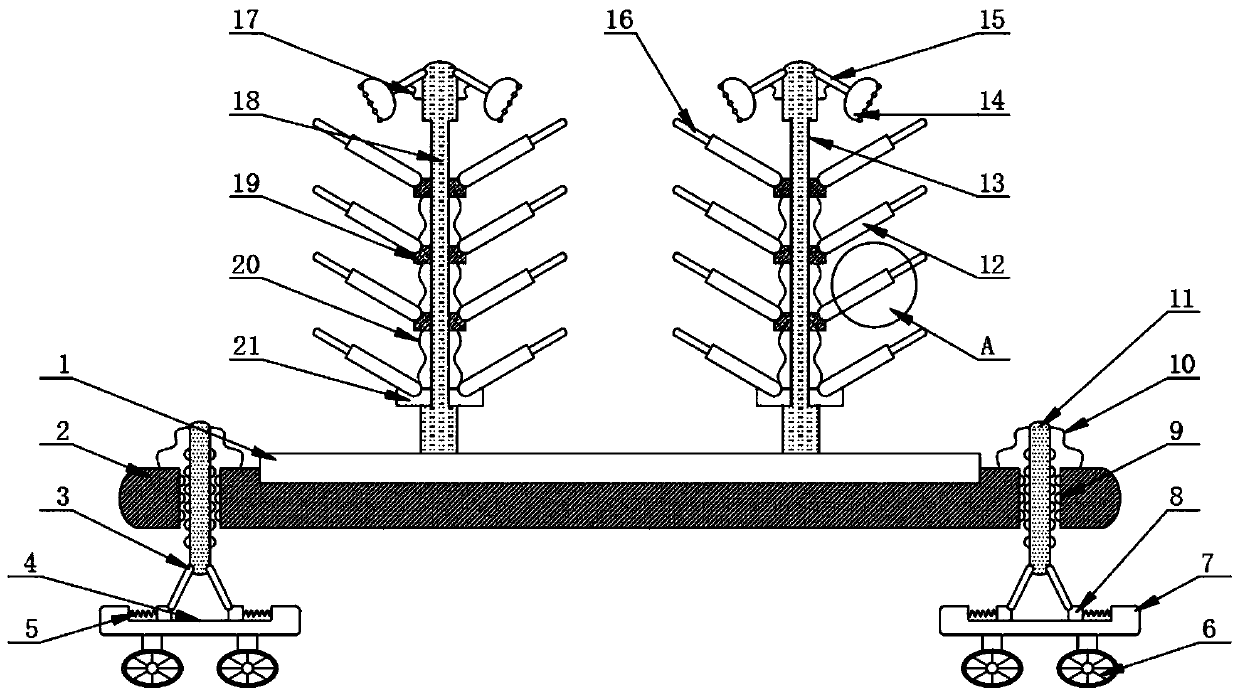

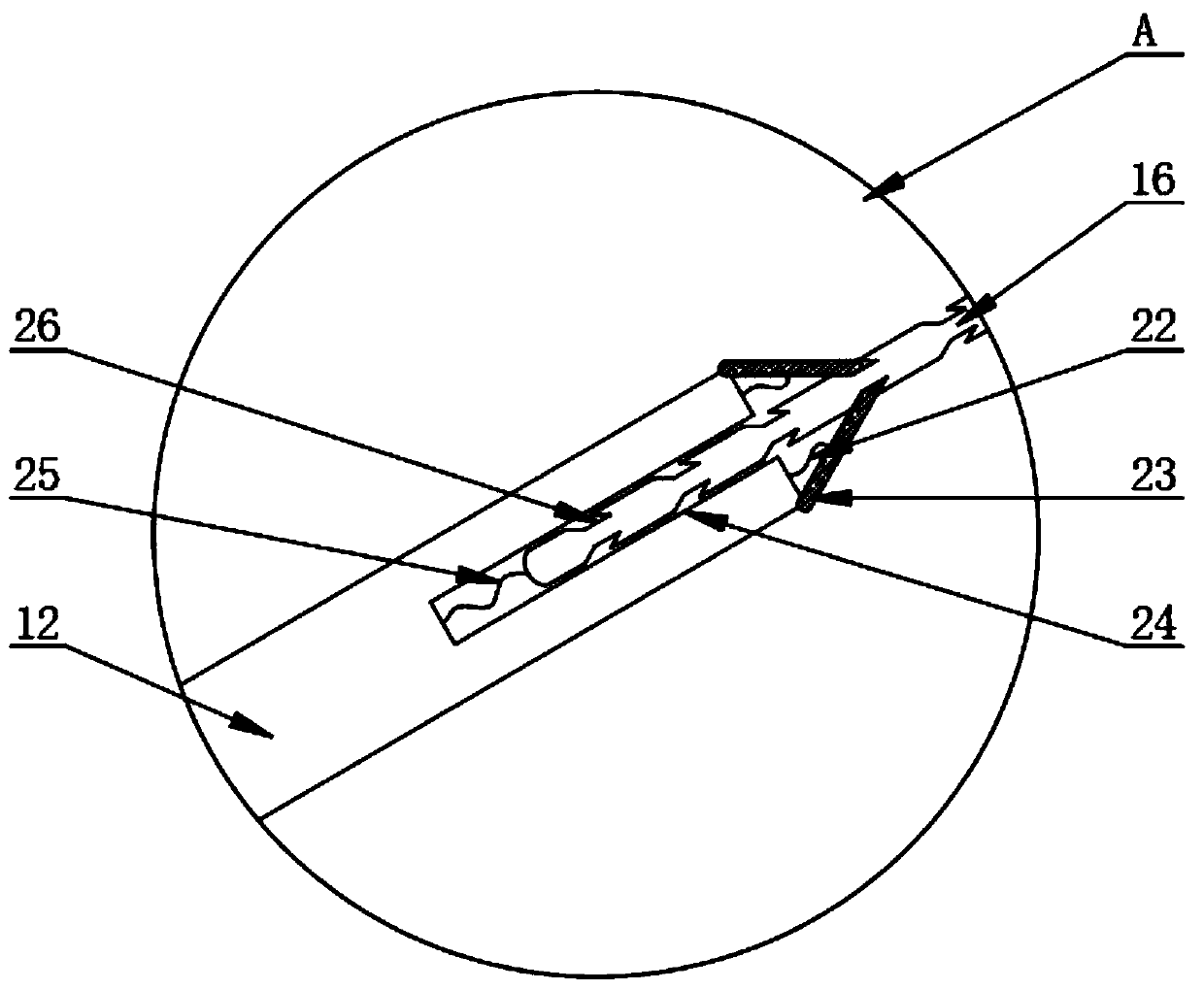

[0025] Such as Figure 1-2 As shown, a stacked collection device for a resistance melting and holding furnace includes a load plate 1, a bottom plate 2, a movable rod 3, a first chute 4, a first telescopic spring 5, a universal wheel 6, a connecting plate 7, a first Slide block 8, through hole 9, first torsion spring 10, column 11, fixed plate 12, second chute 13, rubber block 14, movable block 15, support plate 16, second torsion spring 17, fixed column 18, the first Two slide blocks 19, the second telescopic spring 20, the stopper 21, the third telescopic spring 22, the oblique limit block 23, the draw-in groove 24, the third torsion spring 25 and the oblique limit groove 26, the bottom of the connecting plate 7 The universal wheel 6 is correspondingly installed, and the universal wheel 6 and the connecting plate 7 are all fixed by bolts;

[0026] The top center of the connecting plate 7 is provided with a first chute 4, the inside of the first chute 4 is correspondingly eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com