Pendant structure and precast concrete wallboard system

A pendant and steel structure technology, applied to walls, building components, building structures, etc., can solve the problems of difficult position adjustment, large installation errors, and high construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

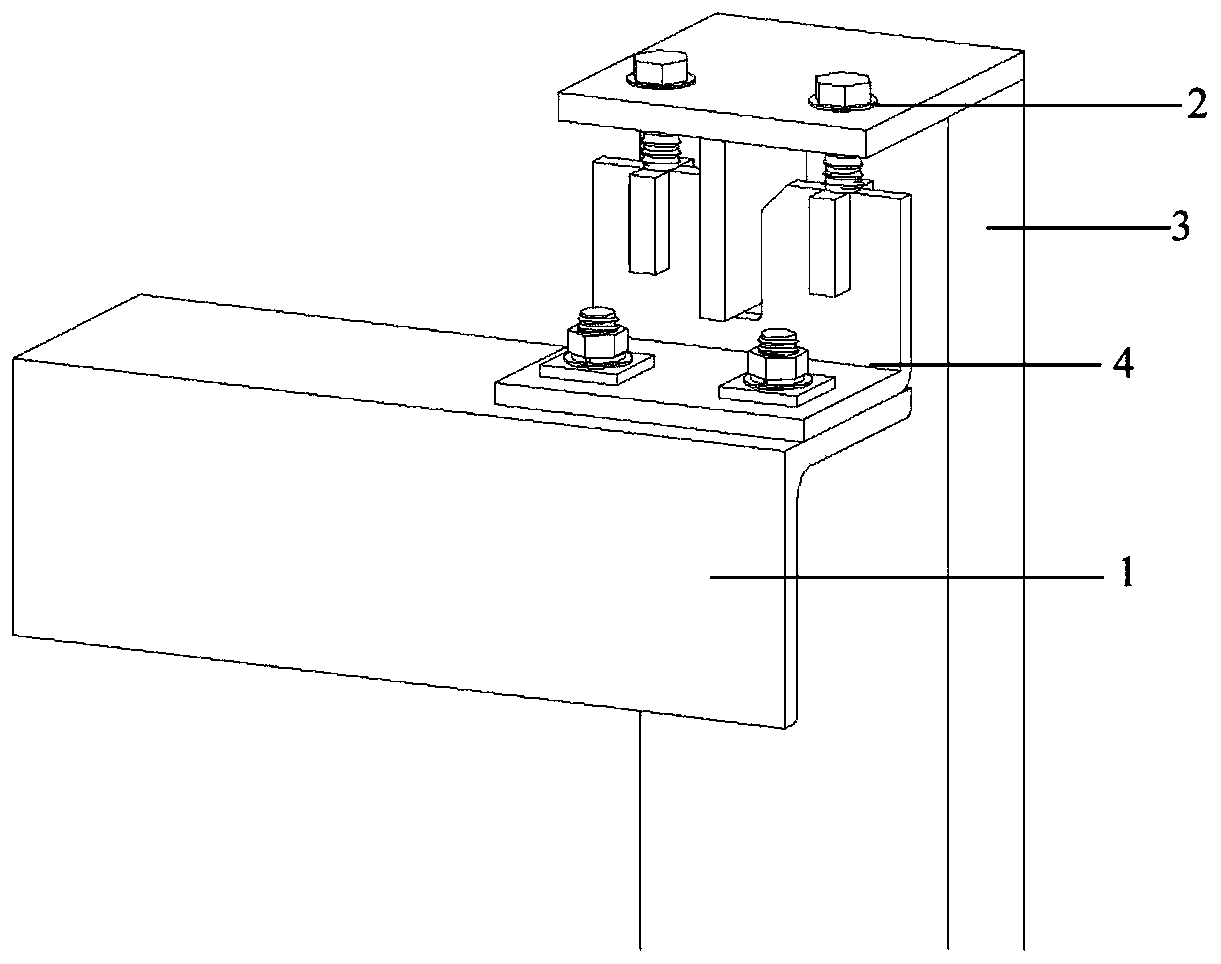

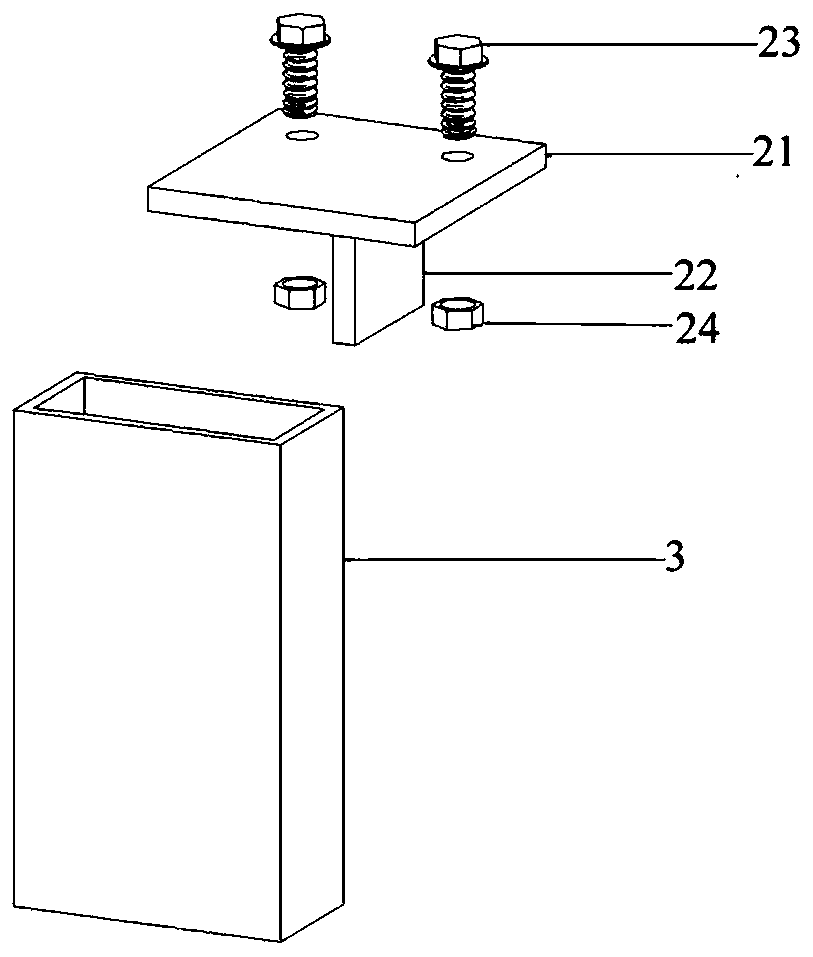

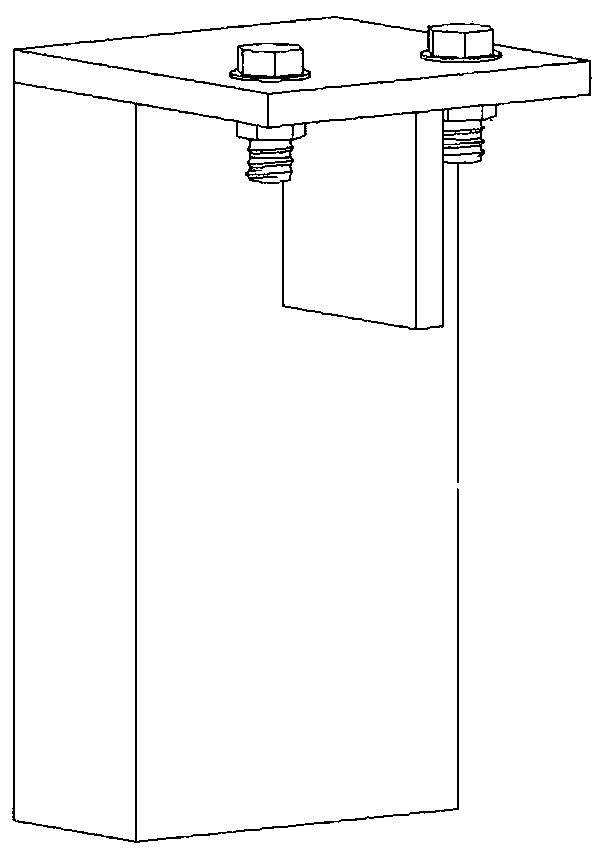

[0025] refer to figure 1 , figure 2 , image 3 with Figure 4 , figure 1 is a structural schematic diagram of a pendant structure provided in this embodiment; figure 2 It is an assembly diagram of the pendant assembly of a pendant structure provided in this embodiment; image 3 is a structural schematic diagram of the pendant assembly of a pendant structure provided in this embodiment; Figure 4 It is an assembly diagram of the base assembly of a pendant structure provided in this embodiment.

[0026] The pendant structure provided in this embodiment is used to install the prefabricated building PC integrated board on the main steel structure, including the pendant component 2 and the base component 4;

[0027] The base assembly 4 includes a connection assembly 42 and an L-shaped load-bearing member 41, the connection assembly 42 is fixedly connected to the main steel structure 1, and the first side plate of the L-shaped load-bearing member 41 is connected to the The...

Embodiment 2

[0044] This embodiment provides a prefabricated concrete wall panel system, including a main steel structure and a prefabricated building PC integrated board, and the prefabricated building PC integrated board is installed on the main steel structure through the pendant structure as described in Embodiment 1 .

[0045] To sum up, the pendant structure of the prefabricated building PC integrated board provided by the present invention has the following advantages: a pendant structure for installing the prefabricated building PC integrated board on the main steel structure, including the pendant assembly and A base assembly, the base assembly includes a connection assembly and an L-shaped load-bearing member, the connection assembly is fixedly connected to the main steel structure, and the first side plate of the L-shaped load-bearing member is connected to the main steel structure through the connection assembly The structure is flexibly connected, the free end of the second si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com