Ball throwing type high-pressure hydraulic drilling and cutting integrated permeability increasing device and permeability increasing method

A high-pressure, hydraulic technology, applied in drilling equipment and methods, safety devices, and production fluids, etc., can solve problems such as restricting development, affecting equipment applicability and stability, and achieving an enlarged influence radius, wide application value, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

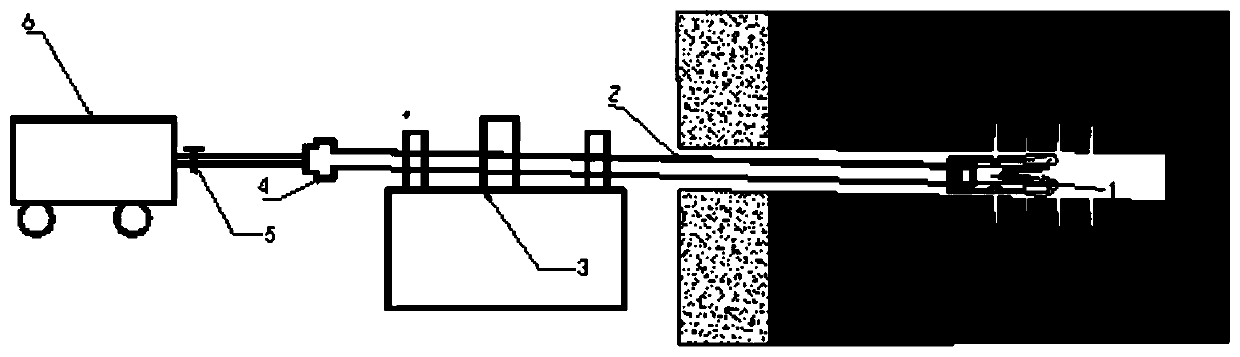

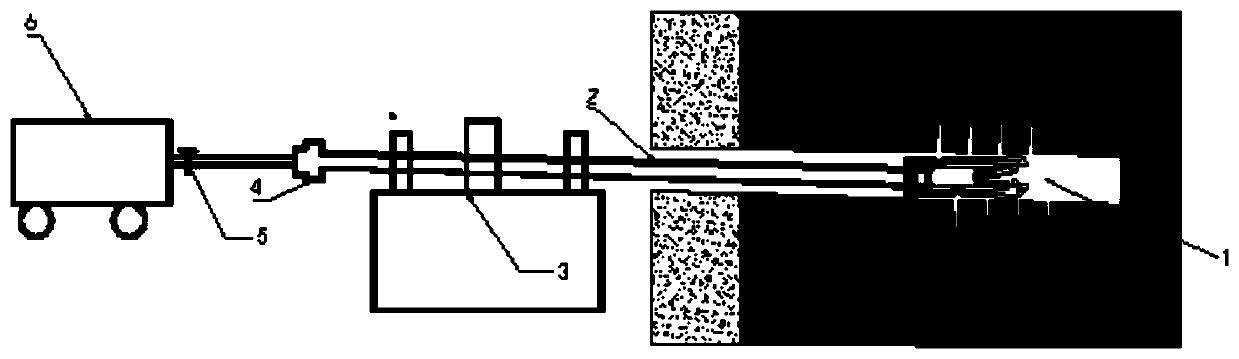

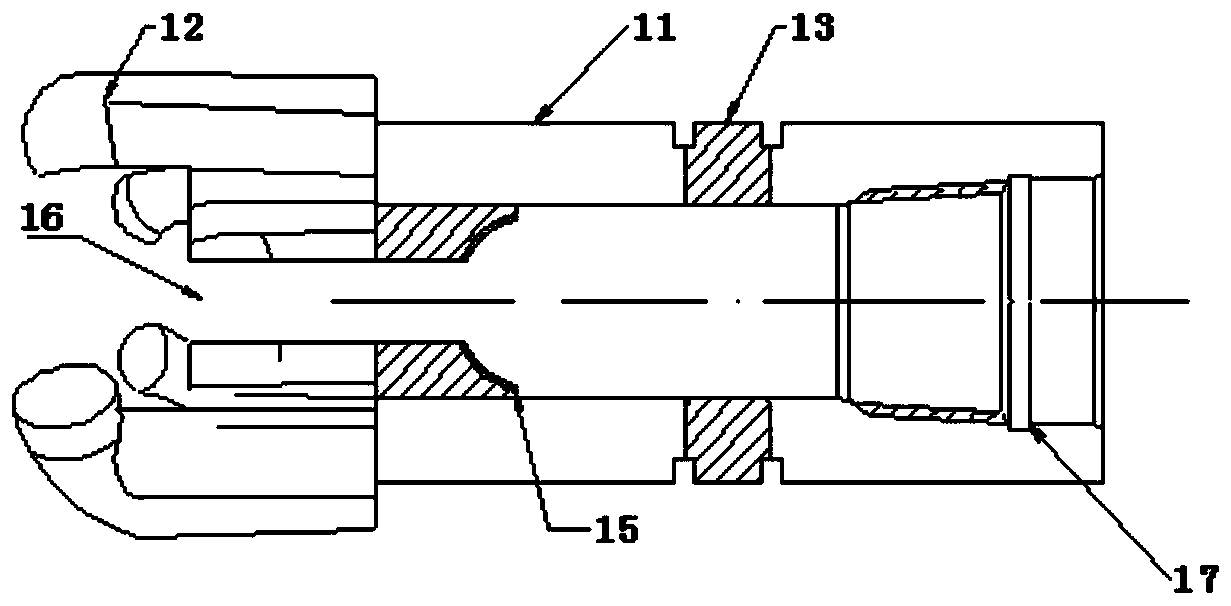

[0035] Such as Figure 1-Figure 7As shown, the pitching type high-pressure hydraulic drilling and cutting integrated seepage enhancement device of the present invention proposed in this embodiment includes a drill bit 1, a high-pressure sealed drill pipe 2, a rotary joint 3, a hydraulic drilling rig 4, an ultra-high pressure manifold 5 and a high-pressure hydraulic pump station 6 connected in turn to form. The high-pressure sealing drill pipe 2 is installed on the hydraulic drilling rig 3 and is driven to rotate axially by the hydraulic drilling rig 3. The drill bit 1 is fixed on the front end of the high-pressure sealing drilling pipe 2; the high-pressure manifold 5 is connected to the high-pressure sealing The rear end of the drill pipe 2; the high-pressure manifold 5 is connected to the high-pressure hydraulic pump station 6 and connected to the tail end of the drill pipe 2 through the high-pressure rotary joint 4, and is used to deliver high-pressure water to the drill bit...

Embodiment 2

[0047] In this embodiment, a method for increasing the penetration of a ball-pitching high-pressure hydraulic drilling and cutting integrated permeation device includes: 1) a drill bit 1, a high-pressure sealed drill pipe 2, a hydraulic drilling rig 3, a high-pressure rotary joint 4, and an ultra-high pressure manifold 5 and the high-pressure hydraulic pumping station 6 are sequentially connected to form a pitching-type high-pressure hydraulic drilling and cutting integrated seepage increasing device; Remove the high-pressure rotary joint 4, put the sealing ball 14 into the high-pressure sealing drill pipe 2, and then install the high-pressure rotary joint 4; 3) Turn on the high-pressure hydraulic pump station 6, and the sealing ball 14 passes through the high-pressure sealing drill pipe 2 driven by high-pressure water. After entering the drill bit 1, it is in close contact with the sealing ball seat 15 to block the drill bit outlet 16. At this time, the high-pressure water jet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com