Pilot control oil way of super-tonnage excavator and control method

A pilot-controlled, super-large tonnage technology, used in earth movers/shovels, mechanical equipment, engine components, etc., can solve problems such as consuming hydraulic energy, reduce energy consumption, and avoid high-pressure overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

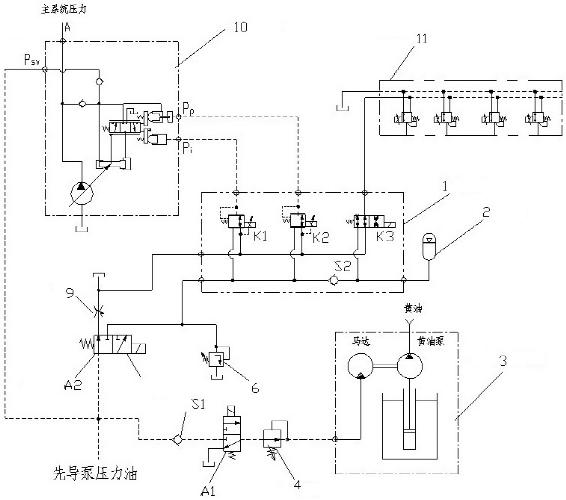

[0026] A super large tonnage excavator pilot control oil circuit,

[0027] The pressure oil of the pilot pump is respectively connected to the 10Psv port of the variable pump, the solenoid valve A2, and the solenoid valve A1;

[0028] The first oil outlet of the solenoid valve A2 is connected to the fuel tank through the throttle valve 9, and the second oil outlet of the solenoid valve A2 is respectively connected to the solenoid valve group 1 and the overflow valve 6;

[0029] The oil outlet of the solenoid valve A1 is connected to the motor in the butter filling system; a check valve S1 is installed in the oil circuit between the pressure oil of the pilot pump and the solenoid valve A1; a check valve S1 is installed in the oil circuit between the solenoid valve A1 and the motor in the butter filling system A pressure reducing valve 4 is installed in the oil circuit, and the pressure reducing valve is an adjustable pressure reducing valve, so as to prevent the motor from bein...

Embodiment 2

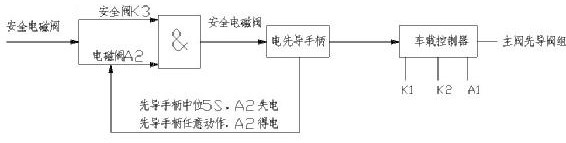

[0032] A super-large-tonnage excavator pilot control oil circuit control method, on the basis of the first embodiment above, includes the following steps:

[0033] In this embodiment, the solenoid valve A2 is used to switch between high and low pressure;

[0034] After the excavator starts,

[0035] When the safety handle is not opened, the solenoid valve A1 is energized; the pressure oil of the pilot pump first returns to the oil tank through the solenoid valve A2 and the throttle valve 9, and the back pressure is generated through the throttle valve, and the pressure is 20 bar, which is the enabling of the variable displacement pump 10 The control port Psv and the oil supply of the butter filling system; specifically: the second channel of pilot pump pressure oil controls the enable control port Psv of the variable pump 10, so that the variable pump 10 starts to work; the third channel of pilot pump pressure oil passes through the one-way Valve S1, solenoid valve A1, pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com