Controllable soluble sleeve blanking plug and under-pressure-free oil pipe well descending method

A plug and casing technology, applied in the field of oil and gas well fracturing reconstruction, can solve the problems of high operation cost, long operation period, high construction risk, etc., and achieve the effect of saving operation cost and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

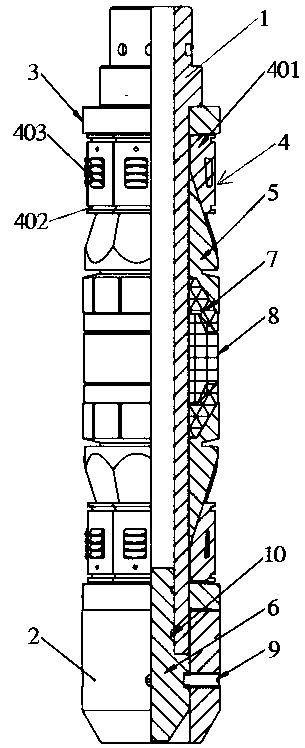

[0029] refer to figure 1 , the embodiment of the present invention proposes a controllable dissolvable casing plug, including: a mandrel 1, two pressure rings 3, two sets of slip assemblies 4, two taper sleeves 5 and a plug 6; the mandrel The upper end of 1 can be connected with the setting device, and the lower end of mandrel 1 is connected with tailstock 2 through external thread; two pressure rings 3 are respectively set on the upper and lower parts of mandrel 1, and the pressure ring 3 set on the lower part of mandrel 1 Lean against the upper end surface of the tailstock 2; two sets of slip assemblies 4 are set opposite to each other in the opening direction, the upper part of one set of slip assemblies 4 leans against the lower end surface of a pressure ring 3, and the lower part of one set of slip assemblies 4 Lean against the upper end surface of a pressure ring 3; two taper sleeves 5 are respectively fitted on the mandrel 1, and the taper surface of each taper sleeve 5...

Embodiment 2

[0032] refer to figure 1 , On the basis of Example 1, the mandrel 1 is made of magnesium-aluminum alloy, and the mandrel 1 is sprayed with a waterproof coating except for the part where the plug 6 is assembled.

[0033] The mandrel 1 is made of magnesium-aluminum alloy, which will slowly dissolve when exposed to water. After the plug 6 is installed at the bottom of the mandrel 1, a waterproof coating is sprayed on the surface and inside of the mandrel 1, so that the invention is controllable and After the melting casing plug is set and sealed in the oil well casing, high-pressure liquid is injected into the oil well casing after the tubing is lowered. After the plug 6 at the lower end of the mandrel 1 is separated from the mandrel 1, the place where the plug 6 is installed on the mandrel 1 is exposed. Under the liquid environment, the mandrel 1 can start to dissolve until it completely disappears, which will not affect the next step of construction.

Embodiment 3

[0035] refer to figure 1 , On the basis of Example 1, the taper sleeve 5 is made of magnesium-aluminum alloy, and the outer surface of the taper sleeve 5 is sprayed with a waterproof coating.

[0036] The taper sleeve 5 is installed on the mandrel 1 and then sprayed with a waterproof coating. When the mandrel 1 dissolves, the inner surface of the taper sleeve 5 in contact with the mandrel 1 is exposed to the liquid environment, and the taper sleeve 5 begins to dissolve until it is completely disappear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com