An Efficient Dust Reduction Method for Open-air Step Blasting

A technology of step blasting and dust reduction, which is applied in the direction of blasting, separation methods, chemical instruments and methods, etc., can solve the problems of unsatisfactory dust reduction effects, and achieve the effect of not easy to lose, burn quickly, and easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention proposes a highly efficient dust reduction method for open-air step blasting. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

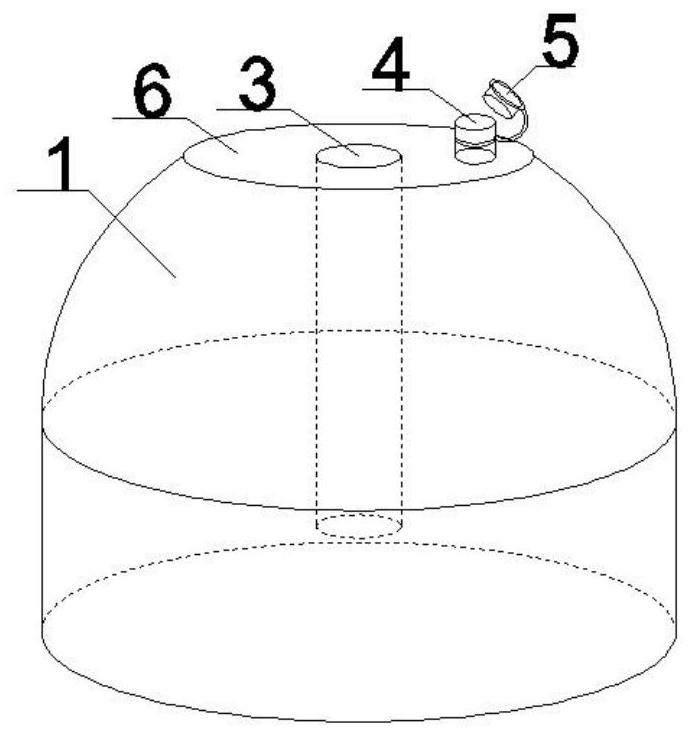

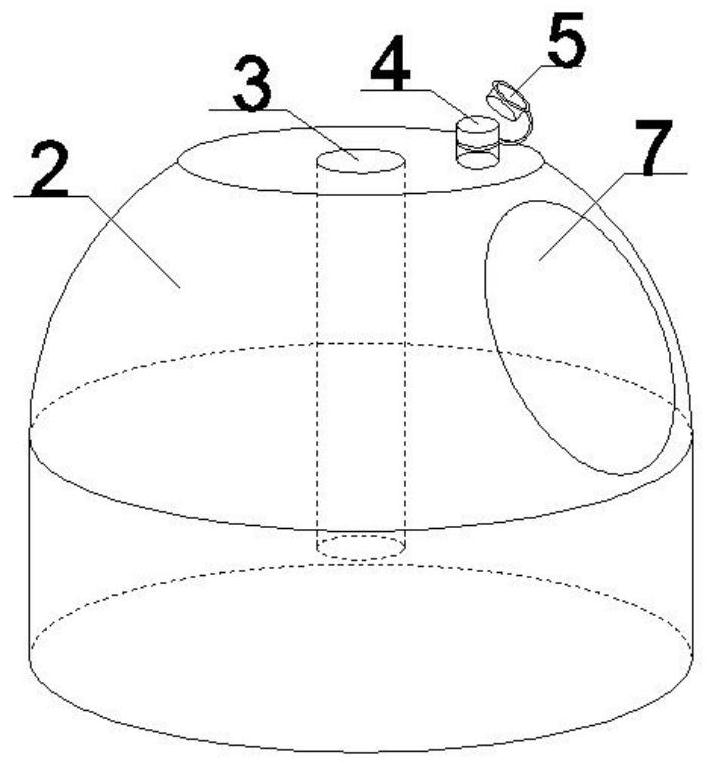

[0033] Such as figure 1 As shown, the first water bag 1 of the present invention includes a bag body, and the bag body includes upper and lower parts, the lower part is a cylinder, the upper part is a hemisphere, and there is a circular plane on the top of the hemisphere, and the circular plane on the top 6 is used as a weak surface, and a water injection port 4 is set on the weak circular plane, and there is a cavity 3 near the water injection port, and the cavity 3 is used to place an explosion source.

[0034] In the above-mentioned first water bag, the weak circular plane means that the thickness of this place is smaller than the thickness of the rest of the first water ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com