A Method of Absolute Code Wheel Coarse Code Correction

An absolute code disc technology, which is applied in the field of photoelectric sensors, can solve the problems of discontinuous angle values of absolute code discs, achieve accurate calibration, reduce assembly accuracy requirements, and improve the accuracy of code discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] A method for correcting coarse codes on an absolute code wheel is characterized in that an absolute code wheel is used, and the steps are as follows:

[0090] (1) The design and installation of the absolute code disc finally make the absolute code disc have the following structure:

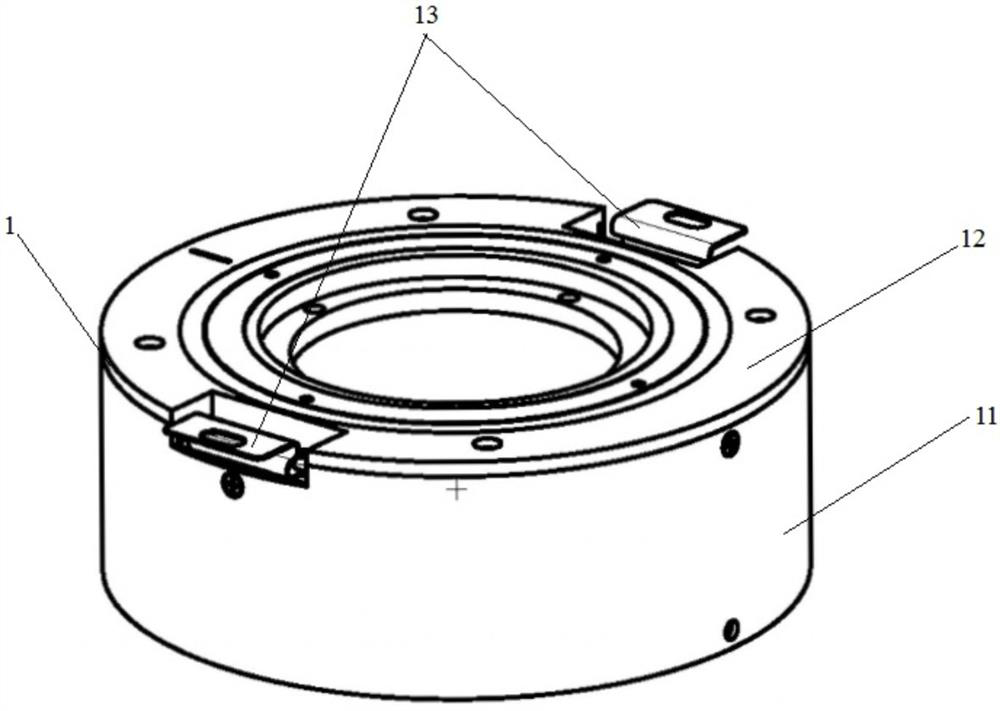

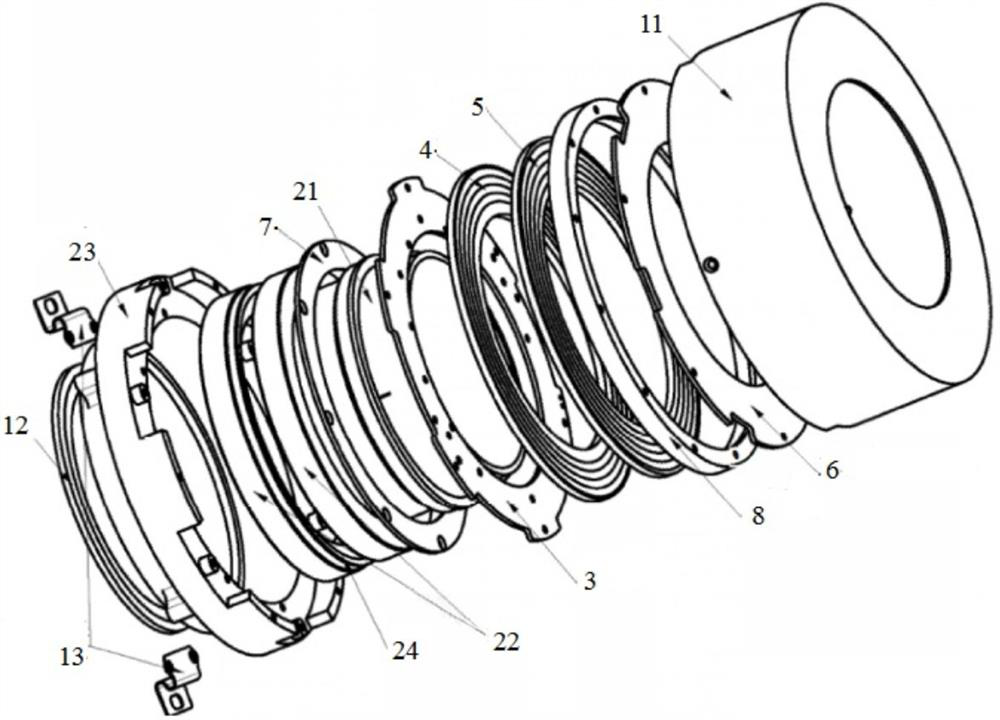

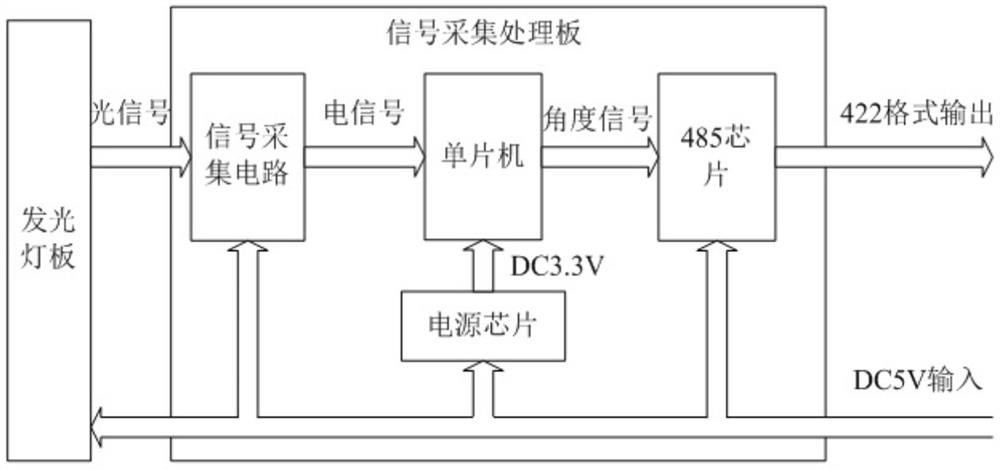

[0091] The absolute code wheel involved includes a housing 1 , a shaft 21 system structure, a light emitting lamp board 3 , a main grating 4 , a sub grating 5 and a signal processing board 6 .

[0092] The housing 1 includes an upper housing 11, a lower housing 12 and an elastic coupling 13; the upper housing 12 is fixed on the upper part of the shafting structure, the elastic coupling 13 is installed on both sides of the upper housing 11, and the lower housing 12 is fixed on The lower part of the bearing seat 23 forms a hollow housing 1; the shafting structure, the light emitting lamp board 3, the main and auxiliary gratings 5 and the signal processing board 6 are all installed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com